INTRODUCTION AND THE SITE

Bottisham lies in south-east Cambridgeshire in the East Anglian Chalk region. The surrounding topography is generally flat with a slight fall in ground to the north and west towards the Fens and a rise in elevation to the east towards Newmarket. The River Cam runs 5 km north-west of the site.

Excavations at the site of Crystal Park (fig. 1) in 2016 revealed a series of early third- to early fourth-century enclosures and three buildings with stone and brick foundations, one of which was a possible bath-house.Footnote 1 This suggests that the site at Bottisham was part of a villa or villa estate. The full archive report of the excavation, including all specialist reports, is available via the Archaeological Data Service (ADS) Library.Footnote 2

FIG. 1. Site location. (© Pre-Construct Archaeology Ltd)

Although the Cambridgeshire Fen Edge, of which Bottisham is a part, has seen intensive levels of excavation, with large numbers of Roman rural settlements recorded, there are still gaps on the map.Footnote 3 The Cambridge Historic Environment Record (CHER) lists ten sites as possible ‘villas’ in a 10 km radius around Bottisham, the majority of which are identified through surface scatters of building materials, cropmarks and metal-detecting finds. Examples include the villa complex at Swaffham Balbeck c. 2 km to the north of Bottisham (CHER 11545), described as a ‘large building with much roofing tile, concrete and opus signinum’, and Great Wilbraham (CHER 06279), c. 4 km to the south, which has a cobbled floor associated with a rich finds assemblage. Excavated examples are the Roman villa at Hinton Fields (CHER 05099) where buildings with rubble walls and associated tesserae were found, and a courtyard villa with Roman wall plaster excavated in 1892 north of Reach Bridge (CHER 06809). Parts of a late Roman large rectangular aisled building with stone foundations, suggesting a settlement of some significance, were recently excavated at Upware, c. 9 km north of Bottisham.Footnote 4

While Bottisham is a rural site that has seen excavation over several years and comprises many elements of a villa complex or rural farmstead, this article focuses on three buildings found at the site and their building materials, as these provide a unique insight into their construction, chronology, form and function and the sourcing, use and reuse of building materials on the Roman fen edge. It is also the first time that building materials in this part of Cambridgeshire have been extensively classified.

SITE SUMMARY

The excavation was the latest in a series of investigations that took place prior to development off Tunbridge Lane in the north-eastern part of Bottisham.Footnote 5 Tunbridge Lane is used here as a convenient geographical marker, but it is likely that it already existed as a routeway in the Roman period.Footnote 6 All investigations revealed parts of the same high-status Roman settlement, either a wealthy farmstead or part of a villa estate.

Villas in the east of England tend to develop from existing farmsteads with a peak of occupation in the later third centuryFootnote 7 and the settlement at Bottisham seems to conform to this type. An early phase of the settlement, dating to c. a.d. 70–270, was located north of Tunbridge Lane and is represented by pits, ditches and post-holes.Footnote 8 The focus of activity shifted southwards in the mid- to late Roman period. Excavations south of Tunbridge Lane in 2014 revealed the northern part of the later third- to early fourth-century settlement,Footnote 9 while the investigations at Crystal Park revealed its southern extent. The sites need to be seen in context with each other.

On both sites a system of enclosures, dating to the late second/early third century, was replaced by larger enclosures. At Crystal Park these included three buildings (Buildings 1, 2 and 3), dated to the third century, set around a possible courtyard (fig. 2). Building 1 was a double-apsidal building and possible bath-house, Building 2 a simpler two-roomed structure with a clay tile roof and Building 3 a complex structure with at least three rooms and walls lined with box-flue tiles. Both the bath-house Building 1 and box-flue heating system of Building 3 show limited signs of use.

FIG. 2. Crystal Park, Bottisham, and adjacent sites. All features plans. (© Pre-Construct Archaeology Ltd)

Analysis of the building materials suggests that there were at least two phases of building, demolition and rebuilding on the site, with Buildings 1 and 3 built first with changes in their building fabric over time and Building 2 built at a later stage. This sequence is based on the comparison of use and reuse of building materials within each building (see separate building descriptions below).

There was little evidence to indicate the kind of activity that was going on inside the enclosures. The enclosure ditches and internal pits contained a sparse, mixed finds assemblage and modern truncation had made environmental sampling difficult. Two hearths were located on the site, one third-century keyhole-shaped oven [739] close to Building 1, with no signs of firing, and one late third- to early fourth-century L-shaped oven [641] which may have been a corn-drying kiln.

This is in contrast to the third-century a.d. enclosures identified on the Tunbridge Hall site to the north, which were closely associated with large hearths for the processing of produce and food, the malting of grain and the drying of corn. The site also yielded evidence for metalled surfaces and three buildings with stone footings or of a post and beam-slot type construction (S2901, S4348 and S5500), possibly used for industrial purposes and the storage of agricultural produce. It is therefore possible that any large-scale, possibly noisy and smelly, industrial and agricultural activity was located away from the main buildings.Footnote 10

The buildings fell into disrepair and either collapsed, or were demolished and extensively robbed, in the late third and early fourth century, while the system of enclosures adjacent to them in the west was re-defined and continued in use. A large amount of building material from the buildings was dumped into adjacent features, most notably the well [678], Ditch 18, particularly its ditch terminus [418], and associated pit [416].

There is some evidence, in the demolition debris of the buildings, for possible occupation nearby into the fourth century, in the form of fourth-century coins and a small mid-fourth- to early fifth-century glass vessel.

METHODOLOGY: RECORDING, SAMPLING AND ANALYSIS

The retention of the entire building material assemblage from the excavation at Bottisham provided a unique chance to examine the fabrics and forms of the mortar, brick, tile and stone at a level of detail not previously possible at a Roman rural site in Cambridgeshire. It was hoped that a detailed review of its distribution would establish what the buildings were used for and whether their function changed over time.

The entire roofing tile, brick and box-flue tile assemblage was catalogued and quantified in-house by number of fragments and weight. The stonework underwent detailed hand specimen geological comparative analysis to establish stone types and where the material types were being quarried and supplied from.

The application of a 1 kg mason's hammer and sharp chisel to each example ensured that a small fresh fabric surface was exposed. The fabric was examined at ×20 magnification using a long arm stereomicroscope (Brunel Microscope TLA 250V) or hand lens (Gowlland ×10). Colour was recorded using a Munsell Color Chart.Footnote 11 In the absence of an existing Cambridgeshire Roman Ceramic Building Material Fabric Collection, analysis primarily aimed at establishing a site-specific reference collection as well as describing and relating the different fabrics to particular buildings and phases of construction. Stone samples compiled from earlier researchFootnote 12 provided comparative reference material.

Consultation of the relevant 1:50,000 geological maps for this area, Sheet 188 (Cambridge) and memoir,Footnote 13 provided an understanding of the local clay and stone resources. An additional source of information was provided by the recently published volumes on the nearby Horningsea Pottery Industry,Footnote 14 which included a section on tile fabrics.Footnote 15

Owing to the sheer size of the ceramic building assemblage (9249 examples, 2600 kg),Footnote 16 a targeted sampling strategy of the ceramic building material by fabric was a necessity. Targeted sampling focused on contexts relating to walls surviving in situ, robbed-out walls and demolition or collapsed roofing of the three buildings, and reused and dumped material in adjacent features such as the L-shaped oven [641], well [678], the terminus of Ditch 18 [418] and pit [416], which were key to understanding the function and chronological development of the site. Here a 25 per cent fabric sampling policy was initiated for each category of building material, already subdivided by form at assessment stage primarily to obtain quantifiable data on the fabric types.

Detailed investigation of the form of 50 of the more complete examples also helped the study focus on the character and production of the individual brick, tegulae, imbrex and box-flue tile from the site. This included the form of some of the more unusual items such as the washed or red-slipped tegulae and imbrex from Ditch 18.Footnote 17 Each of these is commented on below.

CAMBRIDGESHIRE GEOLOGY AND RESOURCES FOR BUILDING IN STONE AND TILE

In Cambridgeshire, brick clay has been the building material of choice since the Roman occupation. At Bottisham, for example, approaching four times the amount of ceramic building material (2600 kg) relative to stone (466 kg) was recovered. This is due to the extensive Upper Jurassic, Cretaceous and Pleistocene clay cover that blankets much of this region.

There are numerous brick-clay reserves close by in Cretaceous Gault to the south-west and east of Cambridge, while Kimmeridge clay and the underlying glacial till have in the past been used as a source of clay for the brick in Cambridgeshire.Footnote 18 Despite an absence of Roman tile kilns, the clay associated with the pottery kilns associated with the nearby long-lasting Horningsea pottery industryFootnote 19 was seen as a likely source for the finer oxidised sandy Horningsea Fabric which characterises Roman ceramic building material throughout much of south Cambridgeshire. Detailed descriptions and definitions of the forms and a list of mortar fabrics can be found in the appendices below.

The geologically young underlying Upper Cretaceous (Lower Chalk) bedrock at Bottisham is usually too soft to be worked into rubblestone or dressed into cohesive, structurally sound building blocks. Instead, chalk is used as a major source of lime for mortar production, due to its almost pure 100 per cent CaCO3 content. Harder building stone is a valuable commodity in eastern and southern Cambridgeshire as it is very rare, with the notable exception of harder Chalk Rock, also known as Clunch or Burwell stone.Footnote 20

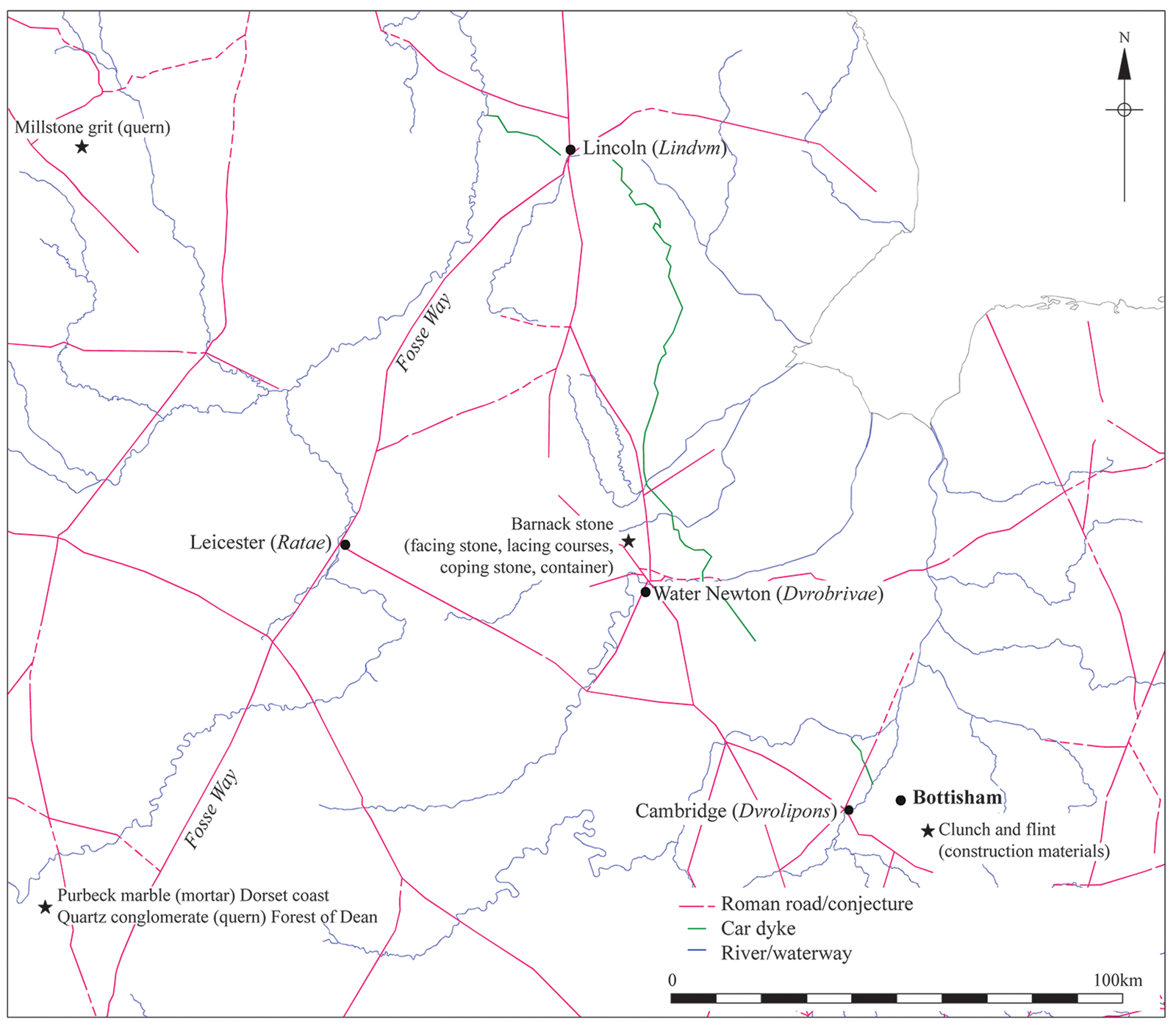

The opportunistic use of older, harder glacial erratics from the overlying Anglian Till as rubblestone walling is known. However, the impact of this array of highly dispersed, very hard to work, igneous (e.g. basalts, dolerites, granites), metamorphic (schists and gneiss) and Palaeozoic and Mesozoic sandstones and limestone was at best minimal. Instead, rock suitable for rubblestone and freestone use was often brought in from a distance. Bottisham has access via the River Cam and the Car Dyke to older more suitable freestoneFootnote 21 outcrops to the west from Middle Jurassic escarpment (e.g. Barnack stone, Weldon stone; Blisworth limestone; Ketton stone) (fig. 3). Included here is Collyweston slate, which supplied much of the stone roofing tile to villas and bath-houses from this region such as HaddonFootnote 22 and the nearby villa at Whittlesford.Footnote 23 This route also tapped into the wider provincial supply of portable utilitarian stone objects from much further afield, most notably quernstones from the Millstone Grit of South Yorkshire but also many other sources from West Sussex, Forest of Dean and even the Rhineland.

FIG. 3. Sources and transport routes of building stone. (© Pre-Construct Archaeology Ltd)

BUILDING MATERIALS

CERAMIC BUILDING MATERIAL

Form – overall distribution and condition

table 1, which quantifies by weight the distribution of the three main types of ceramic building material retained from Bottisham (roofing tile, brick and box-flue), shows considerable variation from one building to another, each a reflection of a separate function and construction history. It can be seen, for example, that box-flue tile was especially common in Building 3 (85 per cent of all box-flue tile from the site and 50 per cent of building material specific to this building) and hardly present at all in Building 1 (2 per cent), while roofing material (tegulae and imbrices) characterises Building 2 (63 per cent of building material) and hardly features in Building 1 (18 per cent). Brick, on the other hand, much of it complete and with fresh mortar adhering, characterises the more robust structural Building 1 (64 per cent) and accounts for 92 per cent of material from well [678].

TABLE 1 WEIGHT (KG) FOR EACH CATEGORY OF ROMAN CERAMIC BUILDING MATERIAL BY FEATURE AND BUILDING AT BOTTISHAM

Fabrics

Six ceramic building material fabrics (Bottisham 1-6) can be distinguished, each characterised by a distinctive hue, inclusion type, grain-size and moulding sand (table 2). This section highlights the overall distinguishing features of each, some idea of their clay source, and their frequency and distribution. Because of the targeted sampling strategy during fabric analysis stage, it is only possible to estimate the proportion of each fabric type.

TABLE 2 DESCRIPTION, SOURCE, FREQUENCY, FUNCTION, DISTRIBUTION, AND CONDITION OF BOTTISHAM FABRIC TYPES

Bottisham 1 is the most versatile and abundant fabric found in quantity in broken-up tegulae, imbrex, box-flue tile and perhaps to a lesser extent the brick from all buildings. It is comparable to finer oxidised red sandy Horningsea fabric T51/1 that is common throughout southern Cambridgeshire with inclusions of flint, chalk and quartzite inclusions that clearly indicate derivation from a Quaternary glacial clay.

Other fabrics show derivation from Upper Jurassic (Kimmeridgian or Oxfordian) or Cretaceous (Gault) clays. The softer, black organic core rich Bottisham 5, which is restricted mainly to the production of lydion sized bricks and roofing elements, has impressions of brachiopods in the core of the fabric in examples from [2012]. The calcareous rich fawn and yellow fabrics Bottisham 3 and 4 were almost certainly dug from outcrops of Lower Cretaceous Gault which lie within 2–3 km of the site. Both fabrics were restricted to Building 2 and Ditch 18 and with a few exceptions nearly always used for the production of roofing tile (tegulae and imbrex).

Four distinctive mortar fabrics (M1–M4) were identified at Bottisham, each having a characteristic hue, inclusion type and grain-size, and it was possible to link the distribution of each mortar type to a particular building, feature or even style of construction. These are not discussed in detail here and the reader is referred to the archive report in appendix 1.

BRICKS AND CURVED ARCHES

It is a feature of the site that there were no small bessales bricks and just a handful of fragments of larger bricks used to cap the bessalis pilae, typically pedalis, sesquipedalis or bi-pedalis size.Footnote 24 Instead, complete bricks, either dumped into well [678] or recorded in situ in the walls of Building 1 and Building 3, were nearly all found to conform in size to the standard rectangular lydion size measurement,Footnote 25 typically 380 mm (1 ft 3 ins) long by 280 mm (11 ins) wide, averaging 36.8 mm (1½ ins) thick and weighing 7–8 kg. It has long been recognised, especially by Gerald Brodribb,Footnote 26 that these brick shapes are highly versatile and at Bottisham they have been put to a range of uses. These include use as lacing courses, complete removal and reuse as paving floor materials, or the use of broken examples as walling rubble.

With brick and stone such a valuable commodity, and in short supply for an isolated farmstead such as Bottisham, the need for materials to be versatile and reusable becomes more important. One further example of the versatility of brick and its use for curved arches is noted by Brodribb, who states that ‘It is possible to make curved arches with any size of flat brick from bessales to bipedales simply by adjusting the amount of mortar to induce a curve’.Footnote 27 Two potential brick arch components were identified at Bottisham, where lydion bricks were separated by increasing thicknesses (up to 70 mm) by low-density waterproof pale orange pink mortar (2.5YR 5/8) (fig. 4). One was a definite arch fragment dumped into well [678], the other was a possible arch base in situ in wall [2048] of Building 1. It is likely that the arch fragment and arch base were part of the same structure. Both arch components correspond in form and dimension with the structure described by Brodribb, rather than usimg the more conventional brick shaping, or tapering called a Cuneatus or Solid Voussoir arch.

FIG. 4. Ceramic Building Material arch fragments. (© Pre-Construct Archaeology Ltd)

An identical brick arch to the fragments found at Bottisham was found in situ recently at the Silchester ‘Neronian’ bath-house where it topped a drain conducting water in or out from a latrine.Footnote 28

PIGMENTATION ON ROOF-TILE

Detailed visual analysis of the ceramic building material assemblage has shown the identification of red pigment in a group of imbrices and tegulae from the demolition debris of Building 2, also dumped into adjoining Ditch 18 and Ditch 47. The red slip appears all over the flanged tegulae and curved imbrices but is especially prominent along the flange edges and top of the tegulae (fig. 5) and the point of maximum curvature along the apex of the imbrex, as if meant to be seen. The decision to dip these different yellow-clayed roofing materials into a red-coloured solution may have been an aesthetic choice in keeping with the pre-existing red roof skyline for the bath-house and outhouse buildings (Building 1 and Building 3) of a possible courtyard area. Associated with the yellow Gault-rich Bottisham 3 and 4 fabrics (table 2), nearly all the tegulae were also found to have nail-holes.

FIG. 5. Red slip on tegula. (© Pre-Construct Archaeology Ltd)

Pigmentation of Roman ceramic building material occurs in only a few examples at villas in Northamptonshire (Piddington and Croughton) and at Southwark, where a deep red slip coats the finished tile.Footnote 29

CAVITY WALLING

Tubulus or box-tile, the most efficient way of circulating heat into a space behind the walls and round the room, was concentrated in the demolition layers of the two westernmost rooms of Building 3. There is so much box-flue tile (365 kg) that in situ collapse would seem to be the most likely explanation, supported by the fact that there are many entire rectangular combed and vented faced elements in good condition, with complete examples measuring 220 × 170 × 21 mm in length, width and depth. Present in a limited range of standard combed designs on alternate faces, they are all made from the fine red sandy Horningsea Type fabric (Bottisham 1) and clearly form part of a single cavity walling.

An interesting feature of the assemblage is that there are no signs of soot, scorching and burning marks on the inside of the vents. Instead, the combing is fresh and there is sometimes a bulbous calcareous residue on the inside of the vent or the jacketing. Whether or not this is hard limescale precipitate from heated, hard, chalky water is not clear. The absence of soot may indicate that the box-flue tiles were only used a couple of times or indeed not at all.

THE STONE

table 3 summarises the principal rock types, their geological source, distance from outcrop and function at Bottisham. These are stone types that are encountered again and again in Roman rural farmsteads and villas throughout Cambridgeshire.

TABLE 3 PRINCIPAL ROCK TYPES, GEOLOGICAL SOURCE, DISTANCE FROM OUTCROP AND FUNCTION AT BOTTISHAM

Two roughly dressed stone materials were used in the construction of the three buildings at Bottisham. Barnack stone was used for their structural integrity, while Burwell stone, the accessible local very soft chalk rock, was used for decorative facing, like the small sub-square petit appareil facing blocks in Building 3. More unexpected was the significant quantity of Barnack limestone, of which 40 pieces were recovered with an individual block weight of 15–60 kg and a typical size of 300 × 280 × 160 mm. These were quarried and supplied from distances of over 65 km.

The use of Barnack limestone for very roughly tooled rectangular structural elements (fig. 6) in the facing and lacing of the substructure of Building 1 contrasts with what is known of its use in later Roman Britain as stone for sarcophagiFootnote 30 and for architectural embellishment.Footnote 31 However, this limestone, which is extremely hard and durable and has a very low porosity, is ideally suited to the construction of a subterranean bath-house, with its resistance to the higher moisture content and temperature especially when it is bonded and coated using hard, waterproof, pink opus signinum-type mortars.

FIG. 6. Barnack stone architectural block with hammer and chisel tool marks. (© Pre-Construct Archaeology Ltd)

In an area of soft underlying geology, this demonstrates that the owners of Bottisham and other high-status masonry farmsteads were prepared to put in a significant effort to obtain desirable stone materials from quite distant sources.

THE BUILDINGS

BUILDING 1: DOUBLE-APSED BATH-HOUSE

The sunken double-apsed Building 1 was a substantial masonry structure, 6.6 m long x 5 m wide x 0.9 m deep consisting of lacing courses of lydion brick made from Bottisham 5 and Bottisham 6 brick fabrics, used in conjunction with large structural blocks of Barnack stone (figs 7 and 8). Elsewhere, precisely worked petit appareil sub-rectangular blocks of clunch and chalk were used to define the outlines of two apsidal features [2012]/[2050] and [2015], each 2.15 m in diameter, as well as a rectangular section of wall [2044] that demarcates the north-east–south-west side of the building. The overall impression is of a sub-structure constructed with thought to aesthetics using fresh and carefully chosen brick and Barnack stone structural elements, the latter brought in over distances of 60 km from north-west Cambridgeshire. Two different mortars, the loose earthy-brown flint chalk mortar M2 and a very high-quality low-density pale orange pink mortar and render M3 define the apsidal and north-east–south-west side sections of wall from the south-west side and buttress, respectively. What is immediately apparent is how intact and pristine all these surviving subterranean elements are, completely undisturbed by subsequent robbing.

FIG. 7. Building 1 plan. (© Pre-Construct Archaeology Ltd)

FIG. 8. Building 1. (© Pre-Construct Archaeology Ltd)

There are some elements in this building that are typical of a bath-house building. One is its apsidal plan. A very similar double-apsidal configuration of rooms, used as a caldarium and tepidarium, was found at the Truckle Hill bath-house in Wiltshire.Footnote 32 Structural elements supporting the function of the building as a bath-house are a small fragment of surviving opus signinum floor in the easternmost apsidal structure, a single coursed ledge or rim of 13 horizontally placed opus spicatum paving bricks encircling the apse and some relict opus spicatum or herring-bone flooring in the westernmost apsidal structure.Footnote 33

An opening on the south-west side of Building 1, which is flanked by two twin lydion tile stacks [2009] [2048], has a comparable mortar (M3) and brick fabric (Bottisham 5 and 6) to an archway fragment dumped into well [678] as well as another internal wall of Building 1 [2046]. From this we may deduce that this opening was an archway, possibly to channel freshwater flow in or effluence out of Building 1, if there was a latrine present, as at the Neronian bath-house at Silchester.Footnote 34 More probably the arch would have formed a flue-opening for hot air to enter, or alternatively providing an exit for the draught and allowing smoke and hot air to exit like a chimney in a caldarium. There is no evidence for any features external to the bath-house, like a flue for firing or ditches or channels to transport water or effluence. All of the bricks near the opening and within the building are in very good, almost pristine condition with no evidence of sooting or burning. No evidence was found of hypocausts.

Low density tufa, the product of spring water deposition in a chalk- and limestone-rich area and used as vaulting for the roofing of numerous baths in villas, is also conspicuous by its absence. Decorative flooring elements such as stone and ceramic tesserae are entirely lacking, as is the evidence for decorative stone veneers. Finally, there is a complete absence of wall plaster fragments from this building.Footnote 35

There is little sign of cavity walling (box-flue) being used to circulate heat into the space behind the walls in Building 1, with only 12 kg recovered, certainly in comparison with the large assemblage from Building 3 (503 kg). Furthermore, where it has been found in the demolition layers, e.g. (2031), it merely forms a handful of small fragments of background material by comparison with numerous examples of large structural lydion bricks and clunch from the substructure.

Due to their complete absence from the excavation, even in other features, it seems that, rather than being robbed out, the cavity walling, like the bessalis pilae stacks, the larger capping bricks, tufa for the vaulting and the more ornamental elements, was never added.

There is evidence, however, to suggest that Building 1 may have had a tiled roof at some point. Relatively small quantities of tegulae were recovered (55 kg, 17 per cent by weight) from the building, present in the earliest demolition layer (2031). The first stage in the failure and decay of any unoccupied masonry building would be the slippage and breakage of the heavy roofing tile, and it is possible the roof collapsed and many of its tegulae were re-used, possibly in neighbouring Building 2.

In essence, Building 1 appears to represent the surviving substructure of a never-completed bath-house. The basic structural brick and stone elements, the archways for the flues, the outline of the two elements of a bath complex and some of the flooring had been laid out ready for the installation of box-flue tiles, pilae and decorative elements, which were never added. The possibility exists, of course, that this was not a bath-house at all, but a building of some other, unknown use.

BUILDING 2: ANCILLARY BUILDING WITH RED-SLIPPED ROOF

The northernmost structure (Building 2) consists of a rectangular room and part of an external curved wall section, both defined by the surviving foundations of a heavily mortared thick (0.9 m) wall containing tile and Barnack stone fragments (figs 9 and 10). The walls that delineate the 8 × 4.5 m rectangular building and the curved wall are made in the same very hard concretionary flint mortar M1, or opus caementatum, suggesting a single build. This mortar, which was also identified in Building 3, is applied liberally both as a rammed foundation and as a construction material per se, making up perhaps for a dearth of recyclable stone and brick from other structures.

FIG. 9. Building 2 plan. (© Pre-Construct Archaeology Ltd)

FIG. 10. Building 2. (© Pre-Construct Archaeology Ltd)

The defining feature of this building is a concentration of roofing tile, in particular fresh yellow and orange-beige Gault roofing tile (Bottisham 3 and 4) from the building's main demolition layer (5001). Many of the tegulae also have a nail-hole inserted. Common in later tegulae,Footnote 36 Brodribb suggests that the nail would been used to affix only those tiles forming the lowest course overhanging the eaves.Footnote 37 Quantities of tegulae are also present in the terminus [418] of Ditch 18 and pit [416], which both lie just a couple of metres from Building 2.

The tile (both imbrex and tegulae) had been treated with a red slip, which may have been an aesthetic choice in keeping with the pre-existing red roofs of Building 1 and Building 3, suggesting that Building 2 was a later addition. Other evidence for a later construction date of Building 2 is shown by the fragmentary condition of the 70 kg of Barnack stone in the foundation walls of both the rectangular room and curved wall. It has been shown that large blocks of Barnack stone were used in the earlier bath-house Building 1. Here, however, in the foundation of Building 2, they appear as reused rubble in walls (5002), (5006) and (5009), and as post pad (5060), and were clearly brought over as robbed stone to construct this building.

A limited quantity of brick (48 kg or 15 per cent by weight) was recovered, which may suggest that Building 2 was a timber-framed construction on stone footings or that the brick had simply been robbed.

Rapidly constructed, with copious amounts of opus caementatum and reused Barnack stone in its foundations, roofed with new yellow Gault tile supported by timber posts, the apsidal and rectangular rooms of Building 2 could have had a number of distinct functions. It has been shown that all the large Quartz Conglomerate querns and Millstone Grit (70 kg) from this excavation were identified either from the demolition layer (5001) in the rectangular room or dumped in a well [678]. Therefore Building 2 may have had a secondary (or even primary) use as a mill or an ancillary building with a raised stone footing, used as grain or fodder storage, a barn or even a domestic building.

It is interesting to note that Building 2 is the only structure on site to have wall plaster, albeit reused as building material. Fragments of painted wall plaster also came from Ditch 18. For a detailed discussion of the painted wall plaster, see Seddon Reference Seddon2018.

BUILDING 3: RECTANGULAR BUILDING WITH HYPOCAUST HEATING SYSTEM

The largest building from the excavation, the four-roomed 14.5 × 11.5 m Building 3 lay 34 m SE of Building 1 and 32 m SE of Building 2 (figs 11 and 12). The walls of Rooms 1–4 survive only to the lowest course within their foundation cuts but there is evidence for extensive robbing.

FIG. 11. Building 3 plan. (© Pre-Construct Archaeology Ltd)

FIG. 12. Building 3. (© Pre-Construct Archaeology Ltd)

The walls are in the main constructed using the same type of very hard concretionary flint mortar (M1) as that of Building 2, although it is noticeable that the three walls delineating R1 and R2 [3018] [3021] [3024] are characterised by the similar/same pink light mortar M3 as that of Building 1. Similar to Building 1, the walls also contain appreciable amounts of complete lydion brick and, in the case of wall [3021], 108 kg of very large intact slabs of Barnack stone up to 400 × 300 × 150 mm in size.

The early phase of Building 3 may therefore be contemporary with Building 1. A second, later phase of construction is present in the walls of R1 [3040], R2 [3048] R4 [3001] using the same very hard concretionary flint mortar (M1) or opus caementatum as that used in all the walls of Building 2. Furthermore, it was used to repoint walls [3018], [3021] and [3024]. The mortar type would therefore indicate that Building 3 continued to be occupied or was refurbished at the same time as Building 2 was constructed.

It is in R1 and R2, too, that 376 kg of fragmentary combed box-flue tile was present in the demolition fills forming approximately 50 per cent of all building material (by weight) for Building 3, and 85 per cent of all box-flue tile from the entire site assemblage. These small (220 × 170 × 21 mm) box-flue tiles or tubuli have a standardised fabric (Horningsea very fine sandy Bottisham 1) and combed form (deep chevron or two inward facing circles) with large 50–70 mm sub-ovoid circular vents with the venting sometimes infilled with the same low density pink mortar M3 seen in the brick from walls [3018] [3021] [3024] and Building 1. The fills (3051) (3052) of robber cuts in other parts of Building 3, for example in the south-eastern corner of R4, also contained quantities of box-flue, most probably from these rooms too.

Such a concentration, albeit accentuated by subsequent robbing of the square and rectangular-shaped brick elements from these rooms, can only mean that the walls of R1 and R2 were lined with vertically stacked tubuli to circulate heat around the rooms. Accounting for the enormous quantities in such small rooms is easy as it has been calculated that 190 box-flue tiles are needed for a single room.Footnote 38 The thick mortar M3 attached to one side only, and sometimes as vent infill, would have insulated the circulated hot air for use as either a sweat room, laconicum, or the heated opulent caldarium of a bath-house. There is a notable lack of sooting on the tubuli from Building 3, but this could be the result of the distance of the box-flue from the heat source rather than a sign of complete non-use. The calcareous residue seen on some examples certainly suggests some exposure to heat, but the absence of pilae, as in Building 1, again calls into question how these two rooms were heated. However, only the southern part of R1 has been excavated and it is possible that the heat source (from the praefurnium) was situated in a part of the building located outside the area of excavation.

DISCUSSION AND SYNTHESIS

The 100 per cent retention policy of all the ceramic building material and stone from a large late Roman complex farmstead in south-east Cambridgeshire has allowed a detailed investigation of the fabric, form, construction style and function of the various elements used in three masonry buildings and associated features. This has been a useful analysis in an area where very little is known about the types and forms of stone and tile and where very few rural masonry buildings have been uncovered.

How does this complex of masonry buildings fit into the existing classification of rural structures from this part of eastern England, defined in the recent nationwide survey as the East Anglian chalk zone (in which Bottisham is defined as a rare example of a farmstead with masonry buildings)?Footnote 39 The findings presented here have shown that the farmstead did have some elements of wealth and prestige, shown by the carefully planned substructure of the double-apsidal probable bath Building 1 and the two heated rooms (R1 and R2) of Building 3. The use of tough, very heavy 50–100 kg Barnack stone slabs, quarried 60 km away, for the structural elements of the double apsidal building would have been a major logistical undertaking.

Bath-houses of similar size belonging to bigger and more elaborate farmsteads have been identified at Haddon and Itter Cresent, both near Peterborough,Footnote 40 and Whittlesford, south Cambridgeshire (CHER MCB19295), as well as Linton, near Hadstock, Essex.Footnote 41 The bath-houses of those villas were similar in size to that at Bottisham and either stood alone or were incorporated into the main residential building.

However, on two counts the site falls short of what is expected of buildings associated with a larger villa. First is the near-complete absence of stone roofing tile, the nearest source being the flaggy, calcareous Collyweston slate from the Middle Jurassic of Northamptonshire. This stone tile is frequently associated with the more prestigious villa buildings, particularly at distance from the outcrop, a good example being the identification of a stone roof from the ongoing excavations of the ‘villa’ buildings at Whittlesford.Footnote 42 Second, there is an absence of opulent floor surfaces, most typically stone and ceramic tessellated pavements (again noted at Whittlesford), fine limestone pavement materials or low-density tufa used as archway vaulting. Instead, ceramic roofing tile was the chosen construction material. Suitable, though more brittle than stone, tile was for example dug from Gault clays as close as 2 km away to roof Building 3, rather than using the more robust stone roofing from 50 km away at Collyweston.

CONCLUSION

The excavations at Bottisham identified a number of buildings of a rural farmstead or possible ‘villa’ complex but the main dwelling or dwellings of the site are as yet elusive. It is possible that heated Building 3 may represent a ‘wing’ of a larger high-status building extending beyond the limit of excavation, or that the main building was located elsewhere. It is also possible that the settlement consisted entirely of smaller structures, predominantly for agricultural purposes, and with facilities for estate workers and other inhabitants.

The material culture of the site, other than the building material, suggests that the inhabitants enjoyed a degree of comfort, as shown by the presence of dress fittings, glass vessels and a stylus. However, there were also signs of frugality, as shown by the long-term use of dress fittings elsewhere on the site (Tunbridge Hall), and a bone pin possibly worn in imitation of a more expensive item (Crystal Park). Interestingly, the ceramic assemblage of Tunbridge Hall with a preponderance for bowl/dish forms over jars, indicating a more affluent ‘urban'’assemblage,Footnote 43 was not replicated at Crystal Park.

Bottisham may be seen, perhaps, as a high-status farmstead, with many buildings similar to a villa type complex but no traditional main villa building. It is also possible that the site was part of an agricultural estate associated with a villa building located elsewhere, such as the villa complex excavated at Chignall, Essex, which included a possible detached bath-house and timber structures of agricultural and domestic function.Footnote 44

Further investigations in and around Bottisham can only add to the narrative of this interesting site.

ACKNOWLEDGEMENTS

The authors would like to thank Pre-Construct Archaeology Ltd (PCA), especially the staff involved with the excavation, post-excavation and curation at Crystal Park, Tunbridge Lane, Bottisham. Special thanks go to Rosie Scales for the figures and to Heidi Hauser for the meticulous recording of the ceramic building material assemblage, including illustrations.

APPENDIX 1: MORTAR FABRICS

APPENDIX 1, TABLE 1 DESCRIPTION, FREQUENCY AND DISTRIBUTION OF BOTTISHAM MORTAR FABRICS

APPENDIX 2: CERAMIC BUILDING MATERIAL FORM AND METRICS

Comment on the form and size of the individual Roman brick, box-flue tile, tegulae and imbrex used in the three buildings (B1–B3) was possible from the 50 complete or near complete examples recovered from the excavations. Information on the form and size (mm thickness) of the smaller box-flue tile fragments (including vent shape and keying) tegulae (cut-aways and flange profile) was recorded in detail (by Heidi Hauser) in a comprehensive review of the entire ceramic building material assemblage by form conducted during the assessment phase.

BRICK

APPENDIX 2, TABLE 1 SIZE, FORM, AND DISTRIBUTION OF BRICK FROM BOTTISHAM

ROOFING TILE

a) Tegulae

APPENDIX 2, TABLE 2 SIZE, FORM, AND DISTRIBUTION OF TEGULAE FROM BOTTISHAM

b) Imbrex (no complete examples)

APPENDIX 2, TABLE 3 SIZE, FORM, AND DISTRIBUTION OF IMBREX FROM BOTTISHAM

CAVITY WALLING (BOX-FLUE TILE)

APPENDIX 2, TABLE 4 SIZE, FORM, AND QUANTITIES OF BOX-FLUE TILE FROM BOTTISHAM

APPENDIX 2, FIG. 1. Doughnut chart showing proportions of different combed designs on box-flue tile fragments Bottisham 1 = Saltire 53.7%; 2 = Diagonal 10.4%; 3 = Linear 27.8%; 4 = Wave 3.3%; 5 = Curved 2.7%; 6 = Semi-Circle 0.7%; 7 = ‘Bird Wing’ 0.4%; 8 = Letter D 0.1%; 9 = Back-to-Back Letter C 0.8%.