Article contents

Multi-scale modeling of fatigue damage in a metal wire film with the thickness effect

Published online by Cambridge University Press: 16 November 2020

Abstract

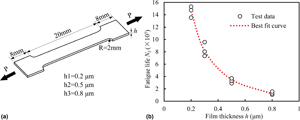

The thickness effect has a significant influence on the fatigue life of micro–nanometer thin films. Due to the increasing application of micro–nanometer thin films in the field of microelectronics, a suitable fatigue prediction model is urgently needed. To reveal the impact of the thickness effect on the fatigue life of a copper wire film, cyclic tension fatigue test of four groups of copper wire films were carried out. Based on the theory of continuous damage mechanics and damage homogenization method, a fatigue damage accumulation model that considered the film thickness was proposed. Based on the proposed fatigue damage prediction model, the damage evolution law and fatigue life of copper wire films with different thickness and strain range were predicted. Furthermore, the size effect of the copper films was analyzed. The results showed that the fatigue life of copper wire films will decrease with the increase of thickness and strain amplitude; the thinner the film, the more significant the thickness effect on the fatigue life is; with the increase of the film thickness, the film thickness effect will gradually decrease.

- Type

- Article

- Information

- Copyright

- Copyright © The Author(s), 2020, published on behalf of Materials Research Society by Cambridge University Press

References

- 2

- Cited by