Introduction

Vegetable production in the United States, valued at $13.6 billion, is critical to the nation’s agricultural economy (USDA-NASS 2022a). Georgia is a key contributor, with more than 33 high-value fruit and vegetable crops grown in the state, including growing 27% of the 2019 national supply of fresh-market cucumbers (Stubbs Reference Stubbs2020; USDA-NASS 2022b). During 2019, 3,497 ha of cucumber were gown in Georgia, valued at nearly $76 million. The total production area has increased 21% (2,760 ha) since 2015, with the economic value of the crop increasing 12% ($67 million), further emphasizing the importance of the cucumber industry to the state (Stubbs Reference Stubbs2020; Wolfe and Stubbs Reference Wolfe and Stubbs2016). Within Georgia, half of the cucumber crop is grown on raised beds covered with plastic mulch (plasticulture), while the other half is planted into non-mulched (bareground) fields (Boatright and McKissick Reference Boatright and McKissick2010). Plasticulture production often results in higher crop quality and yields; however, costs associated with the system (including mulch, drip tape for irrigation, and fumigation plus the labor and equipment required for this production system) can be prohibitive to implement for some producers (Bonanno Reference Bonanno1996; Lamont Reference Lamont1993, Reference Lamont1996).

Although weed management is a challenge for both of these vegetable production systems across the Southeast, bareground systems face greater threats from weeds, because the plastic mulch is an effective weed control barrier for many weeds (Boatright and McKissick Reference Boatright and McKissick2010; Bonanno Reference Bonanno1996). Most bareground systems rely on tillage to prepare the land in tandem with applications of the fumigant 1,3-dicloropropene (1,3-D) to manage nematodes (Dutta Reference Dutta2022; O’Bannon and Tarjan Reference O’Bannon and Tarjan1973; Qiao et al. Reference Qiao, Wang, Shi, Ji and Wang2010). Following fumigation, growers are required to wait between 7 and 21 d before planting, depending on the fumigant rate, environmental conditions, and soil characteristics (Anonymous 2020a). During this time weeds can emerge, as no residual weed control is provided by the fumigant. If weeds are present at planting, cucumber will be unable to effectively compete for light, space, water, nutrients, and pollinating insects throughout the growing season, which results in reductions of fruit quality and yield (Berry et al. Reference Berry, Stall, Rathinasabapathi, Macdonald and Charudattan2006; McGowen et al. Reference McGowen, Jennings, Chaudhari, Monks, Schultheis and Reberg-Horton2018; William and Warren Reference William and Warren1975; Zimdahl Reference Zimdahl2004). It is critical that fields are weed-free at the time of planting, and burndown herbicides are often used to accomplish this goal.

Currently, growers either seed or transplant cucumbers in Georgia. Both systems are complex and costly, and the sensitivity of young transplants or emerging seedlings to herbicide residues from previous crops, or herbicides applied to the current crop, require careful planning (Culpepper Reference Culpepper2022; Fennimore and Doohan Reference Fennimore and Doohan2008; Kemble et al. Reference Kemble, Bertucci, Jennings, Meadows, Rodrigues, Walgenbach and Wszelaki2022; Paret et al. Reference Paret, Dittmar, Agehara and Smith2021). Preplant herbicide options for transplanting cucumber in Georgia include halosulfuron-methyl, carfentrazone-ethyl, pyraflufen-ethyl, glyphosate, and paraquat (Culpepper Reference Culpepper2022). Halosulfuron-methyl is one the most valuable tools in vegetable production, but its most beneficial use in cucumber is for postemergence (POST) applications during the growing season to manage nutsedge species (Anonymous 2017a). Carfentrazone-ethyl and pyraflufen-ethyl provide contact burndown control of Ipomoea and Amaranthus species, but these herbicides offer a narrow weed control spectrum, with efficacy greatly limited by weed size (Anonymous 2017b, 2020b). Paraquat and glyphosate are extensively used for burndown weed control, however, weed resistance due to overreliance is prevalent (Bewick et al. Reference Bewick, Kostewicz, Stall, Shilling and Smith1990; Buker et al. Reference Buker, Steed and Stall2002; Heap and Duke Reference Heap and Duke2018). Additional herbicide options that are available as preemergence (PRE) applications in seeded production include clomazone, bensulide, and ethalfluralin. These herbicides provide residual in-season weed control, but do not control emerged weeds. Thus, the lack of options for the control of weeds immediately before planting or directly after seeding vegetables has motivated a team of multi-state/multi-institutional and industry researchers in cooperation with the Interregional Project No.4 (IR-4) to investigate glufosinate as an alternative. This partnership is determining the potential of labeling glufosinate for preplant or PRE applications in cucurbits, fruiting vegetables, and several other specialty crops (IR-4 2022).

Glufosinate, a broad spectrum, nonselective herbicide, could provide an additional option for preplant or PRE burndown control of emerged weeds in bareground cucumber production systems (Anonymous 2019; Shaner Reference Shaner2014). Commonly used for burndown or POST weed control in transgenic agronomic crops, glufosinate registrations and previous research report control of emerged broadleaf and grassy weeds, including Amaranthus, Ipomoea, and annual grass species (Anonymous 2019; Coetzer et al. Reference Coetzer, Al-Khatib and Peterson2002; Koger et al. Reference Koger, Burke, Miller, Kendig, Reddy and Wilcut2007; Krausz et al. Reference Krausz, Kapusta, Matthews, Baldwin and Maschoff1999; Shaner Reference Shaner2014; Tharp et al. Reference Tharp, Schabenberger and Kells1999). Thus, glufosinate has the potential to control many of the most common weeds present at cucumber planting in the Southeast (Webster Reference Webster2014). Currently, labels permit the use of glufosinate prior to planting, but only when an interval of 180 d is observed between application and planting. The potential impact of soil active residues from glufosinate applied just before planting is unknown. When considering vegetable crops, how the crop responds to an herbicide is often more important than the level of weed control obtainable. Therefore, it is critical that research fully evaluate the potential for residual activity of glufosinate in cucumber and other vegetable crops.

In reviewing labels and the Weed Science Society of America’s herbicide handbook, there is no reported evidence for or against glufosinate soil residues injuring crops (Anonymous 2019, 2020c; Shaner Reference Shaner2014). Research by Smith et al. (Reference Smith, Culpepper, Stewart and Rucker2017) noted that glufosinate applications over plastic mulch just prior to transplanting injured multiple vegetables crops up to 75%, including cucumber. Resulting injury was not due to residual activity, but rather the result of the herbicide splashing off the mulch onto the crop with the first rainfall event. Leiva Soto et al. (Reference Leiva Soto, Edwards, Chapman, Hu and Doohan2017) applied glufosinate 24 h before transplanting bell pepper into soils with varying levels of organic matter (0.1%, 2%, and 12%), with significant crop injury resulting from applications to soils with less than 2% organic matter. These results indicate that bell pepper may not be tolerant to preplant glufosinate applications for soils with less than 2% organic matter, which would include nearly all of the vegetable producing areas in Georgia (Kelley Reference Kelley2018; USDA-NRCS 2022).

Vegetable production in Georgia is unique in that a large number of high-value vegetable crops are produced continuously throughout the year on sandy soils with low levels of organic matter, using intense irrigation programs (Anonymous 2022; Kelley Reference Kelley2018; USDA-NRCS 2022; Westerfield and Linvill Reference Westerfield and Linvill2012). Therefore, additional research is paramount to gain a better understanding of how the residual activity of glufosinate influences vegetable crop production. The objectives of this project were to determine 1) the tolerance of transplant cucumber to preplant glufosinate applications as influenced by rate, overhead irrigation, and interval between application and planting; and 2) the response of seeded cucumber to PRE glufosinate applications as influenced by rate, overhead irrigation, and planting depth.

Materials and Methods

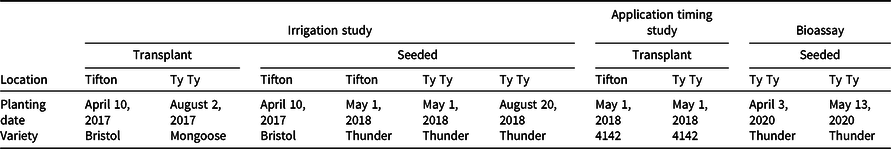

Two different transplant production experiments and one seeded production experiment were conducted twice, with an additional seeded experiment conducted four times between 2017 and 2020 to fulfill project objectives (Table 1). Experiments were conducted at the Tifton Vegetable Park in Tifton, GA (31.4863°N, 83.5211°W, elevation 117 m) and the Ponder research farm in Ty Ty, GA (31.5056°N, 83.6558°W, elevation 109 m). Soils at both sites were Tifton loamy sand (fine-loamy, kaolinitic, thermic Plinthic Kandiudult). At the Tifton location, soil texture was 84% sand, 11% silt, 5% clay, and 0.5% organic matter, pH 6.3. Soils at Ty Ty consisted of 89% to 90% sand, 8 to 10% silt, and 2% clay, pH 6.3 to 6.5; in 2017 and 2019 soils contained 0.5% organic matter, and in 2018 soil consisted of 0.9% organic matter. Prior to experiment initiation, land was conventionally tilled to remove plant debris while applying 1,3-D (64 kg ai ha−1) 30 cm deep using shanks on 91-cm row spacing. While fumigating, plant beds were formed 2 m apart while laying a single drip tape (Rivulis Irrigation, San Diego, CA) down the center of each row for watering and fertilizing after planting (Kemble et al. Reference Kemble, Bertucci, Jennings, Meadows, Rodrigues, Walgenbach and Wszelaki2022). Herbicides were applied using a CO2-pressurized backpack sprayer equipped with 11002 Teejet air induction nozzles (Teejet Technologies, Wheaton, IL), set to deliver 140 L ha−1 at 165 kPa.

Table 1. Cucumber planting location, date, and variety for the 10 field studies.

For transplanted cucumber studies, after glufosinate treatments were applied, transplant holes were formed using a tractor-mounted hole punch wheel (Kennco Manufacturing Inc., Ruskin, FL), and cucumber plants were immediately transplanted by hand in a single row down the center of each bed, spaced 30 cm apart. For seeded cucumber studies, the tractor-mounted hole punch wheel was used to form plant holes in the same configuration as transplant studies. Cucumber seeds were planted by hand at an appropriate depth according to treatment protocol and covered with soil.

Planting locations, dates, and cucumber varieties for each study are listed in Table 1. Land preparation, fumigation, fertilization, insect and disease management, drip irrigation scheduling, and harvesting were implemented in accordance with University of Georgia recommendations for the region (Kemble et al. Reference Kemble, Bertucci, Jennings, Meadows, Rodrigues, Walgenbach and Wszelaki2022). To eliminate the confounding effects of weed presence on crop response, plots were maintained weed-free by selecting areas with low weed infestations and applying labeled herbicides across the entire experiment. Remaining weeds were removed by hand throughout the season, prior to the weed reaching a height or diameter of 5 cm (Culpepper Reference Culpepper2022).

Glufosinate Rate and Irrigation Experiment for Transplant Production

The experimental design was a randomized complete block with a split-plot arrangement of treatments. Each treatment was applied to an area 2 m wide by 6 m long, and included four replications per study. Glufosinate rate was the whole-plot and included 0, 330, 660, 980, or 1,640 g ai ha−1 with the subplot being either overhead irrigation or no irrigation. To implement the study, glufosinate treatments to be followed by irrigation were applied to appropriate whole-plots first. Four hours after application, 0.75 cm of overhead irrigation was applied to the entire experimental area, representing an irrigation event to saturate the soil for optimum planting conditions and move the herbicide into the soil profile. One hour after overhead irrigating, all nonirrigated glufosinate treatments were applied. Twenty-four hours after the final treatment application, cucumber was transplanted.

Glufosinate Rate and Irrigation Experiment for Seeded Production

The experimental design, glufosinate rates, irrigation parameters, and plot layout were identical to those in the transplant study. Thus, after seeding glufosinate treatments receiving irrigation were applied first followed by irrigation. An hour after irrigation, the nonirrigated glufosinate treatments were applied.

Time Interval between Glufosinate Application and Transplanting Experiment

The experimental design included a factorial arrangement of three application timings and three glufosinate rates. Treatments were arranged in a randomized complete block, replicated four times, and plots were 2 m by 9 m. Herbicide treatments were glufosinate applied at 660, 1,310, or 1,970 g ha−1 either 7, 4, or 1 d before planting (DBP). A nontreated control was included for comparisons, and no irrigation or rainfall occurred between applications and planting at either location.

Cucumber Seeding Depth Experiment

The factorial treatment arrangement consisted of four glufosinate rates (0, 660, 980, or 1,640 g ha−1) applied immediately after seeding cucumber at two depths (1 or 2 cm below the soil surface). Plots measured 2 m by 9 m, and included four replications per study in a randomized complete block design.

Data Collection Across Experiments

Crop injury was visually evaluated throughout the season using a scale of 0% (no crop injury) to 100% (complete plant death) to assess the visual tolerance of cucumber to glufosinate. In all studies, crop injury was assessed 2 d after planting (DAP) and continued weekly until harvest. Crop height and vine lengths were measured two to four times during the season, from nine consecutive plants in each plot, beginning 10 DAP and continuing through the season. Height was determined by measuring from the soil line to the tallest point of the plant, while vine length was determined by measuring from the end of the longest vine to the ground where the seed had emerged, or the transplant was placed. Early-season plant biomass was assessed 12 to 22 DAP, when plants exhibited maximum injury symptoms; biomass measurements were made once in each study except with the seedling depth experiment. At this time, 8 to 10 plants per plot were cut off at the soil line and collectively weighed for calculation. To adjust for differences in observation interval, all vine length, plant height, and early-season fresh weight biomass data has been converted to a percentage of the nontreated control for analysis and discussion. In all experiments, except when focusing on planting depth, cucumbers were picked 11 to 13 times with yield determined by recording the number of mature marketable fruit and their collective weights. Data associated with harvest, including fruit number and mass were similar, thus only the yield in terms of weight will be discussed. For the seedling plant depth study, cucumber was not harvested.

Statistical Analysis

Collected data were assessed for normality and analyzed using the GLIMMIX procedure in SAS software (SAS Enterprise Guide 8.3; SAS Institute, Cary, NC) to determine whether the combined treatment effects of glufosinate rate and overhead irrigation option, rate, and plant-back interval, or rate and seeding depth impacted cucumbers. Treatments and their interactions were treated as fixed effects, where location and replication (nested within location) were treated as random effects. Interactions between locations and treatment effects were evaluated, and when appropriate, data were separated by location for analysis. Significant means were separated using the Tukey-Kramer least square means test (P ≤ 0.05). When appropriate, regression analysis was used to further describe relationships between herbicide rate and response variables.

Results and Discussion

Glufosinate Rate and Irrigation Experiment for Transplant Production

Combined across locations, visual ratings of cucumber injury were affected by the interaction of glufosinate rate and overhead irrigation. At 10 DAP when maximum injury was observed, glufosinate at 330, 660, 980, and 1,640 g ha−1 injured cucumber by 11%, 20%, 43%, and 52%, respectively (Table 2). When irrigation was implemented after treatment but before planting, injury levels of 8%, 12%, 16%, and 20% were noted at the aforementioned glufosinate rates, respectively. Previous research conducted by Smith et al. (Reference Smith, Culpepper, Stewart and Rucker2017) noted the elimination of cucumber injury when overhead irrigation followed preplant glufosinate applications over plastic mulched beds. Although Smith et al. (Reference Smith, Culpepper, Stewart and Rucker2017) used transplanted cucumber, similar glufosinate application rates, and 1 cm of overhead irrigation following glufosinate applications, the elimination of cucumber injury was not observed in our study. The difference in their research is likely a result of the overhead irrigation removing glufosinate from the surface of the mulch prior to punching the hole for transplanting, eliminating the possibility of soil uptake from the transplant root ball. Although in our research irrigation significantly reduced injury by 62% to 63% at the two highest glufosinate rates (Table 2), injury exceeded the acceptable level (<10%) by growers of most high-value vegetable crops (Shaner Reference Shaner2014; Smith et al. Reference Smith, Culpepper, Stewart and Rucker2017).

Table 2. Transplant cucumber visual injury, vine length, and fresh-weight biomass as influenced by preplant glufosinate applications and overhead irrigation 1 d before planting during 2017 and 2018. a,b

a Glufosinate applications were followed by overhead irrigation or no irrigation 1 d before planting.

b Abbreviations: DAP, days after planting; NTC, non-treated control.

c Means followed by the same letter within each response variable are not significantly different (P ≤ 0.05).

d Transplant cucumber injury evaluations were reported 10 DAP when maximum injury was observed; vine lengths were reported 14 DAP, and biomass was reported 12 to 22 DAP.

Similar to injury, vine length was also impacted by the interaction between herbicide rate and overhead irrigation. Relative to the nontreated control, vine lengths were reduced by 14%, 26%, and 28% when glufosinate was used at 660, 980, and 1,640 g ha−1, respectively, at 14 DAP (Table 2). When overhead irrigation was implemented, vine lengths were reduced by 9% only at the highest glufosinate application rate. Early-season biomass, 12 to 22 DAP, also noted the value of irrigation, reducing injury by 20% to 36% with the three highest rates of glufosinate.

Cucumber early-season and full-season yields were influenced by an herbicide rate by overhead irrigation interaction as well as location. Early-season yield is an indicator of timely crop maturity in vegetable production and is often the most important and most valuable of all fruit harvested (Ilic Reference Ilic1990). Early-season yield was negatively influenced by glufosinate at 980 and 1,640 g ha−1, when fruit weight was reduced by 48% and 42% in Ty Ty, and by 46% and 60% in Tifton (data not shown). When overhead irrigation was implemented at both locations, glufosinate did not impact early-season yield.

Total cucumber weight over 15 harvests was reduced by 18%, 46%, and 41% from glufosinate applied at 660, 980, and 1,640 g ha−1, respectively (Figure 1) in Ty Ty. Regression models estimate a 3.58 kg ha−1 decrease in yield for each gram per hectare increase in glufosinate rate. Implementing overhead irrigation reduced the impact from glufosinate with a 32% yield loss recorded only at the highest rate. Compared with injury observed in Ty Ty, cucumber recovery from herbicide injury in Tifton was rapid, therefore, treatments did not impact total yield (data not shown). Just prior to harvest, maximum injury recorded in Tifton was 25%, while in Ty Ty, maximum injury was 44%; differences that were likely influenced by the growing season. The spring-planted crop in Tifton grew into increasing heat units during the summer months, which likely helped the crop overcome injury more effectively than that observed with the fall-planted crop in Ty Ty (NeSmith and Hoogenboom Reference Hoogenboom1994).

Figure 1. Total yield of transplant cucumber as influenced by preplant glufosinate applications, followed by overhead irrigation or no irrigation, 1 d before planting in Ty Ty. Total cucumber yield data were linearly regressed against glufosinate rate using the equation yIrrigated = 14,007.464 − 2.828 *rate (R 2 = 0.79) and yNonrrigated = 12,603.645 - 3.584 *rate (R 2 = 0.61).

Time Interval Between Glufosinate Application and Transplanting Experiment

A location interaction was noted for all variables including crop injury, vine lengths, early-season biomass, and cucumber yield. Thus, data were analyzed and reported by location.

Visual crop injury reached its maximum at 22 DAT for both locations. In Tifton, the interval between glufosinate application and planting did not influence injury. Although herbicides degrade over time (Shaner Reference Shaner2014), 7 d was not an adequate amount of time needed for glufosinate degradation to occur without rainfall/irrigation, or tillage at this location. When combined over application intervals of 7, 4, and 1 DBP in Tifton, glufosinate at 660, 1,310, and 1,970 g ha−1 injured cucumber by 13%, 64%, and 93%, respectively (data not shown). In Ty Ty, less overall injury was observed and the significant interaction between application interval and glufosinate rate showed less injury with the two highest rates applied 7 d before planting when compared with 1 d (Table 3). Although less injury was noted in Ty Ty when compared with that in Tifton, injury of 10% to 14%, 23% to 25%, and 69% to 70% was still recorded with glufosinate rates of 660, 1,310, and 1,970 g ha−1, respectively, when applied 4 or 1 d before planting. The 7-d interval noted less than 6% injury with 660 and 1,310 g ha−1, but 33% injury at 1,970 g ha−1. When comparing Tifton and Ty Ty, environmental conditions and production practices were essentially identical (Table 1). The one detectable difference was noted in organic matter levels, with nearly twice as much present in Ty Ty (0.9% organic matter) where injury was less compared to that in Tifton (0.5% organic matter). As suggested by Leiva Soto et al. (Reference Leiva Soto, Edwards, Chapman, Hu and Doohan2017), the residual activity of glufosinate may be influenced by the level of organic matter present.

Table 3. Transplant cucumber visual injury, vine length, and fresh-weight biomass as influenced by glufosinate applied 7, 4, and 1 d before planting in Ty Ty during 2018. a,b,c

a Abbreviations: DAP, days after planting; DBP, days before planting; NTC, nontreated control.

b Means followed by the same letter within a variable are not significantly different (P ≤ 0.05).

c Transplant cucumber injury evaluations were reported 22 DAP when maximum injury was observed; vine lengths were reported 23 DAP, and biomass was reported 13 DAP.

Cucumber vine length measurements followed trends noted with visual injury. Combined over application interval in Tifton, 23 DAP, cucumber vine lengths were reduced by 62% and 86% with glufosinate applied at 1,310 and 1,970 g ha−1 (data not shown). In Ty Ty, however, vine reductions of 35% and 42% were noted only from the highest rate applied 4 and 1 d prior to planting (Table 3).

Cucumber early-season biomass taken at 13 DAP, just prior to maximum visual injury, noted a reduction in biomass of 37%, 74%, and 89% with glufosinate applied at 660, 1,310, and 1,970 g ha−1 in Tifton, respectively (data not shown). In Ty Ty, glufosinate rates of 1,310 and 1,970 g ha−1 applied within 4 d of planting reduced growth by 29% to 52%, respectively (Table 3). Applications made 7 DBP reduced biomass only when applied at the highest rate in Ty Ty (32%).

Cucumber yield reported as total weight of marketable fruit were combined over 11 harvests in Tifton and 13 harvests in Ty Ty. In Tifton, when combined over interval between application and planting, cucumber was able to recover from early-season damage when glufosinate was applied at only 660 g ha−1 (Figure 2). At higher rates, yield loss of 55% to 87% was recorded. In Ty Ty, where less injury and impact on vine development was observed from treatments, cucumber was able to recover from 660 and 1,310 g ha−1 of glufosinate regardless of application interval (Figure 3). However, 1,970 g ha−1 of glufosinate applied within 4 d of planting reduced yield by 22% to 30%.

Figure 2. Total yield of transplanted cucumber as influenced by preplant glufosinate application rates of 0, 660, 1,310, and 1,970 g ha−1 in Tifton. Total cucumber yield data were pooled over application timing, and linearly regressed against glufosinate rate using the equation yyield = 5,218.044 − 2.349 *rate (R 2 = 0.62).

Figure 3. Total yield of transplanted cucumber as influenced by preplant glufosinate applied 7, 4, and 1 d before planting (DBP) in Ty Ty. Total cucumber yield data were linearly regressed against glufosinate rate using the equation y1DBP = 18,900.094 − 2.034 *rate (R 2 = 0.57), y4DBP = 19,360.103 − 2.725 *rate (R 2 = 0.61), and y7DBP = 19,232.843 − 1.843 *rate (R 2 = 0.31).

Glufosinate Rate and Irrigation Experiment for Seeded Production

No significant interaction was noted between study locations and response variables, therefore, data for crop injury, plant vine length, early-season biomass, early-harvest yield, and total cucumber yield were combined over all four experimental runs for analysis. Additionally, irrigation did not influence results, thus main effect means for glufosinate rates are discussed.

The maximum level of visual injury throughout the season was 6%, which was observed when glufosinate was applied at 1,640 g ha−1 (Table 4). These results are vastly different from those observed in transplant cucumber experiments with similar treatments. Differences in injury observed are likely a result of the planting process. When transplanting after a preplant herbicide application, holes are punched in the treated soil that carries the herbicide into the hole, thereby surrounding the moist transplant root ball for immediate root absorption. In seeded production, it is likely that the herbicide remained above the developing root system during the 5- to 7-d emergence window and/or the herbicide was absorbed to the soil at a high enough level to facilitate microbial breakdown and inhibit root uptake (Anonymous 2019; Shaner Reference Shaner2014). With injury levels being low, the addition of irrigation after applying glufosinate PRE was of no benefit.

Table 4. Seeded cucumber visual injury, vine length, and fresh-weight biomass as influenced by glufosinate applied preemergence in Tifton and Ty Ty, during 2017 and 2018. a,b,c

a Abbreviations: DAP, days after planting; NTC, nontreated control.

b Means (averaged over four locations) followed by the same letter within column do not significantly differ (P ≤ 0.05); the absence of letters indicates a lack of significant differences between treatments.

c Seeded cucumber injury evaluations were reported 20 to 22 DAP when maximum injury was observed; vine lengths were reported 23 DAP, and biomass was reported 20 DAP.

Cucumber vine lengths, early-season biomass, early-season marketable yield, and full season marketable yield were not influenced by glufosinate treatment (Table 4). With visual injury being 6% or less across locations and minimal negative impacts on plant growth, yield loss would not be expected in a production system that provides ample water and fertilizer daily. The total weight of fruit harvested averaged 26,254 kg ha−1 combined across locations for 7 to 12 harvests.

Cucumber Seeding Depth Experiment

Due to the minimal impacts of overhead irrigation following glufosinate applications in the previously discussed seeded cucumber research, an additional experiment was conducted to determine whether a combination of seeding depth and glufosinate application rate influenced visual injury and crop growth. Data from both runs was statistically similar, therefore, results have been combined across experimental run for analysis. Results indicated significant interactions between glufosinate application rate and seeding depth for visual crop injury and plant height.

Maximum seeded cucumber injury, recorded 20 DAP, significantly increased as the glufosinate rate increased from 660 to 1,640 g ha−1 when cucumber was seeded at a depth of 1 cm; however, resulting injury was 11% or less, regardless of rate (Table 5). When seeded 2 cm deep, cucumber injury was 8% only at the highest glufosinate application rate; lower rates did not significantly impact cucumber injury, and total injury from all applications was below an acceptable threshold (<10%) of most high-value vegetable growers.

Table 5. Seeded cucumber visual injury and plant height as influenced by preemergence glufosinate applications and seeding depth in Ty Ty, during 2020. a,b,c

a Abbreviations: DAP, days after planting; NTC, nontreated control.

b Means followed by the same letter for each response variable do not significantly differ (P ≤ 0.05); averaged over two studies.

c Seeded cucumber injury and height evaluations reported 20 DAP when maximum injury was observed.

Plant heights were impacted by both seeding depth and glufosinate rate. Heights were no different from the nontreated control when cucumber was seeded to a depth of 2 cm at the two lowest rates; however, plant height was reduced 15% when glufosinate was applied at 1,640 g ha−1 (Table 5). At a shallower seeding depth, cucumber height was reduced by 17%, 15%, and 21% from glufosinate applied at all application rates. While cucumber is slow to emerge from deeper planting depths, a shallower seeding depth may have allowed more glufosinate uptake before degradation.

In conclusion, for cucumber being transplanted by hand using a mechanical hole puncher, glufosinate applied between 330 and 1,640 g ha−1 within 7 d of transplanting posed a significant risk for unacceptable crop injury coupled with a reduction in plant growth and marketable yield, when production fields are high in sand content and low in organic matter. The addition of 0.75 cm of overhead irrigation between a glufosinate application and transplanting generally reduced herbicide injury 20% to 60% with corresponding benefits in crop growth and yield. In seeded cucumber production, a PRE application of glufosinate with rates below 1,640 g ha−1 pose no relevant risk to crop injury, growth, or yield. When seeding, a deeper depth does reduce damage potential from a PRE glufosinate application, but selecting the ideal planting depth to ensure ideal agronomic production practices are followed is more important.

Acknowledgments

We thank Tim Richards and Dewayne Dales for their technical assistance, ensuring each trial made it through harvest. Additionally, we also thank the Georgia Commodity Commission for Vegetable and the IR-4 for their financial support. No conflicts of interest have been declared.