Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Yan, Shaohua

Zhou, Haiyang

Xing, Bobin

Zhang, Shuang

Li, Li

and

Qin, Qing H.

2018.

Crystal plasticity in fusion zone of a hybrid laser welded Al alloys joint: From nanoscale to macroscale.

Materials & Design,

Vol. 160,

Issue. ,

p.

313.

Gan, K.F.

and

Ngan, A.H.W.

2018.

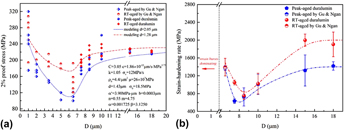

The unusual size effect of eutectic Sn/Pb alloys in the micro regime: Experiments and modeling.

Acta Materialia,

Vol. 151,

Issue. ,

p.

282.

Pan, Yan

Wu, Haijun

Wang, Xiaofei

Sun, Qiaoyan

Xiao, Lin

Ding, Xiangdong

Sun, Jun

and

Salje, Ekhard K. H.

2019.

Rotatable precipitates change the scale-free to scale dependent statistics in compressed Ti nano-pillars.

Scientific Reports,

Vol. 9,

Issue. 1,

Pan, Yan

Sun, Qiaoyan

Xiao, Lin

Ding, Xiangdong

and

Sun, Jun

2019.

Plastic deformation behavior and microscopic mechanism of metastable Ti-10V-2Fe-3Al alloy single crystal pillars orientated to <011>β in submicron scales Part I: Double size effects and martensitic transformation prediction.

Materials Science and Engineering: A,

Vol. 743,

Issue. ,

p.

798.

Yan, Shaohua

Zhou, Haiyang

and

Qin, Qing H.

2019.

Microstructure versus size: nano/microscale deformation of solute-strengthening Al alloys via pillar compression tests.

Materials Research Letters,

Vol. 7,

Issue. 2,

p.

53.

Li, Xiaohua

Liu, Yongchang

Gan, Kefu

Dong, Ji

and

Liu, Chenxi

2020.

Acquiring a low yield ratio well synchronized with enhanced strength of HSLA pipeline steels through adjusting multiple-phase microstructures.

Materials Science and Engineering: A,

Vol. 785,

Issue. ,

p.

139350.

Gan, Kefu

Zhu, Shuya

Jiang, Songshan

and

Huang, Yongjiang

2020.

Study on stochastic nature of plasticity of Cu/Zr metallic glass micropillars.

Journal of Alloys and Compounds,

Vol. 831,

Issue. ,

p.

154719.

Li, Xiaohua

Shi, Lei

Liu, Yongchang

Gan, Kefu

and

Liu, Chenxi

2020.

Achieving a desirable combination of mechanical properties in HSLA steel through step quenching.

Materials Science and Engineering: A,

Vol. 772,

Issue. ,

p.

138683.

Gan, Kefu

Yan, Dingshun

Zhu, Shuya

and

Li, Zhiming

2021.

Interstitial effects on the incipient plasticity and dislocation behavior of a metastable high-entropy alloy: Nanoindentation experiments and statistical modeling.

Acta Materialia,

Vol. 206,

Issue. ,

p.

116633.

Zeng, Quanqing

Gan, Kefu

and

Wang, Yin

2021.

Effect of Heat Treatment on Microstructures and Mechanical Behaviors of 316L Stainless Steels Synthesized by Selective Laser Melting.

Journal of Materials Engineering and Performance,

Vol. 30,

Issue. 1,

p.

409.

Chen, Wufan

Wang, Xiaoyuan

Yan, Yabin

Sumigawa, Takashi

Kitamura, Takayuki

Feng, Miaolin

and

Xuan, Fu-Zhen

2021.

Bending stress relaxation of microscale single-crystal copper at room temperature: An in situ SEM study.

European Journal of Mechanics - A/Solids,

Vol. 90,

Issue. ,

p.

104377.

Liu, Ying

Liu, Wenbin

Yu, Long

Sui, Haonan

Cheng, Yangyang

and

Duan, Huiling

2022.

Size-dependent to size-independent transition in creep of single crystalline Cu micropillars.

Extreme Mechanics Letters,

Vol. 56,

Issue. ,

p.

101843.

Wan, H.Y.

Yang, W.K.

Wang, L.Y.

Zhou, Z.J.

Li, C.P.

Chen, G.F.

Lei, L.M.

and

Zhang, G.P.

2022.

Toward qualification of additively manufactured metal parts: Tensile and fatigue properties of selective laser melted Inconel 718 evaluated using miniature specimens.

Journal of Materials Science & Technology,

Vol. 97,

Issue. ,

p.

239.

Huang, Weiying

Zhang, Wen

Yu, Qiang

Wu, Pengfei

Tong, Yonggang

and

Gan, Kefu

2024.

A promising strategy of multicomponent alloy intermedium for enhancing the mechanical performance of inertia friction welding joints of Inconel 718 alloys.

Materials Science and Engineering: A,

Vol. 899,

Issue. ,

p.

146480.

Liu, W.B.

Cheng, Y.Y.

and

Duan, H.L.

2024.

Innovative Lightweight and High-Strength Alloys.

p.

213.

Huang, Weiying

Zhang, Song

Tong, Yonggang

Wu, Pengfei

and

Gan, Kefu

2024.

Exceptional creep resistance enabled by thermally stable cellular dislocation structures in an additively manufactured multicomponent alloy.

Materials Science and Engineering: A,

Vol. 890,

Issue. ,

p.

145902.