Article contents

Preparation of porous zirconium microspheres by magnesiothermic reduction and their microstructural characteristics

Published online by Cambridge University Press: 09 August 2011

Abstract

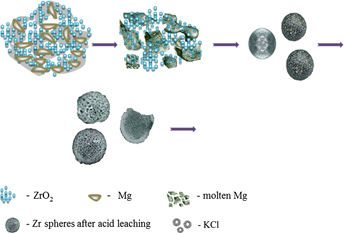

Porous zirconium metal microspheres were synthesized successfully by a combustion technique using ZrO2 + 2Mg starting mixture. In this process, a controlled amount of KClO3 + 3Mg is mixed with ZrO2 + 2Mg to enable a self-sustaining combustion process and to promote a reduction of the ZrO2. The framework structure, morphology, and porosity of zirconium microspheres were determined using various techniques. Microscopic visualization suggested that the spherical structure has macroporous windows of diameter ∼0.5–5.0 μm and the space between the macropores has a wormhole-like mesoporous/microporous structure. The mesoporous structure had a pore diameter of ∼1.19 nm. This procedure provides an easy method for the synthesis of porous microspherical assemblies of Zr composed of submicrometer size particles.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2011

References

REFERENCES

- 3

- Cited by