Prospective Articles

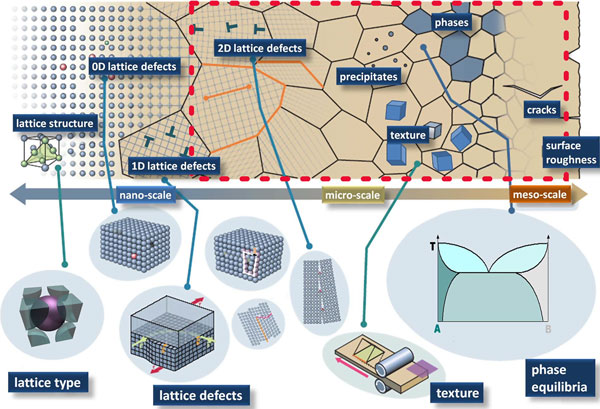

Review and outlook: mechanical, thermodynamic, and kinetic continuum modeling of metallic materials at the grain scale

-

- Published online by Cambridge University Press:

- 16 October 2017, pp. 735-746

-

- Article

- Export citation

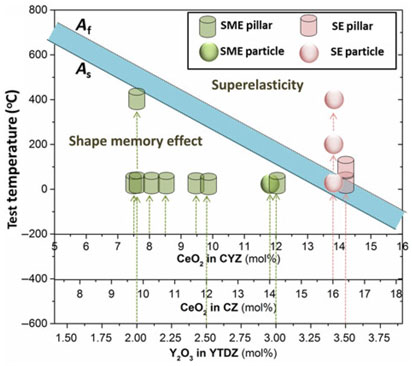

Enhanced shape memory and superelasticity in small-volume ceramics: a perspective on the controlling factors

-

- Published online by Cambridge University Press:

- 23 October 2017, pp. 747-754

-

- Article

-

- You have access

- HTML

- Export citation

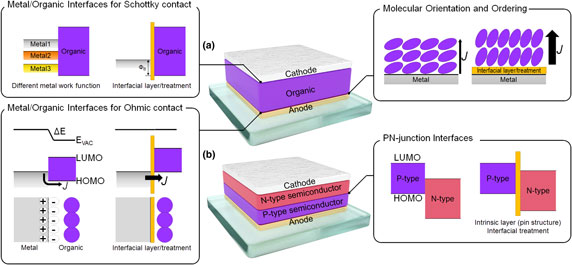

High-frequency organic rectifiers through interface engineering

-

- Published online by Cambridge University Press:

- 20 September 2017, pp. 755-769

-

- Article

- Export citation

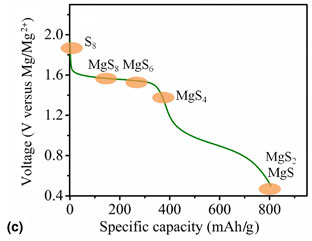

Magnesium–sulfur battery: its beginning and recent progress

-

- Published online by Cambridge University Press:

- 25 September 2017, pp. 770-784

-

- Article

- Export citation

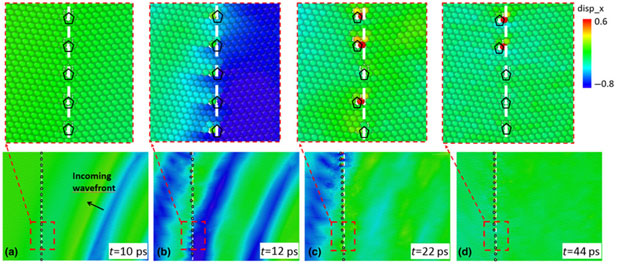

Recent progress in the concurrent atomistic-continuum method and its application in phonon transport

-

- Published online by Cambridge University Press:

- 24 October 2017, pp. 785-797

-

- Article

- Export citation

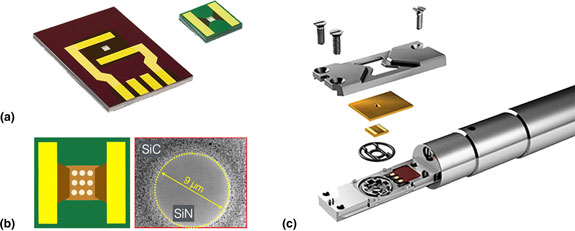

Transmission electron microscopy with atomic resolution under atmospheric pressures

-

- Published online by Cambridge University Press:

- 21 November 2017, pp. 798-812

-

- Article

- Export citation

Research Letters

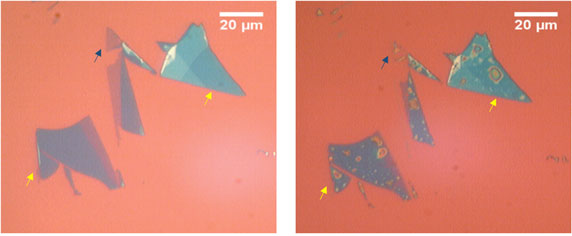

Long-term stability of mechanically exfoliated MoS2 flakes

-

- Published online by Cambridge University Press:

- 28 September 2017, pp. 813-818

-

- Article

- Export citation

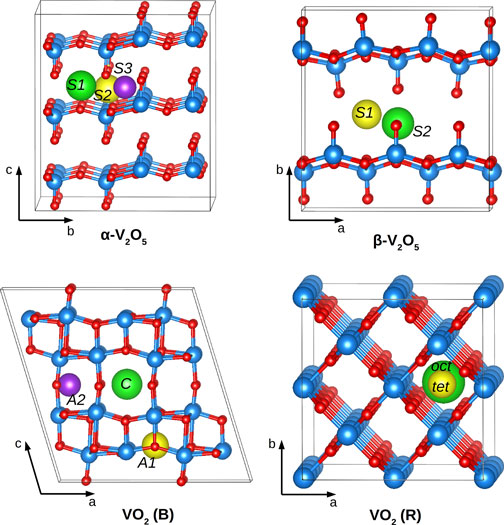

A first-principles study of potassium insertion in crystalline vanadium oxide phases as possible potassium-ion battery cathode materials

-

- Published online by Cambridge University Press:

- 09 October 2017, pp. 819-825

-

- Article

- Export citation

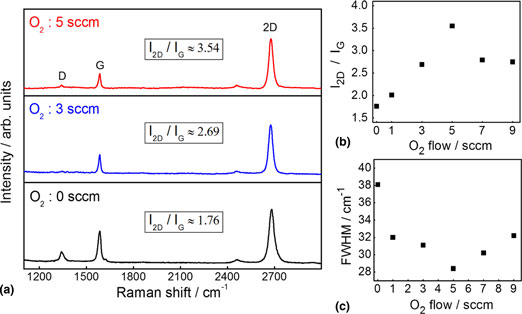

Effect of intermittent oxygen exposure on chemical vapor deposition of graphene

-

- Published online by Cambridge University Press:

- 09 October 2017, pp. 826-831

-

- Article

- Export citation

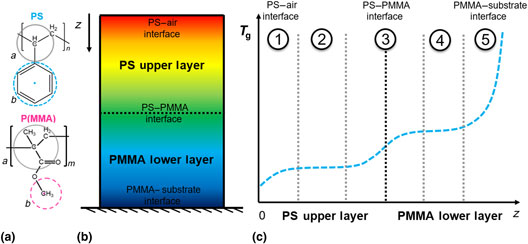

Dynamics of interacting interphases in polymer bilayer thin films

-

- Published online by Cambridge University Press:

- 17 October 2017, pp. 832-839

-

- Article

- Export citation

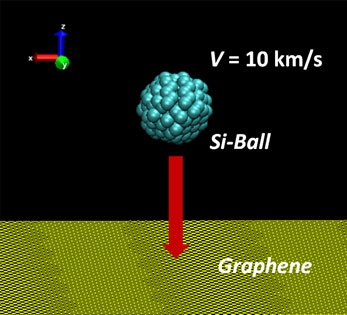

Anomalous characteristics of pore formation in Graphene induced by Si-nanoparticle bombardment

-

- Published online by Cambridge University Press:

- 24 November 2017, pp. 840-847

-

- Article

- Export citation

Dewetting of Co thin films obtained by atomic layer deposition due to the thermal reduction process

-

- Published online by Cambridge University Press:

- 11 September 2017, pp. 848-853

-

- Article

- Export citation

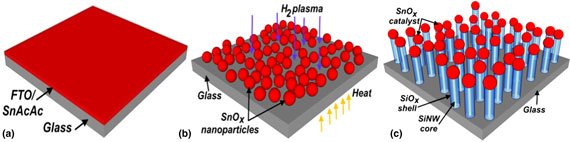

Birth of silicon nanowires covered with protective insulating blanket

-

- Published online by Cambridge University Press:

- 20 September 2017, pp. 854-861

-

- Article

- Export citation

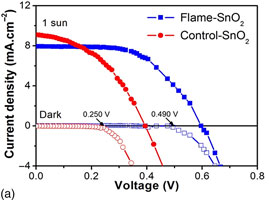

Rapid and scalable synthesis of crystalline tin oxide nanoparticles with superior photovoltaic properties by flame oxidation

-

- Published online by Cambridge University Press:

- 19 September 2017, pp. 862-866

-

- Article

- Export citation

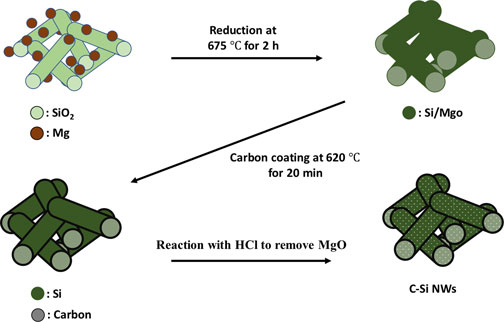

Electrode architecture of carbon-coated silicon nanowires through magnesiothermic reduction for lithium-ion batteries

-

- Published online by Cambridge University Press:

- 09 October 2017, pp. 867-872

-

- Article

- Export citation

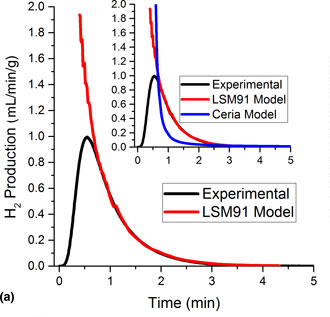

Impact of enhanced oxide reducibility on rates of solar-driven thermochemical fuel production

-

- Published online by Cambridge University Press:

- 09 October 2017, pp. 873-878

-

- Article

- Export citation

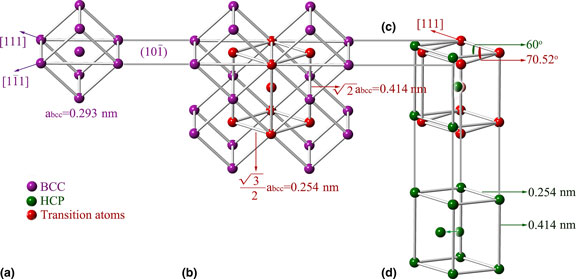

Formation of a hexagonal closed-packed phase in Al0.5CoCrFeNi high entropy alloy

-

- Published online by Cambridge University Press:

- 09 October 2017, pp. 879-884

-

- Article

- Export citation

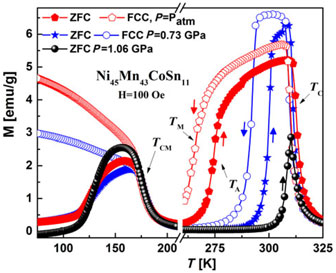

The effects of hydrostatic pressure on the martensitic transition, magnetic, and magnetocaloric effects of Ni45Mn43CoSn11

-

- Published online by Cambridge University Press:

- 11 October 2017, pp. 885-890

-

- Article

- Export citation

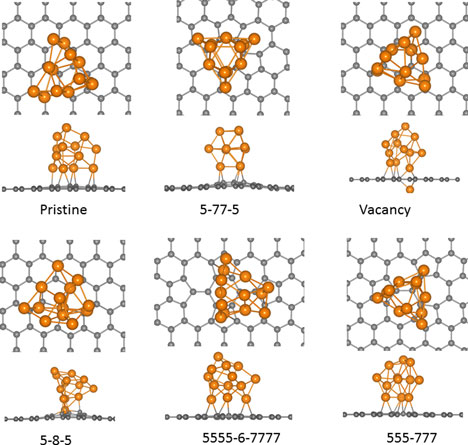

Stable Pt clusters anchored to monovacancies on graphene sheets

-

- Published online by Cambridge University Press:

- 09 October 2017, pp. 891-895

-

- Article

- Export citation

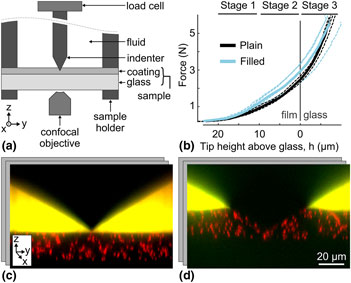

Three-dimensional microscale flow of polymer coatings on glass during indentation

-

- Published online by Cambridge University Press:

- 17 October 2017, pp. 896-903

-

- Article

- Export citation