1. Introduction

Investigations of the physical mechanisms determining the interfacial instability in gas–liquid mixing layer flows date back to two centuries ago (Helmholtz Reference Helmholtz1868). Typical industrial configurations where this kind of two-phase flow can be encountered are the air-blast atomizers, such as liquid fuel injectors in combustion engines. In these applications, a relatively low-speed liquid jet interacts with a faster parallel co-flowing gaseous phase downstream of a separator (or splitter) plate, which initially separates the fluids (Raynal et al. Reference Raynal, Villermaux, Lasheras and Hopfinger1997; Ben Rayana, Cartellier & Hopfinger Reference Ben Rayana, Cartellier and Hopfinger2006; Eggers & Villermaux Reference Eggers and Villermaux2008). The velocity difference existing between the two phases triggers a shear instability at the separating interface, leading to the generation of waves in the liquid phase, which are in turn affected by secondary instabilities, determining the formation, corrugation and finally breaking of liquid ligaments into droplets (primary atomization). This process leads to the generation of mutually interacting gas–droplets mixtures, in the so-called secondary atomization, i.e. the last stage of an ‘instability cascade’ (Marmottant & Villermaux Reference Marmottant and Villermaux2004). Among others, the application of such a flow configuration to fuel injection is a topic of primary interest for both automotive and aerospace industrial sectors. The quality of combustion and then pollutant generation in fuel injection depend crucially on the characteristics of the liquid phase atomization (Lefebvre Reference Lefebvre1989). For these reasons, the understanding and modelling of such a process have been leading scientific research through extensive theoretical, experimental and numerical investigations for decades. However, a comprehensive understanding of the physical mechanisms governing the different stages of the instability cascade is yet to be obtained, making the modelling and control of two-phase mixing layer flows still challenging tasks nowadays.

The present study focuses on the early stages of the primary instability of the gas–liquid interface, and it aims to investigate the salient features of mixing layer flow that establishes just downstream of the splitter plate. The elucidation of the flow dynamics in the near field region is of critical importance, due to its impact on the downstream turbulent flow field development (Ling et al. Reference Ling, Fuster, Tryggvason and Zaleski2019). From a theoretical point of view, the dynamics of the interfacial waves developing in proximity of the splitter plate edge has been investigated in the literature usually through linear stability analysis. Through superposition of small perturbations to a proper time-invariant base flow, within the parallel (or quasi-parallel) flow approximation, the general aim is to determine the most unstable frequency and wavelength of the interfacial instability.

First investigations were carried out assuming an inviscid regime for both the base flow and the evolution of perturbations (Marmottant & Villermaux Reference Marmottant and Villermaux2004; Eggers & Villermaux Reference Eggers and Villermaux2008). Later, Matas, Marty & Cartellier (Reference Matas, Marty and Cartellier2011) observed that the inclusion of a velocity deficit in the base flow, to mimic the splitter plate effect on the near-field flow region, is crucial to obtain reasonable quantitative agreement between inviscid stability analysis predictions and experimental measurements of the interface oscillations frequency, although the spatial growth rate was significantly underestimated with this approach.

A good quantitative match between measured and theoretically predicted spatial growth rates of the interfacial wave was obtained through the inclusion of viscous effects in the temporal linear stability analysis, i.e. by formulating an Orr–Sommerfeld problem for the two-phase shear layer (Boeck & Zaleski Reference Boeck and Zaleski2005; Yecko, Zaleski & Fullana Reference Yecko, Zaleski and Fullana2005); however, predictions of the interfacial oscillations frequency resulted in overestimates. To obtain a more satisfactory and systematic agreement between stability analysis predictions and experimental measurements, Otto, Rossi & Boeck (Reference Otto, Rossi and Boeck2013) developed a local spatio-temporal linear stability approach, improving the theoretical–experimental match for both frequency and spatial growth rate. Moreover, their method provided for the first time evidence of a transition from convective to absolute instability for the injection conditions reported in the work by Matas et al. (Reference Matas, Marty and Cartellier2011), with experimental data spanning both instability regimes. This aspect was clarified further by Fuster et al. (Reference Fuster, Matas, Marty, Popinet, Hoepffner, Cartellier and Zaleski2013), who showed that the transition from convective to absolute flow behaviour depends crucially on the dynamic pressure ratio parameter (![]() $M$).

$M$).

More recently, Matas (Reference Matas2015) found that the absolute instability can also be triggered by a confinement effect, consisting in the finite thicknesses of gas (![]() $H_g$) and liquid (

$H_g$) and liquid (![]() $H_l$) streams at the injection. By means of linear stability analysis, Matas, Delon & Cartellier (Reference Matas, Delon and Cartellier2018) highlighted that the confinement instability is related to a resonance mechanism taking place between normal-to-flow velocity perturbations within the gaseous phase, which are induced by the streamwise liquid waves development, and the gas injector size (

$H_l$) streams at the injection. By means of linear stability analysis, Matas, Delon & Cartellier (Reference Matas, Delon and Cartellier2018) highlighted that the confinement instability is related to a resonance mechanism taking place between normal-to-flow velocity perturbations within the gaseous phase, which are induced by the streamwise liquid waves development, and the gas injector size (![]() $H_g$).

$H_g$).

The survey of past works summarized above points out that one of the most challenging aims to enhance the agreement between linear stability predictions and experimental measurements of the two-phase mixing layer flow behaviour is an accurate knowledge of the selected base flow. Numerical simulations performed in both three-dimensional (Agbaglah, Chiodi & Desjardins Reference Agbaglah, Chiodi and Desjardins2017; Ling et al. Reference Ling, Fuster, Zaleski and Tryggvason2017, Reference Ling, Fuster, Tryggvason and Zaleski2019) and two-dimensional (Fuster et al. Reference Fuster, Matas, Marty, Popinet, Hoepffner, Cartellier and Zaleski2013; Bozonnet et al. Reference Bozonnet, Matas, Balarac and Desjardins2022) scenarios have shown that the two-phase mixing layer is characterized by strong spatial variations in the near-field region, where the flow field can be considered two-dimensional (i.e. invariant along the span of the splitter plate). The locally parallel flow assumption usually made for linear stability calculations is thus generally not accurate. As pointed out by Bozonnet et al. (Reference Bozonnet, Matas, Balarac and Desjardins2022), a global stability analysis should be performed on linear and/or nonlinear mean flows to improve the capability to predict the flow dynamics in most of the experimental conditions.

The two-phase mean flow characterization of such a mixing layer configuration, and in general of free surface flows in the presence of a wavy interface, poses severe challenges from an experimental point of view (Kosiwczuk et al. Reference Kosiwczuk, Cessou, Trinitè and Lecordier2005; Sanchis & Jensen Reference Sanchis and Jensen2011; Ayati et al. Reference Ayati, Kolaas, Jensen and Johnson2014; Andrè & Bardet Reference Andrè and Bardet2015; Buckley & Veron Reference Buckley and Veron2017). In most cases, when studying interfacial phenomena through particle image velocimetry (PIV) or particle tracking velocimetry (PTV), the illuminating light sheet is oriented perpendicular to the interface, eventually causing undesirable reflections in the form of bright spots. Dynamic masking techniques can be used to detect the interface in such cases, as done in Sanchis & Jensen (Reference Sanchis and Jensen2011) by applying the Radon transform algorithm to PIV images of a stratified air–water flow in a circular pipe, obtaining also the velocity field within the liquid phase.

The large difference in refractive index between phases can also lead to glare and prevent optical access. Particular care must be taken to ensure that the flow tracers do not modify the liquid properties, such as surface tension and viscosity. Finally, the large disparity in the two phases injection velocities (about two orders of magnitude in mixing layer configurations of practical interest, where the liquid stream is slower) makes the simultaneous PIV characterization of the two phases a severe issue when using a single-laser single-camera measuring configuration.

Combined PIV and laser-induced fluorescence have been used recently to perform the interface detection and mean flow measurements in the gaseous phase over wind driven surface waves (Buckley & Veron Reference Buckley and Veron2017), while both phases of a stratified air–water flow in a horizontal pipe (Ayati et al. Reference Ayati, Kolaas, Jensen and Johnson2014) and a turbulent spray mixture (Kosiwczuk et al. Reference Kosiwczuk, Cessou, Trinitè and Lecordier2005) have been characterized by means of sophisticated multi-camera (Kosiwczuk et al. Reference Kosiwczuk, Cessou, Trinitè and Lecordier2005; Ayati et al. Reference Ayati, Kolaas, Jensen and Johnson2014) and multi-laser (Buckley & Veron Reference Buckley and Veron2017) instrumentation. Measurements by PIV of the mean gaseous velocity field have also been performed by Descamps, Matas & Cartellier (Reference Descamps, Matas and Cartellier2008) for a planar air–water mixing layer configuration.

It is noteworthy that despite the strong spatial and temporal dynamics coupling between the two phases, previous investigations have so far eluded simultaneous velocity measurements. Therefore, as an important step to assist future global stability studies, the major objective of this work is to provide a detailed experimental characterization of the planar air–water mixing flow developing downstream of a splitter plate, which initially separates the two gaseous and liquid streams. The present measurements constitute a database that could be used in data-driven reduced order models to investigate the global behaviour of the flow system. Linear and nonlinear approaches have been proposed recently, as documented for example by Colanera, Della Pia & Chiatto (Reference Colanera, Della Pia and Chiatto2022), for the case of vertical liquid jets in still air, and Li et al. (Reference Li, Fernex, Semaan, Tan, Morzyński and Noack2021), who introduced the cluster-based network models to reproduce the dynamics of a system by means of a directed network of nodes. The transition properties between the nodes are based on high-order direct transition probabilities identified from the data. In the configuration studied here, such an analysis could be performed on experimental snapshots.

By means of carefully arranged light sheet optics, two-component time-resolved particle image velocimetry (TR-PIV) measurements are performed simultaneously in air and water streams, employing a single-laser single-camera set-up. The adopted measurement configuration allows one to acquire instantaneous snapshots of the two phases, which are then separated by post-processing.

The two-phase mean (time-averaged) and unsteady features of the flow are characterized for several injection conditions, providing to the authors’ knowledge the first simultaneous TR-PIV measurements of a planar mixing layer in gas and liquid phases. The mean flow is analysed in terms of detailed velocity profiles and overall portraits, first focusing on a selected reference case. A parametric study of the mean flow topology is then performed by varying the liquid (![]() $Re_l$) and gas (

$Re_l$) and gas (![]() $Re_g$) Reynolds numbers, and as a consequence also the gas-to-liquid dynamic pressure ratio (

$Re_g$) Reynolds numbers, and as a consequence also the gas-to-liquid dynamic pressure ratio (![]() $M$). Finally, physical insights on the unsteady flow characteristics are gained through the spectral analysis and proper orthogonal decomposition (POD) of velocity fluctuations, discussed through comparisons with previous findings in the literature.

$M$). Finally, physical insights on the unsteady flow characteristics are gained through the spectral analysis and proper orthogonal decomposition (POD) of velocity fluctuations, discussed through comparisons with previous findings in the literature.

2. Flow configuration and methodology

The set-up realized to perform air–water mixing layer experiments (inspired by the previous works of Raynal et al. Reference Raynal, Villermaux, Lasheras and Hopfinger1997; Ben Rayana et al. Reference Ben Rayana, Cartellier and Hopfinger2006; Matas et al. Reference Matas, Marty and Cartellier2011) is presented first (§ 2.1), followed by a description of the PIV measurement technique employed to characterize the two-phase flow (§ 2.2).

2.1. Experimental set-up

A schematic representation of the experimental apparatus is shown in figure 1. Figure 1(a) gives an overview of all the main components, including the measurement set-up (discussed later, in § 2.2), while figure 1(b) focuses on the near-field flow region of the mixing layer, i.e. immediately after the nozzle exit section, which is located at ![]() $x=0$. A water stream flows along the streamwise direction (

$x=0$. A water stream flows along the streamwise direction (![]() $x$) below a parallel faster air stream, the two fluids being separated initially by a stainless steel splitter plate with thickness

$x$) below a parallel faster air stream, the two fluids being separated initially by a stainless steel splitter plate with thickness ![]() $e=2$ mm (figure 1b). The shapes of the water and air channels are the same. The walls are made from Plexiglas, with cross-sectional area (in the

$e=2$ mm (figure 1b). The shapes of the water and air channels are the same. The walls are made from Plexiglas, with cross-sectional area (in the ![]() $yz$ plane) initially

$yz$ plane) initially ![]() $100\,\text {mm}\times 100\,\text {mm}$ (where

$100\,\text {mm}\times 100\,\text {mm}$ (where ![]() $y$ and

$y$ and ![]() $z$ are the normal-to-flow and spanwise coordinates, respectively). Then a two-dimensional converging nozzle reduces the channel height from 100 mm to

$z$ are the normal-to-flow and spanwise coordinates, respectively). Then a two-dimensional converging nozzle reduces the channel height from 100 mm to ![]() $H_g = H_l = 20$ mm at

$H_g = H_l = 20$ mm at ![]() $x=0$ (see table 1), where the flows issue into a test section. Three-dimensional effects due to the lateral confinement of the test section walls on the liquid jet are negligible in the near-field region of the flow, where the two-dimensional PIV measurements are realized.

$x=0$ (see table 1), where the flows issue into a test section. Three-dimensional effects due to the lateral confinement of the test section walls on the liquid jet are negligible in the near-field region of the flow, where the two-dimensional PIV measurements are realized.

Figure 1. (a) Overall schematic representation and (b) two-dimensional sketch close to the nozzle exit section of the experimental set-up. In (b), the PIV measurement region of interest is highlighted in green.

Table 1. Relevant geometrical quantities of the experimental set-up (see also figure 1b).

An overflow tank (figure 1a) positioned 1.5 m above the splitter plate drives the liquid flow by gravity, and is filled up continuously by a pump (T.I.P. TVX 12 000 Dompelpomp), thus realizing a closed-loop circuit for the water stream. At the end of the test section, the liquid flow spills out into a water collector. The flow rate, which is kept constant during each experiment, is regulated by means of a valve located upstream of the water channel entry; different values measured by a LVB-25-A vortex flowmeter are obtained, corresponding to liquid inlet velocities in the range ![]() $U_l \in [0.10,0.30]$ m s

$U_l \in [0.10,0.30]$ m s![]() $^{-1}$. For each liquid flow rate value, the height of the water stream at the splitter plate edge (i.e. at

$^{-1}$. For each liquid flow rate value, the height of the water stream at the splitter plate edge (i.e. at ![]() $x=0$) is kept constant (equal to

$x=0$) is kept constant (equal to ![]() $H_l$) by adjusting the height of a gate placed at the end of the test section (

$H_l$) by adjusting the height of a gate placed at the end of the test section (![]() $x=500$ mm), before the liquid is dispensed into a collector. In this way, air ingestion into the water channel at the splitter plate edge is avoided for all the testing conditions.

$x=500$ mm), before the liquid is dispensed into a collector. In this way, air ingestion into the water channel at the splitter plate edge is avoided for all the testing conditions.

The air stream is generated by a blowing machine (Rück Ventilatoren RS315LEC) allowing us to obtain injection velocities in the range ![]() $U_g \in [2,15]$ m s

$U_g \in [2,15]$ m s![]() $^{-1}$, as measured by a Pitot tube located at the gas nozzle exit section midpoint (i.e. at

$^{-1}$, as measured by a Pitot tube located at the gas nozzle exit section midpoint (i.e. at ![]() $x=0$,

$x=0$, ![]() $y = 10$ mm), and cross-checked by static pressure probes positioned at the inlet (

$y = 10$ mm), and cross-checked by static pressure probes positioned at the inlet (![]() $x=-250$ mm) and outlet (

$x=-250$ mm) and outlet (![]() $x=0$) sections of the convergent nozzle. Flow conditioners are used in both the liquid and gas channels to damp velocity fluctuations; two aluminum honeycombs (aluNID from Alucoat) with 50 mm long hexagonal cells are employed in the liquid phase, while a combination of the same honeycomb and mesh screens is used in the air channel.

$x=0$) sections of the convergent nozzle. Flow conditioners are used in both the liquid and gas channels to damp velocity fluctuations; two aluminum honeycombs (aluNID from Alucoat) with 50 mm long hexagonal cells are employed in the liquid phase, while a combination of the same honeycomb and mesh screens is used in the air channel.

Particular care is taken in designing the flow conditioners for the gas phase to control its turbulence intensity level, which has been shown to affect the mixing layer development in both experimental (Matas et al. Reference Matas, Marty, Dem and Cartellier2015) and numerical (Jiang & Ling Reference Jiang and Ling2020, Reference Jiang and Ling2021) studies, and that depends strongly on screen geometrical properties and relative streamwise spacing in a multiple screens configuration (see, for example, the works by Mehta & Bradshaw Reference Mehta and Bradshaw1979; Marshall Reference Marshall1985; Groth & Johansson Reference Groth and Johansson1988). Following Groth & Johansson (Reference Groth and Johansson1988), we chose a combination of metal meshes (figure 1b), with mesh size decreasing progressively from ![]() $1$ mm (coarse screen) to

$1$ mm (coarse screen) to ![]() $0.5$ mm (fine), and constant relative spacing

$0.5$ mm (fine), and constant relative spacing ![]() $d=20$ mm, while a distance

$d=20$ mm, while a distance ![]() $D_g = 50$ mm was selected between the honeycomb and the first (i.e. located more upstream) coarse screen (see table 1). This configuration gives a turbulence intensity level below 1 % for all the testing conditions, as reported in figure 2(a). The turbulence intensity is quantified in terms of root mean square (rms) of the gas velocity fluctuation

$D_g = 50$ mm was selected between the honeycomb and the first (i.e. located more upstream) coarse screen (see table 1). This configuration gives a turbulence intensity level below 1 % for all the testing conditions, as reported in figure 2(a). The turbulence intensity is quantified in terms of root mean square (rms) of the gas velocity fluctuation ![]() $u^\prime (t)= u(t) - \bar {u}$, where

$u^\prime (t)= u(t) - \bar {u}$, where ![]() $u(t)$ is the streamwise velocity component measured (in absence of liquid stream) by a hot wire located at the gas nozzle exit section midpoint, and

$u(t)$ is the streamwise velocity component measured (in absence of liquid stream) by a hot wire located at the gas nozzle exit section midpoint, and ![]() $\bar {u}$ its time-averaged value. Note that the values of the gas turbulence intensity reported here are close to the lowest value (

$\bar {u}$ its time-averaged value. Note that the values of the gas turbulence intensity reported here are close to the lowest value (![]() $u^\prime _{rms}/\bar {u} = 0.8\,\%$) found by Matas et al. (Reference Matas, Marty, Dem and Cartellier2015) in their experimental analysis of the gas turbulence effect on the dynamics of an air–water mixing layer. Moreover, Matas et al. (Reference Matas, Marty, Dem and Cartellier2015) found that the peak frequency of the air–water interface oscillations was influenced by the gas turbulence only for values

$u^\prime _{rms}/\bar {u} = 0.8\,\%$) found by Matas et al. (Reference Matas, Marty, Dem and Cartellier2015) in their experimental analysis of the gas turbulence effect on the dynamics of an air–water mixing layer. Moreover, Matas et al. (Reference Matas, Marty, Dem and Cartellier2015) found that the peak frequency of the air–water interface oscillations was influenced by the gas turbulence only for values ![]() $u^\prime _{rms}/\bar {u} > 3.5\,\%$. Therefore, we can assert that results reported in the present work are not influenced by the turbulence intensity level of the gaseous phase.

$u^\prime _{rms}/\bar {u} > 3.5\,\%$. Therefore, we can assert that results reported in the present work are not influenced by the turbulence intensity level of the gaseous phase.

Figure 2. (a) Air flow turbulence intensity level ![]() $u^\prime _{rms}/\bar {u}$, and (b) inlet gas vorticity thickness

$u^\prime _{rms}/\bar {u}$, and (b) inlet gas vorticity thickness ![]() $\delta _g$, varying with gas Reynolds number

$\delta _g$, varying with gas Reynolds number ![]() $Re_{H_g}$. Comparisons with past works are also reported in (b). (c) An overview of the testing conditions in terms of dynamic pressure ratio

$Re_{H_g}$. Comparisons with past works are also reported in (b). (c) An overview of the testing conditions in terms of dynamic pressure ratio ![]() $M$ values as a function of the gas velocity

$M$ values as a function of the gas velocity ![]() $U_g$ at different liquid velocities

$U_g$ at different liquid velocities ![]() $U_l$.

$U_l$.

Reynolds number values reported in figure 2(a) correspond to ![]() $U_g = 2, 5, 7, 10, 12,$

$U_g = 2, 5, 7, 10, 12,$ ![]() $15$ m s

$15$ m s![]() $^{-1}$, the Reynolds number here being defined as

$^{-1}$, the Reynolds number here being defined as ![]() $Re_{H_g} = \rho _g U_g H_g / \mu _g$, where

$Re_{H_g} = \rho _g U_g H_g / \mu _g$, where ![]() $\rho _g$ and

$\rho _g$ and ![]() $\mu _g$ are respectively the gas density and dynamic viscosity. The inlet gas vorticity thickness

$\mu _g$ are respectively the gas density and dynamic viscosity. The inlet gas vorticity thickness ![]() $\delta _g$, which is defined as

$\delta _g$, which is defined as ![]() $\delta _g = {\rm \Delta} \bar {u}/({\rm d} \bar {u}/{{\rm d}y})|_{max}$ (

$\delta _g = {\rm \Delta} \bar {u}/({\rm d} \bar {u}/{{\rm d}y})|_{max}$ (![]() ${\rm \Delta} \bar {u} = \bar {u}(y=H_g/2)-\bar {u}(y=e/2)$) and is known to play a crucial role in the mixing layer instability selection mechanisms (Matas et al. Reference Matas, Marty and Cartellier2011; Fuster et al. Reference Fuster, Matas, Marty, Popinet, Hoepffner, Cartellier and Zaleski2013), has also been measured by positioning the hot wire at a downstream distance

${\rm \Delta} \bar {u} = \bar {u}(y=H_g/2)-\bar {u}(y=e/2)$) and is known to play a crucial role in the mixing layer instability selection mechanisms (Matas et al. Reference Matas, Marty and Cartellier2011; Fuster et al. Reference Fuster, Matas, Marty, Popinet, Hoepffner, Cartellier and Zaleski2013), has also been measured by positioning the hot wire at a downstream distance ![]() $x=e/2$. The obtained values are reported in figure 2(b) as a function of

$x=e/2$. The obtained values are reported in figure 2(b) as a function of ![]() $Re_{H_g}$, revealing a good agreement with the scaling law

$Re_{H_g}$, revealing a good agreement with the scaling law ![]() $\delta _g / H_g = 5.2/ \sqrt {Re_{H_g}}$ proposed by Fuster et al. (Reference Fuster, Matas, Marty, Popinet, Hoepffner, Cartellier and Zaleski2013). An overview of the testing conditions considered in this work is summarized in figure 2(c), where liquid and gas injection velocities are reported together with the corresponding dynamic pressure ratio

$\delta _g / H_g = 5.2/ \sqrt {Re_{H_g}}$ proposed by Fuster et al. (Reference Fuster, Matas, Marty, Popinet, Hoepffner, Cartellier and Zaleski2013). An overview of the testing conditions considered in this work is summarized in figure 2(c), where liquid and gas injection velocities are reported together with the corresponding dynamic pressure ratio ![]() $M = \rho _g U^2_g/(\rho _l U^2_l)$ values.

$M = \rho _g U^2_g/(\rho _l U^2_l)$ values.

2.2. Measurement technique

The single-laser single-camera measurement system designed to achieve the TR-PIV characterization of the flow simultaneously in the two phases is shown schematically in figure 1(a). As discussed in the Introduction, performing this type of measurement is challenging, and other strategies such as combining PIV with laser-induced fluorescence (Buckley & Veron Reference Buckley and Veron2017) or employing multi-camera multi-laser configurations (Kosiwczuk et al. Reference Kosiwczuk, Cessou, Trinitè and Lecordier2005; Ayati et al. Reference Ayati, Kolaas, Jensen and Johnson2014) have been explored to date. The major issues are related to the laser light reflection and refraction across the interface, and to the high velocity difference between the two phases (about two orders of magnitude).

In the present work, to enlighten simultaneously air and water flows overcoming light reflections at the interface, a Continuum Mesa PIV 532-120M laser operated at 2 kHz double pulse rate (pulse energy 18 mJ) is used to generate a light beam, which is then separated into two beams by a prism. The first beam goes through a combination of two spherical and one cylindrical lenses and a mirror, thus becoming a thin sheet enlightening the liquid phase. The second beam is rotated horizontally by a mirror, and is transformed into an analogous sheet for the air flow by the same combination of lenses and mirror. A high-speed (2 kHz repetition rate in double exposure mode) camera (Photron, Fastcam SA-1, ![]() $1024\times 1024$ pixels), whose axis is orthogonal to the laser sheets plane, and a programmable timing unit (LaVision, HSC, not shown in figure 1), complete the measurement set-up. Atomized droplets (mean diameter

$1024\times 1024$ pixels), whose axis is orthogonal to the laser sheets plane, and a programmable timing unit (LaVision, HSC, not shown in figure 1), complete the measurement set-up. Atomized droplets (mean diameter ![]() $1\,\mathrm {\mu } \text {m}$) are seeded in the air channel by a fog generator (SAFEX, Fog 2010+) using a working fluid of water–glycol mixture, while a

$1\,\mathrm {\mu } \text {m}$) are seeded in the air channel by a fog generator (SAFEX, Fog 2010+) using a working fluid of water–glycol mixture, while a ![]() $20\,\mathrm {\mu }\text {m}$ polyamide Vestosint powder is used to seed the liquid phase.

$20\,\mathrm {\mu }\text {m}$ polyamide Vestosint powder is used to seed the liquid phase.

A field of view ![]() $[-18,108] \times [-21,21]\,\text {mm}^2$ (shown qualitatively in green in figure 1b) is imaged by mounting a 105 mm objective (Nikon, Micro-Nikkor) on the high-speed camera, thus giving a two-dimensional region of interest within the

$[-18,108] \times [-21,21]\,\text {mm}^2$ (shown qualitatively in green in figure 1b) is imaged by mounting a 105 mm objective (Nikon, Micro-Nikkor) on the high-speed camera, thus giving a two-dimensional region of interest within the ![]() $xy$ plane positioned midway from the channel side walls. By adjusting the camera focus, particle images approximately 2–3 px in diameter are obtained in both liquid and gas phases, as shown in the raw image reported in figure 3(a). An algorithm written in MATLAB is used to pre-process the raw images (figure 3b) and separate air and water phases (figures 3c,d), which are then post-processed separately through LaVision DaVis 10. An iterative multi-grid cross-correlation scheme with window deformation (Scarano & Riethmuller Reference Scarano and Riethmuller2000) is used to compute velocity fields, and results are post-processed with the universal outlier detection algorithm (Westerweel & Scarano Reference Westerweel and Scarano2005). The time delay between two successive frames in air is adjusted from

$xy$ plane positioned midway from the channel side walls. By adjusting the camera focus, particle images approximately 2–3 px in diameter are obtained in both liquid and gas phases, as shown in the raw image reported in figure 3(a). An algorithm written in MATLAB is used to pre-process the raw images (figure 3b) and separate air and water phases (figures 3c,d), which are then post-processed separately through LaVision DaVis 10. An iterative multi-grid cross-correlation scheme with window deformation (Scarano & Riethmuller Reference Scarano and Riethmuller2000) is used to compute velocity fields, and results are post-processed with the universal outlier detection algorithm (Westerweel & Scarano Reference Westerweel and Scarano2005). The time delay between two successive frames in air is adjusted from ![]() ${\rm \Delta} t_g=200\,\mathrm {\mu }$s to

${\rm \Delta} t_g=200\,\mathrm {\mu }$s to ![]() ${\rm \Delta} t_g=70\,\mathrm {\mu }$s for

${\rm \Delta} t_g=70\,\mathrm {\mu }$s for ![]() $U_g \in [2, 15]$ m s

$U_g \in [2, 15]$ m s![]() $^{-1}$, while values ranging from

$^{-1}$, while values ranging from ![]() ${\rm \Delta} t_l=10.5$ ms to

${\rm \Delta} t_l=10.5$ ms to ![]() ${\rm \Delta} t_l=1.2$ ms are employed for cross-correlation in water (

${\rm \Delta} t_l=1.2$ ms are employed for cross-correlation in water (![]() $U_l \in [0.10, 0.30]$ m s

$U_l \in [0.10, 0.30]$ m s![]() $^{-1}$), to guarantee a peak particle displacement of approximately 10 pixels in both phases. For each pair of

$^{-1}$), to guarantee a peak particle displacement of approximately 10 pixels in both phases. For each pair of ![]() $U_g$ and

$U_g$ and ![]() $U_l$ values, the time delay

$U_l$ values, the time delay ![]() ${\rm \Delta} t_l$ for cross-correlation in water is adjusted simply by skipping the number of frames necessary to achieve the same peak particle displacement as in air, i.e.

${\rm \Delta} t_l$ for cross-correlation in water is adjusted simply by skipping the number of frames necessary to achieve the same peak particle displacement as in air, i.e. ![]() $U_l\, {\rm \Delta} t_l = U_g\,{\rm \Delta} t_g$. In the final pass of the cross-correlation operation, the interrogation window size and the overlapping ratio are

$U_l\, {\rm \Delta} t_l = U_g\,{\rm \Delta} t_g$. In the final pass of the cross-correlation operation, the interrogation window size and the overlapping ratio are ![]() $16\,{\rm px} \times 16\,{\rm px}$ and 50 %, respectively, leading to spatial resolution 1 mm per vector. Mean quantities are estimated based on

$16\,{\rm px} \times 16\,{\rm px}$ and 50 %, respectively, leading to spatial resolution 1 mm per vector. Mean quantities are estimated based on ![]() $N_t=8000$ realizations, with average measurement uncertainty on the streamwise and normal-to-flow velocity components respectively in the ranges

$N_t=8000$ realizations, with average measurement uncertainty on the streamwise and normal-to-flow velocity components respectively in the ranges ![]() $[0.62, 9.43]$ % and

$[0.62, 9.43]$ % and ![]() $[0.71, 6.28]$ % of the injection velocities (increasing value moving towards walls).

$[0.71, 6.28]$ % of the injection velocities (increasing value moving towards walls).

Figure 3. Single-laser single-camera PIV measurement workflow: (a) acquired raw image, (b) pre-processing, and (c,d) phase separations.

The PIV measurements allow us to complement the air stream characterization in terms of inflow conditions as shown in figure 4. In particular, the mean streamwise velocity component profile ![]() $\bar {u}$ is shown at three different streamwise stations upstream of the injection section:

$\bar {u}$ is shown at three different streamwise stations upstream of the injection section: ![]() $x/H_g = -1$ (figure 4a),

$x/H_g = -1$ (figure 4a), ![]() $x/H_g = -0.5$ (figure 4b) and

$x/H_g = -0.5$ (figure 4b) and ![]() $x/H_g = -0.1$ (figure 4c). Note that the normal-to-flow coordinate

$x/H_g = -0.1$ (figure 4c). Note that the normal-to-flow coordinate ![]() $y$ has been shifted by

$y$ has been shifted by ![]() $e/2$ (

$e/2$ (![]() $y^\star = y -e/2$), such that

$y^\star = y -e/2$), such that ![]() $\bar {u} = 0$ at

$\bar {u} = 0$ at ![]() $y^\star = 0$, and

$y^\star = 0$, and ![]() $\bar {U}_g$ denotes the mean velocity at each station. Three velocity profiles are reported in each panel, corresponding to

$\bar {U}_g$ denotes the mean velocity at each station. Three velocity profiles are reported in each panel, corresponding to ![]() $Re_{H_g} = 6.7\times 10^{3}$ (black curves),

$Re_{H_g} = 6.7\times 10^{3}$ (black curves), ![]() $9.6\times 10^{3}$ (red curves) and

$9.6\times 10^{3}$ (red curves) and ![]() $16.2\times 10^{3}$ (blue curves), and the numerical solution of the fully developed turbulent channel flow obtained by Kim et al. (Reference Kim, Moin and Moser1987) at Reynolds number 13 750 is also reported for comparison (green curve). The velocity profile tends to the fully developed turbulent channel flow solution as

$16.2\times 10^{3}$ (blue curves), and the numerical solution of the fully developed turbulent channel flow obtained by Kim et al. (Reference Kim, Moin and Moser1987) at Reynolds number 13 750 is also reported for comparison (green curve). The velocity profile tends to the fully developed turbulent channel flow solution as ![]() $Re_g$ increases, thus highlighting a transition towards turbulent inflow conditions. This occurrence seems to be confirmed by the trend of the turbulence intensity reported in figure 2(a), showing an initially increasing behaviour followed by a plateau. Of course, each velocity profile is not symmetric with respect to the

$Re_g$ increases, thus highlighting a transition towards turbulent inflow conditions. This occurrence seems to be confirmed by the trend of the turbulence intensity reported in figure 2(a), showing an initially increasing behaviour followed by a plateau. Of course, each velocity profile is not symmetric with respect to the ![]() $y$ direction, due to the intrinsic shape of the exit nozzle, limited by the flat splitter plate and the converging lateral wall (where the boundary layer is thinner).

$y$ direction, due to the intrinsic shape of the exit nozzle, limited by the flat splitter plate and the converging lateral wall (where the boundary layer is thinner).

Figure 4. Velocity profile in air at different streamwise stations upstream of the injection section by varying the Reynolds number: ![]() $Re_{H_g} = 6.7\times 10^{3}$ (black curves),

$Re_{H_g} = 6.7\times 10^{3}$ (black curves), ![]() $Re_{H_g}=9.6\times 10^{3}$ (red curves),

$Re_{H_g}=9.6\times 10^{3}$ (red curves), ![]() $Re_{H_g} = 16.2\times 10^{3}$ (blue curves). The numerical solution of the fully developed turbulent channel flow obtained by Kim, Moin & Moser (Reference Kim, Moin and Moser1987) at Reynolds number 13 750 is also reported for comparison (green curve).

$Re_{H_g} = 16.2\times 10^{3}$ (blue curves). The numerical solution of the fully developed turbulent channel flow obtained by Kim, Moin & Moser (Reference Kim, Moin and Moser1987) at Reynolds number 13 750 is also reported for comparison (green curve).

3. Mean flow analysis

The mean flow topology is discussed first for a selected case, which has been defined as the REF case and is characterized by values of flow quantities reported in table 2. Later, the effect of injection conditions on the two-phase flow field is investigated by means of a parametric analysis involving the dimensionless numbers

whose values are reported in table 3 for the main cases considered in the analysis. The inlet liquid vorticity thickness ![]() $\delta _l$, which is defined analogously to

$\delta _l$, which is defined analogously to ![]() $\delta _g$ and is obtained from the PIV measured velocity profiles in water, is used to define the liquid Reynolds number

$\delta _g$ and is obtained from the PIV measured velocity profiles in water, is used to define the liquid Reynolds number ![]() $Re_l$, which varies from 302 (L1 case) to 807 (L3 case). The gas Reynolds number

$Re_l$, which varies from 302 (L1 case) to 807 (L3 case). The gas Reynolds number ![]() $Re_g$, based on the gas vorticity thickness

$Re_g$, based on the gas vorticity thickness ![]() $\delta _g$, varies from 384 (G1 case) to 768 (G5 case). We note explicitly that the three dimensionless numbers defined in (3.1a–c) are not all independent of each other: for example, one can vary

$\delta _g$, varies from 384 (G1 case) to 768 (G5 case). We note explicitly that the three dimensionless numbers defined in (3.1a–c) are not all independent of each other: for example, one can vary ![]() $Re_g$ by fixing

$Re_g$ by fixing ![]() $Re_l$, but as a consequence, the third parameter

$Re_l$, but as a consequence, the third parameter ![]() $M$ also varies. Note also that as the ratio

$M$ also varies. Note also that as the ratio ![]() $e/\delta _g$ is greater than unity for all the cases examined (last row of table 3), the present investigation lies within the so-called injector-influenced regime outlined by Fuster et al. (Reference Fuster, Matas, Marty, Popinet, Hoepffner, Cartellier and Zaleski2013).

$e/\delta _g$ is greater than unity for all the cases examined (last row of table 3), the present investigation lies within the so-called injector-influenced regime outlined by Fuster et al. (Reference Fuster, Matas, Marty, Popinet, Hoepffner, Cartellier and Zaleski2013).

Table 2. Dimensional quantities corresponding to the REF case.

Table 3. Overview of the main cases considered in the analysis. The dimensionless parameters ![]() $Re_l$,

$Re_l$, ![]() $Re_g$ and

$Re_g$ and ![]() $M$ are defined by (3.1a–c).

$M$ are defined by (3.1a–c).

3.1. The REF case

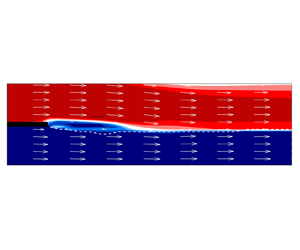

The time-averaged velocity magnitude ![]() $\bar {V}$ contour is shown in figure 5(a) together with the velocity vectors distribution, and a zoom around the splitter plate immediately downstream of the nozzle exit section is provided in figure 5(b). For all cases discussed within this work, the mean quantities

$\bar {V}$ contour is shown in figure 5(a) together with the velocity vectors distribution, and a zoom around the splitter plate immediately downstream of the nozzle exit section is provided in figure 5(b). For all cases discussed within this work, the mean quantities ![]() $\bar {u}$ and

$\bar {u}$ and ![]() $\bar {v}$ are computed over a total of 8000 temporal realizations of the flow.

$\bar {v}$ are computed over a total of 8000 temporal realizations of the flow.

Figure 5. (a) Time-averaged velocity magnitude ![]() $\bar {V}/U_g$ contour, with (b) zoom next to the nozzle exit section. The splitter plate is highlighted in black, the time-averaged interface location is represented as a white dashed line, and velocity vectors are also reported. REF case of table 3.

$\bar {V}/U_g$ contour, with (b) zoom next to the nozzle exit section. The splitter plate is highlighted in black, the time-averaged interface location is represented as a white dashed line, and velocity vectors are also reported. REF case of table 3.

Note that in figure 5, the velocity magnitude has been scaled with respect to ![]() $U_g$, the spatial coordinates have been made dimensionless by means of the splitter plate thickness, i.e.

$U_g$, the spatial coordinates have been made dimensionless by means of the splitter plate thickness, i.e. ![]() $\tilde {x} = x/e$ and

$\tilde {x} = x/e$ and ![]() $\tilde {y} = y/e$, and the time-averaged interface location has been represented as a white dashed line. Moreover, here as elsewhere, velocity vectors in the liquid phase have been magnified by a factor of

$\tilde {y} = y/e$, and the time-averaged interface location has been represented as a white dashed line. Moreover, here as elsewhere, velocity vectors in the liquid phase have been magnified by a factor of ![]() ${O}(10^2)$.

${O}(10^2)$.

After issuing from the injection section (![]() $\tilde {x}=0$), the air and water flows meet downstream of the splitter plate. By moving along the streamwise direction, two distinct regions can be detected: a wake (

$\tilde {x}=0$), the air and water flows meet downstream of the splitter plate. By moving along the streamwise direction, two distinct regions can be detected: a wake (![]() $0<\tilde {x}<\tilde {x}_w$) and a pure mixing layer (

$0<\tilde {x}<\tilde {x}_w$) and a pure mixing layer (![]() $\tilde {x} > \tilde {x}_w$) region, with

$\tilde {x} > \tilde {x}_w$) region, with ![]() $\tilde {x}_w = x_w/e = 17.5$. The wake region length

$\tilde {x}_w = x_w/e = 17.5$. The wake region length ![]() $\tilde {x}_w$ has been calculated as the last streamwise station (starting from

$\tilde {x}_w$ has been calculated as the last streamwise station (starting from ![]() $\tilde {x}=0$) where

$\tilde {x}=0$) where ![]() $\bar {u}(\tilde {y}) < 0$ (i.e.

$\bar {u}(\tilde {y}) < 0$ (i.e. ![]() $\bar {u} > 0$ for

$\bar {u} > 0$ for ![]() $\tilde {x} > \tilde {x}_w$). The spatial development of the mixing layer is more clearly quantified in figure 6, which reports

$\tilde {x} > \tilde {x}_w$). The spatial development of the mixing layer is more clearly quantified in figure 6, which reports ![]() $\bar {u}(\tilde {y})$ profiles at different streamwise stations spanning both air and water streams, together with the corresponding average measurement uncertainty. The reverse flow component within the wake region is highlighted by the negative values of

$\bar {u}(\tilde {y})$ profiles at different streamwise stations spanning both air and water streams, together with the corresponding average measurement uncertainty. The reverse flow component within the wake region is highlighted by the negative values of ![]() $\bar {u}$ for

$\bar {u}$ for ![]() $\tilde {y}$ around zero. Far from

$\tilde {y}$ around zero. Far from ![]() $\tilde {y}=0$, the velocity profile is characterized by an almost uniform distribution in both air (

$\tilde {y}=0$, the velocity profile is characterized by an almost uniform distribution in both air (![]() $\tilde {y} > 2$) and water (

$\tilde {y} > 2$) and water (![]() $\tilde {y} < -1.1$) streams, while it undergoes strong spatial variations within the region

$\tilde {y} < -1.1$) streams, while it undergoes strong spatial variations within the region ![]() $-1.1<\tilde {y} < 2$. Downstream of the wake region, the velocity profile is influenced by the air–air mixing layer forming between the injected gas stream and the external still ambient, with consequent reduction of the local

$-1.1<\tilde {y} < 2$. Downstream of the wake region, the velocity profile is influenced by the air–air mixing layer forming between the injected gas stream and the external still ambient, with consequent reduction of the local ![]() $\bar {u}$ value by increasing

$\bar {u}$ value by increasing ![]() $\tilde {y}$ (phenomenon of jet expansion; see Descamps et al. Reference Descamps, Matas and Cartellier2008).

$\tilde {y}$ (phenomenon of jet expansion; see Descamps et al. Reference Descamps, Matas and Cartellier2008).

Figure 6. Time-averaged streamwise ![]() $\bar {u}(\tilde {y})/U_g$ velocity component profiles at different

$\bar {u}(\tilde {y})/U_g$ velocity component profiles at different ![]() $\tilde {x}$ stations:

$\tilde {x}$ stations: ![]() $0.55$ (black circles),

$0.55$ (black circles), ![]() $10.88$ (red diamonds),

$10.88$ (red diamonds), ![]() $21.76$ (blue squares),

$21.76$ (blue squares), ![]() $32.10$ (black stars),

$32.10$ (black stars), ![]() $42.98$ (red triangles),

$42.98$ (red triangles), ![]() $53.31$ (blue circles). The dashed and dotted lines represent the values

$53.31$ (blue circles). The dashed and dotted lines represent the values ![]() $\bar {u}/U_g = 0$ and

$\bar {u}/U_g = 0$ and ![]() $1$, respectively, and error bars denote the average measurement uncertainty, while green circles highlight the interface location. REF case of table 3.

$1$, respectively, and error bars denote the average measurement uncertainty, while green circles highlight the interface location. REF case of table 3.

By moving along ![]() $\tilde {x}$, the momentum exchange between the faster gas and the slower water stream leads to the progressive reduction of the velocity deficit, which is the difference between the minimum and the free-stream local liquid velocities (

$\tilde {x}$, the momentum exchange between the faster gas and the slower water stream leads to the progressive reduction of the velocity deficit, which is the difference between the minimum and the free-stream local liquid velocities (![]() $\bar {u}_{min} - U_l$). This aspect is clarified in figure 7, which shows the velocity profile at three selected downstream stations, respectively inside (

$\bar {u}_{min} - U_l$). This aspect is clarified in figure 7, which shows the velocity profile at three selected downstream stations, respectively inside (![]() $\tilde {x} = 0.55$, black curve), just outside (

$\tilde {x} = 0.55$, black curve), just outside (![]() $\tilde {x} = 20.13$, red curve) and far from (

$\tilde {x} = 20.13$, red curve) and far from (![]() $\tilde {x} = 53.31$, blue curve) the wake region (figures 7a,b), and the velocity deficit streamwise distribution (figure 7c), together with the corresponding average measurement uncertainty.

$\tilde {x} = 53.31$, blue curve) the wake region (figures 7a,b), and the velocity deficit streamwise distribution (figure 7c), together with the corresponding average measurement uncertainty.

Figure 7. (a) Time-averaged streamwise ![]() $\bar {u}(\tilde {y})/U_g$ velocity component profiles at different

$\bar {u}(\tilde {y})/U_g$ velocity component profiles at different ![]() $\tilde {x}$ stations, with (b) zoom near the liquid phase, and (c) velocity deficit

$\tilde {x}$ stations, with (b) zoom near the liquid phase, and (c) velocity deficit ![]() $(\bar {u}_{min} - U_l)/U_g$ streamwise distribution. In (c), the vertical red line denotes the wake region length

$(\bar {u}_{min} - U_l)/U_g$ streamwise distribution. In (c), the vertical red line denotes the wake region length ![]() $\tilde {x}_w$, the horizontal blue dashed line denotes the zero, and error bars represent the average measurement uncertainty. REF case of table 3.

$\tilde {x}_w$, the horizontal blue dashed line denotes the zero, and error bars represent the average measurement uncertainty. REF case of table 3.

The different regions characterizing the flow topology are further highlighted by ![]() $\bar {u}(\tilde {x})$ and

$\bar {u}(\tilde {x})$ and ![]() $\bar {v}(\tilde {x})$ velocity profiles, shown respectively in figures 8(a,b), for normal-to-flow stations spanning both air and water streams. The distribution

$\bar {v}(\tilde {x})$ velocity profiles, shown respectively in figures 8(a,b), for normal-to-flow stations spanning both air and water streams. The distribution ![]() $\bar {u}(\tilde {x},\tilde {y}=0)$ highlights the strong spatial variation characterizing the flow field in the wake region (blue curve in figure 8a), while

$\bar {u}(\tilde {x},\tilde {y}=0)$ highlights the strong spatial variation characterizing the flow field in the wake region (blue curve in figure 8a), while ![]() $\bar {v}(\tilde {x})$ profiles reveal the downward deviation of the gas stream (i.e. negative values of

$\bar {v}(\tilde {x})$ profiles reveal the downward deviation of the gas stream (i.e. negative values of ![]() $\bar {v}(\tilde {x})$) in the near-field region, as a result of the combination of water jet contraction (Agbaglah et al. Reference Agbaglah, Chiodi and Desjardins2017) and air recirculation within the wake.

$\bar {v}(\tilde {x})$) in the near-field region, as a result of the combination of water jet contraction (Agbaglah et al. Reference Agbaglah, Chiodi and Desjardins2017) and air recirculation within the wake.

Figure 8. (a) Time-averaged streamwise ![]() $\bar {u}(\tilde {x})/U_g$ and (b) normal-to-flow

$\bar {u}(\tilde {x})/U_g$ and (b) normal-to-flow ![]() $\bar {v}(\tilde {x})/U_g$ velocity component profiles at different

$\bar {v}(\tilde {x})/U_g$ velocity component profiles at different ![]() $\tilde {y}$ stations. REF case of table 3.

$\tilde {y}$ stations. REF case of table 3.

Figures 9 and 10 show the Reynolds stress tensor components ![]() $\overline {u^\prime u^\prime }$,

$\overline {u^\prime u^\prime }$, ![]() $\overline {v^\prime v^\prime }$ and

$\overline {v^\prime v^\prime }$ and ![]() $\overline {u^\prime v^\prime }$ in terms of contour representations and

$\overline {u^\prime v^\prime }$ in terms of contour representations and ![]() $\tilde {y}$ profiles, respectively. The

$\tilde {y}$ profiles, respectively. The ![]() $\tilde {x}$ velocity component fluctuation is evaluated as

$\tilde {x}$ velocity component fluctuation is evaluated as ![]() $u^\prime = u - \bar {u}$, and the same applies for

$u^\prime = u - \bar {u}$, and the same applies for ![]() $v^\prime$. The

$v^\prime$. The ![]() $\overline {u^\prime u^\prime }(\tilde {y})$ distribution (figures 9a and 10a) is characterized by larger peaks than the others (figures 9b,c and 10b,c), as also found by Ling et al. (Reference Ling, Fuster, Tryggvason and Zaleski2019) by means of three-dimensional direct numerical simulations. Moreover, all the distributions are peaked in correspondence with the maximum momentum exchange locations, namely at the air–water and air–air mixing layers (the latter on the image top), as already evidenced in discussing figure 6 (see also Jiang & Ling Reference Jiang and Ling2021). Similarly, the streamwise

$\overline {u^\prime u^\prime }(\tilde {y})$ distribution (figures 9a and 10a) is characterized by larger peaks than the others (figures 9b,c and 10b,c), as also found by Ling et al. (Reference Ling, Fuster, Tryggvason and Zaleski2019) by means of three-dimensional direct numerical simulations. Moreover, all the distributions are peaked in correspondence with the maximum momentum exchange locations, namely at the air–water and air–air mixing layers (the latter on the image top), as already evidenced in discussing figure 6 (see also Jiang & Ling Reference Jiang and Ling2021). Similarly, the streamwise ![]() $\overline {u^\prime u^\prime }(\tilde {x})$ distribution reported in figure 10(d) reveals two peaks, the first immediately downstream of the splitter plate, and the second at

$\overline {u^\prime u^\prime }(\tilde {x})$ distribution reported in figure 10(d) reveals two peaks, the first immediately downstream of the splitter plate, and the second at ![]() $\tilde {x}_w = 17.5$, namely at the end of the recirculation region. It is also possible to appreciate that for each

$\tilde {x}_w = 17.5$, namely at the end of the recirculation region. It is also possible to appreciate that for each ![]() $\tilde {y}$ location, a constant value is approached asymptotically as

$\tilde {y}$ location, a constant value is approached asymptotically as ![]() $\tilde {x}$ increases, revealing that the mixing layer progressively achieves a self-similar state moving far from the wake region (Mehta Reference Mehta1991).

$\tilde {x}$ increases, revealing that the mixing layer progressively achieves a self-similar state moving far from the wake region (Mehta Reference Mehta1991).

Figure 9. Contours of (a) ![]() $\overline {u^\prime u^\prime }/U^2_g$, (b)

$\overline {u^\prime u^\prime }/U^2_g$, (b) ![]() $\overline {v^\prime v^\prime }/U^2_g$ and (c)

$\overline {v^\prime v^\prime }/U^2_g$ and (c) ![]() $\overline {u^\prime v^\prime }/U^2_g$. The splitter plate is highlighted in black, while the white dashed line denotes the time-averaged interface location. REF case of table 3.

$\overline {u^\prime v^\prime }/U^2_g$. The splitter plate is highlighted in black, while the white dashed line denotes the time-averaged interface location. REF case of table 3.

Figure 10. Profiles of (a) ![]() $\overline {u^\prime u^\prime }/U^2_g$, (b)

$\overline {u^\prime u^\prime }/U^2_g$, (b) ![]() $\overline {v^\prime v^\prime }/U^2_g$ and (c)

$\overline {v^\prime v^\prime }/U^2_g$ and (c) ![]() $\overline {u^\prime v^\prime }/U^2_g$ at different streamwise stations

$\overline {u^\prime v^\prime }/U^2_g$ at different streamwise stations ![]() $\tilde {x}$:

$\tilde {x}$: ![]() $0.55$ (black circles),

$0.55$ (black circles), ![]() $21.76$ (red diamonds),

$21.76$ (red diamonds), ![]() $53.31$ (blue triangles). (d) Profiles of

$53.31$ (blue triangles). (d) Profiles of ![]() $\overline {u^\prime u^\prime }/U^2_g$ at different

$\overline {u^\prime u^\prime }/U^2_g$ at different ![]() $\tilde {y}$ stations. REF case of table 3.

$\tilde {y}$ stations. REF case of table 3.

The analysis of the REF case is concluded by reporting a comparison between the measured velocity profiles and the theoretical base flows proposed by Otto et al. (Reference Otto, Rossi and Boeck2013) and Fuster et al. (Reference Fuster, Matas, Marty, Popinet, Hoepffner, Cartellier and Zaleski2013) in the context of the local stability analysis. The comparison is performed at two distinct streamwise stations: the first inside the wake region (![]() $\tilde {x} < \widetilde {x_w}$, figures 11a,b), and the second just outside it (

$\tilde {x} < \widetilde {x_w}$, figures 11a,b), and the second just outside it (![]() $\tilde {x} > \widetilde {x_w}$, figures 11c,d). Note that the measured profiles (black curves) have been represented by employing the shifted coordinate

$\tilde {x} > \widetilde {x_w}$, figures 11c,d). Note that the measured profiles (black curves) have been represented by employing the shifted coordinate ![]() $y^\star$, defined previously in § 2.2, to facilitate the comparisons with theoretical formulae (red curves) provided hereafter.

$y^\star$, defined previously in § 2.2, to facilitate the comparisons with theoretical formulae (red curves) provided hereafter.

Figure 11. Theoretical–experimental comparison of velocity profiles (a,b) inside (![]() $\tilde {x}=0.55$) and (c,d) outside (

$\tilde {x}=0.55$) and (c,d) outside (![]() $\tilde {x}=20.13$) the wake region of length

$\tilde {x}=20.13$) the wake region of length ![]() $\tilde {x}_w=17.5$. REF case of table 3.

$\tilde {x}_w=17.5$. REF case of table 3.

The analytical velocity profile used in figures 11(c,d) reads as

\begin{equation} \frac{u^+}{U_m} =

\begin{cases} -\dfrac{U_l}{U_m}\,\text{erf}

\left(\dfrac{y^\star}{\delta_l}\right) +

\dfrac{\bar{u}_0}{U_m} \left[1 + \text{erf}

\left(\dfrac{y^\star}{\delta_d}\right)\right], &

y^\star{\leq} 0,\\

\dfrac{U_g}{U_m}\,\text{erf}

\left(\dfrac{y^\star}{\delta_g}\right) +

\dfrac{\bar{u}_0}{U_m} \left[1 - \text{erf}

\left(\dfrac{y^\star}{\delta_d}\right)\right], &

y^\star{\geq} 0, \end{cases}

\end{equation}

\begin{equation} \frac{u^+}{U_m} =

\begin{cases} -\dfrac{U_l}{U_m}\,\text{erf}

\left(\dfrac{y^\star}{\delta_l}\right) +

\dfrac{\bar{u}_0}{U_m} \left[1 + \text{erf}

\left(\dfrac{y^\star}{\delta_d}\right)\right], &

y^\star{\leq} 0,\\

\dfrac{U_g}{U_m}\,\text{erf}

\left(\dfrac{y^\star}{\delta_g}\right) +

\dfrac{\bar{u}_0}{U_m} \left[1 - \text{erf}

\left(\dfrac{y^\star}{\delta_d}\right)\right], &

y^\star{\geq} 0, \end{cases}

\end{equation}

which is the same as that reported by Fuster et al. (Reference Fuster, Matas, Marty, Popinet, Hoepffner, Cartellier and Zaleski2013) once small notational differences are rectified, while a modified version (discontinuous at ![]() $y^\star =0$) is adopted for comparisons in the wake region (figures 11a,b),

$y^\star =0$) is adopted for comparisons in the wake region (figures 11a,b),

\begin{equation} \frac{u^-}{U_m} =

\begin{cases} -\dfrac{U_l}{U_m}\,\text{erf}

\left(\dfrac{y^\star}{\delta_l}\right) +

\dfrac{\bar{u}_0}{U_m} \left[1 + \text{erf}

\left(\dfrac{y^\star}{\delta_d}\right)\right], &

y^\star{\leq} 0,\\

\dfrac{U_g}{U_m}\,\text{erf}

\left(\dfrac{y^\star{-}y^\star_{min}}{\delta_g}\right) +

\dfrac{\bar{u}_{min}}{U_m} \left[1 - \text{erf}

\left(\dfrac{y^\star{-}y^\star_{min}}{\delta_d}\right)\right], & y^\star{>} 0.

\end{cases}\end{equation}

\begin{equation} \frac{u^-}{U_m} =

\begin{cases} -\dfrac{U_l}{U_m}\,\text{erf}

\left(\dfrac{y^\star}{\delta_l}\right) +

\dfrac{\bar{u}_0}{U_m} \left[1 + \text{erf}

\left(\dfrac{y^\star}{\delta_d}\right)\right], &

y^\star{\leq} 0,\\

\dfrac{U_g}{U_m}\,\text{erf}

\left(\dfrac{y^\star{-}y^\star_{min}}{\delta_g}\right) +

\dfrac{\bar{u}_{min}}{U_m} \left[1 - \text{erf}

\left(\dfrac{y^\star{-}y^\star_{min}}{\delta_d}\right)\right], & y^\star{>} 0.

\end{cases}\end{equation}

In (3.2)–(3.3), the error function ![]() $\text {erf}(y^\star )$ is employed,

$\text {erf}(y^\star )$ is employed, ![]() $U_m = (U_g + U_l)/2$,

$U_m = (U_g + U_l)/2$, ![]() $\bar {u}_0$ is the measured velocity at the air–water interface (an analytical estimation based on continuity of shear stresses across the interface was used by Fuster et al. Reference Fuster, Matas, Marty, Popinet, Hoepffner, Cartellier and Zaleski2013),

$\bar {u}_0$ is the measured velocity at the air–water interface (an analytical estimation based on continuity of shear stresses across the interface was used by Fuster et al. Reference Fuster, Matas, Marty, Popinet, Hoepffner, Cartellier and Zaleski2013), ![]() $\bar {u}_{min}$ is the minimum (negative) measured value within the wake region (at the location

$\bar {u}_{min}$ is the minimum (negative) measured value within the wake region (at the location ![]() $y^\star = y^\star _{min}$), and

$y^\star = y^\star _{min}$), and ![]() $\delta _d$ is an adjustable parameter introduced by Otto et al. (Reference Otto, Rossi and Boeck2013) to mimic experimental velocity profiles in the near-field region of the mixing layer.

$\delta _d$ is an adjustable parameter introduced by Otto et al. (Reference Otto, Rossi and Boeck2013) to mimic experimental velocity profiles in the near-field region of the mixing layer.

Results of the comparison reveal a strict agreement between the measured and theoretical velocity profiles, both inside (i.e. negative value of velocity deficit) and outside the wake region. Values of the ratio ![]() $\delta _d/\delta _g$ giving the best match with experimental data are respectively

$\delta _d/\delta _g$ giving the best match with experimental data are respectively ![]() $0.75$ (for

$0.75$ (for ![]() $\tilde {x} < \tilde {x}_w$) and

$\tilde {x} < \tilde {x}_w$) and ![]() $0.78$ (

$0.78$ (![]() $\tilde {x} > \tilde {x}_w$). In agreement with Otto et al. (Reference Otto, Rossi and Boeck2013), we have

$\tilde {x} > \tilde {x}_w$). In agreement with Otto et al. (Reference Otto, Rossi and Boeck2013), we have ![]() $\delta _d/\delta _g < 1$ in both cases, due to the presence of a velocity deficit in the mean flow profile.

$\delta _d/\delta _g < 1$ in both cases, due to the presence of a velocity deficit in the mean flow profile.

3.2. Effect of liquid Reynolds number

The effect of the liquid Reynolds number ![]() $Re_l$ variation on the two-phase flow topology at fixed

$Re_l$ variation on the two-phase flow topology at fixed ![]() $Re_g$ is investigated by modifying the injection velocity

$Re_g$ is investigated by modifying the injection velocity ![]() $U_l$. Results are shown in figure 12, where

$U_l$. Results are shown in figure 12, where ![]() $\bar {u}(\tilde {y})$ distributions at different streamwise stations are reported for the REF and L3 cases, and in figure 13 in terms of time-averaged velocity magnitude contours and vectors distribution. The liquid Reynolds number varies between

$\bar {u}(\tilde {y})$ distributions at different streamwise stations are reported for the REF and L3 cases, and in figure 13 in terms of time-averaged velocity magnitude contours and vectors distribution. The liquid Reynolds number varies between ![]() $Re_l=302$ (L1 case) and

$Re_l=302$ (L1 case) and ![]() $Re_l = 807$ (L3 case), while the gas Reynolds number is

$Re_l = 807$ (L3 case), while the gas Reynolds number is ![]() $Re_g = 493$, as in the REF case discussed previously.

$Re_g = 493$, as in the REF case discussed previously.

Figure 12. Liquid Reynolds number ![]() $Re_l$ effect on the time-averaged streamwise

$Re_l$ effect on the time-averaged streamwise ![]() $\bar {u}(\tilde {y})/U_g$ velocity component at different

$\bar {u}(\tilde {y})/U_g$ velocity component at different ![]() $\tilde {x}$ stations:

$\tilde {x}$ stations: ![]() $0.55$ (black circles),

$0.55$ (black circles), ![]() $21.76$ (red diamonds),

$21.76$ (red diamonds), ![]() $53.31$ (blue triangles). Cases (a) REF and (b) L3 of table 3.

$53.31$ (blue triangles). Cases (a) REF and (b) L3 of table 3.

Figure 13. Liquid Reynolds number ![]() $Re_l$ effect on the time-averaged velocity magnitude

$Re_l$ effect on the time-averaged velocity magnitude ![]() $\bar {V}/U_g$. The mean interface location is represented as a white dashed line, and velocity vectors are also reported. Cases (a) L1, (b) REF, (c) L2 and (d) L3 of table 3.

$\bar {V}/U_g$. The mean interface location is represented as a white dashed line, and velocity vectors are also reported. Cases (a) L1, (b) REF, (c) L2 and (d) L3 of table 3.

The velocity maps reported in figure 13 show that the recirculation region characterizing the flow immediately downstream of the injection section progressively reduces as ![]() $Re_l$ increases, until it vanishes in the last (L3) case. The increase in inlet velocity of the liquid phase produces a shear effect at the interface, which accelerates locally the (transitional) gas flow and determines the progressive absorption of the wake. For the L3 case, the absence of the wake flow component determines an almost unperturbed air–water interface at the splitter plate edge. As a consequence, the two-phase mixing layer flow becomes spatially invariant along the streamwise direction up to

$Re_l$ increases, until it vanishes in the last (L3) case. The increase in inlet velocity of the liquid phase produces a shear effect at the interface, which accelerates locally the (transitional) gas flow and determines the progressive absorption of the wake. For the L3 case, the absence of the wake flow component determines an almost unperturbed air–water interface at the splitter plate edge. As a consequence, the two-phase mixing layer flow becomes spatially invariant along the streamwise direction up to ![]() $\tilde {y}=5$ (see figure 12b), where differences among the streamwise-spaced velocity profiles are due to the presence of the air–air mixing layer, as observed previously in § 3.1.

$\tilde {y}=5$ (see figure 12b), where differences among the streamwise-spaced velocity profiles are due to the presence of the air–air mixing layer, as observed previously in § 3.1.

It is important to note that when no wake is present due to a high ![]() $Re_l$ value, the liquid velocity field is basically not influenced by the co-flowing gaseous phase, developing parallel to the streamwise direction and to the injected air stream (figure 13d). This aspect will be highlighted further in § 3.3, where the effect of the gas Reynolds number on the variation of the flow topology will be presented and compared with the present discussion. A complete parametric trend of the wake length as a function of

$Re_l$ value, the liquid velocity field is basically not influenced by the co-flowing gaseous phase, developing parallel to the streamwise direction and to the injected air stream (figure 13d). This aspect will be highlighted further in § 3.3, where the effect of the gas Reynolds number on the variation of the flow topology will be presented and compared with the present discussion. A complete parametric trend of the wake length as a function of ![]() $Re_l$ for various

$Re_l$ for various ![]() $Re_g$ values will also be shown in § 3.3.

$Re_g$ values will also be shown in § 3.3.

3.3. Effect of gas Reynolds number

Results of the investigation performed by varying the gas Reynolds number are first shown in figures 14 and 15, respectively in terms of velocity magnitude contours with superposed vectors distributions, and ![]() $\bar {u}(\tilde {y})$ profiles at different streamwise locations; the liquid velocity is kept constant and equal to that of the REF case, so that

$\bar {u}(\tilde {y})$ profiles at different streamwise locations; the liquid velocity is kept constant and equal to that of the REF case, so that ![]() $Re_l = 454$.

$Re_l = 454$.

Figure 14. Gas Reynolds number ![]() $Re_g$ effect on the time-averaged velocity magnitude

$Re_g$ effect on the time-averaged velocity magnitude ![]() $\bar {V}/U_g$. The mean interface location is represented as a white dashed line, and velocity vectors are also reported. Cases (a) G1, (b) REF, (c) G3 and (d) G4 of table 3.

$\bar {V}/U_g$. The mean interface location is represented as a white dashed line, and velocity vectors are also reported. Cases (a) G1, (b) REF, (c) G3 and (d) G4 of table 3.

Figure 15. Gas Reynolds number ![]() $Re_g$ effect on the time-averaged streamwise

$Re_g$ effect on the time-averaged streamwise ![]() $\bar {u}(\tilde {y})/U_g$ velocity component at different

$\bar {u}(\tilde {y})/U_g$ velocity component at different ![]() $\tilde {x}$ stations: (a)

$\tilde {x}$ stations: (a) ![]() $0.55$, (b)

$0.55$, (b) ![]() $21.76$, (c)

$21.76$, (c) ![]() $53.31$. Cases G1 (black circles), REF (red diamonds), G3 (blue triangles) and G4 (green squares) of table 3.

$53.31$. Cases G1 (black circles), REF (red diamonds), G3 (blue triangles) and G4 (green squares) of table 3.

By looking at the two-dimensional flow fields in figures 14(a–c) and the velocity profiles in figure 15(a), it can be seen that the wake region shortens progressively by increasing ![]() $Re_g$ from the G1 to the G3 case, with

$Re_g$ from the G1 to the G3 case, with ![]() $\tilde {x}_w$ decreasing from

$\tilde {x}_w$ decreasing from ![]() $21.2$ to

$21.2$ to ![]() $9.8$. Accordingly, the peak of the Reynolds stress component

$9.8$. Accordingly, the peak of the Reynolds stress component ![]() $\overline {u^\prime u^\prime }$ is shifted towards lower

$\overline {u^\prime u^\prime }$ is shifted towards lower ![]() $\tilde {x}$ values, and it achieves its maximum at

$\tilde {x}$ values, and it achieves its maximum at ![]() $Re_g=704$ (G2 case of table 3), as reported in figure 16. Due to the sudden change of the shear boundary condition downstream of the plate, the liquid velocity relaxes, and the water jet accelerates progressively and contracts along the streamwise direction

$Re_g=704$ (G2 case of table 3), as reported in figure 16. Due to the sudden change of the shear boundary condition downstream of the plate, the liquid velocity relaxes, and the water jet accelerates progressively and contracts along the streamwise direction ![]() $x$ (Tillett Reference Tillett1968), as can be appreciated by looking at figures 14(a,b,c) in turn. Moreover, outside the wake region, the gas jet goes down progressively as

$x$ (Tillett Reference Tillett1968), as can be appreciated by looking at figures 14(a,b,c) in turn. Moreover, outside the wake region, the gas jet goes down progressively as ![]() $Re_g$ increases (see also Agbaglah et al. Reference Agbaglah, Chiodi and Desjardins2017). The momentum flux difference in the air–air mixing layer also increases by increasing

$Re_g$ increases (see also Agbaglah et al. Reference Agbaglah, Chiodi and Desjardins2017). The momentum flux difference in the air–air mixing layer also increases by increasing ![]() $Re_g$, leading to a reduction in

$Re_g$, leading to a reduction in ![]() $\bar {u}(\tilde {y})$ moving towards the top of the domain, as shown by the evolution of velocity profiles in figures 15(b,c).

$\bar {u}(\tilde {y})$ moving towards the top of the domain, as shown by the evolution of velocity profiles in figures 15(b,c).

Figure 16. Profiles of ![]() $\overline {u^\prime u^\prime }/U^2_g$ at

$\overline {u^\prime u^\prime }/U^2_g$ at ![]() $\tilde {y} = 0$ for different values of the gas Reynolds number, for cases REF (black curve), G2 (red curve) and G4 (blue curve) of table 3.

$\tilde {y} = 0$ for different values of the gas Reynolds number, for cases REF (black curve), G2 (red curve) and G4 (blue curve) of table 3.

For the highest value of gas Reynolds number considered (G4 case, see figure 14(d) and green curves in figure 15), the wake region vanishes, i.e. ![]() $\tilde {x}_w = 0$. As a consequence, no peak in the Reynolds stress component

$\tilde {x}_w = 0$. As a consequence, no peak in the Reynolds stress component ![]() $\overline {u^\prime u^\prime }$ distribution is detected (blue curve in figure 16). It is important to note that when

$\overline {u^\prime u^\prime }$ distribution is detected (blue curve in figure 16). It is important to note that when ![]() $\tilde {x}_w = 0$ due to a high

$\tilde {x}_w = 0$ due to a high ![]() $Re_g$ value, the flow topology is significantly different from the case

$Re_g$ value, the flow topology is significantly different from the case ![]() $\tilde {x}_w = 0$ at high

$\tilde {x}_w = 0$ at high ![]() $Re_l$ discussed previously in § 3.2, as can be appreciated by comparing figures 14(d) and 13(d). As a matter of fact, the momentum exchanged by shear at the interface between the gas and liquid jets as

$Re_l$ discussed previously in § 3.2, as can be appreciated by comparing figures 14(d) and 13(d). As a matter of fact, the momentum exchanged by shear at the interface between the gas and liquid jets as ![]() $Re_g$ increases accelerates the liquid, which then has to contract to conserve the mass flow rate (figure 14d). As a consequence, the flow is no longer spatially invariant along the streamwise direction, as instead it has been observed at high

$Re_g$ increases accelerates the liquid, which then has to contract to conserve the mass flow rate (figure 14d). As a consequence, the flow is no longer spatially invariant along the streamwise direction, as instead it has been observed at high ![]() $Re_l$ value (figure 13d).

$Re_l$ value (figure 13d).

An overall picture of the wake extension variation with ![]() $Re_l$ and

$Re_l$ and ![]() $Re_g$ parameters is given in figure 17, where the trend

$Re_g$ parameters is given in figure 17, where the trend ![]() $\tilde {x}_w(Re_l)$ is reported for different values of the gas Reynolds number

$\tilde {x}_w(Re_l)$ is reported for different values of the gas Reynolds number ![]() $Re_g$, corresponding to the flow fields shown in figures 13 and 14. Note that additional cases characterized by a lower gas Reynolds number (

$Re_g$, corresponding to the flow fields shown in figures 13 and 14. Note that additional cases characterized by a lower gas Reynolds number (![]() $Re_g=256$) have also been reported (black curve in figure 17). It can be seen that the progressive decreasing of the recirculation region with

$Re_g=256$) have also been reported (black curve in figure 17). It can be seen that the progressive decreasing of the recirculation region with ![]() $Re_l$ is enhanced by increasing the gas Reynolds number. At

$Re_l$ is enhanced by increasing the gas Reynolds number. At ![]() $Re_g = 768$, no wake is detected for any value greater than

$Re_g = 768$, no wake is detected for any value greater than ![]() $Re_l=302$ (orange curve in figure 17). The trend

$Re_l=302$ (orange curve in figure 17). The trend ![]() $\tilde {x}_w(Re_l)$ is qualitatively the same for all the other

$\tilde {x}_w(Re_l)$ is qualitatively the same for all the other ![]() $Re_g$ values: it is approximately constant up to

$Re_g$ values: it is approximately constant up to ![]() $Re_l = 454$, then it decreases, reaching zero value for

$Re_l = 454$, then it decreases, reaching zero value for ![]() $Re_l = 807$.

$Re_l = 807$.

Figure 17. Liquid Reynolds number ![]() $Re_l$ effect on the wake region length

$Re_l$ effect on the wake region length ![]() $\tilde {x}_w$ at different

$\tilde {x}_w$ at different ![]() $Re_g$ values.

$Re_g$ values.

3.4. Effect of gas-to-liquid dynamic pressure ratio

Finally, the trend of the wake length as a function of the gas-to-liquid dynamic pressure ratio ![]() $M$ is summarized in figure 18, for different values of the gas Reynolds number. It can be seen that for a fixed

$M$ is summarized in figure 18, for different values of the gas Reynolds number. It can be seen that for a fixed ![]() $Re_g$, relatively low

$Re_g$, relatively low ![]() $M$ values (high liquid velocities) promote a reduction of the wake, which vanishes eventually. This is analogous to the

$M$ values (high liquid velocities) promote a reduction of the wake, which vanishes eventually. This is analogous to the ![]() $Re_l$ effect outlined in figure 17 and by the velocity contours reported in figure 13. Moreover, the

$Re_l$ effect outlined in figure 17 and by the velocity contours reported in figure 13. Moreover, the ![]() $M$ value denoting the transition from a wake regime to a pure mixing layer regime increases with

$M$ value denoting the transition from a wake regime to a pure mixing layer regime increases with ![]() $Re_g$. Therefore, only at relatively high values of the gas Reynolds number does the flow behave as a pure mixing layer in a wide range of liquid injection velocities (i.e. wide range of

$Re_g$. Therefore, only at relatively high values of the gas Reynolds number does the flow behave as a pure mixing layer in a wide range of liquid injection velocities (i.e. wide range of ![]() $M$ values).

$M$ values).

Figure 18. Dynamic pressure ratio ![]() $M$ effect on the wake region length

$M$ effect on the wake region length ![]() $\tilde {x}_w$ at different values of the gas Reynolds number

$\tilde {x}_w$ at different values of the gas Reynolds number ![]() $Re_g$.

$Re_g$.

As a first summary of the results concerning the mean (time-averaged) flow analysis, a comprehensive characterization of the flow fields in both the phases has been described, including velocity profiles in various streamwise stations, Reynolds stress tensor components, and wake size. The measured velocity profiles agree well with analytical formulae proposed in past works for locally parallel flows in spatio-temporal stability analysis. The transition from a mixed wake mixing layer to a pure mixing layer regime as a function of the governing parameters has been highlighted. In § 4, which reports the unsteady flow characteristics, the dominant flow oscillations will be interpreted in connection with the velocity profiles and the overall flow topology analysed here, giving insights into the global dynamics of the gas–liquid interface.

4. Unsteady flow characteristics

The unsteady development of the air–water mixing layer is first analysed by computing the power spectral density (PSD) of the PIV measurements of normal-to-flow velocity component fluctuations ![]() $v^\prime$, monitored at different

$v^\prime$, monitored at different ![]() $\tilde {x}$ and

$\tilde {x}$ and ![]() $\tilde {y}$ locations (white circles in figure 19). We start by focusing attention on the gas Reynolds number (

$\tilde {y}$ locations (white circles in figure 19). We start by focusing attention on the gas Reynolds number (![]() $Re_g$) and the gas-to-liquid dynamic pressure ratio (

$Re_g$) and the gas-to-liquid dynamic pressure ratio (![]() $M$) effects on the frequency spectra evaluated at a monitoring station immediately downstream of the splitter plate in the air flow, namely

$M$) effects on the frequency spectra evaluated at a monitoring station immediately downstream of the splitter plate in the air flow, namely ![]() $(\tilde {x},\tilde {y}) = (0.55,2.72)$.

$(\tilde {x},\tilde {y}) = (0.55,2.72)$.

Figure 19. Contour map of ![]() $\overline {v^\prime v^\prime }/U^2_g$ for the G5 case of table 3. The splitter plate is highlighted in black, while the white dashed line denotes the time-averaged interface location. The white circles denote the monitoring locations employed for the analysis of unsteady velocity fluctuations.

$\overline {v^\prime v^\prime }/U^2_g$ for the G5 case of table 3. The splitter plate is highlighted in black, while the white dashed line denotes the time-averaged interface location. The white circles denote the monitoring locations employed for the analysis of unsteady velocity fluctuations.