1 Introduction

A detonation in a condensed-phase high explosive (HE) consists of a shock sustained by the hydrodynamic flow induced by spatially distributed chemical reaction in the explosive. In many multi-dimensional flow configurations, lateral motion of the detonating explosive due to yielding of surrounding confinement induces streamline divergence, which causes the shock to become divergently curved, whereupon the dynamics of a steadily propagating detonation is controlled by the chemical energy release that occurs within a subsonic elliptic flow region known as the detonation driving zone, or DDZ. A review of this structure was recently presented by Short & Quirk (Reference Short and Quirk2018b ). The DDZ is the region encompassing the detonation shock and sonic flow locus (relative to the frame of the detonation shock). The DDZ structure is influenced by the lateral size of the HE, the degree of reactivity and the strength of the confinement.

For fixed confinement, decreasing the charge size causes an increase in divergent curvature of the shock, which drives the flow sonic locus into regions of increasingly incomplete reaction (Bdzil Reference Bdzil1981). The available reactant energy that feeds into driving the detonation forward consequently decreases, and the detonation propagation speed drops. As a result of this mechanism, too small a charge size leads to the inability of the detonation to propagate steadily, and typically the detonation fails. For two-dimensional (2-D) axisymmetric cylindrical geometries, the variation of the steady axial detonation speed with the inverse of the HE charge radius is known, paradoxically, as the diameter effect curve, while the HE radius at which failure occurs is known as the failure radius (Fickett & Davis Reference Fickett and Davis1979). In 2-D planar slab geometries, the variation of the steady axial detonation speed with HE charge width is known as the thickness effect curve, while the HE slab width at which failure occurs is known as the failure thickness (Jackson & Short Reference Jackson and Short2015).

A number of experiments on size effect curves and failure diameters/thicknesses have been conducted on several HEs with no confinement (Campbell & Engelke Reference Campbell and Engelke1976). Measurements of failure diameters suggest that there is a correlation between detonation reaction zone size in a given HE and the failure diameter. Specifically, the more sensitive the explosive (shorter reaction zone), the smaller the failure diameter for unconfined charges. For an insensitive explosive such as PBX 9502 (95 wt% TATB (2,4,6-triamino-1,3,5-trinitrobenzene)/5 wt% Kel-F 800 (poly(chlorotrifluoroethylene-co-vinylidene fluoride))), the detonation reaction zone length is believed to be in the region of 1–1.5 mm (Seitz et al. Reference Seitz, Stacy, Engelke, Tang and Wackerle1989), while its failure diameter is between 7.5 and 8 mm and its failure thickness is between 3.5 mm and 3.75 mm (Jackson & Short Reference Jackson and Short2015). Non-ideal HEs with large reaction zones have larger failure diameters. For example, ammonium-nitrate fuel oil (ANFO) has a reaction zone thickness of 12–16 mm (Short & Jackson Reference Short and Jackson2015) and a failure diameter of 77 mm (Bdzil et al. Reference Bdzil, Aslam, Catanach, Hill and Short2002). Generally, for unconfined charges, the failure diameter is approximately a few reaction zone thicknesses.

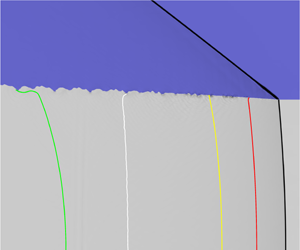

In contrast to unconfined explosives, there have been comparatively few studies on the size effect curve and failure diameter/thickness for confined charges. We know that strong confinement of the explosive significantly reduces the charge size that leads to detonation failure. This is because strong confinement limits the amount of streamline divergence in the DDZ, and thus the degree of energy losses to which the detonation is subjected. The most detailed, relevant study on this effect is that of Ramsay (Reference Ramsay1985), who examined the detonation failure thickness of PBX 9502 as a function of the impedance and thickness of the surrounding confiner. These results are summarized in figure 1. For aluminium confinement, the failure thickness decreased significantly as the confiner thickness increased, down to the order of a reaction zone thickness. For thin confinement walls of fixed width, the PBX 9502 failure thickness decreased going from aluminium to lead to copper confinement, i.e. as the impedance of the confiner increased.

The results of Ramsay (Reference Ramsay1985) for thin walls of the materials, aluminium, lead and copper suggest that, for even higher density materials, such as tantalum or platinum, the HE thickness at the failure point could be smaller than the reaction zone thickness. This conjecture motivates us to consider the dynamics of detonation propagation and failure for a problem of a strongly confined explosive (small material interface deflection angle) in which the channel width is small relative to the reaction zone length. As shown below, the consideration of this limit reveals some significant insights into the dynamics of how confinement affects both detonation propagation and failure. For all but the most sensitive of explosives, the latter requires a theory for which the detonation speed

![]() $D_{0}({<}D_{CJ})$

is such that

$D_{0}({<}D_{CJ})$

is such that

![]() $1-D_{0}/D_{CJ}=O(1),$

where

$1-D_{0}/D_{CJ}=O(1),$

where

![]() $D_{CJ}$

is the Chapman–Jouguet (CJ) detonation speed (Fickett & Davis Reference Fickett and Davis1979), with the relative departures of

$D_{CJ}$

is the Chapman–Jouguet (CJ) detonation speed (Fickett & Davis Reference Fickett and Davis1979), with the relative departures of

![]() $D_{0}$

from

$D_{0}$

from

![]() $D_{CJ}$

at the failure point increasing as the explosive becomes more non-ideal (Campbell & Engelke Reference Campbell and Engelke1976). In analogy with studies in laminar flames, we refer to this as a thick detonation limit (Daou & Matalon Reference Daou and Matalon2001; Short & Kessler Reference Short and Kessler2009; Kurdyumov & Matalon Reference Kurdyumov and Matalon2013; Pearce & Daou Reference Pearce and Daou2014; Kagan, Gordon & Sivashinsky Reference Kagan, Gordon and Sivashinsky2015).

$D_{CJ}$

at the failure point increasing as the explosive becomes more non-ideal (Campbell & Engelke Reference Campbell and Engelke1976). In analogy with studies in laminar flames, we refer to this as a thick detonation limit (Daou & Matalon Reference Daou and Matalon2001; Short & Kessler Reference Short and Kessler2009; Kurdyumov & Matalon Reference Kurdyumov and Matalon2013; Pearce & Daou Reference Pearce and Daou2014; Kagan, Gordon & Sivashinsky Reference Kagan, Gordon and Sivashinsky2015).

Figure 1. Summary of the PBX 9502 failure thickness results from Ramsay (Reference Ramsay1985).

2 Model

We consider a steady, symmetrical detonation propagating axially with constant speed

![]() $D_{0}$

in either a 2-D planar or axisymmetric cylindrical geometry, as shown in figure 2(a). The planar geometry has thickness

$D_{0}$

in either a 2-D planar or axisymmetric cylindrical geometry, as shown in figure 2(a). The planar geometry has thickness

![]() $T(=2W)$

, while the cylinder has radius

$T(=2W)$

, while the cylinder has radius

![]() $R(=W)$

. Ahead of the detonation the HE/confiner material interface lies at the fixed location

$R(=W)$

. Ahead of the detonation the HE/confiner material interface lies at the fixed location

![]() $r=W$

(figure 2

a). Upon detonation arrival, the material interface between the HE and confiner is deflected. For steady flow, and in a coordinate system travelling with the detonation shock at speed

$r=W$

(figure 2

a). Upon detonation arrival, the material interface between the HE and confiner is deflected. For steady flow, and in a coordinate system travelling with the detonation shock at speed

![]() $D_{0}$

, the material interface is stationary, and thus the material interface boundary can be considered equivalent to an HE streamline defining the edge of the deflected HE flow behind the shock. In contrast to our previous studies that have set this boundary streamline to be straight (Chiquete et al.

Reference Chiquete, Short, Meyer and Quirk2018; Chiquete, Short & Quirk Reference Chiquete, Short and Quirk2019; Chiquete & Short Reference Chiquete and Short2019), here, we assume that the shape of the streamline can be arbitrarily prescribed, thus enabling us to study the effects on detonation propagation of boundary streamline curvature. In § 6, we determine the curved HE boundary streamline (material interface) shape for a series of confinement materials via multi-material simulation.

$D_{0}$

, the material interface is stationary, and thus the material interface boundary can be considered equivalent to an HE streamline defining the edge of the deflected HE flow behind the shock. In contrast to our previous studies that have set this boundary streamline to be straight (Chiquete et al.

Reference Chiquete, Short, Meyer and Quirk2018; Chiquete, Short & Quirk Reference Chiquete, Short and Quirk2019; Chiquete & Short Reference Chiquete and Short2019), here, we assume that the shape of the streamline can be arbitrarily prescribed, thus enabling us to study the effects on detonation propagation of boundary streamline curvature. In § 6, we determine the curved HE boundary streamline (material interface) shape for a series of confinement materials via multi-material simulation.

The detonation flow is governed by the 2-D reactive Euler equations. These are written in non-dimensionalized form for general unsteady flows as

Figure 2. (a) Schematic of steady axial detonation propagation in either a planar 2-D geometry (

![]() $W=T/2$

) or axisymmetric 2-D cylindrical geometry

$W=T/2$

) or axisymmetric 2-D cylindrical geometry

![]() $(W=R)$

in which the HE boundary is deflected upon arrival of the detonation shock. For analysis purposes, the

$(W=R)$

in which the HE boundary is deflected upon arrival of the detonation shock. For analysis purposes, the

![]() $(r,z)$

geometry in (a) is mapped to the shock- and deflected boundary-fitted frame

$(r,z)$

geometry in (a) is mapped to the shock- and deflected boundary-fitted frame

![]() $(\unicode[STIX]{x1D709},\unicode[STIX]{x1D702})$

as shown in (b).

$(\unicode[STIX]{x1D709},\unicode[STIX]{x1D702})$

as shown in (b).

where,

Here,

![]() $r$

and

$r$

and

![]() $z$

denote spatial coordinates perpendicular and parallel to the undeflected boundary streamline, respectively (figure 2

a),

$z$

denote spatial coordinates perpendicular and parallel to the undeflected boundary streamline, respectively (figure 2

a),

![]() $t$

is time, while

$t$

is time, while

![]() $\unicode[STIX]{x1D70C}$

,

$\unicode[STIX]{x1D70C}$

,

![]() $\boldsymbol{u}$

,

$\boldsymbol{u}$

,

![]() $E$

and

$E$

and

![]() $p$

are the density, laboratory-frame flow velocity vector, total energy and pressure, respectively. For the two-dimensional flow being considered, the velocity vector

$p$

are the density, laboratory-frame flow velocity vector, total energy and pressure, respectively. For the two-dimensional flow being considered, the velocity vector

![]() $\boldsymbol{u}=(u_{r},u_{z})^{\intercal }$

. The reaction progress variable,

$\boldsymbol{u}=(u_{r},u_{z})^{\intercal }$

. The reaction progress variable,

![]() $\unicode[STIX]{x1D706}\in [0,1]$

, tracks the conversion of reactants

$\unicode[STIX]{x1D706}\in [0,1]$

, tracks the conversion of reactants

![]() $(\unicode[STIX]{x1D706}=0)$

to products

$(\unicode[STIX]{x1D706}=0)$

to products

![]() $(\unicode[STIX]{x1D706}=1)$

at the rate

$(\unicode[STIX]{x1D706}=1)$

at the rate

![]() $\unicode[STIX]{x1D6EC}$

. The symmetry parameter

$\unicode[STIX]{x1D6EC}$

. The symmetry parameter

![]() $s=0$

for the planar geometry, while

$s=0$

for the planar geometry, while

![]() $s=1$

for the cylindrical geometry. The total energy and frozen sound speed

$s=1$

for the cylindrical geometry. The total energy and frozen sound speed

![]() $c$

are given by

$c$

are given by

respectively, where

![]() $e$

is the internal energy. The detonation shock conditions are

$e$

is the internal energy. The detonation shock conditions are

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}\displaystyle \unicode[STIX]{x1D70C}_{s}(u_{n,s}-D_{n,s})=-\unicode[STIX]{x1D70C}_{0}D_{n,s},\quad p_{s}=\unicode[STIX]{x1D70C}_{0}^{2}D_{n,s}^{2}\left({\displaystyle \frac{1}{\unicode[STIX]{x1D70C}_{0}}}-\frac{1}{\unicode[STIX]{x1D70C}_{s}}\right),\\ e_{s}-e_{0}={\displaystyle \frac{1}{2}}p_{s}\left({\displaystyle \frac{1}{\unicode[STIX]{x1D70C}_{0}}}-{\displaystyle \frac{1}{\unicode[STIX]{x1D70C}_{s}}}\right),\quad \unicode[STIX]{x1D706}_{s}=0,\quad u_{t,s}=0,\end{array}\right\}\end{eqnarray}$$

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}\displaystyle \unicode[STIX]{x1D70C}_{s}(u_{n,s}-D_{n,s})=-\unicode[STIX]{x1D70C}_{0}D_{n,s},\quad p_{s}=\unicode[STIX]{x1D70C}_{0}^{2}D_{n,s}^{2}\left({\displaystyle \frac{1}{\unicode[STIX]{x1D70C}_{0}}}-\frac{1}{\unicode[STIX]{x1D70C}_{s}}\right),\\ e_{s}-e_{0}={\displaystyle \frac{1}{2}}p_{s}\left({\displaystyle \frac{1}{\unicode[STIX]{x1D70C}_{0}}}-{\displaystyle \frac{1}{\unicode[STIX]{x1D70C}_{s}}}\right),\quad \unicode[STIX]{x1D706}_{s}=0,\quad u_{t,s}=0,\end{array}\right\}\end{eqnarray}$$

where

![]() $u_{t,s}$

and

$u_{t,s}$

and

![]() $u_{n,s}$

are the tangential and normal flow speeds at the shock,

$u_{n,s}$

are the tangential and normal flow speeds at the shock,

![]() $D_{n,s}$

is the shock speed in the shock normal direction and

$D_{n,s}$

is the shock speed in the shock normal direction and

![]() $\unicode[STIX]{x1D70C}_{0}$

and

$\unicode[STIX]{x1D70C}_{0}$

and

![]() $e_{0}$

are the density and internal energy of the unshocked reactant material, respectively. The subscript

$e_{0}$

are the density and internal energy of the unshocked reactant material, respectively. The subscript

![]() $\{\}_{s}$

is used here to denote the shock state.

$\{\}_{s}$

is used here to denote the shock state.

The non-dimensional scaling employed above is similar to that used by Short et al. (Reference Short, Quirk, Chiquete and Meyer2018) and given by

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}\displaystyle (r,z)={\displaystyle \frac{(\tilde{r},\tilde{z})}{\tilde{l}_{ref}}},~t={\displaystyle \frac{\tilde{t}}{(\tilde{l}_{ref}/\tilde{u} _{ref})}},~\unicode[STIX]{x1D70C}={\displaystyle \frac{\tilde{\unicode[STIX]{x1D70C}}}{\tilde{\unicode[STIX]{x1D70C}}_{ref}}},~\boldsymbol{u}={\displaystyle \frac{\tilde{\boldsymbol{u}}}{\tilde{u} _{ref}}},~p={\displaystyle \frac{\tilde{p}}{\tilde{\unicode[STIX]{x1D70C}}_{ref}\tilde{u} _{ref}^{2}}},~e={\displaystyle \frac{\tilde{e}}{\tilde{u} _{ref}^{2}}},\\ \displaystyle D_{CJ}={\displaystyle \frac{\tilde{D}_{CJ}}{\tilde{u} _{ref}}},~c={\displaystyle \frac{\tilde{c}}{\tilde{u} _{ref}}},~\end{array}\right\}\end{eqnarray}$$

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}\displaystyle (r,z)={\displaystyle \frac{(\tilde{r},\tilde{z})}{\tilde{l}_{ref}}},~t={\displaystyle \frac{\tilde{t}}{(\tilde{l}_{ref}/\tilde{u} _{ref})}},~\unicode[STIX]{x1D70C}={\displaystyle \frac{\tilde{\unicode[STIX]{x1D70C}}}{\tilde{\unicode[STIX]{x1D70C}}_{ref}}},~\boldsymbol{u}={\displaystyle \frac{\tilde{\boldsymbol{u}}}{\tilde{u} _{ref}}},~p={\displaystyle \frac{\tilde{p}}{\tilde{\unicode[STIX]{x1D70C}}_{ref}\tilde{u} _{ref}^{2}}},~e={\displaystyle \frac{\tilde{e}}{\tilde{u} _{ref}^{2}}},\\ \displaystyle D_{CJ}={\displaystyle \frac{\tilde{D}_{CJ}}{\tilde{u} _{ref}}},~c={\displaystyle \frac{\tilde{c}}{\tilde{u} _{ref}}},~\end{array}\right\}\end{eqnarray}$$

where

![]() $\tilde{\{~\}}$

quantities are dimensional. However, in contrast to Short et al. (Reference Short, Quirk, Chiquete and Meyer2018), where a partial reaction length scale is used for

$\tilde{\{~\}}$

quantities are dimensional. However, in contrast to Short et al. (Reference Short, Quirk, Chiquete and Meyer2018), where a partial reaction length scale is used for

![]() $\tilde{l}_{ref}$

, for the purposes of conducting the asymptotic analysis described in § 4, we initially set the reference length scale

$\tilde{l}_{ref}$

, for the purposes of conducting the asymptotic analysis described in § 4, we initially set the reference length scale

![]() $\tilde{l}_{ref}$

to be characteristic of the total length of the DDZ, i.e. representative of the distance between the detonation shock and sonic flow boundary. We return to the discussion of

$\tilde{l}_{ref}$

to be characteristic of the total length of the DDZ, i.e. representative of the distance between the detonation shock and sonic flow boundary. We return to the discussion of

![]() $\tilde{l}_{ref}$

to best present the results of the asymptotic analysis in § 5. Also, we take

$\tilde{l}_{ref}$

to best present the results of the asymptotic analysis in § 5. Also, we take

![]() $\tilde{u} _{ref}=1~\text{mm}~\unicode[STIX]{x03BC}\text{s}^{-1}$

and

$\tilde{u} _{ref}=1~\text{mm}~\unicode[STIX]{x03BC}\text{s}^{-1}$

and

![]() $\tilde{\unicode[STIX]{x1D70C}}_{ref}=1~\text{g}~\text{cm}^{-3}$

as in Short et al. (Reference Short, Quirk, Chiquete and Meyer2018).

$\tilde{\unicode[STIX]{x1D70C}}_{ref}=1~\text{g}~\text{cm}^{-3}$

as in Short et al. (Reference Short, Quirk, Chiquete and Meyer2018).

3 Shock- and boundary streamline-attached frame

We are concerned with steady flows, and to facilitate the analysis, coordinates

![]() $r$

and

$r$

and

![]() $z$

are transformed according to

$z$

are transformed according to

assuming that ahead of the detonation shock front the HE boundary streamline (material interface) lies at

![]() $r=W.$

The HE boundary streamline shape as a function of

$r=W.$

The HE boundary streamline shape as a function of

![]() $\unicode[STIX]{x1D702}({\leqslant}0)$

is given by

$\unicode[STIX]{x1D702}({\leqslant}0)$

is given by

![]() $-m_{e}h(\unicode[STIX]{x1D702}),h(0)=0,$

with

$-m_{e}h(\unicode[STIX]{x1D702}),h(0)=0,$

with

![]() $m_{e}$

representing the magnitude of the boundary streamline gradient at

$m_{e}$

representing the magnitude of the boundary streamline gradient at

![]() $\unicode[STIX]{x1D702}=0,$

so that

$\unicode[STIX]{x1D702}=0,$

so that

![]() $h^{\prime }(0)=1.$

For the majority of cases of interest,

$h^{\prime }(0)=1.$

For the majority of cases of interest,

![]() $m_{e}>0$

and

$m_{e}>0$

and

![]() $h(\unicode[STIX]{x1D702})<0$

for

$h(\unicode[STIX]{x1D702})<0$

for

![]() $\unicode[STIX]{x1D702}<0,$

although some situations can arise where

$\unicode[STIX]{x1D702}<0,$

although some situations can arise where

![]() $m_{e}<0$

as discussed in § 6.2. In terms of the boundary streamline deflection angle

$m_{e}<0$

as discussed in § 6.2. In terms of the boundary streamline deflection angle

![]() $\unicode[STIX]{x1D703}_{e}$

(figure 2

a) at

$\unicode[STIX]{x1D703}_{e}$

(figure 2

a) at

![]() $\unicode[STIX]{x1D702}=0,$

$\unicode[STIX]{x1D702}=0,$

![]() $m_{e}=\tan \unicode[STIX]{x1D703}_{e}$

. Also,

$m_{e}=\tan \unicode[STIX]{x1D703}_{e}$

. Also,

![]() $W=T/2$

(planar) or

$W=T/2$

(planar) or

![]() $W=R$

(cylindrical), while

$W=R$

(cylindrical), while

![]() $z=z_{s}(\unicode[STIX]{x1D709})$

is the steady shock shape, aligned so that

$z=z_{s}(\unicode[STIX]{x1D709})$

is the steady shock shape, aligned so that

![]() $z_{s}(0)=0.$

$z_{s}(0)=0.$

The Jacobian

should be positive to ensure an appropriate mapping from

![]() $(r,z)$

to

$(r,z)$

to

![]() $(\unicode[STIX]{x1D709},\unicode[STIX]{x1D702})$

. This generates the coordinate system shown in figure 2(b), where

$(\unicode[STIX]{x1D709},\unicode[STIX]{x1D702})$

. This generates the coordinate system shown in figure 2(b), where

![]() $\unicode[STIX]{x1D702}=0$

is the transformed shock position,

$\unicode[STIX]{x1D702}=0$

is the transformed shock position,

![]() $\unicode[STIX]{x1D709}=W$

is the location of the deflected streamline boundary and

$\unicode[STIX]{x1D709}=W$

is the location of the deflected streamline boundary and

![]() $\unicode[STIX]{x1D709}=0$

represents the axis of symmetry. Boundary conditions are applied along

$\unicode[STIX]{x1D709}=0$

represents the axis of symmetry. Boundary conditions are applied along

![]() $\unicode[STIX]{x1D702}=0,\unicode[STIX]{x1D709}=0$

and

$\unicode[STIX]{x1D702}=0,\unicode[STIX]{x1D709}=0$

and

![]() $\unicode[STIX]{x1D709}=W,$

thus reducing the problem to consideration of the flow domain

$\unicode[STIX]{x1D709}=W,$

thus reducing the problem to consideration of the flow domain

![]() $\unicode[STIX]{x1D702}\leqslant 0$

and

$\unicode[STIX]{x1D702}\leqslant 0$

and

![]() $0\leqslant \unicode[STIX]{x1D709}\leqslant W.$

$0\leqslant \unicode[STIX]{x1D709}\leqslant W.$

Under (3.1), the steady version of the flow (2.1) becomes

where

and

Symmetry conditions are applied along the central axis (

![]() $\unicode[STIX]{x1D709}=0$

), while along the boundary streamline (

$\unicode[STIX]{x1D709}=0$

), while along the boundary streamline (

![]() $\unicode[STIX]{x1D709}=W$

) the only condition to be applied is that the normal flow component is zero, giving

$\unicode[STIX]{x1D709}=W$

) the only condition to be applied is that the normal flow component is zero, giving

On the shock front, the flow solution is determined from the jump conditions (2.6) as a function of

![]() $D_{n,s}=D_{n,s}(\unicode[STIX]{x1D709}),$

where, from the geometric shock surface evolution,

$D_{n,s}=D_{n,s}(\unicode[STIX]{x1D709}),$

where, from the geometric shock surface evolution,

4 Thin channel, strong confinement, asymptotic analysis

Based on the discussion in § 1, we look for strong confinement solutions in which the lateral extent of the charge is smaller than the detonation driving zone thickness, the latter of which is characterized spatially by

![]() $\unicode[STIX]{x1D702}=O(1)$

. Consequently, we set

$\unicode[STIX]{x1D702}=O(1)$

. Consequently, we set

![]() $\unicode[STIX]{x1D709}=O(\unicode[STIX]{x1D6FF}),\unicode[STIX]{x1D6FF}\ll 1,$

with

$\unicode[STIX]{x1D709}=O(\unicode[STIX]{x1D6FF}),\unicode[STIX]{x1D6FF}\ll 1,$

with

![]() $W=O(\unicode[STIX]{x1D6FF}).$

We are then left with the objective of setting a scale on the boundary streamline gradient

$W=O(\unicode[STIX]{x1D6FF}).$

We are then left with the objective of setting a scale on the boundary streamline gradient

![]() $m_{e}$

. As noted in § 1, our aim is to develop a theory that can describe detonation propagation and failure regimes in which the detonation speed

$m_{e}$

. As noted in § 1, our aim is to develop a theory that can describe detonation propagation and failure regimes in which the detonation speed

![]() $D_{0}$

departs from

$D_{0}$

departs from

![]() $D_{CJ}$

by

$D_{CJ}$

by

![]() $O(1)$

amounts, such that

$O(1)$

amounts, such that

![]() $1-D_{0}/D_{CJ}=O(1).$

In the absence of any boundary streamline deflection (

$1-D_{0}/D_{CJ}=O(1).$

In the absence of any boundary streamline deflection (

![]() $m_{e}=0$

), the leading-order solution is a detonation wave propagating at the Chapman–Jouguet speed

$m_{e}=0$

), the leading-order solution is a detonation wave propagating at the Chapman–Jouguet speed

![]() $D_{CJ}.$

Consequently, the streamline gradient must be sufficient in magnitude so that the induced rate of change of mass flux through the detonation, and thereby the associated energy change, from the boundary streamline deflection directly influences the determination of the leading-order detonation structure, thus resulting in departures of

$D_{CJ}.$

Consequently, the streamline gradient must be sufficient in magnitude so that the induced rate of change of mass flux through the detonation, and thereby the associated energy change, from the boundary streamline deflection directly influences the determination of the leading-order detonation structure, thus resulting in departures of

![]() $D_{0}/D_{CJ}$

from one by

$D_{0}/D_{CJ}$

from one by

![]() $O(1)$

amounts. As is apparent below, this can only be achieved if the boundary streamline gradient behind the shock is similar in magnitude, asymptotically, to the lateral charge size, i.e.

$O(1)$

amounts. As is apparent below, this can only be achieved if the boundary streamline gradient behind the shock is similar in magnitude, asymptotically, to the lateral charge size, i.e.

![]() $O(\unicode[STIX]{x1D6FF})$

. Thus we also set

$O(\unicode[STIX]{x1D6FF})$

. Thus we also set

![]() $m_{e}=O(\unicode[STIX]{x1D6FF}),$

with

$m_{e}=O(\unicode[STIX]{x1D6FF}),$

with

![]() $h^{\prime }(\unicode[STIX]{x1D702})=O(1).$

Concurrently, the magnitude of the shock slope variation due to the boundary streamline deflection is

$h^{\prime }(\unicode[STIX]{x1D702})=O(1).$

Concurrently, the magnitude of the shock slope variation due to the boundary streamline deflection is

![]() $O(\unicode[STIX]{x1D6FF}).$

Consideration of other scalings on

$O(\unicode[STIX]{x1D6FF}).$

Consideration of other scalings on

![]() $m_{e}$

such that

$m_{e}$

such that

![]() $m_{e}=o(\unicode[STIX]{x1D6FF})$

, for example

$m_{e}=o(\unicode[STIX]{x1D6FF})$

, for example

![]() $m_{e}=O(\unicode[STIX]{x1D6FF}^{2})$

, would result in the leading-order solution remaining as a detonation wave propagating at speed

$m_{e}=O(\unicode[STIX]{x1D6FF}^{2})$

, would result in the leading-order solution remaining as a detonation wave propagating at speed

![]() $D_{CJ},$

and a resulting theory would only describe departures of

$D_{CJ},$

and a resulting theory would only describe departures of

![]() $D_{0}/D_{CJ}$

from one by

$D_{0}/D_{CJ}$

from one by

![]() $O(\unicode[STIX]{x1D6FF})$

amounts. This limit is not of interest for the phenomena we wish to capture in the current study. In addition, the latter weaker limit is likely to be included within the richer limit

$O(\unicode[STIX]{x1D6FF})$

amounts. This limit is not of interest for the phenomena we wish to capture in the current study. In addition, the latter weaker limit is likely to be included within the richer limit

![]() $m_{e}=O(\unicode[STIX]{x1D6FF})$

considered in this paper.

$m_{e}=O(\unicode[STIX]{x1D6FF})$

considered in this paper.

These balance arguments lead to the introduction of the scaled variables,

so that

giving

![]() $\unicode[STIX]{x2202}z_{s}/\unicode[STIX]{x2202}\unicode[STIX]{x1D709}=\unicode[STIX]{x1D6FF}\unicode[STIX]{x2202}\hat{z}_{s}/\unicode[STIX]{x2202}\hat{\unicode[STIX]{x1D709}},$

and

$\unicode[STIX]{x2202}z_{s}/\unicode[STIX]{x2202}\unicode[STIX]{x1D709}=\unicode[STIX]{x1D6FF}\unicode[STIX]{x2202}\hat{z}_{s}/\unicode[STIX]{x2202}\hat{\unicode[STIX]{x1D709}},$

and

With this, the shock normal speed

![]() $D_{n,s}=D_{0}+O(\unicode[STIX]{x1D6FF}^{2})$

from (3.7). Balance arguments for the shock conditions and flow equations then lead us to consider

$D_{n,s}=D_{0}+O(\unicode[STIX]{x1D6FF}^{2})$

from (3.7). Balance arguments for the shock conditions and flow equations then lead us to consider

![]() $O(\unicode[STIX]{x1D6FF})$

changes in the lateral flow velocity component, and thus we define

$O(\unicode[STIX]{x1D6FF})$

changes in the lateral flow velocity component, and thus we define

We now seek solutions for which

all have

![]() $O(1)$

variation. The normal flow velocity component at the shock becomes

$O(1)$

variation. The normal flow velocity component at the shock becomes

![]() $u_{n,s}=u_{z}^{0}+O(\unicode[STIX]{x1D6FF}^{2}),$

so that, to leading order, (2.6) become

$u_{n,s}=u_{z}^{0}+O(\unicode[STIX]{x1D6FF}^{2}),$

so that, to leading order, (2.6) become

at

![]() $\unicode[STIX]{x1D702}=0.$

The shock tangential flow condition,

$\unicode[STIX]{x1D702}=0.$

The shock tangential flow condition,

![]() $u_{t,s}=0,$

also gives

$u_{t,s}=0,$

also gives

while the symmetry and boundary streamline conditions (3.6) lead to

With the axial detonation phase speed

![]() $D_{0}$

constant for steady flows, guided by the shock relations (4.6), we now seek solutions of the scaled flow equations

$D_{0}$

constant for steady flows, guided by the shock relations (4.6), we now seek solutions of the scaled flow equations

for which

In general, for each flow vector component, we find

![]() $\boldsymbol{F}_{\unicode[STIX]{x1D743}}=O(\unicode[STIX]{x1D6FF}),\boldsymbol{F}_{\!\boldsymbol{\unicode[STIX]{x1D702}}}=O(1)$

and

$\boldsymbol{F}_{\unicode[STIX]{x1D743}}=O(\unicode[STIX]{x1D6FF}),\boldsymbol{F}_{\!\boldsymbol{\unicode[STIX]{x1D702}}}=O(1)$

and

![]() $\boldsymbol{G}=O(1),$

with the leading-order balance for each component occurring at

$\boldsymbol{G}=O(1),$

with the leading-order balance for each component occurring at

![]() $O(\unicode[STIX]{x1D6FF})$

in (4.9).

$O(\unicode[STIX]{x1D6FF})$

in (4.9).

For the continuity equation,

Integrating, and applying the symmetry condition (4.8),

so that

![]() $\hat{u} _{r}^{1}$

increases linearly with

$\hat{u} _{r}^{1}$

increases linearly with

![]() $\hat{\unicode[STIX]{x1D709}}.$

Then, applying the boundary streamline condition (4.8) on

$\hat{\unicode[STIX]{x1D709}}.$

Then, applying the boundary streamline condition (4.8) on

![]() $\hat{u} _{r}^{1},$

$\hat{u} _{r}^{1},$

which can be integrated to give

after the use of the first of the shock relations (4.6). Consequently, the boundary streamline deflection induces a

![]() $|J^{0}|^{-1-s}$

change in the mass flux magnitude through the wave relative to its shock value (

$|J^{0}|^{-1-s}$

change in the mass flux magnitude through the wave relative to its shock value (

![]() $\unicode[STIX]{x1D70C}_{0}D_{0}$

), where

$\unicode[STIX]{x1D70C}_{0}D_{0}$

), where

![]() $|J^{0}|=1-\hat{m}_{e}h(\unicode[STIX]{x1D702})/{\hat{W}}$

. Geometrically,

$|J^{0}|=1-\hat{m}_{e}h(\unicode[STIX]{x1D702})/{\hat{W}}$

. Geometrically,

![]() $|J^{0}|$

simply represents the ratio of the modified domain width

$|J^{0}|$

simply represents the ratio of the modified domain width

![]() $r={\hat{W}}-\hat{m}_{e}h(\unicode[STIX]{x1D702})$

relative to the initial HE width

$r={\hat{W}}-\hat{m}_{e}h(\unicode[STIX]{x1D702})$

relative to the initial HE width

![]() $r={\hat{W}}$

at any

$r={\hat{W}}$

at any

![]() $\unicode[STIX]{x1D702}$

, i.e. it is a stretch factor. For

$\unicode[STIX]{x1D702}$

, i.e. it is a stretch factor. For

![]() $\hat{m}_{e}>0$

and

$\hat{m}_{e}>0$

and

![]() $h^{\prime }(\unicode[STIX]{x1D702})>0(h^{\prime }(0)=1)$

, covering the majority of boundary streamline deflection cases studied later in § 6, where

$h^{\prime }(\unicode[STIX]{x1D702})>0(h^{\prime }(0)=1)$

, covering the majority of boundary streamline deflection cases studied later in § 6, where

![]() $-\hat{m}_{e}h(\unicode[STIX]{x1D702})>0$

and increasing in magnitude with increasing distance behind the shock, the magnitude of the mass flux monotonically decreases through the wave. For such cases, a curved boundary streamline in which

$-\hat{m}_{e}h(\unicode[STIX]{x1D702})>0$

and increasing in magnitude with increasing distance behind the shock, the magnitude of the mass flux monotonically decreases through the wave. For such cases, a curved boundary streamline in which

![]() $h^{\prime }(\unicode[STIX]{x1D702})$

decreases from its shock value,

$h^{\prime }(\unicode[STIX]{x1D702})$

decreases from its shock value,

![]() $h^{\prime }(0)=1,$

leads to a lowering of the rate at which the mass flux decreases through the wave, relative to a boundary streamline deflection that is assumed straight

$h^{\prime }(0)=1,$

leads to a lowering of the rate at which the mass flux decreases through the wave, relative to a boundary streamline deflection that is assumed straight

![]() $(h^{\prime }(\unicode[STIX]{x1D702})=1)$

. For one confinement case studied in § 6.2 where

$(h^{\prime }(\unicode[STIX]{x1D702})=1)$

. For one confinement case studied in § 6.2 where

![]() $m_{e}<0,$

i.e. the boundary streamline is initially deflected into the HE, the magnitude of the mass flux monotonically increases relative to its shock value in the region behind the shock front where

$m_{e}<0,$

i.e. the boundary streamline is initially deflected into the HE, the magnitude of the mass flux monotonically increases relative to its shock value in the region behind the shock front where

![]() $h^{\prime }(\unicode[STIX]{x1D702})>0.$

$h^{\prime }(\unicode[STIX]{x1D702})>0.$

Returning to (4.12), we can now write

![]() $\hat{u} _{r}^{1}$

in the form

$\hat{u} _{r}^{1}$

in the form

With this, the tangential shock condition (4.7) gives the shock slope,

so that the shock shape is given by

noting that

![]() $h^{\prime }(0)=1$

and

$h^{\prime }(0)=1$

and

![]() $\hat{z}_{s}(0)=0$

by definition. With the aid of (4.12) and (4.14), the leading-order axial momentum equation results in

$\hat{z}_{s}(0)=0$

by definition. With the aid of (4.12) and (4.14), the leading-order axial momentum equation results in

with the leading-order rate equation resulting in

Consideration of the energy equation remains to close the system. After using (4.12), the leading-order energy equation results in

Noting that

![]() $E=e+((u_{z}^{0})^{2}+\unicode[STIX]{x1D6FF}^{2}(\hat{u} _{r}^{1})^{2})/2,$

and

$E=e+((u_{z}^{0})^{2}+\unicode[STIX]{x1D6FF}^{2}(\hat{u} _{r}^{1})^{2})/2,$

and

![]() $\text{d}e/\text{d}\unicode[STIX]{x1D702}=e_{,p}\,\text{d}p/\text{d}\unicode[STIX]{x1D702}+e_{,\unicode[STIX]{x1D70C}}\,\text{d}\unicode[STIX]{x1D70C}/\text{d}\unicode[STIX]{x1D702}+e_{,\unicode[STIX]{x1D706}}\text{d}\unicode[STIX]{x1D706}/\text{d}\unicode[STIX]{x1D702},$

where

$\text{d}e/\text{d}\unicode[STIX]{x1D702}=e_{,p}\,\text{d}p/\text{d}\unicode[STIX]{x1D702}+e_{,\unicode[STIX]{x1D70C}}\,\text{d}\unicode[STIX]{x1D70C}/\text{d}\unicode[STIX]{x1D702}+e_{,\unicode[STIX]{x1D706}}\text{d}\unicode[STIX]{x1D706}/\text{d}\unicode[STIX]{x1D702},$

where

![]() $\{~\}_{,p}=\unicode[STIX]{x2202}\{~\}/\unicode[STIX]{x2202}p$

etc., and then using (4.14), (4.18) and (4.19) to eliminate

$\{~\}_{,p}=\unicode[STIX]{x2202}\{~\}/\unicode[STIX]{x2202}p$

etc., and then using (4.14), (4.18) and (4.19) to eliminate

![]() $\text{d}p^{0}/\text{d}\unicode[STIX]{x1D702},\text{d}\unicode[STIX]{x1D70C}^{0}/\text{d}\unicode[STIX]{x1D702}$

and

$\text{d}p^{0}/\text{d}\unicode[STIX]{x1D702},\text{d}\unicode[STIX]{x1D70C}^{0}/\text{d}\unicode[STIX]{x1D702}$

and

![]() $\text{d}\unicode[STIX]{x1D706}^{0}/\text{d}\unicode[STIX]{x1D702},$

we can rewrite the energy equation (4.20) with the only derivatives in

$\text{d}\unicode[STIX]{x1D706}^{0}/\text{d}\unicode[STIX]{x1D702},$

we can rewrite the energy equation (4.20) with the only derivatives in

![]() $\unicode[STIX]{x1D702}$

associated with

$\unicode[STIX]{x1D702}$

associated with

![]() $u_{z}^{0},$

$u_{z}^{0},$

Equations (4.14), (4.18), (4.19) and (4.21) are solved subject to shock relations (4.6) at

![]() $\unicode[STIX]{x1D702}=0.$

An implication of (4.21) is that the system contains a saddle point when the axial flow becomes sonic, i.e. when

$\unicode[STIX]{x1D702}=0.$

An implication of (4.21) is that the system contains a saddle point when the axial flow becomes sonic, i.e. when

![]() $(u_{z}^{0}-D_{0})^{2}=(c^{0})^{2}.$

This equates to an eigenvalue problem for the detonation phase speed

$(u_{z}^{0}-D_{0})^{2}=(c^{0})^{2}.$

This equates to an eigenvalue problem for the detonation phase speed

![]() $D_{0},$

such that any trajectory passing through the sonic flow saddle point, subject to (4.6), must involve the cancellation of the two terms on the right-hand side of (4.21) at the saddle point. For specific choices of the reaction rate and equation of state (see § 5), this would typically necessitate the use of a shooting method, iterating on

$D_{0},$

such that any trajectory passing through the sonic flow saddle point, subject to (4.6), must involve the cancellation of the two terms on the right-hand side of (4.21) at the saddle point. For specific choices of the reaction rate and equation of state (see § 5), this would typically necessitate the use of a shooting method, iterating on

![]() $D_{0}$

until the appropriate trajectory for

$D_{0}$

until the appropriate trajectory for

![]() $u_{z}^{0}(\unicode[STIX]{x1D702})$

is found that can pass through the saddle. Of particular significance in (4.14), (4.18), (4.19) and (4.21) is that, for any fixed streamline deflection component

$u_{z}^{0}(\unicode[STIX]{x1D702})$

is found that can pass through the saddle. Of particular significance in (4.14), (4.18), (4.19) and (4.21) is that, for any fixed streamline deflection component

![]() $h(\unicode[STIX]{x1D702}),$

the solution depends only on the ratio

$h(\unicode[STIX]{x1D702}),$

the solution depends only on the ratio

![]() $\hat{m}_{e}/{\hat{W}}.$

Thus once one thickness effect curve (

$\hat{m}_{e}/{\hat{W}}.$

Thus once one thickness effect curve (

![]() $D_{0}$

versus

$D_{0}$

versus

![]() $\hat{m}_{e}/{\hat{W}}$

) has been calculated, for example for varying

$\hat{m}_{e}/{\hat{W}}$

) has been calculated, for example for varying

![]() $\hat{m}_{e}$

at fixed

$\hat{m}_{e}$

at fixed

![]() ${\hat{W}}$

, the variation is known for all

${\hat{W}}$

, the variation is known for all

![]() ${\hat{W}}.$

${\hat{W}}.$

Physically, the left-hand side of (4.21) is related to the longitudinal propagation and advection of acoustic and kinetic energy. The first term on the right-hand side represents an energy deposition due to chemical reaction that serves to accelerate the longitudinal flow from a subsonic state immediately behind the shock to a downstream sonic state. It is always positive for an irreversible reaction. The second term on the right-hand side of (4.21) is an energy contribution resulting from the effects of the boundary streamline deflection, specifically the induced rate of change of mass flux through the wave (this term can alternatively be written as

![]() $+((c^{0})^{2}/\unicode[STIX]{x1D70C}^{0})~\text{d}/\text{d}\unicode[STIX]{x1D702}[\unicode[STIX]{x1D70C}^{0}(u_{z}^{0}-D_{0})].$

It serves to either counteract or reinforce the acceleration of longitudinal flow depending on the sign of the gradient of the streamline deflection,

$+((c^{0})^{2}/\unicode[STIX]{x1D70C}^{0})~\text{d}/\text{d}\unicode[STIX]{x1D702}[\unicode[STIX]{x1D70C}^{0}(u_{z}^{0}-D_{0})].$

It serves to either counteract or reinforce the acceleration of longitudinal flow depending on the sign of the gradient of the streamline deflection,

![]() $-m_{e}h^{\prime }(\unicode[STIX]{x1D702}).$

For

$-m_{e}h^{\prime }(\unicode[STIX]{x1D702}).$

For

![]() $m_{e}>0$

and

$m_{e}>0$

and

![]() $h^{\prime }(\unicode[STIX]{x1D702})>0,$

i.e. where the boundary streamline moves outward, the term is negative and thus serves to reduce the energy available to drive the longitudinal flow acceleration. The larger the magnitude of the streamline deflection, the greater the associated energy loss, consequently reducing the magnitude of the eigenvalue solution

$h^{\prime }(\unicode[STIX]{x1D702})>0,$

i.e. where the boundary streamline moves outward, the term is negative and thus serves to reduce the energy available to drive the longitudinal flow acceleration. The larger the magnitude of the streamline deflection, the greater the associated energy loss, consequently reducing the magnitude of the eigenvalue solution

![]() $D_{0}.$

As will be seen in § 6, for too large an energy loss, there is no eigenvalue solution for

$D_{0}.$

As will be seen in § 6, for too large an energy loss, there is no eigenvalue solution for

![]() $D_{0},$

corresponding to the loss of steady flow solutions. For

$D_{0},$

corresponding to the loss of steady flow solutions. For

![]() $m_{e}<0,$

where the boundary streamline deflection is inward at least initially, i.e. when

$m_{e}<0,$

where the boundary streamline deflection is inward at least initially, i.e. when

![]() $-m_{e}h^{\prime }(\unicode[STIX]{x1D702})>0$

, the rate of change of mass flux is positive, an effect which supports the longitudinal acceleration of the flow. As will be seen in § 6, this latter scenario can result in the eigenvalue solution

$-m_{e}h^{\prime }(\unicode[STIX]{x1D702})>0$

, the rate of change of mass flux is positive, an effect which supports the longitudinal acceleration of the flow. As will be seen in § 6, this latter scenario can result in the eigenvalue solution

![]() $D_{0}$

rising above

$D_{0}$

rising above

![]() $D_{CJ}.$

Finally, based on the form of the energy change resulting from the boundary streamline deflection, being proportional to

$D_{CJ}.$

Finally, based on the form of the energy change resulting from the boundary streamline deflection, being proportional to

![]() $h^{\prime }(\unicode[STIX]{x1D702})$

, we expect that curvature of the boundary streamline will play a significant role in determining the detonation propagation and failure properties.

$h^{\prime }(\unicode[STIX]{x1D702})$

, we expect that curvature of the boundary streamline will play a significant role in determining the detonation propagation and failure properties.

4.1 HE streamlines shapes

After specifying the boundary streamline shape, the steady flow streamline paths within the HE region can also be calculated. To leading order these are determined by

after using (4.14) and (4.15). Integrating gives

with

![]() $\unicode[STIX]{x1D6FC}(0\leqslant \unicode[STIX]{x1D6FC}\leqslant 1)$

signifying the streamline label. The symmetry line

$\unicode[STIX]{x1D6FC}(0\leqslant \unicode[STIX]{x1D6FC}\leqslant 1)$

signifying the streamline label. The symmetry line

![]() $r=0$

is a streamline, with the streamline gradient along the shock

$r=0$

is a streamline, with the streamline gradient along the shock

![]() $(\unicode[STIX]{x1D702}=0)$

increasing from the symmetry line to the boundary. The gradient of a given HE streamline at any

$(\unicode[STIX]{x1D702}=0)$

increasing from the symmetry line to the boundary. The gradient of a given HE streamline at any

![]() $\unicode[STIX]{x1D702}$

is a fixed multiple of the corresponding boundary streamline gradient. Consequently, the HE streamlines bend toward the symmetry axis if the boundary streamline also bends in that direction (§ 6.2).

$\unicode[STIX]{x1D702}$

is a fixed multiple of the corresponding boundary streamline gradient. Consequently, the HE streamlines bend toward the symmetry axis if the boundary streamline also bends in that direction (§ 6.2).

5 Equation of state and reaction rate models

The analysis above is valid for any equation of state (EOS) and reaction rate law. We now present results for both the ideal and stiffened condensed-phase detonation models (Short, Bdzil & Anguelova Reference Short, Bdzil and Anguelova2006; Short et al.

Reference Short, Anguelova, Aslam, Bdzil, Henrick and Sharpe2008), whereupon the EOS model for the internal energy,

![]() $e$

, the specific reaction enthalpy of the HE,

$e$

, the specific reaction enthalpy of the HE,

![]() $q(=\tilde{q}/\tilde{u} _{ref}^{2})$

, and frozen sound speed,

$q(=\tilde{q}/\tilde{u} _{ref}^{2})$

, and frozen sound speed,

![]() $c$

, are given by

$c$

, are given by

respectively, where

![]() $\unicode[STIX]{x1D6FE}$

is the adiabatic exponent,

$\unicode[STIX]{x1D6FE}$

is the adiabatic exponent,

![]() $A$

is the stiffened constant and, as before,

$A$

is the stiffened constant and, as before,

![]() $\unicode[STIX]{x1D70C}_{0}$

is the initial density of the HE and

$\unicode[STIX]{x1D70C}_{0}$

is the initial density of the HE and

![]() $D_{CJ}$

is the Chapman–Jouguet speed. The ideal condensed-phase model (Short et al.

Reference Short, Anguelova, Aslam, Bdzil, Henrick and Sharpe2008; Chiquete & Short Reference Chiquete and Short2019) is recovered by setting

$D_{CJ}$

is the Chapman–Jouguet speed. The ideal condensed-phase model (Short et al.

Reference Short, Anguelova, Aslam, Bdzil, Henrick and Sharpe2008; Chiquete & Short Reference Chiquete and Short2019) is recovered by setting

![]() $A=0.$

Having

$A=0.$

Having

![]() $A>0$

allows for a non-zero sound speed in the unshocked explosive (Short & Quirk Reference Short and Quirk2018b

), since the initial pressure

$A>0$

allows for a non-zero sound speed in the unshocked explosive (Short & Quirk Reference Short and Quirk2018b

), since the initial pressure

![]() $p_{0}=0$

. The parameter

$p_{0}=0$

. The parameter

![]() $A$

mimics the effects of molecular attraction in solid- or liquid-state matter (Le Métayer & Saurel Reference Le Métayer and Saurel2016). The required partial derivatives of

$A$

mimics the effects of molecular attraction in solid- or liquid-state matter (Le Métayer & Saurel Reference Le Métayer and Saurel2016). The required partial derivatives of

![]() $e$

in (5.1) are

$e$

in (5.1) are

The reaction rate,

![]() $\unicode[STIX]{x1D6EC}$

, is pressure dependent and given by

$\unicode[STIX]{x1D6EC}$

, is pressure dependent and given by

where

![]() $k$

is a rate constant,

$k$

is a rate constant,

![]() $n$

is the pressure exponent and

$n$

is the pressure exponent and

![]() $\unicode[STIX]{x1D708}$

is a reaction-order variable. Variations of the above model have been used to study the flow physics of a variety of detonation confinement problems, e.g. Bdzil (Reference Bdzil1981), Sharpe & Braithwaite (Reference Sharpe and Braithwaite2005), Short et al. (Reference Short, Quirk, Chiquete and Meyer2018) and Short & Quirk (Reference Short and Quirk2018a

,Reference Short and Quirk

b

). The model has consistently captured the primary detonation flow physics that are present when more complex equation- of state and reaction rate models are used. The fixed model parameter choices are (Short & Quirk Reference Short and Quirk2018b

; Short et al.

Reference Short, Quirk, Chiquete and Meyer2018; Chiquete & Short Reference Chiquete and Short2019)

$\unicode[STIX]{x1D708}$

is a reaction-order variable. Variations of the above model have been used to study the flow physics of a variety of detonation confinement problems, e.g. Bdzil (Reference Bdzil1981), Sharpe & Braithwaite (Reference Sharpe and Braithwaite2005), Short et al. (Reference Short, Quirk, Chiquete and Meyer2018) and Short & Quirk (Reference Short and Quirk2018a

,Reference Short and Quirk

b

). The model has consistently captured the primary detonation flow physics that are present when more complex equation- of state and reaction rate models are used. The fixed model parameter choices are (Short & Quirk Reference Short and Quirk2018b

; Short et al.

Reference Short, Quirk, Chiquete and Meyer2018; Chiquete & Short Reference Chiquete and Short2019)

Below, we explore the detonation dynamics for changes in

![]() $A$

,

$A$

,

![]() $n$

and

$n$

and

![]() $\unicode[STIX]{x1D708}.$

Finally, for the ideal and stiffened models, the shock conditions (4.6) become

$\unicode[STIX]{x1D708}.$

Finally, for the ideal and stiffened models, the shock conditions (4.6) become

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}u_{z,s}^{0}={\displaystyle \frac{2D_{0}}{\unicode[STIX]{x1D6FE}+1}}\left(1-{\displaystyle \frac{A}{\unicode[STIX]{x1D70C}_{0}D_{0}^{2}}}\right),\quad p_{s}^{0}=2{\displaystyle \frac{\unicode[STIX]{x1D70C}_{0}D_{0}^{2}}{\unicode[STIX]{x1D6FE}+1}}\left(1-{\displaystyle \frac{A}{\unicode[STIX]{x1D70C}_{0}D_{0}^{2}}}\right),\\ \unicode[STIX]{x1D70C}_{s}^{0}=(\unicode[STIX]{x1D6FE}+1)\unicode[STIX]{x1D70C}_{0}\left[\unicode[STIX]{x1D6FE}-1+{\displaystyle \frac{2A}{\unicode[STIX]{x1D70C}_{0}D_{0}^{2}}}\right]^{-1},\quad \unicode[STIX]{x1D706}_{s}^{0}=0.\end{array}\right\}\end{eqnarray}$$

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}u_{z,s}^{0}={\displaystyle \frac{2D_{0}}{\unicode[STIX]{x1D6FE}+1}}\left(1-{\displaystyle \frac{A}{\unicode[STIX]{x1D70C}_{0}D_{0}^{2}}}\right),\quad p_{s}^{0}=2{\displaystyle \frac{\unicode[STIX]{x1D70C}_{0}D_{0}^{2}}{\unicode[STIX]{x1D6FE}+1}}\left(1-{\displaystyle \frac{A}{\unicode[STIX]{x1D70C}_{0}D_{0}^{2}}}\right),\\ \unicode[STIX]{x1D70C}_{s}^{0}=(\unicode[STIX]{x1D6FE}+1)\unicode[STIX]{x1D70C}_{0}\left[\unicode[STIX]{x1D6FE}-1+{\displaystyle \frac{2A}{\unicode[STIX]{x1D70C}_{0}D_{0}^{2}}}\right]^{-1},\quad \unicode[STIX]{x1D706}_{s}^{0}=0.\end{array}\right\}\end{eqnarray}$$

With (5.1) and (5.2), the energy equation (4.21) becomes

Thus, the chemical energy deposition term,

![]() $(\unicode[STIX]{x1D6FE}-1)q\unicode[STIX]{x1D6EC},$

only varies with the reaction rate for constant

$(\unicode[STIX]{x1D6FE}-1)q\unicode[STIX]{x1D6EC},$

only varies with the reaction rate for constant

![]() $\unicode[STIX]{x1D6FE}$

and

$\unicode[STIX]{x1D6FE}$

and

![]() $q$

. Also, we have, without loss of generality, reverted to the use of the unscaled quantities

$q$

. Also, we have, without loss of generality, reverted to the use of the unscaled quantities

![]() $m_{e}=\unicode[STIX]{x1D6FF}\hat{m}_{e}$

and

$m_{e}=\unicode[STIX]{x1D6FF}\hat{m}_{e}$

and

![]() $W=\unicode[STIX]{x1D6FF}{\hat{W}}$

, where

$W=\unicode[STIX]{x1D6FF}{\hat{W}}$

, where

![]() $m_{e}$

and

$m_{e}$

and

![]() $W$

represent physically measurable quantities. For the purposes of discussion in § 6, we now write (5.6) in the form

$W$

represent physically measurable quantities. For the purposes of discussion in § 6, we now write (5.6) in the form

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}\unicode[STIX]{x1D714}{\displaystyle \frac{\text{d}u_{z}^{0}}{\text{d}\unicode[STIX]{x1D702}}}=(\unicode[STIX]{x1D6FE}-1)q\unicode[STIX]{x1D6EC}-\unicode[STIX]{x1D70E},\quad \unicode[STIX]{x1D714}=(c^{0})^{2}-(u_{z}^{0}-D_{0})^{2},\\ \unicode[STIX]{x1D70E}={\displaystyle \frac{(c^{0})^{2}}{\unicode[STIX]{x1D70C}^{0}}}\unicode[STIX]{x1D70C}_{0}D_{0}(1+s)\left[1-{\displaystyle \frac{m_{e}}{W}}h(\unicode[STIX]{x1D702})\right]^{-(2+s)}{\displaystyle \frac{m_{e}}{W}}h^{\prime }(\unicode[STIX]{x1D702}),\end{array}\right\}\end{eqnarray}$$

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}\unicode[STIX]{x1D714}{\displaystyle \frac{\text{d}u_{z}^{0}}{\text{d}\unicode[STIX]{x1D702}}}=(\unicode[STIX]{x1D6FE}-1)q\unicode[STIX]{x1D6EC}-\unicode[STIX]{x1D70E},\quad \unicode[STIX]{x1D714}=(c^{0})^{2}-(u_{z}^{0}-D_{0})^{2},\\ \unicode[STIX]{x1D70E}={\displaystyle \frac{(c^{0})^{2}}{\unicode[STIX]{x1D70C}^{0}}}\unicode[STIX]{x1D70C}_{0}D_{0}(1+s)\left[1-{\displaystyle \frac{m_{e}}{W}}h(\unicode[STIX]{x1D702})\right]^{-(2+s)}{\displaystyle \frac{m_{e}}{W}}h^{\prime }(\unicode[STIX]{x1D702}),\end{array}\right\}\end{eqnarray}$$

where

![]() $\unicode[STIX]{x1D714}$

is a sonic flow parameter and

$\unicode[STIX]{x1D714}$

is a sonic flow parameter and

![]() $\unicode[STIX]{x1D70E}$

is the energy change associated with the rate of change of mass flux through the detonation. The detonation speed eigenvalue

$\unicode[STIX]{x1D70E}$

is the energy change associated with the rate of change of mass flux through the detonation. The detonation speed eigenvalue

![]() $D_{0}$

for the asymptotically derived system (5.7), given any geometry parameters

$D_{0}$

for the asymptotically derived system (5.7), given any geometry parameters

![]() $s$

and

$s$

and

![]() $W$

and confinement conditions specified by

$W$

and confinement conditions specified by

![]() $m_{e}$

and

$m_{e}$

and

![]() $h(\unicode[STIX]{x1D702})$

, is determined by a shooting method similar to that described in § 4. Specifically, we make an initial guess for the eigenvalue

$h(\unicode[STIX]{x1D702})$

, is determined by a shooting method similar to that described in § 4. Specifically, we make an initial guess for the eigenvalue

![]() $D_{0}.$

With that

$D_{0}.$

With that

![]() $D_{0}$

, the shock condition at

$D_{0}$

, the shock condition at

![]() $\unicode[STIX]{x1D702}=0$

for

$\unicode[STIX]{x1D702}=0$

for

![]() $u_{z}^{0}$

is given by (5.5), whereupon the ordinary differential equation for

$u_{z}^{0}$

is given by (5.5), whereupon the ordinary differential equation for

![]() $u_{z}^{0}(\unicode[STIX]{x1D702})$

, given by (5.7), is integrated numerically. Note that this also requires the determination of

$u_{z}^{0}(\unicode[STIX]{x1D702})$

, given by (5.7), is integrated numerically. Note that this also requires the determination of

![]() $p^{0}(\unicode[STIX]{x1D702}),\unicode[STIX]{x1D70C}^{0}(\unicode[STIX]{x1D702})$

and

$p^{0}(\unicode[STIX]{x1D702}),\unicode[STIX]{x1D70C}^{0}(\unicode[STIX]{x1D702})$

and

![]() $\unicode[STIX]{x1D706}^{0}(\unicode[STIX]{x1D702})$

obtained from the simultaneous integration of (4.18) and (4.19) and the use of (4.14). The eigenvalue

$\unicode[STIX]{x1D706}^{0}(\unicode[STIX]{x1D702})$

obtained from the simultaneous integration of (4.18) and (4.19) and the use of (4.14). The eigenvalue

![]() $D_{0}$

is then iterated on until the (positive) rate term

$D_{0}$

is then iterated on until the (positive) rate term

![]() $(\unicode[STIX]{x1D6FE}-1)q\unicode[STIX]{x1D6EC}$

and (negative) energy change term

$(\unicode[STIX]{x1D6FE}-1)q\unicode[STIX]{x1D6EC}$

and (negative) energy change term

![]() $\unicode[STIX]{x1D70E}$

exactly cancel at the sonic flow point (

$\unicode[STIX]{x1D70E}$

exactly cancel at the sonic flow point (

![]() $\unicode[STIX]{x1D714}=0$

), allowing the trajectory for

$\unicode[STIX]{x1D714}=0$

), allowing the trajectory for

![]() $u_{z}^{0}(\unicode[STIX]{x1D702})$

to pass through the saddle point.

$u_{z}^{0}(\unicode[STIX]{x1D702})$

to pass through the saddle point.

It remains to set the reference length scale that we will use for clarity of presentation of the asymptotic results. In § 6, we will set

![]() $\tilde{l}_{ref}$

to be the familiar and standard choice for detonation propagation studies, namely

$\tilde{l}_{ref}$

to be the familiar and standard choice for detonation propagation studies, namely

![]() $\tilde{l}_{ref}=\tilde{l}_{1/2}$

is the length over which 50 % of the reactants are consumed in the 1-D, steady, CJ wave (Short & Quirk Reference Short and Quirk2018b

). This has the benefit that

$\tilde{l}_{ref}=\tilde{l}_{1/2}$

is the length over which 50 % of the reactants are consumed in the 1-D, steady, CJ wave (Short & Quirk Reference Short and Quirk2018b

). This has the benefit that

![]() $\tilde{l}_{1/2}$

varies only with the model parameters choices

$\tilde{l}_{1/2}$

varies only with the model parameters choices

![]() $A$

,

$A$

,

![]() $n$

and

$n$

and

![]() $\unicode[STIX]{x1D708}$

for fixed

$\unicode[STIX]{x1D708}$

for fixed

![]() $\unicode[STIX]{x1D70C}_{0},D_{CJ}$

and

$\unicode[STIX]{x1D70C}_{0},D_{CJ}$

and

![]() $\unicode[STIX]{x1D6FE}.$

Significantly,

$\unicode[STIX]{x1D6FE}.$

Significantly,

![]() $\tilde{l}_{1/2}$

does not vary with changes in the channel width. Adopting this scale, the channel width

$\tilde{l}_{1/2}$

does not vary with changes in the channel width. Adopting this scale, the channel width

![]() $W$

appearing in (5.7) now becomes

$W$

appearing in (5.7) now becomes

![]() $W=\tilde{W}/\tilde{l}_{1/2}$

, so that

$W=\tilde{W}/\tilde{l}_{1/2}$

, so that

![]() $W$

is always referenced relative to a fixed scale. The downside of using

$W$

is always referenced relative to a fixed scale. The downside of using

![]() $\tilde{l}_{1/2}$

as the reference length is that it does not reflect the changes in overall reaction zone length that occur when the detonation speed

$\tilde{l}_{1/2}$

as the reference length is that it does not reflect the changes in overall reaction zone length that occur when the detonation speed

![]() $D_{0}$

drops below

$D_{0}$

drops below

![]() $D_{CJ}$

as a result of varying

$D_{CJ}$

as a result of varying

![]() $m_{e}$

or

$m_{e}$

or

![]() $W$

(as seen in § 6). The second alternative reference length scale

$W$

(as seen in § 6). The second alternative reference length scale

![]() $\tilde{l}_{ref}=\tilde{l}_{\unicode[STIX]{x1D702}_{s}}$

, more naturally suited to the development of the asymptotic analysis in § 4, is set to the length between the detonation shock and flow sonic point for each HE boundary streamline deflection case such that the position of the sonic flow point (§ 4) is always at

$\tilde{l}_{ref}=\tilde{l}_{\unicode[STIX]{x1D702}_{s}}$

, more naturally suited to the development of the asymptotic analysis in § 4, is set to the length between the detonation shock and flow sonic point for each HE boundary streamline deflection case such that the position of the sonic flow point (§ 4) is always at

![]() $\unicode[STIX]{x1D702}=-1$

. We will denote the channel width relative to this scale as

$\unicode[STIX]{x1D702}=-1$

. We will denote the channel width relative to this scale as

![]() $W_{\unicode[STIX]{x1D702}_{s}}$

. The scaling between

$W_{\unicode[STIX]{x1D702}_{s}}$

. The scaling between

![]() $W(=\tilde{W}/\tilde{l}_{1/2})$

and

$W(=\tilde{W}/\tilde{l}_{1/2})$

and

![]() $W_{\unicode[STIX]{x1D702}_{s}}(=\tilde{W}/\tilde{l}_{\unicode[STIX]{x1D702}_{s}})$

is determined by the ratio of the two reference length scales, i.e.

$W_{\unicode[STIX]{x1D702}_{s}}(=\tilde{W}/\tilde{l}_{\unicode[STIX]{x1D702}_{s}})$

is determined by the ratio of the two reference length scales, i.e.

![]() $W=(\tilde{W}/\tilde{l}_{\unicode[STIX]{x1D702}_{s}})(\tilde{l}_{\unicode[STIX]{x1D702}_{s}}/\tilde{l}_{1/2})=W_{\unicode[STIX]{x1D702}_{s}}(\tilde{l}_{\unicode[STIX]{x1D702}_{s}}/\tilde{l}_{1/2})$

. Since

$W=(\tilde{W}/\tilde{l}_{\unicode[STIX]{x1D702}_{s}})(\tilde{l}_{\unicode[STIX]{x1D702}_{s}}/\tilde{l}_{1/2})=W_{\unicode[STIX]{x1D702}_{s}}(\tilde{l}_{\unicode[STIX]{x1D702}_{s}}/\tilde{l}_{1/2})$

. Since

![]() $\unicode[STIX]{x1D702}=\unicode[STIX]{x1D702}_{s}$

at the sonic point scaled with the reference length scale

$\unicode[STIX]{x1D702}=\unicode[STIX]{x1D702}_{s}$

at the sonic point scaled with the reference length scale

![]() $\tilde{l}_{1/2}$

is larger than one (see § 6), then

$\tilde{l}_{1/2}$

is larger than one (see § 6), then

![]() $\tilde{l}_{\unicode[STIX]{x1D702}_{s}}/\tilde{l}_{1/2}>1,$

and thus choosing

$\tilde{l}_{\unicode[STIX]{x1D702}_{s}}/\tilde{l}_{1/2}>1,$

and thus choosing

![]() $\tilde{l}_{1/2}$

as the reference scale will result in numerically larger values of

$\tilde{l}_{1/2}$

as the reference scale will result in numerically larger values of

![]() $W$

than of

$W$

than of

![]() $W_{\unicode[STIX]{x1D702}_{s}}$

for any fixed

$W_{\unicode[STIX]{x1D702}_{s}}$

for any fixed

![]() $\tilde{W}.$

Consequently,

$\tilde{W}.$

Consequently,

![]() $m_{e}/W<m_{e}/W_{\unicode[STIX]{x1D702}_{s}}$

for fixed

$m_{e}/W<m_{e}/W_{\unicode[STIX]{x1D702}_{s}}$

for fixed

![]() $m_{e}$

. However, since

$m_{e}$

. However, since

![]() $W_{\unicode[STIX]{x1D702}_{s}}$

depends on the location of the sonic flow point, adopting

$W_{\unicode[STIX]{x1D702}_{s}}$

depends on the location of the sonic flow point, adopting

![]() $\tilde{l}_{\unicode[STIX]{x1D702}_{s}}$

will mean that each individual confinement case will now have a different reference length scale. Thus, for clarity purposes, we present the majority of results in § 6 for the asymptotic analysis using the fixed reference length scale

$\tilde{l}_{\unicode[STIX]{x1D702}_{s}}$

will mean that each individual confinement case will now have a different reference length scale. Thus, for clarity purposes, we present the majority of results in § 6 for the asymptotic analysis using the fixed reference length scale

![]() $\tilde{l}_{ref}=\tilde{l}_{1/2}$

, where

$\tilde{l}_{ref}=\tilde{l}_{1/2}$

, where

![]() $W=\tilde{W}/\tilde{l}_{1/2}$

for each set of

$W=\tilde{W}/\tilde{l}_{1/2}$

for each set of

![]() $A,n$

and

$A,n$

and

![]() $\unicode[STIX]{x1D708}$

parameters.

$\unicode[STIX]{x1D708}$

parameters.

5.1 Zeldovich–von Neumann–Döring detonation structure

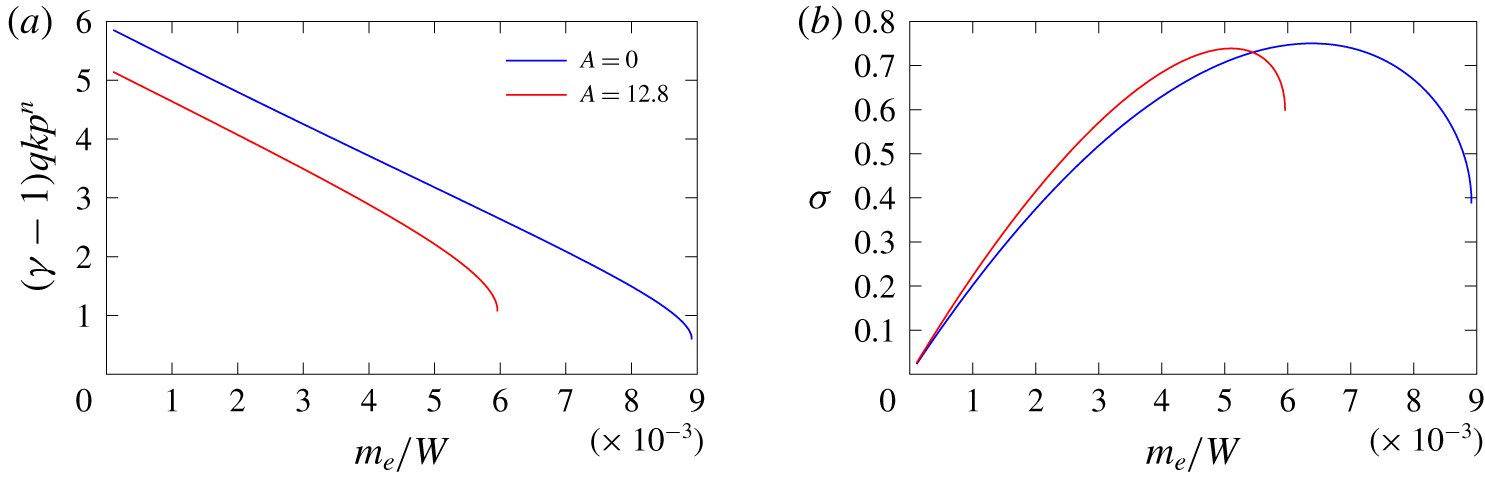

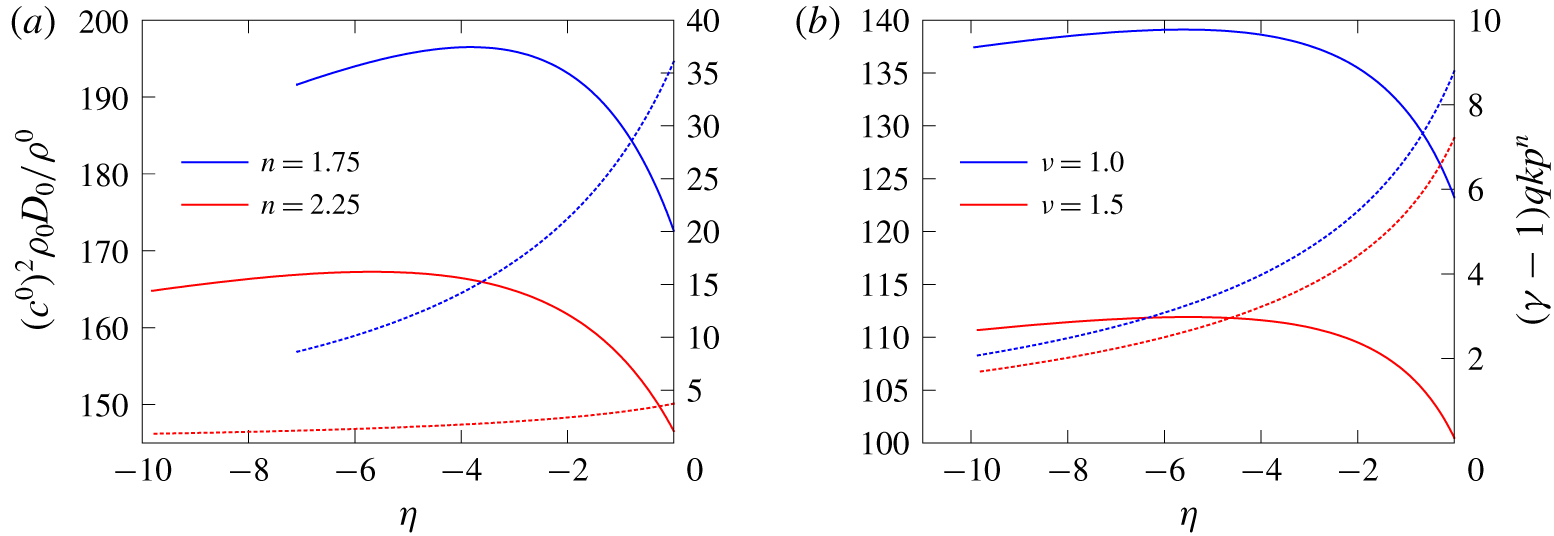

Figure 3 shows the variation in pressure, reaction progress variable and chemical energy deposition rate

![]() $(\unicode[STIX]{x1D6FE}-1)q\unicode[STIX]{x1D6EC}$

through the 1-D, Zeldovich–von Neumann–Döring (ZND) detonation structure running at the CJ speed (

$(\unicode[STIX]{x1D6FE}-1)q\unicode[STIX]{x1D6EC}$

through the 1-D, Zeldovich–von Neumann–Döring (ZND) detonation structure running at the CJ speed (

![]() $D_{CJ}=8$

) for various choices of

$D_{CJ}=8$

) for various choices of

![]() $A,n$

and

$A,n$

and

![]() $\unicode[STIX]{x1D708},$

and with

$\unicode[STIX]{x1D708},$

and with

![]() $\tilde{l}_{ref}=\tilde{l}_{1/2}.$

For

$\tilde{l}_{ref}=\tilde{l}_{1/2}.$

For

![]() $n=2$

and

$n=2$

and

![]() $\unicode[STIX]{x1D708}=0.5,$

the pressure for

$\unicode[STIX]{x1D708}=0.5,$

the pressure for

![]() $A=0$

is uniformly higher through the wave than for

$A=0$

is uniformly higher through the wave than for

![]() $A=12.8$

, while the reaction progress variable variations are similar (figure 3

a). The reaction rate and thus

$A=12.8$

, while the reaction progress variable variations are similar (figure 3

a). The reaction rate and thus

![]() $(\unicode[STIX]{x1D6FE}-1)q\unicode[STIX]{x1D6EC}$

for

$(\unicode[STIX]{x1D6FE}-1)q\unicode[STIX]{x1D6EC}$

for

![]() $A=0$

(

$A=0$

(

![]() $k=7.21869\times 10^{-4}$

which sets

$k=7.21869\times 10^{-4}$

which sets

![]() $\unicode[STIX]{x1D706}=1/2$

at

$\unicode[STIX]{x1D706}=1/2$

at

![]() $\unicode[STIX]{x1D702}=-1$

) is uniformly larger through the wave than for

$\unicode[STIX]{x1D702}=-1$

) is uniformly larger through the wave than for

![]() $A=12.8$

(

$A=12.8$

(

![]() $k=9.67560\times 10^{-4}$

) (figure 3

b). For

$k=9.67560\times 10^{-4}$

) (figure 3

b). For

![]() $A=12.8$

and

$A=12.8$

and

![]() $\unicode[STIX]{x1D708}=0.5$

, the pressure and rate term

$\unicode[STIX]{x1D708}=0.5$

, the pressure and rate term

![]() $(\unicode[STIX]{x1D6FE}-1)q\unicode[STIX]{x1D6EC}$

through the first part of the wave for

$(\unicode[STIX]{x1D6FE}-1)q\unicode[STIX]{x1D6EC}$

through the first part of the wave for

![]() $n=2$

is similar to that for

$n=2$

is similar to that for

![]() $n=2.25\,(k=3.58579\times 10^{-4})$

, while toward the tail, the pressure and rate term

$n=2.25\,(k=3.58579\times 10^{-4})$

, while toward the tail, the pressure and rate term

![]() $(\unicode[STIX]{x1D6FE}-1)q\unicode[STIX]{x1D6EC}$

for

$(\unicode[STIX]{x1D6FE}-1)q\unicode[STIX]{x1D6EC}$

for

![]() $n=2.25$

remain above that for

$n=2.25$

remain above that for

![]() $n=2.$

Thus increasing the reaction exponent

$n=2.$

Thus increasing the reaction exponent

![]() $n$

mostly affects the detonation structure at the rear section of the wave. For

$n$

mostly affects the detonation structure at the rear section of the wave. For

![]() $A=12.8$

and

$A=12.8$

and

![]() $n=2$

, significant changes are seen between

$n=2$

, significant changes are seen between

![]() $\unicode[STIX]{x1D708}=0.5$

and

$\unicode[STIX]{x1D708}=0.5$

and

![]() $\unicode[STIX]{x1D708}=1.5.$

For

$\unicode[STIX]{x1D708}=1.5.$

For

![]() $\unicode[STIX]{x1D708}=1.5,$

the rate term

$\unicode[STIX]{x1D708}=1.5,$

the rate term

![]() $(\unicode[STIX]{x1D6FE}-1)q\unicode[STIX]{x1D6EC}$

near the shock front dominates that of

$(\unicode[STIX]{x1D6FE}-1)q\unicode[STIX]{x1D6EC}$

near the shock front dominates that of

![]() $\unicode[STIX]{x1D708}=0.5,$

before decreasing significantly below that of

$\unicode[STIX]{x1D708}=0.5,$

before decreasing significantly below that of

![]() $\unicode[STIX]{x1D708}=0.5$

(figure 3

b). This results in a more rapid energy release near the shock and an extended tail of reaction downstream. This information will be useful in § 6 below, which analyses the effect of yielding confinement on detonation propagation for varying

$\unicode[STIX]{x1D708}=0.5$

(figure 3

b). This results in a more rapid energy release near the shock and an extended tail of reaction downstream. This information will be useful in § 6 below, which analyses the effect of yielding confinement on detonation propagation for varying

![]() $A$

,

$A$

,

![]() $n$

and

$n$

and

![]() $\unicode[STIX]{x1D708}.$

$\unicode[STIX]{x1D708}.$

Figure 3. Variation of (a) pressure (

![]() $p$

, solid lines) and reaction progress variable (

$p$

, solid lines) and reaction progress variable (

![]() $\unicode[STIX]{x1D706}$

, dotted lines) and (b) chemical energy deposition rate

$\unicode[STIX]{x1D706}$

, dotted lines) and (b) chemical energy deposition rate

![]() $(\unicode[STIX]{x1D6FE}-1)q\unicode[STIX]{x1D6EC}$

with longitudinal distance behind the shock for the 1-D, ZND detonation structure running at the CJ speed

$(\unicode[STIX]{x1D6FE}-1)q\unicode[STIX]{x1D6EC}$

with longitudinal distance behind the shock for the 1-D, ZND detonation structure running at the CJ speed

![]() $(D_{CJ}=8)$

for various choices of

$(D_{CJ}=8)$

for various choices of

![]() $A,n$

and

$A,n$

and

![]() $\unicode[STIX]{x1D708}.$

For the case

$\unicode[STIX]{x1D708}.$

For the case

![]() $A=12.8,n=2$

and

$A=12.8,n=2$

and

![]() $\unicode[STIX]{x1D708}=1.5,$

only a partial region of the reaction zone structure is shown due to the length of the reaction-depletion tail.

$\unicode[STIX]{x1D708}=1.5,$

only a partial region of the reaction zone structure is shown due to the length of the reaction-depletion tail.

6 Results

6.1 Linear HE boundary streamline

We first consider the effects of a straight HE boundary streamline,

![]() $-m_{e}h(\unicode[STIX]{x1D702})=-m_{e}\unicode[STIX]{x1D702},$

with

$-m_{e}h(\unicode[STIX]{x1D702})=-m_{e}\unicode[STIX]{x1D702},$

with

![]() $-m_{e}h^{\prime }(\unicode[STIX]{x1D702})=-m_{e}.$

Curved streamlines are considered below in § 6.2. For practical problems,

$-m_{e}h^{\prime }(\unicode[STIX]{x1D702})=-m_{e}.$

Curved streamlines are considered below in § 6.2. For practical problems,

![]() $m_{e}$

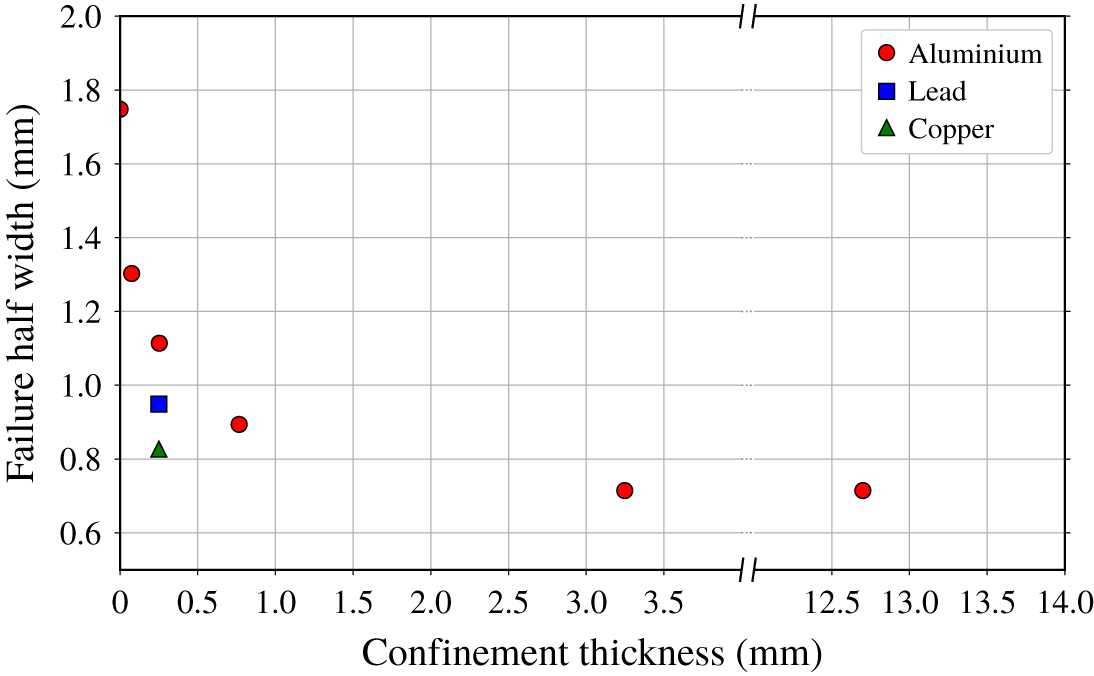

would be obtained via a shock polar analysis (see § 6.2), based on the material properties of a given confinement material. Figure 4(a) shows the variation of the steady detonation speed

$m_{e}$

would be obtained via a shock polar analysis (see § 6.2), based on the material properties of a given confinement material. Figure 4(a) shows the variation of the steady detonation speed

![]() $D_{0}$

, obtained via solution of the asymptotically derived system (5.7) using the shooting method described in § 5, with

$D_{0}$

, obtained via solution of the asymptotically derived system (5.7) using the shooting method described in § 5, with

![]() $(1+s)m_{e}/W$

(

$(1+s)m_{e}/W$

(

![]() $s=0$

for planar geometries, s=1 for cylindrical geometries) for

$s=0$

for planar geometries, s=1 for cylindrical geometries) for

![]() $A=0,A=6.4$

and

$A=0,A=6.4$

and

![]() $A=12.8$

, and with

$A=12.8$

, and with

![]() $n=2$

and

$n=2$

and

![]() $\unicode[STIX]{x1D708}=1/2$

. The values

$\unicode[STIX]{x1D708}=1/2$

. The values

![]() $A=0,6.4$

and

$A=0,6.4$

and

![]() $12.8$

correspond to sound speeds in the ambient reactant material of

$12.8$

correspond to sound speeds in the ambient reactant material of

![]() $c_{0}=0,1.789$

and 2.530, respectively. Each curve shows a monotonic decrease in

$c_{0}=0,1.789$

and 2.530, respectively. Each curve shows a monotonic decrease in

![]() $D_{0}$

with increasing

$D_{0}$

with increasing

![]() $(1+s)m_{e}/W$

, along with a critical value of

$(1+s)m_{e}/W$

, along with a critical value of

![]() $(1+s)m_{e}/W$

beyond which no steady solutions are possible. In each case, the critical point corresponds to a turning point in the

$(1+s)m_{e}/W$

beyond which no steady solutions are possible. In each case, the critical point corresponds to a turning point in the

![]() $D_{0}$

versus

$D_{0}$

versus

![]() $(1+s)m_{e}/W$

relation. In a separate article (Voelkel, Chiquete & Short Reference Voelkel, Chiquete and Short2019), we show that the loss of steady solutions as

$(1+s)m_{e}/W$

relation. In a separate article (Voelkel, Chiquete & Short Reference Voelkel, Chiquete and Short2019), we show that the loss of steady solutions as

![]() $m_{e}/W$

increases corresponds to the failure (or detonability limit) of the detonation.

$m_{e}/W$

increases corresponds to the failure (or detonability limit) of the detonation.

Based on figure 4(a), for both

![]() $s=0$

and

$s=0$

and

![]() $s=1,$

the propagation speed

$s=1,$

the propagation speed

![]() $D_{0}$

decreases for fixed

$D_{0}$

decreases for fixed

![]() $(1+s)m_{e}/W$

as

$(1+s)m_{e}/W$

as

![]() $A$

increases. Increasing the stiffness parameter

$A$

increases. Increasing the stiffness parameter

![]() $A$

also reduces the ratio

$A$

also reduces the ratio

![]() $(1+s)m_{e}/W$

at which steady solutions are lost (detonation failure), with a significantly larger value of

$(1+s)m_{e}/W$

at which steady solutions are lost (detonation failure), with a significantly larger value of

![]() $D_{0}$

for

$D_{0}$

for

![]() $A=12.8$

at the point of failure than for

$A=12.8$

at the point of failure than for

![]() $A=0$

. Thus, for a fixed boundary streamline gradient

$A=0$

. Thus, for a fixed boundary streamline gradient

![]() $m_{e}$

, quenching occurs in a larger charge dimension

$m_{e}$

, quenching occurs in a larger charge dimension

![]() $W$

for

$W$

for

![]() $A=12.8$

than for

$A=12.8$

than for

![]() $A=6.4$

, which in turn fails at a larger

$A=6.4$

, which in turn fails at a larger

![]() $W$

than for

$W$

than for

![]() $A=0.$

Alternatively, for fixed

$A=0.$

Alternatively, for fixed

![]() $W,$

a detonation in an HE with a stiffer equation of state, i.e. one having a larger

$W,$

a detonation in an HE with a stiffer equation of state, i.e. one having a larger

![]() $A$

, will quench for smaller

$A$

, will quench for smaller

![]() $m_{e}.$

This implies that a detonation in an HE with a lower

$m_{e}.$

This implies that a detonation in an HE with a lower

![]() $A$

is able to propagate when confined by materials with smaller impedances.

$A$

is able to propagate when confined by materials with smaller impedances.

Referring to the energy (5.6), the dominant effect of the geometry for larger

![]() $D_{0}$

occurs through the

$D_{0}$

occurs through the

![]() $(1+s)$

factor in the energy change term

$(1+s)$

factor in the energy change term

![]() $\unicode[STIX]{x1D70E}$

, with the

$\unicode[STIX]{x1D70E}$

, with the

![]() $[1-m_{e}h(\unicode[STIX]{x1D702})/W]^{-(2+s)}$

factor in

$[1-m_{e}h(\unicode[STIX]{x1D702})/W]^{-(2+s)}$

factor in

![]() $\unicode[STIX]{x1D70E}$

becoming more significant between

$\unicode[STIX]{x1D70E}$

becoming more significant between

![]() $s=0$

and

$s=0$

and

![]() $s=1$

for lower

$s=1$

for lower

![]() $D_{0}$

and near the failure point. Thus, for larger

$D_{0}$

and near the failure point. Thus, for larger

![]() $D_{0},$

the energy change associated with the rate of change of mass flux is approximately double that for a cylinder with a radius

$D_{0},$

the energy change associated with the rate of change of mass flux is approximately double that for a cylinder with a radius

![]() $W$

than a slab with half-thickness

$W$

than a slab with half-thickness

![]() $W$

. Consequently, when

$W$

. Consequently, when

![]() $D_{0}$

is plotted as a function of

$D_{0}$

is plotted as a function of

![]() $(1+s)m_{e}/W$

the variations are similar for

$(1+s)m_{e}/W$

the variations are similar for

![]() $s=0$

and

$s=0$

and

![]() $s=1$

for any given

$s=1$

for any given

![]() $A$

for larger

$A$

for larger

![]() $D_{0}$

, with deviations observed for lower

$D_{0}$

, with deviations observed for lower

![]() $D_{0}$

and at the turning (failure) point.

$D_{0}$

and at the turning (failure) point.

Figure 4. (a) Variation of

![]() $D_{0}$

with

$D_{0}$

with

![]() $(1+s)m_{e}/W$

for slab (

$(1+s)m_{e}/W$

for slab (

![]() $s=0$

) and cylindrical (

$s=0$