Invited Feature Review

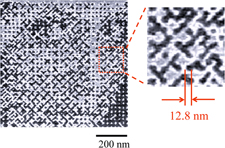

Scanning nonlinear dielectric microscopy

-

- Published online by Cambridge University Press:

- 23 August 2011, pp. 2007-2016

-

- Article

- Export citation

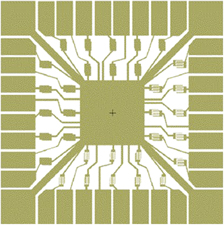

Invited Feature Paper

Fabrication of carbon-nanotube-based sensor array and interference study

-

- Published online by Cambridge University Press:

- 23 August 2011, pp. 2017-2023

-

- Article

- Export citation

Articles

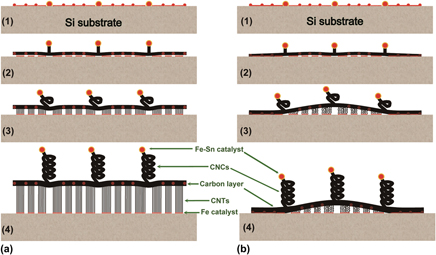

Growth of carbon nanocoils using Fe–Sn–O catalyst film prepared by a spin-coating method

-

- Published online by Cambridge University Press:

- 23 August 2011, pp. 2024-2032

-

- Article

- Export citation

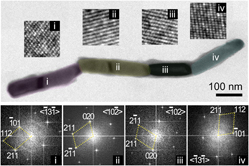

Size-dependent lattice parameters of microstructure-controlled Sn nanowires

-

- Published online by Cambridge University Press:

- 29 July 2011, pp. 2033-2039

-

- Article

- Export citation

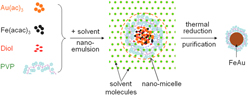

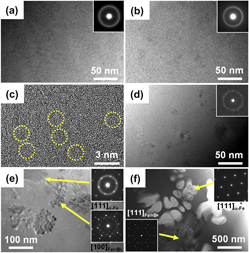

Low-temperature synthesis and characterization of PVP-capped FeAu nanoparticles

-

- Published online by Cambridge University Press:

- 23 June 2011, pp. 2040-2049

-

- Article

- Export citation

Favored composition region for metallic glass formation and atomic configurations in the ternary Ni–Zr–Ti system derived from n-body potential through molecular dynamics simulations

-

- Published online by Cambridge University Press:

- 01 July 2011, pp. 2050-2064

-

- Article

- Export citation

Nanocrystallization of amorphous (Fe1-xCox)88Zr7B4Cu1 alloys and their soft magnetic properties

-

- Published online by Cambridge University Press:

- 27 July 2011, pp. 2065-2071

-

- Article

- Export citation

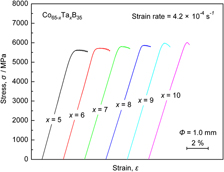

Co-based ternary bulk metallic glasses with ultrahigh strength and plasticity

-

- Published online by Cambridge University Press:

- 13 July 2011, pp. 2072-2079

-

- Article

- Export citation

The influence of in situ formed precipitates on the plasticity of Fe–Nb–B–Cu bulk metallic glasses

-

- Published online by Cambridge University Press:

- 01 August 2011, pp. 2080-2086

-

- Article

- Export citation

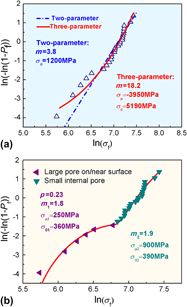

Weibull analysis of fracture strength for Zr55Ti2Co28Al15 bulk metallic glass: Tension–compression asymmetry and porosity effect

-

- Published online by Cambridge University Press:

- 01 August 2011, pp. 2087-2097

-

- Article

- Export citation

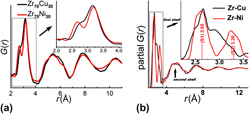

Structural origin of the different glass-forming abilities in ZrCu and ZrNi metallic glasses

-

- Published online by Cambridge University Press:

- 29 July 2011, pp. 2098-2102

-

- Article

- Export citation

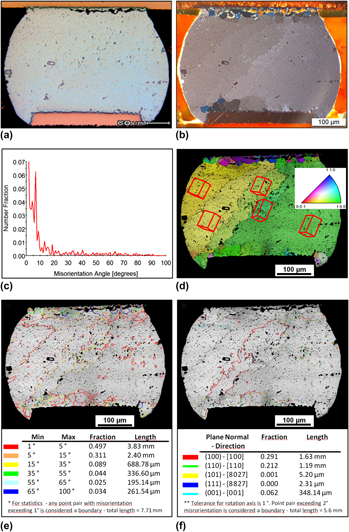

Localized recrystallization and cracking of lead-free solder interconnections under thermal cycling

-

- Published online by Cambridge University Press:

- 16 August 2011, pp. 2103-2116

-

- Article

- Export citation

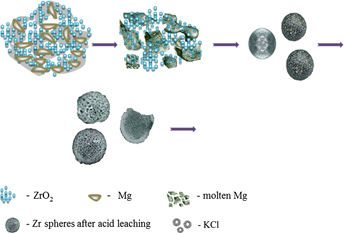

Preparation of porous zirconium microspheres by magnesiothermic reduction and their microstructural characteristics

-

- Published online by Cambridge University Press:

- 09 August 2011, pp. 2117-2122

-

- Article

- Export citation

Erratum

Large-scale integration of single-walled carbon nanotubes and graphene into sensors and devices using dielectrophoresis: A review – ERRATUM

-

- Published online by Cambridge University Press:

- 15 August 2011, p. 2123

-

- Article

-

- You have access

- HTML

- Export citation

Front Cover (OFC, IFC) and matter

JMR volume 26 issue 16 Cover and Front matter

-

- Published online by Cambridge University Press:

- 23 August 2011, pp. f1-f4

-

- Article

-

- You have access

- Export citation

Back Cover (OBC, IBC) and matter

JMR volume 26 issue 16 Cover and Back matter

-

- Published online by Cambridge University Press:

- 23 August 2011, pp. b1-b3

-

- Article

-

- You have access

- Export citation