Article contents

Effect of intrinsic viscosity on solid-state microcellular foaming of polyethylene terephthalate

Published online by Cambridge University Press: 09 July 2013

Abstract

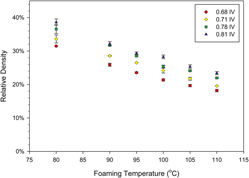

Microcellular foams, with cells of the order 10 μm, have been studied for over two decades. But little research has been done to study the effect of molecular weight on solid-state microcellular foaming. In this study, polyethylene terephthalate (PET) with a range of intrinsic viscosity (IV) 0.68–0.81 dL/g was used to investigate the effect of molecular weight on microcellular foaming process and resulting foam microstructures and properties. In the saturation step, IV showed negligible effect on sorption and desorption of CO2 in PET for all the conditions explored. In the foaming step, we found relative density increased with increasing IV. Also, as IV increased, cell size decreased and cell nucleation density increased. We hypothesize that lower chain mobility in higher IV samples led to more localized cell nucleation, resulting in a higher nucleation density, and also more constraints for cell growth, resulting in a smaller cell size. In addition, higher IV foams were found to have smaller skin thicknesses.

- Type

- Invited Papers

- Information

- Journal of Materials Research , Volume 28 , Issue 17: Focus Issue: Advances in the Synthesis, Characterization, and Properties of Bulk Porous Materials , 14 September 2013 , pp. 2374 - 2379

- Copyright

- Copyright © Materials Research Society 2013

References

REFERENCES

- 12

- Cited by