1. Introduction

Flow-induced particle motion is a fundamental feature of a wide variety of industrial and natural processes. The particles usually reside on a patterned or rough surface or on a granular bed. This includes, for instance, the cleaning of surfaces (Burdick, Berman & Beaudoin Reference Burdick, Berman and Beaudoin2005; Kondo & Ando Reference Kondo and Ando2019), filtration and fractionation (Meland & Norrman Reference Meland and Norrman1966; Charru et al. Reference Charru, Larrieu, Dupont and Zenit2007), pneumatic conveying (Stevanovic et al. Reference Stevanovic, Stanojevic, Jovovic, Radic, Petrovic and Karlicic2014) or sediment transport in rivers, on coastal lines and in dune formation (Groh et al. Reference Groh, Wierschem, Rehberg, Aksel and Kruelle2008; Wierschem et al. Reference Wierschem, Groh, Rehberg, Aksel and Kruelle2008; Carneiro, Pähtz & Herrmann Reference Carneiro, Pähtz and Herrmann2011; Seizilles et al. Reference Seizilles, Devauchelle, Lajeunesse and Metivier2013). It is also of particular importance for the positioning and assembling of particles for construction of metamaterials (Yin et al. Reference Yin, Lu, Gates and Xia2001; Bleil, Marr & Bechinger Reference Bleil, Marr and Bechinger2006; Nguyen & Yoon Reference Nguyen and Yoon2009) and laminar flow assays (Brooks & Tozeren Reference Brooks and Tozeren1996). Consequently, the flow-induced onset of particle motion has been studied intensively over the past decades; see, for instance, the articles by Loiseleux et al. (Reference Loiseleux, Gondret, Rabaud and Doppler2005), Ouriemi et al. (Reference Ouriemi, Aussillous, Medale, Peysoon and Guazzelli2007), Hong, Tao & Kudrolli (Reference Hong, Tao and Kudrolli2015), Métivier, Lajeunesse & Devauchelle (Reference Métivier, Lajeunesse and Devauchelle2017), Dey & Ali (Reference Dey and Ali2018), Topic et al. (Reference Topic, Hou, Illigmann, Luzi, Agudo and Wierschem2019a,Reference Topic, Retzepoglu, Wensing, Illigmann, Luzi, Agudo and Wierschemb), Shih & Diplas (Reference Shih and Diplas2019), Pähtz et al. (Reference Pähtz, Clark, Valyrakis and Durán2020, Reference Pähtz, Liu, Xia, Hu, He and Tholen2021), and references cited therein. Beyond the threshold for particle motion, the particles may roll, slide or lift off (Valyrakis et al. Reference Valyrakis, Diplas, Dancey, Greer and Celik2010; Agudo, Dasilva & Wierschem Reference Agudo, Dasilva and Wierschem2014; Agudo et al. Reference Agudo, Illigmann, Luzi, Laukart, Delgado and Wierschem2017a,Reference Agudo, Luzi, Han, Hwang, Lee and Wierschemb).

For the motion above the threshold, most studies have focused on the mass flow rate in granular beds. For an overview of models for the flow rate in turbulent and laminar flows, see e.g. Ouriemi, Aussillous & Guazzelli (Reference Ouriemi, Aussillous and Guazzelli2009). An important step in understanding the mechanisms governing the particle flow rate is considering the motion of single beads along substrates made from other particles (Charru, Mouilleron & Eiff Reference Charru, Mouilleron and Eiff2004). Yet only a few studies focus on the motion of single particles on granular beds. Meland & Norrman (Reference Meland and Norrman1966) studied the motion of individual beads of different size on regular granular beds exposed to turbulent flow. Near the threshold, they observed discontinuous motion. It became continuous at higher forcing, where the beads did not descend completely into the substrate pockets at higher velocities. Abbott & Francis (Reference Abbott and Francis1977) studied the motion of single grains over a granular bed in a turbulent flow at Shields numbers up to about ten times the critical Shields number. Apart from particle motion along the substrate, they observed saltation and suspension. Yet, already at Shields numbers ![]() $20\,\%$ larger than the critical one, the particle moved mainly in flights. They found a close-to-linear relation between the mean particle velocity in the flow direction and the shear velocity. Although the particle velocity was higher during flights than along the bed, the close-to-linear relation was found to be valid as the grain changed gradually from predominantly moving along the bed to predominantly flying over it.

$20\,\%$ larger than the critical one, the particle moved mainly in flights. They found a close-to-linear relation between the mean particle velocity in the flow direction and the shear velocity. Although the particle velocity was higher during flights than along the bed, the close-to-linear relation was found to be valid as the grain changed gradually from predominantly moving along the bed to predominantly flying over it.

The motion of a single bead along a substrate exposed to laminar shear flow was studied by Charru et al. (Reference Charru, Larrieu, Dupont and Zenit2007). They considered the bead motion on an irregularly arranged bed made of spheres of the same size in an annular channel. At the onset of continuous motion, they measured average bead velocities of about ![]() $10\,\%$ of the Stokes settling velocity. They found that the average streamwise velocity increases linearly with the Shields number as long as it is smaller than the settling velocity. At higher Shields numbers, it increases more strongly. To describe their findings, they developed a model with effective parameters. Based on ideas of Bagnold (Reference Bagnold1973), they assumed for their average properties a dynamic equilibrium between flow-induced forces and an effective friction force representing momentum transfer to the bed. The effective parameters were obtained from fits to the data and using the results of Goldman, Cox & Brenner (Reference Goldman, Cox and Brenner1967b) for the motion of a bead near a flat plane in the creeping-flow limit.

$10\,\%$ of the Stokes settling velocity. They found that the average streamwise velocity increases linearly with the Shields number as long as it is smaller than the settling velocity. At higher Shields numbers, it increases more strongly. To describe their findings, they developed a model with effective parameters. Based on ideas of Bagnold (Reference Bagnold1973), they assumed for their average properties a dynamic equilibrium between flow-induced forces and an effective friction force representing momentum transfer to the bed. The effective parameters were obtained from fits to the data and using the results of Goldman, Cox & Brenner (Reference Goldman, Cox and Brenner1967b) for the motion of a bead near a flat plane in the creeping-flow limit.

Like Charru et al. (Reference Charru, Larrieu, Dupont and Zenit2007), we study the motion of a single bead along a substrate made of particles of the same size. Different from them, we consider the motion over regularly arranged substrates. Apart from being important, for instance, in positioning e.g. in microfluidic systems, it allows highlighting and quantifying the impact of the substrate geometry on the particle motion. We focus on the motion at Shields numbers of same order as the critical one, where the particle moves along the substrate, and on particle Reynolds numbers, where inertia can be neglected. Similar to previous studies on the onset of motion (Agudo & Wierschem Reference Agudo and Wierschem2012), we carry out experiments on triangular and quadratic arrangements, and vary the spacing between the substrate particles. The role of substrate spacing has also been considered in studies on dry granular particle motion down inclined planes in two dimensions. Apart from regular arrangements (Dippel, Batrouni & Wolf Reference Dippel, Batrouni and Wolf1996), it has been varied often randomly to model roughness (Riguidel et al. Reference Riguidel, Jullien, Ristow, Hansen and Bideau1994; Ristow, Riguidel & Bideau Reference Ristow, Riguidel and Bideau1994; Batrouni, Dippel & Samson Reference Batrouni, Dippel and Samson1996; Shojaaee et al. Reference Shojaaee, Brendel, Török and Wolf2012).

While there are numerous approaches to describe and model the particle mass flow rate in bed-load transport (Ouriemi et al. Reference Ouriemi, Aussillous and Guazzelli2009), to the best of our knowledge, the motion of a single particle along a substrate in laminar flow conditions has been described only by Charru et al. (Reference Charru, Larrieu, Dupont and Zenit2007), who determine effective quantities describing the motion along the randomly arranged substrate in their experiments. To focus on the impact of the substrate geometry, we extend our model for the onset of motion (Agudo et al. Reference Agudo, Illigmann, Luzi, Laukart, Delgado and Wierschem2017a; Topic et al. Reference Topic, Retzepoglu, Wensing, Illigmann, Luzi, Agudo and Wierschem2019b) to conditions above the threshold. It allows considering rolling and sliding along the substrates as well as detachment. Depending on the substrate geometry and on the Shields number, the model shows that all three types of motion may occur along the substrate, and reveals the impact of the different types of motion on the average velocity.

The article is arranged as follows. The experimental set-up is described in § 2, and the experimental results in § 3. To describe these findings, we derive a model in § 4. The results are discussed in § 5, and the main conclusions are summarized in § 6.

2. Experimental set-up

A single bead is deposited on regular substrates and exposed to a laminar shear flow. The regular substrates consist of a monolayer of uniformly sized soda-lime glass spheres of ![]() $(405.9 \pm 8.7)\,\mathrm {\mu }$m diameter as in former studies (Agudo et al. Reference Agudo, Dasilva and Wierschem2014; Topic et al. Reference Topic, Retzepoglu, Wensing, Illigmann, Luzi, Agudo and Wierschem2019b). The mobile beads have the same size. The substrate spheres are fixed and arranged in quadratic configurations with different spacing between the particles. Like Agudo & Wierschem (Reference Agudo and Wierschem2012), we use substrates with spacings

$(405.9 \pm 8.7)\,\mathrm {\mu }$m diameter as in former studies (Agudo et al. Reference Agudo, Dasilva and Wierschem2014; Topic et al. Reference Topic, Retzepoglu, Wensing, Illigmann, Luzi, Agudo and Wierschem2019b). The mobile beads have the same size. The substrate spheres are fixed and arranged in quadratic configurations with different spacing between the particles. Like Agudo & Wierschem (Reference Agudo and Wierschem2012), we use substrates with spacings ![]() $a=14$, 94 and

$a=14$, 94 and ![]() $109\,\mathrm {\mu }$m between the spheres, which correspond to a ratio between spacing and bead diameter

$109\,\mathrm {\mu }$m between the spheres, which correspond to a ratio between spacing and bead diameter ![]() $D_P$ of about 0.035, 0.232 and 0.269, respectively. Also, we carry out experiments on a substrate in a triangular arrangement with spheres in direct contact. In this case, the substrate grooves are oriented with respect to the main flow direction at angle

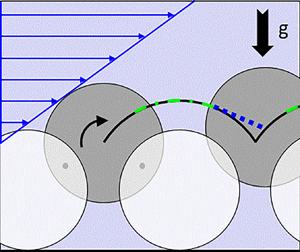

$D_P$ of about 0.035, 0.232 and 0.269, respectively. Also, we carry out experiments on a substrate in a triangular arrangement with spheres in direct contact. In this case, the substrate grooves are oriented with respect to the main flow direction at angle ![]() ${\rm \pi} /6$. Figure 1 shows a view on different substrate geometries.

${\rm \pi} /6$. Figure 1 shows a view on different substrate geometries.

Figure 1. Substrate geometries. Top view on the triangular configuration (a), and on the quadratic configuration with spacings (b) ![]() $14\,\mathrm {\mu }$m and (c)

$14\,\mathrm {\mu }$m and (c) ![]() $109\,\mathrm {\mu }$m. Main flow direction is from left to right as indicated by the large blue arrows in the sketches. On the triangular arrangement, the bead travels in a zigzag manner along the grooves as indicated by the thick black arrows.

$109\,\mathrm {\mu }$m. Main flow direction is from left to right as indicated by the large blue arrows in the sketches. On the triangular arrangement, the bead travels in a zigzag manner along the grooves as indicated by the thick black arrows.

The substrates, with dimensions ![]() $70\times 15\,{\rm mm}^2$, are glued to glass microscope slides measuring

$70\times 15\,{\rm mm}^2$, are glued to glass microscope slides measuring ![]() $70\times 25\,{\rm mm}^2$ and placed off-centre on the bottom of a transparent circular container with inner diameter 176 mm and 25 mm high sidewalls made from Plexiglas. Figure 2 shows a sketch of the container with the rheometer disk. This container is placed into an MCR 301 rotational rheometer from Anton Paar. A laminar shear flow is induced with a parallel-disk configuration. The rotating top plate is made from Plexiglas and has diameter 150 mm. At the bead, which is positioned at distance

$70\times 25\,{\rm mm}^2$ and placed off-centre on the bottom of a transparent circular container with inner diameter 176 mm and 25 mm high sidewalls made from Plexiglas. Figure 2 shows a sketch of the container with the rheometer disk. This container is placed into an MCR 301 rotational rheometer from Anton Paar. A laminar shear flow is induced with a parallel-disk configuration. The rotating top plate is made from Plexiglas and has diameter 150 mm. At the bead, which is positioned at distance ![]() $r$ from the turning axis, the shear rate

$r$ from the turning axis, the shear rate ![]() $\dot \gamma$ is

$\dot \gamma$ is

where ![]() $\varOmega$ is the angular velocity, and

$\varOmega$ is the angular velocity, and ![]() $h$ is the gap width, defined as the distance from the top of the substrate spheres to the rotating plate. Both angular velocity and gap width are controlled with the rheometer. All experiments are performed at gap width 2 mm.

$h$ is the gap width, defined as the distance from the top of the substrate spheres to the rotating plate. Both angular velocity and gap width are controlled with the rheometer. All experiments are performed at gap width 2 mm.

Figure 2. Sketch of the container and the rotating rheometer disk.

The Reynolds number ![]() ${{Re}}$ and particle Reynolds number

${{Re}}$ and particle Reynolds number ![]() ${{Re}}_P$ are defined as

${{Re}}_P$ are defined as

where ![]() $\mu$ is the dynamic viscosity, and

$\mu$ is the dynamic viscosity, and ![]() $\rho _F$ is the liquid density. The impact of the flow on the bead is characterized by the Shields number (Agudo & Wierschem Reference Agudo and Wierschem2012; Agudo et al. Reference Agudo, Dasilva and Wierschem2014; Topic et al. Reference Topic, Retzepoglu, Wensing, Illigmann, Luzi, Agudo and Wierschem2019b), i.e. the ratio between the characteristic shear force acting on the particle and its resistant effective particle weight:

$\rho _F$ is the liquid density. The impact of the flow on the bead is characterized by the Shields number (Agudo & Wierschem Reference Agudo and Wierschem2012; Agudo et al. Reference Agudo, Dasilva and Wierschem2014; Topic et al. Reference Topic, Retzepoglu, Wensing, Illigmann, Luzi, Agudo and Wierschem2019b), i.e. the ratio between the characteristic shear force acting on the particle and its resistant effective particle weight:

where ![]() $\rho _P$ is the particle density, and

$\rho _P$ is the particle density, and ![]() $g$ is the acceleration due to gravity.

$g$ is the acceleration due to gravity.

To study the impact of inertia, we vary the Reynolds number and the particle density by using different liquids and bead materials. Yet the particle Reynolds number remains lower than 2 in our experiments. Table 1 summarizes the properties of the employed beads and fluids. Table 2 depicts the critical Shields number, ![]() $\theta _C$, for the onset of particle motion of each of the substrates determined previously (Agudo & Wierschem Reference Agudo and Wierschem2012). The temperature is fixed at

$\theta _C$, for the onset of particle motion of each of the substrates determined previously (Agudo & Wierschem Reference Agudo and Wierschem2012). The temperature is fixed at ![]() $(295.15 \pm 0.5)\,{\rm K}$. This is controlled with a P-PTD 200 Peltier element connected to the rheometer and measured with an external thermometer.

$(295.15 \pm 0.5)\,{\rm K}$. This is controlled with a P-PTD 200 Peltier element connected to the rheometer and measured with an external thermometer.

Table 1. Bead and fluid properties.

Table 2. Critical Shields numbers for the onset of motion (Agudo & Wierschem Reference Agudo and Wierschem2012).

The experiments are carried out by applying a sudden shear-rate jump on the mobile bead with a step width of the rheometer of about 0.02 s, starting from conditions below the critical Shields number to a state above threshold that is kept constant while the beads move along the substrate. Solving the transient plane Couette flow for flat plates with gap width 2 mm, we arrive at characteristic times of about 0.2 s or less for reaching ![]() $99\,\%$ of the steady value near the bottom (0.2 mm distance) with our oils. Particle motion is recorded from the top through the transparent rotating disk with a digital camera with a chip of

$99\,\%$ of the steady value near the bottom (0.2 mm distance) with our oils. Particle motion is recorded from the top through the transparent rotating disk with a digital camera with a chip of ![]() $752\times 480$ pixels and a frame rate up to 120 Hz coupled to a macro-objective that incorporates a tilted mirror. The bead moving along the substrate is tracked with an image-processing routine (Agudo et al. Reference Agudo, Dasilva and Wierschem2014, Reference Agudo, Luzi, Han, Hwang, Lee and Wierschem2017b, Reference Agudo, Han, Park, Kwon, Loekman, Luzi, Linderberger, Delgado and Wierschem2018).

$752\times 480$ pixels and a frame rate up to 120 Hz coupled to a macro-objective that incorporates a tilted mirror. The bead moving along the substrate is tracked with an image-processing routine (Agudo et al. Reference Agudo, Dasilva and Wierschem2014, Reference Agudo, Luzi, Han, Hwang, Lee and Wierschem2017b, Reference Agudo, Han, Park, Kwon, Loekman, Luzi, Linderberger, Delgado and Wierschem2018).

3. Experimental results

To check the ability of the set-up for analysing the impact of the substrate geometry on the mean particle velocity, we first identify a parameter range that is independent of any boundary conditions. This includes the inherent rotating motion of the rheometer disk. The critical Shields number for the onset of particle motion is hardly affected by the angle between flow direction and the symmetry axis of the substrate around its minimum values within the interval of about ![]() ${\rm \pi} /6$ (Agudo & Wierschem Reference Agudo and Wierschem2012). Accordingly, the mobile bead may follow a straight path of about 17 mm with a reduction of the maximum shear stress by about

${\rm \pi} /6$ (Agudo & Wierschem Reference Agudo and Wierschem2012). Accordingly, the mobile bead may follow a straight path of about 17 mm with a reduction of the maximum shear stress by about ![]() $3\,\%$. A distance of 17 mm corresponds to about 30 positions for the substrate with widest spacing between the spheres. Moreover, for small particle Reynolds numbers as considered in our experiments, centrifugal forces caused by the rotating disk motion are negligible (Agudo & Wierschem Reference Agudo and Wierschem2012; Agudo et al. Reference Agudo, Dasilva and Wierschem2014). In our study, the bead moves along the substrate grooves as reported previously for the onset of motion (Agudo & Wierschem Reference Agudo and Wierschem2012). This holds also for triangular arrangements of substrate spheres.

$3\,\%$. A distance of 17 mm corresponds to about 30 positions for the substrate with widest spacing between the spheres. Moreover, for small particle Reynolds numbers as considered in our experiments, centrifugal forces caused by the rotating disk motion are negligible (Agudo & Wierschem Reference Agudo and Wierschem2012; Agudo et al. Reference Agudo, Dasilva and Wierschem2014). In our study, the bead moves along the substrate grooves as reported previously for the onset of motion (Agudo & Wierschem Reference Agudo and Wierschem2012). This holds also for triangular arrangements of substrate spheres.

Figure 3(a) depicts the trajectory of a single glass bead at Shields number 0.058 on the substrate with narrowest spacing. For this geometry, the Shields number is about ![]() $1.5 \times \theta _C$. The experiment is performed by placing the mobile bead at radius 50 mm from the centre of the disk, and using the less viscous oil. The bead travels over 38 substrate pockets, which corresponds to around 16 mm, showing a straight trajectory during the entire path. The lateral displacement is marginal and due mainly to small defects on the regular substrate. Figure 3(b) shows the streamwise position of the bead as a function of time. The bead achieves a constant mean equilibrium velocity in the early stage of its motion right after the shear-rate jump, being barely affected by the inherent rotating motion of the rheometer disk within the considered pathway.

$1.5 \times \theta _C$. The experiment is performed by placing the mobile bead at radius 50 mm from the centre of the disk, and using the less viscous oil. The bead travels over 38 substrate pockets, which corresponds to around 16 mm, showing a straight trajectory during the entire path. The lateral displacement is marginal and due mainly to small defects on the regular substrate. Figure 3(b) shows the streamwise position of the bead as a function of time. The bead achieves a constant mean equilibrium velocity in the early stage of its motion right after the shear-rate jump, being barely affected by the inherent rotating motion of the rheometer disk within the considered pathway.

Figure 3. (a) Path line of a glass bead during its displacement along 38 substrate pockets. Flow from left to right. Experiment performed with the less viscous oil. (b) Particle position as a function of time. The dashed line is a linear fit to the data, drawn to guide the eye, and ![]() $a/D_P=0.035$,

$a/D_P=0.035$, ![]() $\theta =0.058$.

$\theta =0.058$.

In order to take a close-up tracking of the bead motion, the zoom on the macro-objective is increased to record the particle displacement along seven substrate pockets. Figure 4(a) shows the path of a glass bead at ![]() $\theta = 2.5 \times \theta _C$. The less viscous oil is used to perform the experiments yielding a particle Reynolds number of about 1. The particle is placed at radius 50 mm from the centre of the disk. The initial position on the substrate is given by orientation angle zero with respect to the symmetry axis of the substrate (position A in the inset). The overall distance is measured with a 1 mm stage micrometer. It corresponds to a pathway of

$\theta = 2.5 \times \theta _C$. The less viscous oil is used to perform the experiments yielding a particle Reynolds number of about 1. The particle is placed at radius 50 mm from the centre of the disk. The initial position on the substrate is given by orientation angle zero with respect to the symmetry axis of the substrate (position A in the inset). The overall distance is measured with a 1 mm stage micrometer. It corresponds to a pathway of ![]() $2.99 \pm 0.05$ mm. We remark that this distance is well below the range beyond which the deviation between the path of the bead along the substrate grooves and the main flow direction becomes noticeable, i.e. beyond about 17 mm. Accordingly, the bead follows a straight line.

$2.99 \pm 0.05$ mm. We remark that this distance is well below the range beyond which the deviation between the path of the bead along the substrate grooves and the main flow direction becomes noticeable, i.e. beyond about 17 mm. Accordingly, the bead follows a straight line.

Figure 4. (a) Path line of a glass bead during its displacement along seven substrate pockets, and (b) particle position as a function of time. Black, red and blue curves represent experiments with the particle placed at the initial positions A, B and C, as indicated in the inset, respectively. The experiments are performed with the less viscous oil at radius 50 mm and at constant Shields number 0.1, corresponding to ![]() $\theta / \theta _C = 2.5$. Here,

$\theta / \theta _C = 2.5$. Here, ![]() $a/D_P=0.035$.

$a/D_P=0.035$.

Figure 4(b) shows the streamwise position of the bead as a function of time for the substrate with narrowest spacing. It compares the evolution of the particle position in the same region for the different initial positions indicated in the inset. The experiments are repeated twice. All results are in good agreement, independent of the initial position within a standard deviation of about ![]() $1.6\,\%$. Hence the experimental results confirm that the bead reaches its equilibrium velocity in the early stage of the motion, in line with previous observations (Agudo & Wierschem Reference Agudo and Wierschem2012). The transient plane Couette flow, where

$1.6\,\%$. Hence the experimental results confirm that the bead reaches its equilibrium velocity in the early stage of the motion, in line with previous observations (Agudo & Wierschem Reference Agudo and Wierschem2012). The transient plane Couette flow, where ![]() $99\,\%$ of the steady velocity profile is reached in about 0.2 s in this case, appears not to be relevant. The periodic velocity fluctuations are due to local variations in the substrate geometry. Averaging over the substrate periodicity, the bead position changes linearly in time. At the low particle Reynolds numbers considered, and consistent with former results (Agudo & Wierschem Reference Agudo and Wierschem2012), the bead does not exhibit any acceleration phase beyond neighbouring substrate positions. In what follows, we always study a travel distance of seven substrate pockets to determine a representative value for the mean particle velocity.

$99\,\%$ of the steady velocity profile is reached in about 0.2 s in this case, appears not to be relevant. The periodic velocity fluctuations are due to local variations in the substrate geometry. Averaging over the substrate periodicity, the bead position changes linearly in time. At the low particle Reynolds numbers considered, and consistent with former results (Agudo & Wierschem Reference Agudo and Wierschem2012), the bead does not exhibit any acceleration phase beyond neighbouring substrate positions. In what follows, we always study a travel distance of seven substrate pockets to determine a representative value for the mean particle velocity.

Figures 5(a,b) show the bead position as a function of time for different pathways at ![]() $\theta /\theta _C = 1.3$ and

$\theta /\theta _C = 1.3$ and ![]() $2.5$, respectively. The inset indicates the three neighbouring pathways on the substrate in which the distance from the turning axis of the rheometer changes by

$2.5$, respectively. The inset indicates the three neighbouring pathways on the substrate in which the distance from the turning axis of the rheometer changes by ![]() $\pm$1 %. First, the critical Shields number is measured for all substrate pockets of the different pathways, showing values that agree within the range of uncertainty with those presented in table 2 (Agudo & Wierschem Reference Agudo and Wierschem2012). Above the threshold, the bead travels along the substrate with a velocity that is modulated due to the substrate topology as in figure 4(b). The modulation amplitude diminishes as the Shields number increases, as is apparent from comparing figures 5(a) and 5(b). At

$\pm$1 %. First, the critical Shields number is measured for all substrate pockets of the different pathways, showing values that agree within the range of uncertainty with those presented in table 2 (Agudo & Wierschem Reference Agudo and Wierschem2012). Above the threshold, the bead travels along the substrate with a velocity that is modulated due to the substrate topology as in figure 4(b). The modulation amplitude diminishes as the Shields number increases, as is apparent from comparing figures 5(a) and 5(b). At ![]() $\theta /\theta _C = 2.5$, all particle trajectories coincide within the standard deviation

$\theta /\theta _C = 2.5$, all particle trajectories coincide within the standard deviation ![]() $2\,\%$. At Shields numbers near the threshold as in figure 5(a), where the bead moves rather slowly and the modulation is pronounced, the bead motion is very susceptible to local substrate variations, resulting in larger deviations in the local velocity. For

$2\,\%$. At Shields numbers near the threshold as in figure 5(a), where the bead moves rather slowly and the modulation is pronounced, the bead motion is very susceptible to local substrate variations, resulting in larger deviations in the local velocity. For ![]() $\theta /\theta _C=1.3$, the experiments were repeated twice. Notwithstanding the local variations, the average particle velocity varies by only about

$\theta /\theta _C=1.3$, the experiments were repeated twice. Notwithstanding the local variations, the average particle velocity varies by only about ![]() $3.5\,\%$.

$3.5\,\%$.

Figure 5. Particle position during its motion along seven substrate pockets on the substrate with narrowest spacing at Shields numbers (a) 0.052 and (b) 0.1, corresponding to ![]() $\theta / \theta _C = 1.3$ and 2.5, respectively. Black, red and blue curves correspond to experimental runs with the bead placed on paths 1, 2 and 3 indicated in the inset, respectively. The experiments are performed using the less viscous oil at radius about 50 mm.

$\theta / \theta _C = 1.3$ and 2.5, respectively. Black, red and blue curves correspond to experimental runs with the bead placed on paths 1, 2 and 3 indicated in the inset, respectively. The experiments are performed using the less viscous oil at radius about 50 mm.

Finally we consider the influence of the substrate on the average streamwise bead velocity. To minimize the impact of curvature of the azimuthal flow in the rheometer, we study the average velocity along a symmetric tangential path of seven substrate particles. Figure 6 shows the average bead velocity in the main flow direction, ![]() $\langle U \rangle$, as a function of the Shields number for the different substrates. The velocity is scaled with the Stokes settling velocity,

$\langle U \rangle$, as a function of the Shields number for the different substrates. The velocity is scaled with the Stokes settling velocity, ![]() $U_S$, which depends on both the submerged weight of the bead and on the viscosity. It is defined as (Charru et al. Reference Charru, Larrieu, Dupont and Zenit2007)

$U_S$, which depends on both the submerged weight of the bead and on the viscosity. It is defined as (Charru et al. Reference Charru, Larrieu, Dupont and Zenit2007)

The figure covers the range of Shields numbers from near critical up to about ![]() $5 \theta _C$. The particle Reynolds number ranges from

$5 \theta _C$. The particle Reynolds number ranges from ![]() $5 \times 10^{-3}$ up to about

$5 \times 10^{-3}$ up to about ![]() $2$. Even at the studied particle Reynolds numbers above

$2$. Even at the studied particle Reynolds numbers above ![]() $1$, inertia and centrifugal forces have only a minor impact, as shown by Agudo & Wierschem (Reference Agudo and Wierschem2012). The experiments were usually repeated three times. The error bars in the diagram indicate the range of uncertainty of the measurements.

$1$, inertia and centrifugal forces have only a minor impact, as shown by Agudo & Wierschem (Reference Agudo and Wierschem2012). The experiments were usually repeated three times. The error bars in the diagram indicate the range of uncertainty of the measurements.

Figure 6. Average bead velocity in the mean flow direction. Triangles, squares, diamonds and circles indicate substrates with triangular arrangement and with quadratic arrangements with spacing ![]() $a/D_P=0.035$, 0.232 and 0.269, respectively. Blue, red and grey symbols depict measurements with beads made from glass, PMMA and steel, respectively. Open and closed symbols correspond to lower and higher viscosities, respectively. The lines are exemplary linear fits to data of different arrangements.

$a/D_P=0.035$, 0.232 and 0.269, respectively. Blue, red and grey symbols depict measurements with beads made from glass, PMMA and steel, respectively. Open and closed symbols correspond to lower and higher viscosities, respectively. The lines are exemplary linear fits to data of different arrangements.

For each material and substrate combination, the data can be fitted by a linear relationship between the dimensionless average streamwise bead velocity and the Shields number (regression coefficient ![]() $R^2>0.99$ for all cases). For each substrate, the data for different viscosities and bead materials group within narrow corridors. As a tendency, it appears that the dimensionless velocities of the steel beads seem to be slightly smaller than the others. This may be due to the somewhat smaller diameter; see table 1. Comparing the data of the different oils, it appears that the beads seem to travel slightly faster at lower viscosity.

$R^2>0.99$ for all cases). For each substrate, the data for different viscosities and bead materials group within narrow corridors. As a tendency, it appears that the dimensionless velocities of the steel beads seem to be slightly smaller than the others. This may be due to the somewhat smaller diameter; see table 1. Comparing the data of the different oils, it appears that the beads seem to travel slightly faster at lower viscosity.

The dimensionless average velocity is related to the critical Shields number that corresponds to the different substrates; see table 2. The critical Shields number quantifies the resistance for the onset of motion, and increases with the maximum stability angle and the shielding from the flow (Agudo & Wierschem Reference Agudo and Wierschem2012; Agudo et al. Reference Agudo, Illigmann, Luzi, Laukart, Delgado and Wierschem2017a; Topic et al. Reference Topic, Retzepoglu, Wensing, Illigmann, Luzi, Agudo and Wierschem2019b). Accordingly, as the bead travels along the substrate, it has to overcome larger local slopes and is less exposed to the flow on substrates with higher critical Shields numbers. This is in line with the observation that the increase of the average velocity is slightly weaker for higher critical Shields numbers. Note that the intercept of the fits is slightly below the critical Shields number.

Assuming a linear dependence on the critical Shields number, the observations on the dependence of the dimensionless average velocity on the Shields number and on the critical Shields number can be described as

where ![]() $A_i$ are fit parameters. Figure 7 shows the resulting master curve for the data set. Here, the parameters

$A_i$ are fit parameters. Figure 7 shows the resulting master curve for the data set. Here, the parameters ![]() $A_i$ have been determined without taking into account the data on the steel beads or the triangular substrate. They result in

$A_i$ have been determined without taking into account the data on the steel beads or the triangular substrate. They result in

Although disregarded for the fit, the data on steel beads and in particular on the triangular substrate obey quite well the master curve in figure 7.

Figure 7. Master curve for the average bead velocity in the mean flow direction. Fit parameters obtained without the data on steel beads and triangular substrate. The symbol assignment is identical to that in figure 6. To guide the eye, the line indicates slope 1.

4. Model

To analyse the particle motion along the substrate, we set up a model for the shear-induced motion in the creeping-flow limit. In the model, a rigid bead is considered to be exposed to a linear shear flow. The contact to the substrate is adhesionless. In the creeping-flow limit, the lift force vanishes and the drag can be decomposed into a shear and translational and rotational contributions. The shear contribution has been modelled previously for the onset of flow-induced particle motion (Agudo et al. Reference Agudo, Illigmann, Luzi, Laukart, Delgado and Wierschem2017a; Topic et al. Reference Topic, Hou, Illigmann, Luzi, Agudo and Wierschem2019a,Reference Topic, Retzepoglu, Wensing, Illigmann, Luzi, Agudo and Wierschemb). Likewise, we disregard deviations in the flow field caused by the presence of the substrate spheres, and model the partial shielding of the bead from the flow by the substrate spheres by an effective zero level; see figure 8(a). The effect of the neighbouring substrate spheres on the translational and rotational bead motion is modelled again by flat walls.

Figure 8. Projection of the geometry near the mobile bead onto the ![]() $xz$ plane. The

$xz$ plane. The ![]() $y$ axis points into the plane. (a) Geometrical and kinematic quantities describing the system. The horizontal dashed line indicates the effective zero level of the shear flow. The two circles above the zero level are the bead in its initial position in the substrate pocket (full circle) and next substrate pocket (dotted circle). The dash-dot line indicates the trajectory of the bead centre moving at velocity

$y$ axis points into the plane. (a) Geometrical and kinematic quantities describing the system. The horizontal dashed line indicates the effective zero level of the shear flow. The two circles above the zero level are the bead in its initial position in the substrate pocket (full circle) and next substrate pocket (dotted circle). The dash-dot line indicates the trajectory of the bead centre moving at velocity ![]() $U_P$;

$U_P$; ![]() $\chi$ is the angle between the bead surface at effective zero level and its vertical axis. (b) Forces acting on the bead. The lever arm of the shear force,

$\chi$ is the angle between the bead surface at effective zero level and its vertical axis. (b) Forces acting on the bead. The lever arm of the shear force, ![]() $L_S$, is shown together with the instantaneous inclination angle,

$L_S$, is shown together with the instantaneous inclination angle, ![]() $\phi _T-\phi$.

$\phi _T-\phi$.

We focus on the quadratic arrangement with different spacings, where the grooves are in line with the main flow direction. Initially, the bead rests in a substrate pocket, where it is in contact with the four substrate spheres that confine the pocket. The contact points are on the line between the bead and sphere centres.

As in experiments (Agudo & Wierschem Reference Agudo and Wierschem2012), we consider the motion of the bead through the substrate grooves. At onset, the bead rolls over the substrate without slip (Agudo et al. Reference Agudo, Dasilva and Wierschem2014). Kudrolli, Scheff & Allen (Reference Kudrolli, Scheff and Allen2016) have shown experimentally and theoretically that rolling stands as the mechanism of motion for well-exposed individual beads even at high particle Reynolds numbers. Hence we will start our considerations with this case. Nevertheless, as the bead rolls along the substrate, the Coulomb friction limit may be exceeded and the bead may slide. While it rolls or slides, the bead remains in contact with the substrate spheres that form the grooves at two contact points. Finally, if the normal force between the moving bead and the substrate becomes zero, then the bead may detach from the substrate. In what follows, we will consider each of these three cases in the creeping-flow limit.

At onset, the bead needs to overcome the maximum stability angle in the pocket of the substrate, ![]() $\phi _T$. As it moves along the substrate to the next pocket, the deviation from this angle,

$\phi _T$. As it moves along the substrate to the next pocket, the deviation from this angle, ![]() $\phi$, increases continuously. The momentary angle,

$\phi$, increases continuously. The momentary angle, ![]() $\phi _T-\phi$, first decreases continuously to zero at the crest and then becomes negative until the bead reaches the neighbouring pocket; see figure 8(a).

$\phi _T-\phi$, first decreases continuously to zero at the crest and then becomes negative until the bead reaches the neighbouring pocket; see figure 8(a).

While the effective weight ![]() $F'_G$, i.e. gravity minus buoyancy, keeps the bead in the substrate pocket, the flow-induced force

$F'_G$, i.e. gravity minus buoyancy, keeps the bead in the substrate pocket, the flow-induced force ![]() $F_M$ can destabilize the position in the substrate pocket beyond the critical Shields number, and moves the bead forward. The mobile bead interacts with the substrate via the contact forces in normal and tangential directions

$F_M$ can destabilize the position in the substrate pocket beyond the critical Shields number, and moves the bead forward. The mobile bead interacts with the substrate via the contact forces in normal and tangential directions ![]() $F_N$ and

$F_N$ and ![]() $F_F$, respectively. Both

$F_F$, respectively. Both ![]() $F_N$ and

$F_N$ and ![]() $F_F$ are the resultants of the forces at the contact points with the substrate. We remark that the out-of-plane component of the normal force contributes to the solid friction and is absorbed by the respectively friction coefficients. Balancing the forces in the radial and tangential directions indicated in figure 8(b) by the vectors

$F_F$ are the resultants of the forces at the contact points with the substrate. We remark that the out-of-plane component of the normal force contributes to the solid friction and is absorbed by the respectively friction coefficients. Balancing the forces in the radial and tangential directions indicated in figure 8(b) by the vectors ![]() $\boldsymbol {r}$ and

$\boldsymbol {r}$ and ![]() $\boldsymbol {t}$, and the torque around the bead centre, the equations of motion for the bead read

$\boldsymbol {t}$, and the torque around the bead centre, the equations of motion for the bead read

with the accelerations ![]() $a_r$ and

$a_r$ and ![]() $a_t$, and the flow-induced force contributions

$a_t$, and the flow-induced force contributions ![]() $F_{Mr}$ and

$F_{Mr}$ and ![]() $F_{Mt}$, in the radial and tangential directions, respectively. The mass of the bead is indicated by

$F_{Mt}$, in the radial and tangential directions, respectively. The mass of the bead is indicated by ![]() $m_P=({\rm \pi} /6)\rho _PD_P^3$. With the fluid density

$m_P=({\rm \pi} /6)\rho _PD_P^3$. With the fluid density ![]() $\rho _F$, the added mass due to fluid acceleration can be expressed by

$\rho _F$, the added mass due to fluid acceleration can be expressed by ![]() $m_a=c_a m_P \rho _F/\rho _P$. For a bead moving in a liquid far away from solid surfaces,

$m_a=c_a m_P \rho _F/\rho _P$. For a bead moving in a liquid far away from solid surfaces, ![]() $c_a=1/2$. The moment of inertia of the bead, the angular bead velocity and the flow-induced torques are

$c_a=1/2$. The moment of inertia of the bead, the angular bead velocity and the flow-induced torques are ![]() $I=({\rm \pi} /60)\rho _PD_P^5$,

$I=({\rm \pi} /60)\rho _PD_P^5$, ![]() $\omega$ and

$\omega$ and ![]() $T_M$, respectively. The lever arm of the solid-friction force

$T_M$, respectively. The lever arm of the solid-friction force ![]() $F_F$ is half the distance between the centres of mobile and substrate beads projected into the

$F_F$ is half the distance between the centres of mobile and substrate beads projected into the ![]() $xz$ plane,

$xz$ plane, ![]() $D_T$; see figure 8(a). This turning radius can be expressed with the maximum stability angle:

$D_T$; see figure 8(a). This turning radius can be expressed with the maximum stability angle:

\begin{equation} \phi_T=\arctan\left(\frac{D_P+a}{\sqrt{4D_P^2-2(D_P+a)^2}}\right),\quad D_T=\sqrt{D_P^2-\left(\frac{D_P+a}{2}\right)^2}. \end{equation}

\begin{equation} \phi_T=\arctan\left(\frac{D_P+a}{\sqrt{4D_P^2-2(D_P+a)^2}}\right),\quad D_T=\sqrt{D_P^2-\left(\frac{D_P+a}{2}\right)^2}. \end{equation}The accelerations and the angular velocity can be expressed as

where ![]() $\beta$ is the rotation angle of the bead. To express the equations of motion (4.1) in dimensionless form, we use the shear rate

$\beta$ is the rotation angle of the bead. To express the equations of motion (4.1) in dimensionless form, we use the shear rate ![]() $\dot \gamma$ as the inverse of the characteristic time scale. Hence

$\dot \gamma$ as the inverse of the characteristic time scale. Hence

Here, as in what follows, the hat identifies a dimensionless quantity. As characteristic scale for the normal force, we take the effective gravity ![]() $F'_G=({{\rm \pi} }/{6})(\rho _P-\rho _F)D_P^3 g$. For the solid-friction force

$F'_G=({{\rm \pi} }/{6})(\rho _P-\rho _F)D_P^3 g$. For the solid-friction force ![]() $F_F$ and the flow-induced force and torque, we employ the viscous scaling:

$F_F$ and the flow-induced force and torque, we employ the viscous scaling:

\begin{equation} \left.\begin{gathered} F_M=\frac{3}{2}{\rm \pi}\mu\dot\gamma D_P^2 \hat{F}_M,\quad T_M=\frac{3}{2}{\rm \pi}\mu\dot\gamma D_P^3 \hat{T}_M,\quad F_F=\frac{3}{2}{\rm \pi}\mu\dot\gamma D_P^2 \hat{F}_F,\\ F_N=\frac{\rm \pi}{6}(\rho_P-\rho_F)D_P^3 g \hat{F}_N. \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} F_M=\frac{3}{2}{\rm \pi}\mu\dot\gamma D_P^2 \hat{F}_M,\quad T_M=\frac{3}{2}{\rm \pi}\mu\dot\gamma D_P^3 \hat{T}_M,\quad F_F=\frac{3}{2}{\rm \pi}\mu\dot\gamma D_P^2 \hat{F}_F,\\ F_N=\frac{\rm \pi}{6}(\rho_P-\rho_F)D_P^3 g \hat{F}_N. \end{gathered}\right\} \end{equation}With these scalings, the equations of motion (4.1) take the form

where we have introduced the particle Reynolds number and the Shields number defined in (2.2a,b) and (2.3), respectively.

As we are interested in the creeping-flow limit, we may set the left-hand sides of (4.6) to zero. For small but finite ![]() ${{Re}}_P$, we may neglect the inertia terms if the Stokes number

${{Re}}_P$, we may neglect the inertia terms if the Stokes number ![]() ${{Re}}_P (\rho _P/\rho _F) \ll 1$, as

${{Re}}_P (\rho _P/\rho _F) \ll 1$, as ![]() $D_T/D_P$ is about

$D_T/D_P$ is about ![]() $1$. It ranges between

$1$. It ranges between ![]() $\sqrt {2} /2$ and

$\sqrt {2} /2$ and ![]() $\sqrt {3} /2$ for quadratic lattices, where the maximum spacing is

$\sqrt {3} /2$ for quadratic lattices, where the maximum spacing is ![]() $a/D_P=\sqrt {2}-1$.

$a/D_P=\sqrt {2}-1$.

The flow-induced force is divided into drag and lift forces. In the creeping-flow limit, the lift force vanishes due to symmetry (Goldman et al. Reference Goldman, Cox and Brenner1967b; Leighton & Acrivos Reference Leighton and Acrivos1985; Hornung Reference Hornung2006). At near creeping-flow conditions, the lift force is proportional to the particle Reynolds numbers and may account for about 7 % of the drag force at ![]() ${\it Re}_P=1$ (Leighton & Acrivos Reference Leighton and Acrivos1985). In the creeping-flow limit, the drag force can be decomposed into three contributions: a force due to the shear flow acting on a fixed bead,

${\it Re}_P=1$ (Leighton & Acrivos Reference Leighton and Acrivos1985). In the creeping-flow limit, the drag force can be decomposed into three contributions: a force due to the shear flow acting on a fixed bead, ![]() $\hat {F}_S$, and forces due to bead translation,

$\hat {F}_S$, and forces due to bead translation, ![]() $\hat {F}_T$, and rotation,

$\hat {F}_T$, and rotation, ![]() $\hat {F}_R$, in a quiescent fluid (Goldman et al. Reference Goldman, Cox and Brenner1967b). In the current model, the force vectors are parallel to the vectors drawn in figure 8(b). The Basset history force is neglected; its validity is discussed in Appendix A. For the flow-induced torque, the decomposition is similar.

$\hat {F}_R$, in a quiescent fluid (Goldman et al. Reference Goldman, Cox and Brenner1967b). In the current model, the force vectors are parallel to the vectors drawn in figure 8(b). The Basset history force is neglected; its validity is discussed in Appendix A. For the flow-induced torque, the decomposition is similar.

The shear flow is imposed in the horizontal direction. As the modulation caused by the presence of the substrate spheres can be neglected in a first approximation (Agudo et al. Reference Agudo, Illigmann, Luzi, Laukart, Delgado and Wierschem2017a; Topic et al. Reference Topic, Hou, Illigmann, Luzi, Agudo and Wierschem2019a,Reference Topic, Retzepoglu, Wensing, Illigmann, Luzi, Agudo and Wierschemb), we consider ![]() $\hat {F}_S$ acting in horizontal direction in the model. Since the force contributions

$\hat {F}_S$ acting in horizontal direction in the model. Since the force contributions ![]() $\hat {F}_T$ and

$\hat {F}_T$ and ![]() $\hat {F}_R$ are due to the bead motion in a quiescent fluid, these forces act in the direction of the local bead motion, hence locally tangential to the substrate when the bead is in contact. With these replacements, the equations of motion (4.6) take the following form in the creeping-flow limit:

$\hat {F}_R$ are due to the bead motion in a quiescent fluid, these forces act in the direction of the local bead motion, hence locally tangential to the substrate when the bead is in contact. With these replacements, the equations of motion (4.6) take the following form in the creeping-flow limit:

where the torque induced by the shear flow on a bead at rest is calculated using the lever arm ![]() $L_S$ with respect to the bead centre. The dependence of the lever arm on the geometrical properties is provided in Appendix B. For further details on the derivations of the terms, we refer to Agudo et al. (Reference Agudo, Illigmann, Luzi, Laukart, Delgado and Wierschem2017a). The normal force

$L_S$ with respect to the bead centre. The dependence of the lever arm on the geometrical properties is provided in Appendix B. For further details on the derivations of the terms, we refer to Agudo et al. (Reference Agudo, Illigmann, Luzi, Laukart, Delgado and Wierschem2017a). The normal force ![]() $\hat {F}_N$ can be determined from (4.7a). The solid-friction force

$\hat {F}_N$ can be determined from (4.7a). The solid-friction force ![]() $\hat {F}_F$ can be eliminated by inserting (4.7c) into (4.7b).

$\hat {F}_F$ can be eliminated by inserting (4.7c) into (4.7b).

To solve the resulting equations, we need to specify now the drag force and torque contributions. According to Goldman et al. (Reference Goldman, Cox and Brenner1967b), the contributions due to bead translation and rotation in a quiescent fluid near a flat wall are

\begin{equation} \left.\begin{gathered} \hat{F}_T=\hat{U}_PF_T^*=\frac{D_T}{D_P}\,\frac{\mathrm{d}\phi}{\mathrm{d}\hat{t}}\,F_T^*, \quad \hat{F}_R=\frac{\mathrm{d}\beta}{\mathrm{d}\hat{t}}\,F_R^*,\\ \hat{T}_T=\hat{U}_PT_T^*=\frac{D_T}{D_P}\,\frac{\mathrm{d}\phi}{\mathrm{d}\hat{t}}\,T_T^*, \quad \hat{T}_R=\frac{\mathrm{d}\beta}{\mathrm{d}\hat{t}}\,T_R^*, \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} \hat{F}_T=\hat{U}_PF_T^*=\frac{D_T}{D_P}\,\frac{\mathrm{d}\phi}{\mathrm{d}\hat{t}}\,F_T^*, \quad \hat{F}_R=\frac{\mathrm{d}\beta}{\mathrm{d}\hat{t}}\,F_R^*,\\ \hat{T}_T=\hat{U}_PT_T^*=\frac{D_T}{D_P}\,\frac{\mathrm{d}\phi}{\mathrm{d}\hat{t}}\,T_T^*, \quad \hat{T}_R=\frac{\mathrm{d}\beta}{\mathrm{d}\hat{t}}\,T_R^*, \end{gathered}\right\} \end{equation}

with the bead velocity ![]() $U_P=D_T \,\mathrm {d}\phi / \mathrm {d}t$. The factors with asterisks depend only on the geometrical properties. We approximate the impact of the substrate on the bead translation and rotation by flat walls in contact with the bead; see figure 9. The flow field during the bead motion is influenced mainly by the presence of the directly neighbouring substrate spheres; i.e. as the bead moves along a groove between two spheres, its motion is also affected by the presence of the next neighbouring pair of spheres. While the contribution of the neighbouring spheres vanishes at

$U_P=D_T \,\mathrm {d}\phi / \mathrm {d}t$. The factors with asterisks depend only on the geometrical properties. We approximate the impact of the substrate on the bead translation and rotation by flat walls in contact with the bead; see figure 9. The flow field during the bead motion is influenced mainly by the presence of the directly neighbouring substrate spheres; i.e. as the bead moves along a groove between two spheres, its motion is also affected by the presence of the next neighbouring pair of spheres. While the contribution of the neighbouring spheres vanishes at ![]() $\phi = \phi _T$, it is as large as the one of the substrate spheres if the bead is in the substrate pocket at

$\phi = \phi _T$, it is as large as the one of the substrate spheres if the bead is in the substrate pocket at ![]() $\phi _T = {\rm \pi}/ 2$; see figures 9(a) and 9(b). Accordingly, we model the impact of the neighbouring spheres at smaller

$\phi _T = {\rm \pi}/ 2$; see figures 9(a) and 9(b). Accordingly, we model the impact of the neighbouring spheres at smaller ![]() $\phi _T$ by inclined walls (see figures 9c,d), hence with a contribution proportional to the inclination angle, i.e.

$\phi _T$ by inclined walls (see figures 9c,d), hence with a contribution proportional to the inclination angle, i.e. ![]() ${\phi _T}/({{\rm \pi} /2})$. The same holds for the local angle

${\phi _T}/({{\rm \pi} /2})$. The same holds for the local angle ![]() $\phi _T-\phi$ during the motion of the bead along the substrate. To take into account the major effect of the neighbouring sphere, we may symmetrize the impact disregarding minor variations in the angle. This results in the weighing factor for the local wall effects on the translational and rotational contributions:

$\phi _T-\phi$ during the motion of the bead along the substrate. To take into account the major effect of the neighbouring sphere, we may symmetrize the impact disregarding minor variations in the angle. This results in the weighing factor for the local wall effects on the translational and rotational contributions:

Hence, with this weighing term and using Goldman's results for a bead at a plane (Goldman et al. Reference Goldman, Cox and Brenner1967b), we arrive at the coefficients in the current scaling:

\begin{equation} \left.\begin{gathered} F_T^*={-}\frac{32}{7}\left( 1+\frac{\left| \phi_T-\phi \right|}{{\rm \pi} /2} \right), \quad F_R^*=\frac{1}{8}\left( 1+\frac{\left| \phi_T-\phi \right|}{{\rm \pi} /2} \right), \\ T_T^*=\frac{1}{8}\left( 1+\frac{\left| \phi_T-\phi \right|}{{\rm \pi} /2} \right),\quad T_R^*={-}\frac{7}{8}\left( 1+\frac{\left| \phi_T-\phi \right|}{{\rm \pi} /2} \right). \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} F_T^*={-}\frac{32}{7}\left( 1+\frac{\left| \phi_T-\phi \right|}{{\rm \pi} /2} \right), \quad F_R^*=\frac{1}{8}\left( 1+\frac{\left| \phi_T-\phi \right|}{{\rm \pi} /2} \right), \\ T_T^*=\frac{1}{8}\left( 1+\frac{\left| \phi_T-\phi \right|}{{\rm \pi} /2} \right),\quad T_R^*={-}\frac{7}{8}\left( 1+\frac{\left| \phi_T-\phi \right|}{{\rm \pi} /2} \right). \end{gathered}\right\} \end{equation}Here, we disregard the logarithmic divergence in their expressions that are due to the motion in a thin lubrication film between particle and wall. This is because no significant impact of a lubrication film has been observed in experiment for a bead moving along a flat plane. Its lack has been attributed to e.g. surface roughness (Smart, Beimfohr & Leighton Reference Smart, Beimfohr and Leighton1993), small air bubbles (Yang et al. Reference Yang, Seddon, Mullin, del Pino and Ashmore2006) and cavitation (Goldman, Cox & Brenner Reference Goldman, Cox and Brenner1967a; Ashmore, del Pino & Mullin Reference Ashmore, del Pino and Mullin2005).

Figure 9. Modelling the impact of neighbouring substrate spheres on the force and torque contributions due to bead translation and rotation in a quiescent fluid. (a) Mobile bead deeply buried into the substrate. (b) Modelling the impact of the neighbouring substrate spheres on the bead motion of case (a). (c) Mobile bead travelling along the substrate. (d) Modelling the impact of the neighbouring substrate spheres on the travelling bead of case (c).

For ![]() $\hat {F}_S$ and its lever arm, we apply the model by Agudo et al. (Reference Agudo, Illigmann, Luzi, Laukart, Delgado and Wierschem2017a) replacing the maximum stability angle

$\hat {F}_S$ and its lever arm, we apply the model by Agudo et al. (Reference Agudo, Illigmann, Luzi, Laukart, Delgado and Wierschem2017a) replacing the maximum stability angle ![]() $\phi _T$ by the momentary inclination angle

$\phi _T$ by the momentary inclination angle ![]() $\phi _T-\phi$. Agudo et al. (Reference Agudo, Illigmann, Luzi, Laukart, Delgado and Wierschem2017a) adapted the analytical solution by Goldman et al. (Reference Goldman, Cox and Brenner1967b) for the shear force on a spherical particle near a plane. In the present scaling, it reads

$\phi _T-\phi$. Agudo et al. (Reference Agudo, Illigmann, Luzi, Laukart, Delgado and Wierschem2017a) adapted the analytical solution by Goldman et al. (Reference Goldman, Cox and Brenner1967b) for the shear force on a spherical particle near a plane. In the present scaling, it reads

where ![]() $f$ is approximately 1.7 due to the presence of a flat wall. The factor

$f$ is approximately 1.7 due to the presence of a flat wall. The factor ![]() $b(\phi )$ takes into account the shielding of the bead from the flow. Its relation to the geometrical properties is provided in Appendix B. See Agudo et al. (Reference Agudo, Illigmann, Luzi, Laukart, Delgado and Wierschem2017a) for further details on the derivation of the terms.

$b(\phi )$ takes into account the shielding of the bead from the flow. Its relation to the geometrical properties is provided in Appendix B. See Agudo et al. (Reference Agudo, Illigmann, Luzi, Laukart, Delgado and Wierschem2017a) for further details on the derivation of the terms.

Inserting the forces and torques (4.8) and (4.11) into (4.7) yields

4.1. Rolling motion

For a bead rolling along the substrate, the following kinematic relation holds:

Eliminating ![]() $\hat {F}_F$ by inserting (4.12c) into (4.12b) results in

$\hat {F}_F$ by inserting (4.12c) into (4.12b) results in

\begin{equation} \frac{\mathrm{d}\phi}{\mathrm{d}\hat{t}} ={-}\frac{fb \left(2\,\dfrac{L_S}{D_T} + \cos(\phi_T-\phi) \right)-\dfrac{1}{9 \theta} \sin(\phi_T-\phi)}{F_T^*\, \dfrac{D_T}{D_P}+2F_R^*+2 T_T^*+ 4T_R^*\,\dfrac{D_P}{D_T}}. \end{equation}

\begin{equation} \frac{\mathrm{d}\phi}{\mathrm{d}\hat{t}} ={-}\frac{fb \left(2\,\dfrac{L_S}{D_T} + \cos(\phi_T-\phi) \right)-\dfrac{1}{9 \theta} \sin(\phi_T-\phi)}{F_T^*\, \dfrac{D_T}{D_P}+2F_R^*+2 T_T^*+ 4T_R^*\,\dfrac{D_P}{D_T}}. \end{equation}Inserting the coefficients (4.10), we obtain from (4.14) that

\begin{equation} \frac{\mathrm{d}\phi}{\mathrm{d}\hat{t}} = \frac{fb \left(2\,\dfrac{L_S}{D_T} + \cos(\phi_T-\phi) \right)-\dfrac{1}{9 \theta} \sin(\phi_T-\phi)}{\left( 1+\dfrac{\left| \phi_T-\phi \right|}{{\rm \pi} /2} \right) \left(\dfrac{32}{7}\,\dfrac{D_T}{D_P}+\dfrac{7}{2}\,\dfrac{D_P}{D_T}-\dfrac{1}{2} \right)}. \end{equation}

\begin{equation} \frac{\mathrm{d}\phi}{\mathrm{d}\hat{t}} = \frac{fb \left(2\,\dfrac{L_S}{D_T} + \cos(\phi_T-\phi) \right)-\dfrac{1}{9 \theta} \sin(\phi_T-\phi)}{\left( 1+\dfrac{\left| \phi_T-\phi \right|}{{\rm \pi} /2} \right) \left(\dfrac{32}{7}\,\dfrac{D_T}{D_P}+\dfrac{7}{2}\,\dfrac{D_P}{D_T}-\dfrac{1}{2} \right)}. \end{equation} We remark that the height of the bead centre over the contact points with the substrate is ![]() $(D_T/2)\cos (\phi _T-\phi )$; see figure 8(a). Together with

$(D_T/2)\cos (\phi _T-\phi )$; see figure 8(a). Together with ![]() $L_S$, this height results into the lever arm of the shear force with respect to the contact points with the substrate,

$L_S$, this height results into the lever arm of the shear force with respect to the contact points with the substrate, ![]() $L_{SC}$, and the equation can be rewritten in the form

$L_{SC}$, and the equation can be rewritten in the form

where ![]() $C(\phi )$ abbreviates the denominator in (4.15), which is due to the contribution of translation and rotation of the bead in a quiescent fluid. Now,

$C(\phi )$ abbreviates the denominator in (4.15), which is due to the contribution of translation and rotation of the bead in a quiescent fluid. Now, ![]() $\mathrm {d}\phi / \mathrm {d}\hat {t}$ may be expressed by the critical Shields number

$\mathrm {d}\phi / \mathrm {d}\hat {t}$ may be expressed by the critical Shields number ![]() $\theta _C = D_T \sin \phi _T /(18fb(\phi _T)\,L_{SC}(\phi _T))$, which results from (4.16) for zero angular velocity at

$\theta _C = D_T \sin \phi _T /(18fb(\phi _T)\,L_{SC}(\phi _T))$, which results from (4.16) for zero angular velocity at ![]() $\phi = 0$. We note that this results in the same critical Shields number as given by Agudo et al. (Reference Agudo, Illigmann, Luzi, Laukart, Delgado and Wierschem2017a). Then (4.16) takes the form

$\phi = 0$. We note that this results in the same critical Shields number as given by Agudo et al. (Reference Agudo, Illigmann, Luzi, Laukart, Delgado and Wierschem2017a). Then (4.16) takes the form

At Shields numbers several times the critical one, ![]() $\mathrm {d}\phi /\mathrm {d}\hat {t}$ is around

$\mathrm {d}\phi /\mathrm {d}\hat {t}$ is around ![]() $1/5$, i.e. the bead velocity approaches up to about

$1/5$, i.e. the bead velocity approaches up to about ![]() $20\,\%$ of the characteristic shear velocity. As the Shields number approaches the critical one, it decreases to zero at

$20\,\%$ of the characteristic shear velocity. As the Shields number approaches the critical one, it decreases to zero at ![]() $\phi =\phi _T$.

$\phi =\phi _T$.

We may use any of the forms (4.15)–(4.17) to determine the average bead velocity along the substrate in the streamwise direction ![]() $\langle U \rangle$. In dimensional form, it reads

$\langle U \rangle$. In dimensional form, it reads

where ![]() $\tau$ is the time interval for travelling between neighbouring substrate pockets. With (4.17), it reads

$\tau$ is the time interval for travelling between neighbouring substrate pockets. With (4.17), it reads

\begin{equation} \hat{\tau}=\frac{9\theta}{\sin \phi_T} \int_0^{2\phi_T} \frac{C(\phi)\,\mathrm{d}\phi}{\dfrac{b(\phi_T-\phi)}{b(\phi_T)}\, \dfrac{L_{SC}(\phi_T-\phi)}{L_{SC}(\phi_T)}\,\dfrac{\theta}{\theta_C}-\dfrac{\sin(\phi_T-\phi)}{\sin \phi_T}}. \end{equation}

\begin{equation} \hat{\tau}=\frac{9\theta}{\sin \phi_T} \int_0^{2\phi_T} \frac{C(\phi)\,\mathrm{d}\phi}{\dfrac{b(\phi_T-\phi)}{b(\phi_T)}\, \dfrac{L_{SC}(\phi_T-\phi)}{L_{SC}(\phi_T)}\,\dfrac{\theta}{\theta_C}-\dfrac{\sin(\phi_T-\phi)}{\sin \phi_T}}. \end{equation}

Thus the average bead velocity for pure rolling motion scaled by the Stokes settling velocity ![]() $U_S$ is given by

$U_S$ is given by

\begin{equation} \frac{\langle U \rangle}{U_S} = 4\,\frac{D_T}{D_P}\, \frac{\sin^2{\phi_T}}{\displaystyle\int_0^{2\phi_T}\dfrac{C(\phi)\,\mathrm{d}\phi}{\dfrac{b(\phi_T-\phi)}{b(\phi_T)}\, \dfrac{L_{SC}(\phi_T-\phi)}{L_{SC}(\phi_T)}\,\dfrac{\theta}{\theta_C}-\dfrac{\sin(\phi_T-\phi)}{\sin \phi_T}}}, \end{equation}

\begin{equation} \frac{\langle U \rangle}{U_S} = 4\,\frac{D_T}{D_P}\, \frac{\sin^2{\phi_T}}{\displaystyle\int_0^{2\phi_T}\dfrac{C(\phi)\,\mathrm{d}\phi}{\dfrac{b(\phi_T-\phi)}{b(\phi_T)}\, \dfrac{L_{SC}(\phi_T-\phi)}{L_{SC}(\phi_T)}\,\dfrac{\theta}{\theta_C}-\dfrac{\sin(\phi_T-\phi)}{\sin \phi_T}}}, \end{equation}

where we used the scaling ![]() $\hat {\tau }=\dot \gamma \tau$ and that

$\hat {\tau }=\dot \gamma \tau$ and that ![]() $U_S=D_P \dot \gamma /(18 \theta )$. Since the bead is less exposed in the substrate valley, and the lever arm for the drag force is shortest there, each ratio of the first term in the denominator of the integral is larger than 1, while the second term, i.e. the ratio of the sine terms due to the effective weight, is always smaller than 1 if the bead is not in the substrate pocket. The exposure and lever arm are even functions of

$U_S=D_P \dot \gamma /(18 \theta )$. Since the bead is less exposed in the substrate valley, and the lever arm for the drag force is shortest there, each ratio of the first term in the denominator of the integral is larger than 1, while the second term, i.e. the ratio of the sine terms due to the effective weight, is always smaller than 1 if the bead is not in the substrate pocket. The exposure and lever arm are even functions of ![]() $\phi _T - \phi$, i.e. the denominator is the difference between an even and an odd function, reflecting the situation that the bead travels initially slowly uphill against gravity, and downhill in the later stage.

$\phi _T - \phi$, i.e. the denominator is the difference between an even and an odd function, reflecting the situation that the bead travels initially slowly uphill against gravity, and downhill in the later stage.

The integration in (4.20) is carried out numerically with the fourth-order Runge–Kutta method. Figure 10 shows the average velocity of purely rolling beads for substrate spacings ranging from the minimum to close to the maximum. With increasing substrate spacing, and thus with the maximum stability angle and the shielding from the flow, the average bead velocity declines monotonically. This holds also for its slope at higher Shields numbers. Close to the critical Shields number, the average velocities alter strongly. This is due to the changes of the low uphill velocities. This upsurge very close to the critical Shields numbers increases with substrate spacing.

Figure 10. Average velocity of purely rolling beads for different spacings ![]() $a/D_P$ as a function of the Shields number according to (4.20). The respective values for

$a/D_P$ as a function of the Shields number according to (4.20). The respective values for ![]() $a/D_P$ are printed at the ends of the curves. The thick curve indicates the onset of detachment.

$a/D_P$ are printed at the ends of the curves. The thick curve indicates the onset of detachment.

4.2. Sliding motion

The bead starts sliding if ![]() $|F_F|>\eta _S F_N$, where

$|F_F|>\eta _S F_N$, where ![]() $\eta _S$ is the static solid-friction coefficient (divided by

$\eta _S$ is the static solid-friction coefficient (divided by ![]() $D_T/D_P$ due to the contribution of the normal force out-of-plane component to the solid friction). The development of the ratio of the two forces along the substrate is depicted exemplarily for different Shields numbers and substrate spacings in figure 11. Generally,

$D_T/D_P$ due to the contribution of the normal force out-of-plane component to the solid friction). The development of the ratio of the two forces along the substrate is depicted exemplarily for different Shields numbers and substrate spacings in figure 11. Generally, ![]() $F_F / F_N$ is maximum in the pocket and decreases continuously during its motion along the substrate. Already on the uphill side, it becomes negative. At larger substrate spacings, it tends to infinity as the normal force becomes zero and the bead detaches from the substrate. In the pocket on the uphill side,

$F_F / F_N$ is maximum in the pocket and decreases continuously during its motion along the substrate. Already on the uphill side, it becomes negative. At larger substrate spacings, it tends to infinity as the normal force becomes zero and the bead detaches from the substrate. In the pocket on the uphill side, ![]() $F_F / F_N$ also increases with spacing, as indicated by figure 11. As the Shields number increases,

$F_F / F_N$ also increases with spacing, as indicated by figure 11. As the Shields number increases, ![]() $F_F / F_N$ decreases. Hence at sufficiently small solid-friction coefficient, the bead starts sliding on the downhill side. At smaller

$F_F / F_N$ decreases. Hence at sufficiently small solid-friction coefficient, the bead starts sliding on the downhill side. At smaller ![]() $\eta _S$ or with increasing Shields number, the transition to sliding moves upstream. Furthermore, at low

$\eta _S$ or with increasing Shields number, the transition to sliding moves upstream. Furthermore, at low ![]() $\eta _S$, the bead slides in the pocket. Since the critical Shields number is larger for sliding than for rolling (Agudo et al. Reference Agudo, Illigmann, Luzi, Laukart, Delgado and Wierschem2017a), it may rotate in place at Shields numbers slightly above the threshold, as had been considered by Dey (Reference Dey1999) for turbulent flow conditions.

$\eta _S$, the bead slides in the pocket. Since the critical Shields number is larger for sliding than for rolling (Agudo et al. Reference Agudo, Illigmann, Luzi, Laukart, Delgado and Wierschem2017a), it may rotate in place at Shields numbers slightly above the threshold, as had been considered by Dey (Reference Dey1999) for turbulent flow conditions.

Figure 11. Ratio of tangential force to normal force along the substrate for two Shields number ratios ![]() $\theta / \theta _C$, and three different substrate spacings. The vertical dashed lines indicate the positions where

$\theta / \theta _C$, and three different substrate spacings. The vertical dashed lines indicate the positions where ![]() $F_N$ becomes zero.

$F_N$ becomes zero.

In dimensionless form, the condition for the solid-friction force during sliding reads

where we applied the scaling (4.5a–d) and ![]() $\eta _K$ is the kinematic solid-friction coefficient (along the lines of

$\eta _K$ is the kinematic solid-friction coefficient (along the lines of ![]() $\eta _S$ divided by

$\eta _S$ divided by ![]() $D_T/D_P$ due to the out-of-plane contribution). The kinematic relation (4.13) no longer holds, and

$D_T/D_P$ due to the out-of-plane contribution). The kinematic relation (4.13) no longer holds, and ![]() $\phi$ and

$\phi$ and ![]() $\beta$ are now independent. Solving the set of (4.12) and (4.21) for

$\beta$ are now independent. Solving the set of (4.12) and (4.21) for ![]() $\mathrm {d}\phi /\mathrm {d}\hat {t}$ results in

$\mathrm {d}\phi /\mathrm {d}\hat {t}$ results in

\begin{align} & \left(F_T^*-\frac{F_R^* T_T^*}{T_R^*} \right) \frac{D_T}{D_P}\, \frac{\mathrm{d}\phi}{\mathrm{d}\hat{t}} \nonumber\\ &\quad = fb\left( \frac{F_R^*}{T_R^*}\,\frac{L_S}{D_P} -\cos(\phi_T-\phi) -s\eta_K \left(\frac{1}{2}\,\frac{F_R^*}{T_R^*}\,\frac{D_T}{D_P} +1 \right) \sin(\phi_T-\phi)\right) \nonumber\\ &\qquad +\frac{1}{9 \theta} \left(\sin(\phi_T-\phi) -s\eta_K \left(\frac{1}{2}\,\frac{F_R^*}{T_R^*}\,\frac{D_T}{D_P} +1 \right) \cos(\phi_T-\phi)\right), \end{align}

\begin{align} & \left(F_T^*-\frac{F_R^* T_T^*}{T_R^*} \right) \frac{D_T}{D_P}\, \frac{\mathrm{d}\phi}{\mathrm{d}\hat{t}} \nonumber\\ &\quad = fb\left( \frac{F_R^*}{T_R^*}\,\frac{L_S}{D_P} -\cos(\phi_T-\phi) -s\eta_K \left(\frac{1}{2}\,\frac{F_R^*}{T_R^*}\,\frac{D_T}{D_P} +1 \right) \sin(\phi_T-\phi)\right) \nonumber\\ &\qquad +\frac{1}{9 \theta} \left(\sin(\phi_T-\phi) -s\eta_K \left(\frac{1}{2}\,\frac{F_R^*}{T_R^*}\,\frac{D_T}{D_P} +1 \right) \cos(\phi_T-\phi)\right), \end{align}

and for ![]() $\mathrm {d}\beta /\mathrm {d}\hat {t}$ gives

$\mathrm {d}\beta /\mathrm {d}\hat {t}$ gives

\begin{align} & \left(F_R^*-\frac{F_T^* T_R^*}{T_T^*} \right) \frac{\mathrm{d}\beta}{\mathrm{d}\hat{t}} \nonumber\\ &\quad = fb\left( \frac{F_T^*}{T_T^*}\,\frac{L_S}{D_P} -\cos(\phi_T-\phi) -s\eta_K \left(\frac{1}{2}\,\frac{F_T^*}{T_T^*}\,\frac{D_T}{D_P} +1 \right) \sin(\phi_T-\phi)\right) \nonumber\\ &\qquad +\frac{1}{9 \theta} \left(\sin(\phi_T-\phi) -s\eta_K \left(\frac{1}{2}\,\frac{F_T^*}{T_T^*}\,\frac{D_T}{D_P} +1 \right) \cos(\phi_T-\phi) \right), \end{align}

\begin{align} & \left(F_R^*-\frac{F_T^* T_R^*}{T_T^*} \right) \frac{\mathrm{d}\beta}{\mathrm{d}\hat{t}} \nonumber\\ &\quad = fb\left( \frac{F_T^*}{T_T^*}\,\frac{L_S}{D_P} -\cos(\phi_T-\phi) -s\eta_K \left(\frac{1}{2}\,\frac{F_T^*}{T_T^*}\,\frac{D_T}{D_P} +1 \right) \sin(\phi_T-\phi)\right) \nonumber\\ &\qquad +\frac{1}{9 \theta} \left(\sin(\phi_T-\phi) -s\eta_K \left(\frac{1}{2}\,\frac{F_T^*}{T_T^*}\,\frac{D_T}{D_P} +1 \right) \cos(\phi_T-\phi) \right), \end{align}

where ![]() $s=\pm 1$ determines the direction of the solid-friction force. Inserting the coefficients (4.10), this equation can be solved from the point at which sliding occurs.

$s=\pm 1$ determines the direction of the solid-friction force. Inserting the coefficients (4.10), this equation can be solved from the point at which sliding occurs.

4.3. Contactless motion

Detachment occurs if ![]() $F_N=0$. As appears from (4.7a), this is the case during the downhill motion where the contribution of the shear force becomes negative, i.e. where

$F_N=0$. As appears from (4.7a), this is the case during the downhill motion where the contribution of the shear force becomes negative, i.e. where

Hence the bead detaches if ![]() $\theta > \cot (\phi _T)/(9fb(\phi _T))$, which depends on geometrical parameters only. As the Shields number increases further, the point of detachment moves uphill, as can also be seen in figure 11.

$\theta > \cot (\phi _T)/(9fb(\phi _T))$, which depends on geometrical parameters only. As the Shields number increases further, the point of detachment moves uphill, as can also be seen in figure 11.

After detachment, the bead flies through the fluid until it collides with the next substrate spheres. The collision is considered purely dissipative as bouncing back is not relevant in the inertialess case considered. In Cartesian coordinates and our scaling in the creeping-flow limit, the equations of motion for these flights read

where ![]() $\alpha$ is the angle between the particle path and the

$\alpha$ is the angle between the particle path and the ![]() $x$ axis. From (4.25a) and (4.25b), we arrive at

$x$ axis. From (4.25a) and (4.25b), we arrive at

corresponding to the detachment condition (4.24). The angular velocity ![]() $\mathrm {d}\beta / \mathrm {d}\hat {t}$ and the velocity can be determined from (4.25c) together with one of the other two equations in (4.25). The velocity reads

$\mathrm {d}\beta / \mathrm {d}\hat {t}$ and the velocity can be determined from (4.25c) together with one of the other two equations in (4.25). The velocity reads

\begin{equation} \hat{U}_P=fb\,\frac{\dfrac{F_R^*}{T_R^*}\,\dfrac{L_S}{D_P} \cos \alpha - 1}{\left( F_T^* - \dfrac{F_R^* T_T^*}{T_R^*} \right) \cos \alpha}, \end{equation}

\begin{equation} \hat{U}_P=fb\,\frac{\dfrac{F_R^*}{T_R^*}\,\dfrac{L_S}{D_P} \cos \alpha - 1}{\left( F_T^* - \dfrac{F_R^* T_T^*}{T_R^*} \right) \cos \alpha}, \end{equation}

and for ![]() $\mathrm {d}\beta / \mathrm {d}\hat {t}$ we have

$\mathrm {d}\beta / \mathrm {d}\hat {t}$ we have

\begin{equation} \frac{\mathrm{d}\beta}{\mathrm{d}\hat{t}}=fb\,\frac{\dfrac{F_T^*}{T_T^*}\, \dfrac{L_S}{D_P} \cos \alpha - 1}{\left( F_R^* - \dfrac{F_T^* T_R^*}{T_T^*} \right) \cos \alpha}. \end{equation}

\begin{equation} \frac{\mathrm{d}\beta}{\mathrm{d}\hat{t}}=fb\,\frac{\dfrac{F_T^*}{T_T^*}\, \dfrac{L_S}{D_P} \cos \alpha - 1}{\left( F_R^* - \dfrac{F_T^* T_R^*}{T_T^*} \right) \cos \alpha}. \end{equation}In view of the proximity of the mobile bead to the substrate and because the bead is never completely above the effective zero level, we may use the same coefficients as in (4.10).

The impact of the different types of motion on the angular velocity along the substrate is depicted exemplarily for different spacings and Shields number ratios ![]() $\theta / \theta _C$ in figure 12, which shows the motion from rest. Sliding usually occurs on the downhill side and in the upper part of the path, where the bead is most exposed to the flow. The lower the friction coefficient, the earlier sliding sets in. This is in line with figure 11. As is also apparent from figure 12, sliding generally enhances the particle velocity along the substrate. The different sliding curves meet at the detachment angle due to zero normal force. During the contactless motion,

$\theta / \theta _C$ in figure 12, which shows the motion from rest. Sliding usually occurs on the downhill side and in the upper part of the path, where the bead is most exposed to the flow. The lower the friction coefficient, the earlier sliding sets in. This is in line with figure 11. As is also apparent from figure 12, sliding generally enhances the particle velocity along the substrate. The different sliding curves meet at the detachment angle due to zero normal force. During the contactless motion, ![]() $\mathrm {d}\phi / \mathrm {d}\hat {t}$ declines, which, apart from the increasing distance from the substrate particle, is due mainly to the downward motion of the bead, which results in increased drag and shielding. The curves end before reaching the condition

$\mathrm {d}\phi / \mathrm {d}\hat {t}$ declines, which, apart from the increasing distance from the substrate particle, is due mainly to the downward motion of the bead, which results in increased drag and shielding. The curves end before reaching the condition ![]() $\phi = 2\phi _T$ when the bead touches the neighbouring substrate sphere, from which the bead moves along the substrate according to the local phase angle

$\phi = 2\phi _T$ when the bead touches the neighbouring substrate sphere, from which the bead moves along the substrate according to the local phase angle ![]() $\phi$.

$\phi$.

Figure 12. Angular velocity ![]() $\mathrm {d}\phi / \mathrm {d}\hat {t}$ as a function of the local position

$\mathrm {d}\phi / \mathrm {d}\hat {t}$ as a function of the local position ![]() $\phi$ for

$\phi$ for ![]() $\eta _K=\eta _S$ along the substrate sphere for different spacings

$\eta _K=\eta _S$ along the substrate sphere for different spacings ![]() $a/D_P$ and Shields number ratios

$a/D_P$ and Shields number ratios ![]() $\theta /\theta _C$. Black solid, green dashed and blue dotted lines indicate rolling, sliding and detached motion, respectively. The different sliding curves refer to friction coefficients

$\theta /\theta _C$. Black solid, green dashed and blue dotted lines indicate rolling, sliding and detached motion, respectively. The different sliding curves refer to friction coefficients ![]() $\eta _K$ of 0.1 (dash-dot-dot), 0.5 (dash-dot) and 1 (simply dashed).