Article contents

Fracture toughness of nanocrystalline metal matrix composites reinforced by aligned carbon nanotubes

Published online by Cambridge University Press: 19 October 2015

Abstract

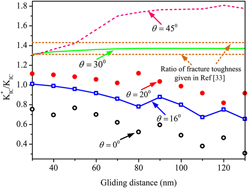

Experimental observations have shown that carbon nanotubes (CNTs)/Al nanocomposites with high level ordered nanolaminates exhibit greatly improved plasticity. The increased plasticity is mainly attributed to enhanced dislocation storage capability and two-dimensional alignment of the reinforcement. Here a theoretical model is proposed with interactions between aligned CNTs and grain boundary dislocations emitted from a crack tip taken into consideration to investigate crack blunting and fracture toughness in nanocrytalline metal matrix composites (MMCs). The critical shear stress for emission of first dislocation from intersections between a long, flat crack and aligned CNTs is quantitatively characterized. The final equilibrium positions and maximum numbers of emitted dislocations for different orientation angles and microstructures of aligned reinforcement are evaluated. In addition, the dependence of enhanced fracture toughness on effective gliding distance of emitted dislocations is also determined. The results show that the existence of aligned CNTs can lead to an increase of critical crack intensity factor by 77% than that in dislocation free case under certain conditions. The model may provide a basis understanding of ductility in aligned CNTs-reinforced nanocrystalline MMCs on respective of emission and motion of dislocations.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2015

Footnotes

Contributing Editor: Yang-T. Cheng

References

REFERENCES

- 5

- Cited by