1. Introduction

Flow-induced vibration (FIV) of structures is an aero- or hydro-elastic phenomenon resulting from the complex coupled interaction between a fluid and a structure (often termed fluid–structure interaction – FSI). FIV poses a critical challenge in various engineering applications, such as the swaying of large structures like bridges and high-rise buildings in strong winds, where undesirable vibration can lead to structural failure or long-term fatigue. Conversely, FIV has been considered as a potential source of renewable energy to harness available kinetic energy from fluid flows (see Bernitsas et al. Reference Bernitsas, Raghavan, Ben-Simon and Garcia2008; Lee & Bernitsas Reference Lee and Bernitsas2011; Wang et al. Reference Wang, Du, Zhao and Sun2017; Soti et al. Reference Soti, Zhao, Thompson, Sheridan and Bhardwaj2018; Tamimi et al. Reference Tamimi, Armin, Shahvaghar-Asl, Naeeni and Zeinoddini2019; Lv et al. Reference Lv, Sun, Bernitsas and Sun2021; Lo et al. Reference Lo, Thompson, Hourigan and Zhao2024c). Therefore, this has motivated an increasing amount of research that aims to characterise, predict and control FIV (see Khalak & Williamson Reference Khalak and Williamson1996; Govardhan & Williamson Reference Govardhan and Williamson2000; Morse & Williamson Reference Morse and Williamson2009b; Wong et al. Reference Wong, Zhao, Lo Jacono, Thompson and Sheridan2017; Lo et al. Reference Lo, Thompson, Hourigan and Zhao2024a). Of interest in the present study, a machine-learning-based active control method is implemented to maximise the cross-flow FIV of a thin elliptical cylinder, which a recent study (Lo et al. Reference Lo, Hourigan, Thompson and Zhao2023) has shown to produce high amplitude oscillations.

The FIV response of an aeroelastic or elastically mounted bluff body can typically be characterised in terms of two distinct phenomena: vortex-induced vibration (VIV) and galloping. VIV occurs as a result of the periodic shedding of vortices, or at least shear layer vorticity variation (Menon & Mittal Reference Menon and Mittal2020), from an elastic or elastically mounted body leading to a periodic cross-flow forcing. VIV is self-limited due to the breakup of the symmetrically alternating von Kármán vortex street at large vibration amplitudes (Blevins Reference Blevins1990). Galloping, however, is caused by the asymmetric pressure distribution across the body arising from the changes in the instantaneous flow incidence angle as the body oscillates in the fluid. As both manifestations of FIV are dependent on the properties of the flow and the cylinder (e.g. flow velocity, Reynolds number, geometry, mass ratio, applied damping, structural stiffness), many past works have chosen parameters such that VIV and galloping occur separately and can be individually investigated (Brooks Reference Brooks1960). However, recent studies (see Nemes et al. Reference Nemes, Zhao, Jacono and Sheridan2012; Zhao, Hourigan & Thompson Reference Zhao, Hourigan and Thompson2018a) have shown that rich and complex fluid–structure interactions can also be observed when both FIV phenomena concurrently manifest in the dynamic response of an elastic or elastically mounted cylinder system.

One example of the co-manifestation of VIV and galloping relates to cylinders with elliptical geometries as parametrised by the elliptical ratio ![]() $\varepsilon = b/a$, where

$\varepsilon = b/a$, where ![]() $a$ and

$a$ and ![]() $b$ are the streamwise and cross-flow (transverse) dimensions, respectively. Since the circular cylinder is considered a special case of the elliptical geometry (with

$b$ are the streamwise and cross-flow (transverse) dimensions, respectively. Since the circular cylinder is considered a special case of the elliptical geometry (with ![]() $\varepsilon = 1$) whose FIV response is VIV due to the inherent symmetry of the system (see the reviews of Bearman Reference Bearman1984; Williamson & Govardhan Reference Williamson and Govardhan2004), numerous studies have shown that the introduction of deformation, where

$\varepsilon = 1$) whose FIV response is VIV due to the inherent symmetry of the system (see the reviews of Bearman Reference Bearman1984; Williamson & Govardhan Reference Williamson and Govardhan2004), numerous studies have shown that the introduction of deformation, where ![]() $\varepsilon > 1$, causes the flow induced by a transversely oscillating elliptical cylinder to become more unstable (Hall Reference Hall1984; Navrose et al. Reference Navrose, Yogeswaran, Sen and Mittal2014; Zhao, Hourigan & Thompson Reference Zhao, Hourigan and Thompson2019; Vijay et al. Reference Vijay, Srinil, Zhu, Bao, Zhou and Han2020). However, it was only recently when Lo et al. (Reference Lo, Hourigan, Thompson and Zhao2023) investigated the effect of structural damping on the FIV dynamics of a thin

$\varepsilon > 1$, causes the flow induced by a transversely oscillating elliptical cylinder to become more unstable (Hall Reference Hall1984; Navrose et al. Reference Navrose, Yogeswaran, Sen and Mittal2014; Zhao, Hourigan & Thompson Reference Zhao, Hourigan and Thompson2019; Vijay et al. Reference Vijay, Srinil, Zhu, Bao, Zhou and Han2020). However, it was only recently when Lo et al. (Reference Lo, Hourigan, Thompson and Zhao2023) investigated the effect of structural damping on the FIV dynamics of a thin ![]() $\varepsilon =5$ cylinder (see figure 1) that large-scale oscillation amplitudes, previously unseen for other geometries at similar

$\varepsilon =5$ cylinder (see figure 1) that large-scale oscillation amplitudes, previously unseen for other geometries at similar ![]() ${U^*}$ values, were discovered. Coined the ‘hyper branch’, the nominal maximum amplitude of

${U^*}$ values, were discovered. Coined the ‘hyper branch’, the nominal maximum amplitude of ![]() $A\approx 8b$ observed for this region was only limited by the width of the water-channel facility in which the experiments were conducted. Furthermore, the presence of a secondary vortex street (SVS) can be identified as the wake formed by the elliptical (airfoil-shaped) cylinder as it translates rapidly across the oncoming flow. It indicates that the approximately factor-of-five increase in maximum amplitude over the elliptical cylinder studies of Zhao et al. (Reference Zhao, Hourigan and Thompson2019) and Vijay et al. (Reference Vijay, Srinil, Zhu, Bao, Zhou and Han2020) can be attributed to the combined effect of VIV and a galloping-like movement-induced instability in the hyper-branch reduced-velocity range. Additionally, when a non-zero orientation angle

$A\approx 8b$ observed for this region was only limited by the width of the water-channel facility in which the experiments were conducted. Furthermore, the presence of a secondary vortex street (SVS) can be identified as the wake formed by the elliptical (airfoil-shaped) cylinder as it translates rapidly across the oncoming flow. It indicates that the approximately factor-of-five increase in maximum amplitude over the elliptical cylinder studies of Zhao et al. (Reference Zhao, Hourigan and Thompson2019) and Vijay et al. (Reference Vijay, Srinil, Zhu, Bao, Zhou and Han2020) can be attributed to the combined effect of VIV and a galloping-like movement-induced instability in the hyper-branch reduced-velocity range. Additionally, when a non-zero orientation angle ![]() $\theta$ is introduced for an

$\theta$ is introduced for an ![]() $\varepsilon =5$ cylinder, Lo et al. (Reference Lo, Thompson, Hourigan and Zhao2024b) showed that the oscillation amplitude is reduced, resulting in a

$\varepsilon =5$ cylinder, Lo et al. (Reference Lo, Thompson, Hourigan and Zhao2024b) showed that the oscillation amplitude is reduced, resulting in a ![]() $60\,\%$ decrease in the peak amplitude value for

$60\,\%$ decrease in the peak amplitude value for ![]() $\theta = 3.5^\circ$ when compared with the zero orientation angle case.

$\theta = 3.5^\circ$ when compared with the zero orientation angle case.

Figure 1. A schematic defining the problem of interest: an elastically mounted elliptical cylinder model constrained to oscillate transverse (![]() $y$) to the velocity

$y$) to the velocity ![]() $U$ of the free stream, which is in the positive

$U$ of the free stream, which is in the positive ![]() $x$ direction. Additionally,

$x$ direction. Additionally, ![]() $m$ is the oscillating mass,

$m$ is the oscillating mass, ![]() $k$ is the spring constant,

$k$ is the spring constant, ![]() $c$ is the structural damping,

$c$ is the structural damping, ![]() $\theta$ is the angle of attack of the body relative to the free stream as a function of the transverse displacement

$\theta$ is the angle of attack of the body relative to the free stream as a function of the transverse displacement ![]() $y$, and

$y$, and ![]() $F_x$ and

$F_x$ and ![]() $F_y$ represent the respective streamwise and the transverse fluid forces acting on the body.

$F_y$ represent the respective streamwise and the transverse fluid forces acting on the body.

Given the vibration amplitude that can be sustained by such a geometry with its implication for energy harvesting from FIV, there is a strong motivation to understand how the coupling between VIV and the galloping-like movement-induced instability influences the body's dynamic response. With the movement-induced instability contribution to the FIV of a thin elliptical cylinder being sensitive to the angle of the incident flow, it raises the question: can further increases in the oscillation amplitude be gained by imposing axial rotation? Such an approach has been implemented in numerous studies as part of an active open-loop control strategy for the canonical circular cylinder constrained to vibrate in the cross-flow direction (Bourguet & Lo Jacono Reference Bourguet and Lo Jacono2014; Zhao, Cheng & Lu Reference Zhao, Cheng and Lu2014c; Du & Sun Reference Du and Sun2015; Seyed-Aghazadeh & Modarres-Sadeghi Reference Seyed-Aghazadeh and Modarres-Sadeghi2015; Wong et al. Reference Wong, Zhao, Lo Jacono, Thompson and Sheridan2017, Reference Wong, Zhao, Lo Jacono, Thompson and Sheridan2018), as well as its three-dimensional equivalent, the sphere (Sareen et al. Reference Sareen, Zhao, Lo Jacono, Sheridan, Hourigan and Thompson2018a,Reference Sareen, Zhao, Sheridan, Hourigan and Thompsonb, Reference Sareen, Zhao, Sheridan, Hourigan and Thompson2019; McQueen et al. Reference McQueen, Zhao, Sheridan and Thompson2021).

However, the rotation imposed on the cylinder in the aforementioned studies is not directly coupled to the system dynamics. Instead, the resulting fluid–structure interaction for such systems arises from the vortex dynamics naturally synchronising with the rotational forcing frequency. To achieve this coupling, Vicente-Ludlam, Barrero-Gil & Velazquez (Reference Vicente-Ludlam, Barrero-Gil and Velazquez2017) proposed a closed-loop feedback control approach where the cylinder's rotation is proportional to either its transverse position or velocity. By conducting a two-dimensional numerical simulation for a zero-damping system with a mass ratio of 12.7 and a Reynolds number of 100, they found that the amplification or suppression of the oscillations with respect to the non-rotating cylinder can be achieved for both types of imposed rotation with appropriately chosen proportional gains. It was also discovered that, for certain gain values where the rotation is proportional to the cylinder's displacement, a galloping-type response was observed that could be predicted with a quasi-steady model. This conclusion agrees well with their later experimental study conducted over a higher Reynolds number range for a circular cylinder (Vicente-Ludlam, Barrero-Gil & Velazquez Reference Vicente-Ludlam, Barrero-Gil and Velazquez2018).

Extending this idea, McQueen et al. (Reference McQueen, Zhao, Sheridan and Thompson2020) investigated a generalised form of the control law where, in addition to the proportional gain, a phase difference is allowed between the transverse and angular displacements of the body. Since the approach by Vicente-Ludlam et al. (Reference Vicente-Ludlam, Barrero-Gil and Velazquez2017, Reference Vicente-Ludlam, Barrero-Gil and Velazquez2018) is equivalent to an imposed rotation at four distinct phase difference values (i.e. ![]() $0^\circ,90^\circ,180^\circ,270^\circ$), the modification allowed finer control over the coupling between the system dynamics and the actuation provided by the body's rotational motion. Consequently, McQueen et al. (Reference McQueen, Zhao, Sheridan and Thompson2020) showed that for a sphere elastically mounted in the cross-flow direction, imposing axial rotation significantly altered the magnitude of the vibration response as well as the reduced velocity at which vibrations commenced. The effectiveness of the closed-loop approach was also highlighted by the almost complete suppression of the mode I, mode II and mode III transition regimes using rotation rates well below those required by open-loop control (Sareen et al. Reference Sareen, Zhao, Lo Jacono, Sheridan, Hourigan and Thompson2018a).

$0^\circ,90^\circ,180^\circ,270^\circ$), the modification allowed finer control over the coupling between the system dynamics and the actuation provided by the body's rotational motion. Consequently, McQueen et al. (Reference McQueen, Zhao, Sheridan and Thompson2020) showed that for a sphere elastically mounted in the cross-flow direction, imposing axial rotation significantly altered the magnitude of the vibration response as well as the reduced velocity at which vibrations commenced. The effectiveness of the closed-loop approach was also highlighted by the almost complete suppression of the mode I, mode II and mode III transition regimes using rotation rates well below those required by open-loop control (Sareen et al. Reference Sareen, Zhao, Lo Jacono, Sheridan, Hourigan and Thompson2018a).

As far as the authors are aware, the implementation of active closed-loop control using imposed body rotation as the main actuation mechanism has not yet been attempted for a thin elliptical cylinder undergoing FIV over similar experimental conditions considered by Lo et al. (Reference Lo, Hourigan, Thompson and Zhao2023, Reference Lo, Thompson, Hourigan and Zhao2024b). Beyond the potential applications of such a study for more efficient energy harvesting, there is also a theoretical interest given that this cross-section is identical to an elliptical airfoil oriented perpendicularly to the free stream. Therefore, by allowing the cylinder to undergo angular displacement, such a system becomes a unique intersection between the literature on the sinusoidally rotating bluff bodies and that on flapping foils (see Xiao & Zhu Reference Xiao and Zhu2014; Young, Lai & Platzer Reference Young, Lai and Platzer2014; Wang et al. Reference Wang, Du, Zhao and Sun2017, Reference Wang, Du, Zhao, Thompson and Sun2020). However, the use of first principles and equation-based models to determine the effect of different control strategies on the FIV of thin elliptical cylinders is made difficult by the nonlinear dynamics arising from the coupling between VIV and movement-induced instability. Furthermore, given the complexity of the fluid–structure interaction and the time frame required for elastically mounted cylinders (especially those subjected to water channel flows) to reach a steady vibration amplitude before the effectiveness of the control strategy can be evaluated, the performance of classical data-driven optimisation strategies (e.g. grid search, random search, Latin hypercube sampling and gradient-based methods) may be constrained by the limited experimental budget (Blanchard et al. Reference Blanchard, Maceda, Fan, Li, Zhou, Noack and Sapsis2021).

To address these challenges, a machine learning (ML) approach can be leveraged to identify the control law parameters that maximise the oscillations of the elastically mounted elliptical cylinder. The review by Brunton, Noack & Koumoutsakos (Reference Brunton, Noack and Koumoutsakos2020) has shown ML's applicability for many fluid dynamics applications, where studies have had success with optimisation-based problems in flow control (see Xue, Zhai & Chen Reference Xue, Zhai and Chen2013; Ren, Hu & Tang Reference Ren, Hu and Tang2020; Blanchard et al. Reference Blanchard, Maceda, Fan, Li, Zhou, Noack and Sapsis2021; Li et al. Reference Li, Noack, Wang, Cornejo Maceda, Pickering, Shaqarin and Tyliszczak2024; Mallor et al. Reference Mallor, Semprini-Cesari, Mukha, Rezaeiravesh and Schlatter2024) and modelling (Babanezhad et al. Reference Babanezhad, Behroyan, Nakhjiri, Marjani, Rezakazemi, Heydarinasab and Shirazian2021; Andersen et al. Reference Andersen, Sævik, Wu, Leira and Langseth2024). For flow around a circular cylinder in particular, machine learning has been used for drag reduction (Sengupta, Deb & Talla Reference Sengupta, Deb and Talla2007; Rabault et al. Reference Rabault, Kuchta, Jensen, Réglade and Cerardi2019; Fan et al. Reference Fan, Yang, Wang, Triantafyllou and Karniadakis2020; Larroque, Fosas de Pando & Lafuente Reference Larroque, Fosas de Pando and Lafuente2022) and vibration suppression (Zheng et al. Reference Zheng, Ji, Xie, Zhang, Zheng and Zheng2021), as well as for an active learning strategy that minimises the number of experiments required to map the nonlinear VIV responses over a large experimental parameter space (Fan et al. Reference Fan, Jodin, Consi, Bonfiglio, Ma, Keyes, Karniadakis and Triantafyllou2019). Among the plethora of existing ML algorithms available to the fluid dynamics community, Bayesian optimisation was found to be an attractive choice given it was specifically designed to optimise expensive-to-evaluate black-box functions and generally converges to a global optimum with few functional evaluations (Brochu, Cora & De Freitas Reference Brochu, Cora and De Freitas2010; Shahriari et al. Reference Shahriari, Swersky, Wang, Adams and De Freitas2015; Blanchard et al. Reference Blanchard, Maceda, Fan, Li, Zhou, Noack and Sapsis2021).

In summary, past studies have shown that the thin elliptical cylinder's FIV behaviour is characterised by nonlinear dynamics resulting in large vibration amplitudes. However, maximising such oscillations using body rotation as an actuation mechanism is made challenging due to the coupling between VIV and the movement-induced instability. Therefore, using Bayesian optimisation, the present study follows on from those of Lo et al. (Reference Lo, Hourigan, Thompson and Zhao2023, Reference Lo, Thompson, Hourigan and Zhao2024b) and identifies the parameters of the control law proposed by McQueen et al. (Reference McQueen, Zhao, Sheridan and Thompson2020) that maximise, both locally and globally, the amplitude response of an ![]() $\varepsilon = 5$ elliptical cylinder started from rest. Additionally, an analysis of the angle of attack, observed wake patterns, frequency responses, and fluid forces and their phases relative to the body displacement will be conducted to understand why the optimal parameters result in the maximum amplification of the vibration amplitude.

$\varepsilon = 5$ elliptical cylinder started from rest. Additionally, an analysis of the angle of attack, observed wake patterns, frequency responses, and fluid forces and their phases relative to the body displacement will be conducted to understand why the optimal parameters result in the maximum amplification of the vibration amplitude.

The article proceeds by outlining the methodology in § 2, which includes the experimental set-up (§ 2.1), the active control approach (§ 2.2), as well as the implementation of Bayesian optimisation used (§ 2.3). Next, the results are presented in § 3, where the effect of axial rotation imposed by the control law on the complex fluid–structure interaction is discussed. Finally, the conclusions are drawn in § 4, highlighting the important findings and the significance of the current study.

2. Methodology

2.1. Experimental set-up

The dynamic response of the elliptical cylinder (figure 1) was investigated by modelling the transverse FIV system as a second-order mass-spring-damper oscillator subjected to a free stream flow. Therefore, the body displacement ![]() $y(t)$ due to the transverse fluid force

$y(t)$ due to the transverse fluid force ![]() $F_y(t)$ is governed by

$F_y(t)$ is governed by

where ![]() $m$ is the total oscillating mass,

$m$ is the total oscillating mass, ![]() $c$ is the structural damping and

$c$ is the structural damping and ![]() $k$ is the spring constant. The fluid–structure system was experimentally modelled in the recirculating water channel facility of the Fluids Laboratory for Aeronautical and Industrial Research (FLAIR) group at Monash University, where the free stream turbulence level in the test section was less than 1 %. A diagram of the full experimental set-up is presented in figure 2.

$k$ is the spring constant. The fluid–structure system was experimentally modelled in the recirculating water channel facility of the Fluids Laboratory for Aeronautical and Industrial Research (FLAIR) group at Monash University, where the free stream turbulence level in the test section was less than 1 %. A diagram of the full experimental set-up is presented in figure 2.

Figure 2. (a) Labelled photograph and (b) top-view diagram detailing the experimental set-up, consisting of an elliptical cylinder (orientated at ![]() $\theta = 90^\circ$) connected to the motor, which in turn is mounted to the air bearing system situated on top of the water channel. The orientation of the guide rails constrains the cylinder to oscillate along the

$\theta = 90^\circ$) connected to the motor, which in turn is mounted to the air bearing system situated on top of the water channel. The orientation of the guide rails constrains the cylinder to oscillate along the ![]() $y$-axis only.

$y$-axis only.

The angular rotation (for control) of the elliptical cylinder was set using a brushless servo motor (model EC-i40, Maxon Group) equipped with an optical rotary encoder (model ENC 16 RIO with 4096 counts per turn, Maxon Group) that had a resolution of 0.02![]() $^\circ$. This system was electronically controlled at a frequency of 4 kHz using Beckhoff TwinCAT

$^\circ$. This system was electronically controlled at a frequency of 4 kHz using Beckhoff TwinCAT![]() $^{\unicode{x00AE}}$ 3 software, with a motor controller (model MAXPOS 50/5, Maxon Group) acting as the hardware interface. Both the cylinder and motor were then mounted on a low-friction air-bearing system (see figure 2) that had been tested and validated (Zhao et al. Reference Zhao, Hourigan and Thompson2018a, Reference Zhao, Lo Jacono, Sheridan, Hourigan and Thompsonb). The guide shafts (which dictate the axis in which the carriage, and by extension, the cylinder, can oscillate) are orientated at a

$^{\unicode{x00AE}}$ 3 software, with a motor controller (model MAXPOS 50/5, Maxon Group) acting as the hardware interface. Both the cylinder and motor were then mounted on a low-friction air-bearing system (see figure 2) that had been tested and validated (Zhao et al. Reference Zhao, Hourigan and Thompson2018a, Reference Zhao, Lo Jacono, Sheridan, Hourigan and Thompsonb). The guide shafts (which dictate the axis in which the carriage, and by extension, the cylinder, can oscillate) are orientated at a ![]() $90^\circ$ angle to the free stream flow, thereby allowing the motion to only be in the cross-flow direction where restoring spring forces are provided by precision extension springs. The transverse displacement was measured using a digital linear encoder with a resolution of

$90^\circ$ angle to the free stream flow, thereby allowing the motion to only be in the cross-flow direction where restoring spring forces are provided by precision extension springs. The transverse displacement was measured using a digital linear encoder with a resolution of ![]() $1\,\mathrm {\mu }{\rm m}$ (model RGH24; Renishaw, UK), which was then differentiated to obtain the velocity and acceleration needed to calculate the transverse force. However, the streamwise force was instead obtained using a force sensor (model Mini40, ATI-IA, USA) with a resolution of 1/200 N. Data acquisition at a sampling rate of 100 Hz was also undertaken over a measurement period of

$1\,\mathrm {\mu }{\rm m}$ (model RGH24; Renishaw, UK), which was then differentiated to obtain the velocity and acceleration needed to calculate the transverse force. However, the streamwise force was instead obtained using a force sensor (model Mini40, ATI-IA, USA) with a resolution of 1/200 N. Data acquisition at a sampling rate of 100 Hz was also undertaken over a measurement period of ![]() $T = 180$ s (equivalent to a non-dimensional time

$T = 180$ s (equivalent to a non-dimensional time ![]() $\tau$ of approximately

$\tau$ of approximately ![]() $129$, where

$129$, where ![]() $\tau = t{{f_{nw}}}$) using the TwinCAT software, with the hardware interface provided by Beckhoff Automation GmbH EtherCAT digital I/O modules.

$\tau = t{{f_{nw}}}$) using the TwinCAT software, with the hardware interface provided by Beckhoff Automation GmbH EtherCAT digital I/O modules.

The elliptical cylinder model tested had a total length of ![]() $465\pm 0.1$ mm and an elliptical ratio of

$465\pm 0.1$ mm and an elliptical ratio of ![]() $\varepsilon = b/a = 5$, where

$\varepsilon = b/a = 5$, where ![]() $b= 25\pm 0.1$ mm and

$b= 25\pm 0.1$ mm and ![]() $a = 5\pm 0.1$ mm were the cross-flow and streamwise dimensions, respectively. The immersed length of the cylinder (i.e. the section of the body in water) was

$a = 5\pm 0.1$ mm were the cross-flow and streamwise dimensions, respectively. The immersed length of the cylinder (i.e. the section of the body in water) was ![]() $L = 450 \pm 0.5$ mm, giving a length-to-diameter (aspect) ratio of

$L = 450 \pm 0.5$ mm, giving a length-to-diameter (aspect) ratio of ![]() $L/b = 18.0$. The resulting mass ratio was

$L/b = 18.0$. The resulting mass ratio was ![]() ${{m^{*}}} = m/m_d = 53$, with

${{m^{*}}} = m/m_d = 53$, with ![]() $m_d = \rho {\rm \pi}a b L/4$ being the displaced mass of fluid of density

$m_d = \rho {\rm \pi}a b L/4$ being the displaced mass of fluid of density ![]() $\rho$. The applied structural damping was described by the damping ratio,

$\rho$. The applied structural damping was described by the damping ratio, ![]() $\zeta = c/(2\sqrt {k(m+m_A)}) = 1.6 \times 10^{-3}$, where

$\zeta = c/(2\sqrt {k(m+m_A)}) = 1.6 \times 10^{-3}$, where ![]() $m_A$ is the (potential-flow) added mass. To promote parallel vortex shedding by suppressing end effects, an end-conditioning platform was positioned approximately 1 mm below the free end of the cylinder. This approach has been validated and used extensively by Zhao et al. (Reference Zhao, Leontini, Lo Jacono and Sheridan2014a, Reference Zhao, Lo Jacono, Sheridan, Hourigan and Thompson2018b), Wong et al. (Reference Wong, Zhao, Lo Jacono, Thompson and Sheridan2018) and Soti et al. (Reference Soti, Zhao, Thompson, Sheridan and Bhardwaj2018). The body vibration was characterised by the normalised amplitude

$m_A$ is the (potential-flow) added mass. To promote parallel vortex shedding by suppressing end effects, an end-conditioning platform was positioned approximately 1 mm below the free end of the cylinder. This approach has been validated and used extensively by Zhao et al. (Reference Zhao, Leontini, Lo Jacono and Sheridan2014a, Reference Zhao, Lo Jacono, Sheridan, Hourigan and Thompson2018b), Wong et al. (Reference Wong, Zhao, Lo Jacono, Thompson and Sheridan2018) and Soti et al. (Reference Soti, Zhao, Thompson, Sheridan and Bhardwaj2018). The body vibration was characterised by the normalised amplitude ![]() $A^* = A/b$, with the FIV dynamics evaluated as a function of reduced velocity,

$A^* = A/b$, with the FIV dynamics evaluated as a function of reduced velocity, ![]() $U^* = U/({{f_{nw}}} b)$, where

$U^* = U/({{f_{nw}}} b)$, where ![]() ${{f_{nw}}} \approx 0.715$ Hz is the natural frequency of the system in quiescent water and

${{f_{nw}}} \approx 0.715$ Hz is the natural frequency of the system in quiescent water and ![]() ${{f_{na}}} \approx 0.718$ Hz is the natural frequency in quiescent air. To determine both the natural frequency of the system and structural damping ratios, free-decay tests were conducted individually in both quiescent air and water.

${{f_{na}}} \approx 0.718$ Hz is the natural frequency in quiescent air. To determine both the natural frequency of the system and structural damping ratios, free-decay tests were conducted individually in both quiescent air and water.

The reduced velocity range of interest was ![]() $3 \leqslant {U^*} \leqslant 8.5$, with values taken in

$3 \leqslant {U^*} \leqslant 8.5$, with values taken in ![]() ${U^*} = 0.5$ increments. This corresponds to a free stream velocity range of

${U^*} = 0.5$ increments. This corresponds to a free stream velocity range of ![]() $54 \leqslant U \leqslant 152\,{\rm mm}\,{\rm s}^{-1}$ and a Reynolds number range of

$54 \leqslant U \leqslant 152\,{\rm mm}\,{\rm s}^{-1}$ and a Reynolds number range of ![]() $1250 \leqslant {{Re}} = Ub/\nu \leqslant 3580$, with

$1250 \leqslant {{Re}} = Ub/\nu \leqslant 3580$, with ![]() $\nu$ being the kinematic viscosity of the water. Due to the operational range of the force sensor used to measure the streamwise force acting on the elliptical cylinder, a limit of

$\nu$ being the kinematic viscosity of the water. Due to the operational range of the force sensor used to measure the streamwise force acting on the elliptical cylinder, a limit of ![]() $A = 150\,{\rm mm}$, which is equal to

$A = 150\,{\rm mm}$, which is equal to ![]() ${A^{*}} = 6$, was imposed on the experiments.

${A^{*}} = 6$, was imposed on the experiments.

It should also be noted that in the present study, the streamwise and transverse forces are described in dimensionless forms defined by ![]() $C_{x} = F_{x}/(\rho U^2bL/2)$ and

$C_{x} = F_{x}/(\rho U^2bL/2)$ and ![]() $C_{y} = F_{y}/(\rho U^2bL/2)$, respectively. In addition, the dimensionless form of the vortex force is given by

$C_{y} = F_{y}/(\rho U^2bL/2)$, respectively. In addition, the dimensionless form of the vortex force is given by ![]() $C_{v} = F_{v}/(\rho U^2bL/2)$, which can be computed through a decomposition of the total transverse force into a vortex force component (

$C_{v} = F_{v}/(\rho U^2bL/2)$, which can be computed through a decomposition of the total transverse force into a vortex force component (![]() $F_v$) and a potential force component (

$F_v$) and a potential force component (![]() $F_P$), namely

$F_P$), namely ![]() $F_y = F_v + F_P$, with the potential force in an inviscid fluid being

$F_y = F_v + F_P$, with the potential force in an inviscid fluid being ![]() $F_{P} =-m_{A}\ddot {y}$ (Govardhan & Williamson Reference Govardhan and Williamson2000; Morse & Williamson Reference Morse and Williamson2009b; Zhao et al. Reference Zhao, Leontini, Lo Jacono and Sheridan2014b,Reference Zhao, Leontini, Lo Jacono and Sheridana).

$F_{P} =-m_{A}\ddot {y}$ (Govardhan & Williamson Reference Govardhan and Williamson2000; Morse & Williamson Reference Morse and Williamson2009b; Zhao et al. Reference Zhao, Leontini, Lo Jacono and Sheridan2014b,Reference Zhao, Leontini, Lo Jacono and Sheridana).

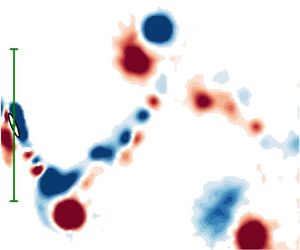

To observe the wake structures associated with the body oscillations, particle image velocimetry (PIV) was employed to visualise a cross-sectional plane in the near wake of the cylinder. The flow was seeded with hollow micro-spheres (model Sphericel 110P8; Potters Industries Inc.) of normal diameter ![]() $13\,\mathrm {\mu }{\rm m}$ and specific weight

$13\,\mathrm {\mu }{\rm m}$ and specific weight ![]() $1.10\,{\rm g}\,{\rm cm}^{-3}$, and a 5 W continuous laser (model: MLL-N-532nm-5W, CNI) was used to provide illumination in the form of a

$1.10\,{\rm g}\,{\rm cm}^{-3}$, and a 5 W continuous laser (model: MLL-N-532nm-5W, CNI) was used to provide illumination in the form of a ![]() $3$-mm-thick laser sheet. The images were then captured using a high-speed camera (Dimax S4, PCO AG, Germany) equipped with a

$3$-mm-thick laser sheet. The images were then captured using a high-speed camera (Dimax S4, PCO AG, Germany) equipped with a ![]() $50\,{\rm mm}$ lens (Nikon Corporation, Japan), resulting in a resolution of

$50\,{\rm mm}$ lens (Nikon Corporation, Japan), resulting in a resolution of ![]() $2016 \times 2016\,{\rm pixel}^2$ and an optical magnification factor of approximately

$2016 \times 2016\,{\rm pixel}^2$ and an optical magnification factor of approximately ![]() $6.23\,{\rm pixel}\,{\rm mm}^{-1}$. For each trial, a set of 3100 image pairs was recorded at a sampling rate of 10 Hz. Validated in-house software, originally developed by Fouras, Lo Jacono & Hourigan (Reference Fouras, Lo Jacono and Hourigan2008), was then used to correlate

$6.23\,{\rm pixel}\,{\rm mm}^{-1}$. For each trial, a set of 3100 image pairs was recorded at a sampling rate of 10 Hz. Validated in-house software, originally developed by Fouras, Lo Jacono & Hourigan (Reference Fouras, Lo Jacono and Hourigan2008), was then used to correlate ![]() $32 \times 32\, \text {pixel}^2$ interrogation windows with 50 % window overlap to obtain the time-dependent vector fields of the wake flow. Finally, employing a phase-band technique, the resultant fields were averaged using a phase portrait with the cylinder displacement and velocity as the

$32 \times 32\, \text {pixel}^2$ interrogation windows with 50 % window overlap to obtain the time-dependent vector fields of the wake flow. Finally, employing a phase-band technique, the resultant fields were averaged using a phase portrait with the cylinder displacement and velocity as the ![]() $x$- and

$x$- and ![]() $y$-axis, respectively. As PIV measurements were sampled at random points of the body motion, transistor–transistor logic (TTL) pulses were first used to synchronise the PIV measurements with the digital linear encoder signal such that the cylinder's displacement and velocity could be determined for each vector field. From this information, the fields were then sorted into 48 different regions (i.e. phases) based on their location in the phase portrait, with averaging conducted over each bin. Consequently, each phase corresponds to a specific time interval within the body oscillation period (for more details, see Zhao et al. Reference Zhao, Leontini, Lo Jacono and Sheridan2014a).

$y$-axis, respectively. As PIV measurements were sampled at random points of the body motion, transistor–transistor logic (TTL) pulses were first used to synchronise the PIV measurements with the digital linear encoder signal such that the cylinder's displacement and velocity could be determined for each vector field. From this information, the fields were then sorted into 48 different regions (i.e. phases) based on their location in the phase portrait, with averaging conducted over each bin. Consequently, each phase corresponds to a specific time interval within the body oscillation period (for more details, see Zhao et al. Reference Zhao, Leontini, Lo Jacono and Sheridan2014a).

2.2. Active control system

To achieve the goal of amplitude maximisation for each ![]() ${U^*}$ case of interest, a machine-learning-based strategy, as represented by the block diagram in figure 3, was used. Such a framework consists of an inner real-time loop and an outer learning loop (Gautier et al. Reference Gautier, Aider, Duriez, Noack, Segond and Abel2015; Duriez, Brunton & Noack Reference Duriez, Brunton and Noack2017; Li et al. Reference Li, Noack, Cordier, Jacques, Kaiser and Harambat2017). This inner loop, which is the feedback control, can be mathematically described by the following set of equations:

${U^*}$ case of interest, a machine-learning-based strategy, as represented by the block diagram in figure 3, was used. Such a framework consists of an inner real-time loop and an outer learning loop (Gautier et al. Reference Gautier, Aider, Duriez, Noack, Segond and Abel2015; Duriez, Brunton & Noack Reference Duriez, Brunton and Noack2017; Li et al. Reference Li, Noack, Cordier, Jacques, Kaiser and Harambat2017). This inner loop, which is the feedback control, can be mathematically described by the following set of equations:

where the bold symbols indicate vector quantities. Here, ![]() $\boldsymbol {a}$ denotes the state of the dynamical system (i.e. the structural vibration, forces and phases),

$\boldsymbol {a}$ denotes the state of the dynamical system (i.e. the structural vibration, forces and phases), ![]() $\theta$ represents the angular position of the cylinder set using the servo motor,

$\theta$ represents the angular position of the cylinder set using the servo motor, ![]() $y^*$ is the measured normalised transverse displacement taken as the feedback sensing state and

$y^*$ is the measured normalised transverse displacement taken as the feedback sensing state and ![]() $\boldsymbol {w}$ is the external forcing due to the fluid flow.

$\boldsymbol {w}$ is the external forcing due to the fluid flow. ![]() $F$,

$F$, ![]() $G$ and

$G$ and ![]() $\mathcal {K}$ respectively represent the time evolution operator, measurement function and control law (whose behaviour is governed by parameters

$\mathcal {K}$ respectively represent the time evolution operator, measurement function and control law (whose behaviour is governed by parameters ![]() $K_p^*$ and

$K_p^*$ and ![]() $\phi _d$ which will be discussed below). While (2.2) formally provides the evolution of the system state and particularly the displacement, in practice, the evolution of the system state is obtained through the experiments.

$\phi _d$ which will be discussed below). While (2.2) formally provides the evolution of the system state and particularly the displacement, in practice, the evolution of the system state is obtained through the experiments.

Figure 3. Block diagram describing the machine-learning-based strategy for FIV control of the elliptical cylinder bluff body. The ‘inner’ real-time loop is responsible for implementing the control law, which instantaneously sets the angular position ![]() $\theta$ of the bluff body as a function of the state measurement (i.e. the normalised transverse displacement

$\theta$ of the bluff body as a function of the state measurement (i.e. the normalised transverse displacement ![]() $y^*$). Meanwhile, the slower outer ‘learning’ loop uses Bayesian optimisation to identify the parameters of the control law that maximises the vibration as measured by the cost function

$y^*$). Meanwhile, the slower outer ‘learning’ loop uses Bayesian optimisation to identify the parameters of the control law that maximises the vibration as measured by the cost function ![]() $C(y^*)$.

$C(y^*)$.

The active closed-loop control of interest in this study used axial rotations (about the ![]() $z$-axis that is perpendicular to both the free stream flow and the free-vibration axis) as the actuation input to modify the FIV dynamics of the thin elliptical cylinder. In line with the study by McQueen et al. (Reference McQueen, Zhao, Sheridan and Thompson2020) for a rotating sphere, the cylinder was rotated as a function of its transverse displacement (with body oscillation frequency

$z$-axis that is perpendicular to both the free stream flow and the free-vibration axis) as the actuation input to modify the FIV dynamics of the thin elliptical cylinder. In line with the study by McQueen et al. (Reference McQueen, Zhao, Sheridan and Thompson2020) for a rotating sphere, the cylinder was rotated as a function of its transverse displacement (with body oscillation frequency ![]() $f$) according to the following control law:

$f$) according to the following control law:

which relates the transverse non-dimensional displacement ![]() $y^* = y/b$ of the elliptical cylinder to its angular displacement

$y^* = y/b$ of the elliptical cylinder to its angular displacement ![]() $\theta$ (in radians). The last step requires that the displacement signal is approximately sinusoidal. Here,

$\theta$ (in radians). The last step requires that the displacement signal is approximately sinusoidal. Here, ![]() $H(y^*(t))$ is the Hilbert transform function that imparts a

$H(y^*(t))$ is the Hilbert transform function that imparts a ![]() $-{\rm \pi} /2$ phase shift to the transverse displacement signal when evaluated in real-time. Therefore, the combination of

$-{\rm \pi} /2$ phase shift to the transverse displacement signal when evaluated in real-time. Therefore, the combination of ![]() $\cos {(\phi _d)}y^*$ and

$\cos {(\phi _d)}y^*$ and ![]() $\sin {(\phi _d)}(-H(y^*))$ allows a phase difference

$\sin {(\phi _d)}(-H(y^*))$ allows a phase difference ![]() $\phi _d$ to be introduced between

$\phi _d$ to be introduced between ![]() $y^*$ and

$y^*$ and ![]() $\theta$, with

$\theta$, with ![]() $K_p^*$ acting as the proportional gain. These two parameters of the control law,

$K_p^*$ acting as the proportional gain. These two parameters of the control law, ![]() $\phi _d$ and

$\phi _d$ and ![]() $K_p^*$, will hence modify the evolution of the system state

$K_p^*$, will hence modify the evolution of the system state ![]() $\boldsymbol {a}$ over time, thereby impacting the vibrational amplitudes achieved. In the experiments, the Hilbert transform was implemented using the Simulink

$\boldsymbol {a}$ over time, thereby impacting the vibrational amplitudes achieved. In the experiments, the Hilbert transform was implemented using the Simulink![]() $^{\circledR}$ ‘Hilbert Filter’ block, and evaluated in real-time by employing a TwinCAT target for Simulink

$^{\circledR}$ ‘Hilbert Filter’ block, and evaluated in real-time by employing a TwinCAT target for Simulink![]() $^{\circledR }$ (model: TE1400; Beckhoff).

$^{\circledR }$ (model: TE1400; Beckhoff).

Meanwhile, the role of the outer loop is to identify the ideal control law for a problem-specific objective. As such, this task can be expressed as a search for the optimum control law parameters ![]() $K_p^*$ and

$K_p^*$ and ![]() $\phi _d$ that minimise the cost function

$\phi _d$ that minimise the cost function ![]() $C(y^*)$. Given that the objective of this study is to understand the coupling between VIV and the galloping-like movement-induced instability by maximising the vibrational amplitude of the elliptical cylinder,

$C(y^*)$. Given that the objective of this study is to understand the coupling between VIV and the galloping-like movement-induced instability by maximising the vibrational amplitude of the elliptical cylinder, ![]() $C(y^*)$ was chosen to be the negative root-mean-square of the displacement signal

$C(y^*)$ was chosen to be the negative root-mean-square of the displacement signal ![]() $y^*$ over the measurement period

$y^*$ over the measurement period ![]() $T$:

$T$:

\begin{equation} J(K_p^*,\phi_d) = C(y^*;K_p^*,\phi_d) ={-} \sqrt{\frac{1}{T}\int_{0}^{T} \left[y^*(t;K_p^*,\phi_d)\right]^2\,{\rm d}t}, \end{equation}

\begin{equation} J(K_p^*,\phi_d) = C(y^*;K_p^*,\phi_d) ={-} \sqrt{\frac{1}{T}\int_{0}^{T} \left[y^*(t;K_p^*,\phi_d)\right]^2\,{\rm d}t}, \end{equation}

where ![]() $J$ is the measured value of the cost function. We note that the energy harvesting performance of this system (with active control imposed) can also be optimised by including the axial rotation as an input in the cost function; however, this is outside the scope of the present study.

$J$ is the measured value of the cost function. We note that the energy harvesting performance of this system (with active control imposed) can also be optimised by including the axial rotation as an input in the cost function; however, this is outside the scope of the present study.

To minimise this cost function, Bayesian optimisation was selected as the machine learning algorithm that determines the ideal control law parameters for the inner real-time loop of figure 3. The offline learning loop is iterative, which means that for the ![]() $i{\text {th}}$ iteration of the algorithm, the cost values from the

$i{\text {th}}$ iteration of the algorithm, the cost values from the ![]() $i-1$ previous iterations will be used to determine the

$i-1$ previous iterations will be used to determine the ![]() $K_p^*$ and

$K_p^*$ and ![]() $\phi _d$ parameters of

$\phi _d$ parameters of ![]() $\mathcal {K}_i$ that will most likely yield the highest vibrational amplitude. After evaluating the performance of

$\mathcal {K}_i$ that will most likely yield the highest vibrational amplitude. After evaluating the performance of ![]() $\mathcal {K}_i$ based on the resultant cost

$\mathcal {K}_i$ based on the resultant cost ![]() $J_i$, the algorithm will again determine, using this new information, the next control law

$J_i$, the algorithm will again determine, using this new information, the next control law ![]() $\mathcal {K}_{i+1}$. This process continues until the iteration limit

$\mathcal {K}_{i+1}$. This process continues until the iteration limit ![]() $n$ is reached, with the ideal control law being the one corresponding to the lowest value in the

$n$ is reached, with the ideal control law being the one corresponding to the lowest value in the ![]() $[J_1, \ldots, J_n]$ vector of total costs. The implementation of the Bayesian optimisation algorithm used in this study is further described in § 2.3.

$[J_1, \ldots, J_n]$ vector of total costs. The implementation of the Bayesian optimisation algorithm used in this study is further described in § 2.3.

To ensure identical initial conditions at the start of each iteration, the elliptical cylinder is first set to ![]() $\theta = 90^{\circ }$ and allowed to reach a steady vibration amplitude. Due to the high elliptical ratio of the cylinder, the dynamics for this angle is desynchronised with vibrations that are near-zero in amplitude (i.e.

$\theta = 90^{\circ }$ and allowed to reach a steady vibration amplitude. Due to the high elliptical ratio of the cylinder, the dynamics for this angle is desynchronised with vibrations that are near-zero in amplitude (i.e. ![]() $A^* \approx 0$). The elliptical cylinder is then rotated to

$A^* \approx 0$). The elliptical cylinder is then rotated to ![]() $\theta = 0$ over a period of

$\theta = 0$ over a period of ![]() $\Delta \tau = 1$ (i.e.

$\Delta \tau = 1$ (i.e. ![]() $1/{{f_{nw}}}$ seconds) before the control law is activated (inner loop of figure 3). After the system is allowed to reach an equilibrium state, measurements of

$1/{{f_{nw}}}$ seconds) before the control law is activated (inner loop of figure 3). After the system is allowed to reach an equilibrium state, measurements of ![]() $\tau \approx 129$ (i.e.

$\tau \approx 129$ (i.e. ![]() $T = 180$ seconds) in length were then taken to evaluate the cost value

$T = 180$ seconds) in length were then taken to evaluate the cost value ![]() $J$ (2.6) for the outer learning loop.

$J$ (2.6) for the outer learning loop.

2.3. Bayesian optimisation of active control parameters

As the main component of the outer offline learning loop as shown in figure 3, Bayesian optimisation was implemented in Matlab (MathWorks) using the Bayesopt function from the Statistics and Machine Learning Toolbox. Since the inner real-time loop was performed in TwinCAT, the TE1410 interface (Beckhoff) was also used to facilitate communication and data transmission between the two programs.

The role of the Bayesian optimisation algorithm within the active control system described in § 2.2 is to minimise the true cost value ![]() $J_T$ for the control law parameters

$J_T$ for the control law parameters ![]() $\boldsymbol {b} =$ (

$\boldsymbol {b} =$ (![]() $K^*_p$,

$K^*_p$, ![]() $\phi _d$) in a pre-specified bounded domain

$\phi _d$) in a pre-specified bounded domain ![]() $\mathcal {B}$. This optimisation problem is formulated as

$\mathcal {B}$. This optimisation problem is formulated as

where ![]() $\mathcal {B} \subset \mathbb {R}^2$ comprises proportional gain and phase difference values over the range

$\mathcal {B} \subset \mathbb {R}^2$ comprises proportional gain and phase difference values over the range ![]() $0 \leq K_p^* \leq 5$ and

$0 \leq K_p^* \leq 5$ and ![]() $0 \leq \phi _d \leq 360^\circ$, respectively. However, minimising the above function is not a straightforward process as the dependence of the cost on

$0 \leq \phi _d \leq 360^\circ$, respectively. However, minimising the above function is not a straightforward process as the dependence of the cost on ![]() $\boldsymbol {b}$ does not have a closed form. These difficulties are further compounded by the additional presence of measurement noise, modelled as additive Gaussian noise with standard deviation

$\boldsymbol {b}$ does not have a closed form. These difficulties are further compounded by the additional presence of measurement noise, modelled as additive Gaussian noise with standard deviation ![]() $\sigma _n$:

$\sigma _n$:

which arise when experimentally evaluating ![]() $J_T$ for a specific combination of control parameters

$J_T$ for a specific combination of control parameters ![]() $\boldsymbol {b}$. Thus, to optimise the cost function in a data-efficient manner, a surrogate model

$\boldsymbol {b}$. Thus, to optimise the cost function in a data-efficient manner, a surrogate model ![]() $\bar {J}$ was employed to approximate the true cost function

$\bar {J}$ was employed to approximate the true cost function ![]() $J_T$. For the

$J_T$. For the ![]() $i\mathrm {th}$ iteration of the Bayesian optimisation algorithm, the corresponding

$i\mathrm {th}$ iteration of the Bayesian optimisation algorithm, the corresponding ![]() $\bar {J}$ is hence constructed by training the model on the actuation-cost pairs

$\bar {J}$ is hence constructed by training the model on the actuation-cost pairs ![]() $\{\boldsymbol {b}_k, J_k\}_{k = 1}^{i-1}$ from the available data

$\{\boldsymbol {b}_k, J_k\}_{k = 1}^{i-1}$ from the available data ![]() $\mathcal {D}_{i-1}$ collected in the previous

$\mathcal {D}_{i-1}$ collected in the previous ![]() $i-1$ iterations. Using this surrogate model, the algorithm determines the optimal control law

$i-1$ iterations. Using this surrogate model, the algorithm determines the optimal control law ![]() $\mathcal {K}_{i}$ to implement next by maximising the acquisition function

$\mathcal {K}_{i}$ to implement next by maximising the acquisition function ![]() $a(\boldsymbol {b};\bar {J})$. After evaluating the performance of

$a(\boldsymbol {b};\bar {J})$. After evaluating the performance of ![]() $\mathcal {K}_{i}$ and obtaining

$\mathcal {K}_{i}$ and obtaining ![]() $J_{i}$, the surrogate model is first updated by including the newly collected actuation-cost pair

$J_{i}$, the surrogate model is first updated by including the newly collected actuation-cost pair ![]() $\{\boldsymbol {b}_i,J_i\}$ in the data set

$\{\boldsymbol {b}_i,J_i\}$ in the data set ![]() $\mathcal {D}_{i}$ before being used in the next iteration of the algorithm. Until the iteration limit

$\mathcal {D}_{i}$ before being used in the next iteration of the algorithm. Until the iteration limit ![]() $n$ has been reached, the algorithm will search the control parameter space

$n$ has been reached, the algorithm will search the control parameter space ![]() $\mathcal {B}$ for the minimum cost and refine the surrogate model in the process, one query at a time.

$\mathcal {B}$ for the minimum cost and refine the surrogate model in the process, one query at a time.

Although different surrogate models have been proposed in the past (see Shahriari et al. Reference Shahriari, Swersky, Wang, Adams and De Freitas2015), Gaussian processes (GPs) will be used in this study due to their ability to account for measurement noise and their previous successful application in active flow control problems (Blanchard et al. Reference Blanchard, Maceda, Fan, Li, Zhou, Noack and Sapsis2021). While a very brief outline of this model will be provided below, a full mathematical description can be found in the book by Rasmussen & Williams (Reference Rasmussen and Williams2006). Gaussian processes are, generally speaking, based on the assumption that control laws with similar ![]() $\boldsymbol {b}=\{K_p^*,\phi _d\}$ parameters in the solution space of possible control laws

$\boldsymbol {b}=\{K_p^*,\phi _d\}$ parameters in the solution space of possible control laws ![]() $\mathcal {B}$ will naturally result in performances (i.e. the cost value

$\mathcal {B}$ will naturally result in performances (i.e. the cost value ![]() $J$) that are also alike. To achieve this, the GP is hence defined as a set of random variables such that they have a joint Gaussian distribution, and that can be completely specified by its mean and covariance function. For generality, the surrogate model employed in this study can be mathematically described as

$J$) that are also alike. To achieve this, the GP is hence defined as a set of random variables such that they have a joint Gaussian distribution, and that can be completely specified by its mean and covariance function. For generality, the surrogate model employed in this study can be mathematically described as

where ![]() $f(\boldsymbol {b})$ is a zero-mean GP prior with covariance imposed by the function

$f(\boldsymbol {b})$ is a zero-mean GP prior with covariance imposed by the function ![]() $k(\boldsymbol {b},\boldsymbol {b}'; \varTheta )$, and

$k(\boldsymbol {b},\boldsymbol {b}'; \varTheta )$, and ![]() $h(\boldsymbol {b})$ and

$h(\boldsymbol {b})$ and ![]() $\beta$ are a set of basis functions (taken to be unity in this study) and its corresponding coefficients, respectively. The covariance function, whose behaviour can be modified with the hyper-parameter

$\beta$ are a set of basis functions (taken to be unity in this study) and its corresponding coefficients, respectively. The covariance function, whose behaviour can be modified with the hyper-parameter ![]() $\varTheta$, determines the influence of the cost value at one point

$\varTheta$, determines the influence of the cost value at one point ![]() $\boldsymbol {b}$ on the cost at other points

$\boldsymbol {b}$ on the cost at other points ![]() $\boldsymbol {b}'$. As such, the covariance plays an important part in encoding our prior understanding of how the cost function varies as a function of

$\boldsymbol {b}'$. As such, the covariance plays an important part in encoding our prior understanding of how the cost function varies as a function of ![]() $K_p^*$ and

$K_p^*$ and ![]() $\phi _d$ since it imposes a limit on the kinds of functions that will be used to fit the data. The ARD (automatic relevance determination, see Neal Reference Neal1996) Matérn 5/2 kernel function (Rasmussen & Williams Reference Rasmussen and Williams2006; Snoek, Larochelle & Adams Reference Snoek, Larochelle and Adams2012) was used in this research to calculate the covariance, which takes the following form:

$\phi _d$ since it imposes a limit on the kinds of functions that will be used to fit the data. The ARD (automatic relevance determination, see Neal Reference Neal1996) Matérn 5/2 kernel function (Rasmussen & Williams Reference Rasmussen and Williams2006; Snoek, Larochelle & Adams Reference Snoek, Larochelle and Adams2012) was used in this research to calculate the covariance, which takes the following form:

$$\begin{gather}r = \sqrt{\sum_{m=1}^{2}\frac{(b_{m}-b'_{m})^2}{\sigma_m^2}}, \end{gather}$$

$$\begin{gather}r = \sqrt{\sum_{m=1}^{2}\frac{(b_{m}-b'_{m})^2}{\sigma_m^2}}, \end{gather}$$

where ![]() $\sigma _f$ is the signal standard deviation. Additionally,

$\sigma _f$ is the signal standard deviation. Additionally, ![]() $\sigma _m$ (

$\sigma _m$ (![]() $m=1, 2$) is the characteristic length scale for each control parameter of

$m=1, 2$) is the characteristic length scale for each control parameter of ![]() $\boldsymbol {b} = (b_1,b_2) =$ (

$\boldsymbol {b} = (b_1,b_2) =$ (![]() $K^*_p$,

$K^*_p$, ![]() $\phi _d$), which was implemented using ARD (Neal Reference Neal1996).

$\phi _d$), which was implemented using ARD (Neal Reference Neal1996).

Whilst the Gaussian process without any knowledge of the dataset ![]() $\mathcal {D}$ is known as the prior distribution, training this model on the available actuation-cost pairs results in the posterior distribution

$\mathcal {D}$ is known as the prior distribution, training this model on the available actuation-cost pairs results in the posterior distribution ![]() $Q$. This process can be thought of as selecting functions available to the prior distribution that also passes through the points in the dataset (accounting for the measurement noise with variance

$Q$. This process can be thought of as selecting functions available to the prior distribution that also passes through the points in the dataset (accounting for the measurement noise with variance ![]() $\sigma _n^2$). This posterior distribution, which can make predictions of

$\sigma _n^2$). This posterior distribution, which can make predictions of ![]() $J$ for unknown

$J$ for unknown ![]() $\boldsymbol {b}$, is hence the surrogate model used in the acquisition function

$\boldsymbol {b}$, is hence the surrogate model used in the acquisition function ![]() $a(\boldsymbol {b};\bar {J})$. Consequently, the

$a(\boldsymbol {b};\bar {J})$. Consequently, the ![]() $\boldsymbol {b}$ vector that maximises this function will be the control law parameters that the Bayesian optimisation algorithm tries in the next iteration. The acquisition function used in this study is ‘expected-improvement-plus’, which is a variant of the expected improvement that is mathematically defined as

$\boldsymbol {b}$ vector that maximises this function will be the control law parameters that the Bayesian optimisation algorithm tries in the next iteration. The acquisition function used in this study is ‘expected-improvement-plus’, which is a variant of the expected improvement that is mathematically defined as

where ![]() $\boldsymbol {b}_{best}$ are the control parameters corresponding to the lowest mean value of the posterior distribution

$\boldsymbol {b}_{best}$ are the control parameters corresponding to the lowest mean value of the posterior distribution ![]() $\mu _Q(\boldsymbol {b}_{best})$. To ensure that the Bayesian optimisation algorithm can escape the local minima of the cost function, the ‘expected-improvement-plus’ function will modify its behaviour whenever it detects that over-exploitation of an area in

$\mu _Q(\boldsymbol {b}_{best})$. To ensure that the Bayesian optimisation algorithm can escape the local minima of the cost function, the ‘expected-improvement-plus’ function will modify its behaviour whenever it detects that over-exploitation of an area in ![]() $\mathcal {B}$ is occurring. Since the variance of the posterior distribution is

$\mathcal {B}$ is occurring. Since the variance of the posterior distribution is

over-exploitation is hence defined to be occurring when ![]() $\sigma _{Q_T} < t_{\sigma }\sigma _n$, where

$\sigma _{Q_T} < t_{\sigma }\sigma _n$, where ![]() $\sigma _{Q_T}$ is the standard deviation of the noiseless posterior distribution (which is the equivalent posterior distribution if the actuation-cost pairs used for training are assumed to be noise-free). Here,

$\sigma _{Q_T}$ is the standard deviation of the noiseless posterior distribution (which is the equivalent posterior distribution if the actuation-cost pairs used for training are assumed to be noise-free). Here, ![]() $t_{\sigma }$ is the exploration ratio that controls the trade-off between exploring new points that may lead to a better global solution (i.e. exploration) versus concentrating on areas of

$t_{\sigma }$ is the exploration ratio that controls the trade-off between exploring new points that may lead to a better global solution (i.e. exploration) versus concentrating on areas of ![]() $\mathcal {B}$ that the previously collected data has shown to result in low cost (i.e. exploitation). This has the effect of raising the standard deviation

$\mathcal {B}$ that the previously collected data has shown to result in low cost (i.e. exploitation). This has the effect of raising the standard deviation ![]() $\sigma _Q$ for

$\sigma _Q$ for ![]() $\boldsymbol {b}$ in between observations, with a larger

$\boldsymbol {b}$ in between observations, with a larger ![]() $t_{\sigma }$ corresponding to a higher degree of exploration. If found to be over-exploiting, the hyper-parameter of the kernel function

$t_{\sigma }$ corresponding to a higher degree of exploration. If found to be over-exploiting, the hyper-parameter of the kernel function ![]() $\varTheta$ will be multiplied by the number of iterations (Bull Reference Bull2011) and a new

$\varTheta$ will be multiplied by the number of iterations (Bull Reference Bull2011) and a new ![]() $\boldsymbol {b}$ will be suggested. If this new point is also found to be over-exploiting,

$\boldsymbol {b}$ will be suggested. If this new point is also found to be over-exploiting, ![]() $\varTheta$ will be multiplied by an additional factor of ten and another new

$\varTheta$ will be multiplied by an additional factor of ten and another new ![]() $\boldsymbol {b}$ generated. This process will continue until a new point is suggested that is not over-exploiting, up to a limit of five times, with the final

$\boldsymbol {b}$ generated. This process will continue until a new point is suggested that is not over-exploiting, up to a limit of five times, with the final ![]() $\boldsymbol {b}$ taken by the acquisition function as the next control law parameters to try.

$\boldsymbol {b}$ taken by the acquisition function as the next control law parameters to try.

As the ability of the Bayesian optimisation algorithm to make suggestions about which ![]() $\boldsymbol {b}$ vectors to sample next depends on the fidelity of the

$\boldsymbol {b}$ vectors to sample next depends on the fidelity of the ![]() $\bar {J}$ model, care must also be taken to maximise the accuracy of the Gaussian process model. Since the model performance depends on selecting the correct hyper-parameter (i.e.

$\bar {J}$ model, care must also be taken to maximise the accuracy of the Gaussian process model. Since the model performance depends on selecting the correct hyper-parameter (i.e. ![]() $\beta, \varTheta, \sigma _n^2$) values, they were hence approximated from the data using maximum likelihood estimation.

$\beta, \varTheta, \sigma _n^2$) values, they were hence approximated from the data using maximum likelihood estimation.

Whilst this study mainly seeks to identify the proportional gain ![]() $K_p^*$ and phase difference

$K_p^*$ and phase difference ![]() $\phi _d$ that maximally amplifies the vibration amplitude of the elliptical cylinder, a secondary objective is to characterise other regions in the control parameters space

$\phi _d$ that maximally amplifies the vibration amplitude of the elliptical cylinder, a secondary objective is to characterise other regions in the control parameters space ![]() $\mathcal {B}$ that correspond to auxiliary peaks in the amplitude response. Local maxima are also of interest as their presence suggests that distinct FIV dynamics, arising from changes in the coupling between VIV and the galloping-like movement-induced instability, exist. To this end, Bayesian optimisation was implemented in a multi-stage process that begins with the algorithm initially set to operate for 100 iterations using an exploration ratio of

$\mathcal {B}$ that correspond to auxiliary peaks in the amplitude response. Local maxima are also of interest as their presence suggests that distinct FIV dynamics, arising from changes in the coupling between VIV and the galloping-like movement-induced instability, exist. To this end, Bayesian optimisation was implemented in a multi-stage process that begins with the algorithm initially set to operate for 100 iterations using an exploration ratio of ![]() $t_\sigma = 1 \times 10 ^{12}$. The large

$t_\sigma = 1 \times 10 ^{12}$. The large ![]() $t_\sigma$ was chosen to prioritise exploration over exploitation, allowing the algorithm to select unknown points to sample that will maximally reduce the variance of the model. The main goal of this stage is to gain as much knowledge of the control law parameter space with as few points as possible, and then use the newly acquired actuation-cost pairs to ascertain the regions of particular interest for vibration amplification.

$t_\sigma$ was chosen to prioritise exploration over exploitation, allowing the algorithm to select unknown points to sample that will maximally reduce the variance of the model. The main goal of this stage is to gain as much knowledge of the control law parameter space with as few points as possible, and then use the newly acquired actuation-cost pairs to ascertain the regions of particular interest for vibration amplification.

For each region manually identified, the Bayesian optimisation will continue for 100 iterations using an exploration ratio of ![]() $t_\sigma = 0.5$ and the points collected in the first stage as the initial knowledge base to build the Gaussian process model. To ensure that the location and magnitude of the peak can be accurately measured for each region, a further 25 iterations using an exploration ratio of

$t_\sigma = 0.5$ and the points collected in the first stage as the initial knowledge base to build the Gaussian process model. To ensure that the location and magnitude of the peak can be accurately measured for each region, a further 25 iterations using an exploration ratio of ![]() $t_\sigma = 0$ are conducted. Thus, this multi-stage approach to Bayesian optimisation allows the entire control law parameter space

$t_\sigma = 0$ are conducted. Thus, this multi-stage approach to Bayesian optimisation allows the entire control law parameter space ![]() $\mathcal {B}$ to be explored, while providing additional resolution to regions corresponding to local maxima in the vibrational amplitude. Table 1 details the regions of interest for each

$\mathcal {B}$ to be explored, while providing additional resolution to regions corresponding to local maxima in the vibrational amplitude. Table 1 details the regions of interest for each ![]() ${U^*}$ case. The total iterations for each

${U^*}$ case. The total iterations for each ![]() ${U^*}$ case are also presented, which is in line with the typical optimisation budget of

${U^*}$ case are also presented, which is in line with the typical optimisation budget of ![]() $\mathcal {O}(100)$ water channel experiments (Blanchard et al. Reference Blanchard, Maceda, Fan, Li, Zhou, Noack and Sapsis2021; Li et al. Reference Li, Cui, Jia, Li, Yang, Morzyński and Noack2022).

$\mathcal {O}(100)$ water channel experiments (Blanchard et al. Reference Blanchard, Maceda, Fan, Li, Zhou, Noack and Sapsis2021; Li et al. Reference Li, Cui, Jia, Li, Yang, Morzyński and Noack2022).

Table 1. Regions of interest in ![]() $\mathcal {B} = \{K_p^*, \phi _d\}$ found using the first 100 iterations of the Bayesian optimisation algorithm (

$\mathcal {B} = \{K_p^*, \phi _d\}$ found using the first 100 iterations of the Bayesian optimisation algorithm (![]() $t_\sigma = 1 \times 10^{12}$) for every

$t_\sigma = 1 \times 10^{12}$) for every ![]() ${U^*}$ case. A further 125 iterations are used to explore each identified region.

${U^*}$ case. A further 125 iterations are used to explore each identified region.

3. Results

To understand how the imposition of axial rotation impacts the FIV of a transversely oscillating thin elliptical cylinder, the case when no rotation is applied (i.e. ![]() $K_p^* = 0$) must first be discussed. As shown by the filled black circles in figure 4(a), the response with the cylinder started from rest (i.e. rotated from

$K_p^* = 0$) must first be discussed. As shown by the filled black circles in figure 4(a), the response with the cylinder started from rest (i.e. rotated from ![]() $\theta = 90^\circ$ to

$\theta = 90^\circ$ to ![]() $0^\circ$ over

$0^\circ$ over ![]() $1/{{f_{nw}}}$ seconds as described in § 2.1) for each

$1/{{f_{nw}}}$ seconds as described in § 2.1) for each ![]() ${U^*}$ increment can be separated into three different wake-body synchronisation regimes: Regime I, II, III, which is in line with the naming convention proposed by Lo et al. (Reference Lo, Hourigan, Thompson and Zhao2023). From figure 5(a), wake-body synchronisation is represented by the matching of the dominant frequencies of

${U^*}$ increment can be separated into three different wake-body synchronisation regimes: Regime I, II, III, which is in line with the naming convention proposed by Lo et al. (Reference Lo, Hourigan, Thompson and Zhao2023). From figure 5(a), wake-body synchronisation is represented by the matching of the dominant frequencies of ![]() ${f^{*}_y}$ and

${f^{*}_y}$ and ![]() ${f^*_{C_y}}$, occurring at

${f^*_{C_y}}$, occurring at ![]() ${{f_{nw}}}$. Regime I (resembling the initial branch of a circular cylinder) is characterised by a negligible mean phase difference of

${{f_{nw}}}$. Regime I (resembling the initial branch of a circular cylinder) is characterised by a negligible mean phase difference of ![]() $\phi _y \approx 10^\circ$ between the body motion and the transverse fluid force (figure 4b) (Lo et al. Reference Lo, Hourigan, Thompson and Zhao2023). However, as the reduced velocity is increased beyond

$\phi _y \approx 10^\circ$ between the body motion and the transverse fluid force (figure 4b) (Lo et al. Reference Lo, Hourigan, Thompson and Zhao2023). However, as the reduced velocity is increased beyond ![]() ${U^*} \approx 4$, the onset of Regime II is marked by the emergence of a third harmonic in

${U^*} \approx 4$, the onset of Regime II is marked by the emergence of a third harmonic in ![]() ${f^*_{C_y}}$ (figure 5a iii), with the strength of both the second and third harmonics increasing with reduced velocity until

${f^*_{C_y}}$ (figure 5a iii), with the strength of both the second and third harmonics increasing with reduced velocity until ![]() ${U^*} = 6.3$. In this regime, the high oscillation amplitudes are likely assisted by positive lift and reduced drag associated with the cylinder acting like an elliptical airfoil as it transverses across the background flow. Regime III then occurs over the range

${U^*} = 6.3$. In this regime, the high oscillation amplitudes are likely assisted by positive lift and reduced drag associated with the cylinder acting like an elliptical airfoil as it transverses across the background flow. Regime III then occurs over the range ![]() $6.4 \leqslant {U^*} \leqslant 7.4$, and corresponds to a monotonic decrease in

$6.4 \leqslant {U^*} \leqslant 7.4$, and corresponds to a monotonic decrease in ![]() ${A^{*}}$ and a jump in the phase to

${A^{*}}$ and a jump in the phase to ![]() $\phi _y \approx 180^\circ$ (figure 4b) (Lo et al. Reference Lo, Hourigan, Thompson and Zhao2023, Reference Lo, Thompson, Hourigan and Zhao2024b). This branch has some similar characteristics to those seen in the lower branch for VIV of a circular cylinder. Unlike Regimes I and II, the oscillation frequency, as shown in figure 5(a iv), gradually increases from

$\phi _y \approx 180^\circ$ (figure 4b) (Lo et al. Reference Lo, Hourigan, Thompson and Zhao2023, Reference Lo, Thompson, Hourigan and Zhao2024b). This branch has some similar characteristics to those seen in the lower branch for VIV of a circular cylinder. Unlike Regimes I and II, the oscillation frequency, as shown in figure 5(a iv), gradually increases from ![]() ${f^{*}} = {{f_{nw}}}$ with the reduced velocity. For

${f^{*}} = {{f_{nw}}}$ with the reduced velocity. For ![]() ${U^*} > 7.4$, the fluid–structure interaction becomes desynchronised as the frequency response of the transverse force is characterised by a broadband frequency response centred about a main signal at the Strouhal vortex shedding frequency,

${U^*} > 7.4$, the fluid–structure interaction becomes desynchronised as the frequency response of the transverse force is characterised by a broadband frequency response centred about a main signal at the Strouhal vortex shedding frequency, ![]() ${f_{St}}$ (figure 5). While the same contribution was observed in the body vibration PSD contours, there was also an additional broadband signal close to the system's natural frequency in quiescent water. For the stationary cylinder case, the Strouhal number was experimentally measured to be

${f_{St}}$ (figure 5). While the same contribution was observed in the body vibration PSD contours, there was also an additional broadband signal close to the system's natural frequency in quiescent water. For the stationary cylinder case, the Strouhal number was experimentally measured to be ![]() ${{St}}={f_{St}} b/U=0.169$.

${{St}}={f_{St}} b/U=0.169$.

Figure 4. (a) Amplitude response (![]() ${A^{*}}$) and (b) mean phase between body displacement and transverse fluid force (

${A^{*}}$) and (b) mean phase between body displacement and transverse fluid force (![]() $\phi _y$) as a function of reduced velocity.

$\phi _y$) as a function of reduced velocity.

Figure 5. Structural response (started from rest) for (a) the non-rotating cylinder and (b) when the control law corresponding to the global maximum ![]() ${A^{*}}$ (i.e. low-gain peak) is imposed. Panel (i) presents the normalised amplitude response, while logarithmic-scale PSD contours of the (ii) normalised vibration (

${A^{*}}$ (i.e. low-gain peak) is imposed. Panel (i) presents the normalised amplitude response, while logarithmic-scale PSD contours of the (ii) normalised vibration (![]() ${f^{*}_y}$), (iii) transverse fluid force (

${f^{*}_y}$), (iii) transverse fluid force (![]() ${f^*_{C_y}}$), (iv) vortex force (

${f^*_{C_y}}$), (iv) vortex force (![]() ${f^*_{C_{v}}}$) and

${f^*_{C_{v}}}$) and ![]() $(v)$ streamwise force (

$(v)$ streamwise force (![]() ${f^*_{C_y}}$) frequencies as a function of

${f^*_{C_y}}$) frequencies as a function of ![]() ${U^*}$ are shown below. In panels (ii)–(iv), the horizontal dashed line highlights the frequencies at

${U^*}$ are shown below. In panels (ii)–(iv), the horizontal dashed line highlights the frequencies at ![]() ${f^{*}} \in \{1,2,3\}$, respectively; the vertical dashed lines represent the boundaries of different response regimes (i.e. I, II, III, IV, V and desynchronisation (D)); and the dash-dotted line in panels (ii)–(iv) represents the Strouhal frequency measured for a stationary cylinder. Note that the frequencies of the horizontal dashed and dash-dotted lines in panel (v) are doubled compared with their counterparts in panels (ii)–(iv).

${f^{*}} \in \{1,2,3\}$, respectively; the vertical dashed lines represent the boundaries of different response regimes (i.e. I, II, III, IV, V and desynchronisation (D)); and the dash-dotted line in panels (ii)–(iv) represents the Strouhal frequency measured for a stationary cylinder. Note that the frequencies of the horizontal dashed and dash-dotted lines in panel (v) are doubled compared with their counterparts in panels (ii)–(iv).

After employing the multi-stage Bayesian optimisation methodology outlined in § 2.3 to find ![]() $(K_p^*,\phi _d)$ that maximises

$(K_p^*,\phi _d)$ that maximises ![]() ${A^{*}}$, the data collected for each

${A^{*}}$, the data collected for each ![]() ${U^*}$ case over the total iterations (table 1) can be visualised using a polar contour plot. It is important to note that while predictions made by the Gaussian process model are used to inform the

${U^*}$ case over the total iterations (table 1) can be visualised using a polar contour plot. It is important to note that while predictions made by the Gaussian process model are used to inform the ![]() $\boldsymbol {b}$ to try in the next iteration of Bayesian optimisation (§ 2.3), the optimised control law (i.e. corresponding to either the local or global peak vibration amplitude for a given

$\boldsymbol {b}$ to try in the next iteration of Bayesian optimisation (§ 2.3), the optimised control law (i.e. corresponding to either the local or global peak vibration amplitude for a given ![]() ${U^*}$ case) reported in this study is directly determined from the sampled actuation-cost pairs and, as such, are only susceptible to measurement noise associated with the sensors.

${U^*}$ case) reported in this study is directly determined from the sampled actuation-cost pairs and, as such, are only susceptible to measurement noise associated with the sensors.

Shown in figures 6 and 7, one peak is observed for ![]() $3 \leqslant {U^*}\leqslant 6$ whilst two peaks exist for

$3 \leqslant {U^*}\leqslant 6$ whilst two peaks exist for ![]() ${U^*}\geqslant 6.5$. Although gain values across the range

${U^*}\geqslant 6.5$. Although gain values across the range ![]() $0 \leqslant K_p^* \leqslant 5$ are also investigated for

$0 \leqslant K_p^* \leqslant 5$ are also investigated for ![]() ${U^*} \leqslant 6$, the contour plots in figures 6 and 7(a) are limited to

${U^*} \leqslant 6$, the contour plots in figures 6 and 7(a) are limited to ![]() $0 \leqslant K_p^* \leqslant 0.25$ due to the primary peak's proximity to the origin and a lack of a secondary peak at high gain values. Given their locations in the plot, maxima with a proportional gain in the range

$0 \leqslant K_p^* \leqslant 0.25$ due to the primary peak's proximity to the origin and a lack of a secondary peak at high gain values. Given their locations in the plot, maxima with a proportional gain in the range ![]() $K_p^* < 0.25$ and

$K_p^* < 0.25$ and ![]() $K_p^* > 1$ will henceforth be referred to as the ‘low-gain’ and ‘high-gain’ peaks, respectively. From figure 4(a), the low-gain solution is the global maxima for all