Novel Synthesis and Processing of Materials

Article

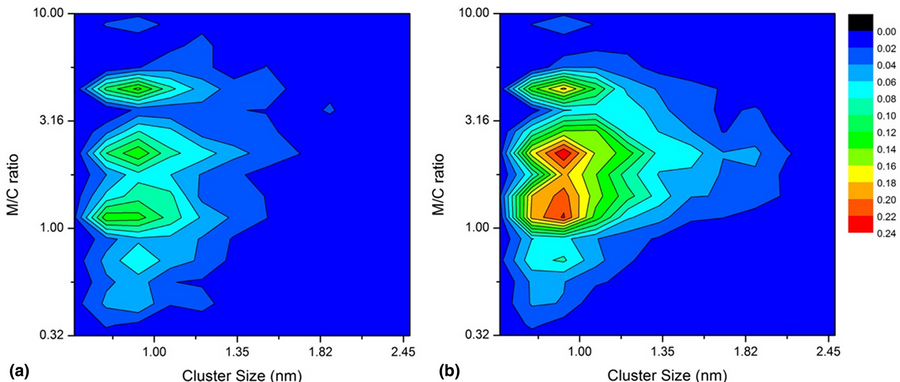

Nanoscale clusters in secondary hardening ultra-high strength steels with 1 and 3 wt% Mo: An atom probe investigation

-

- Published online by Cambridge University Press:

- 18 June 2020, pp. 1763-1776

-

- Article

- Export citation

Novel Synthesis and Processing of Metals

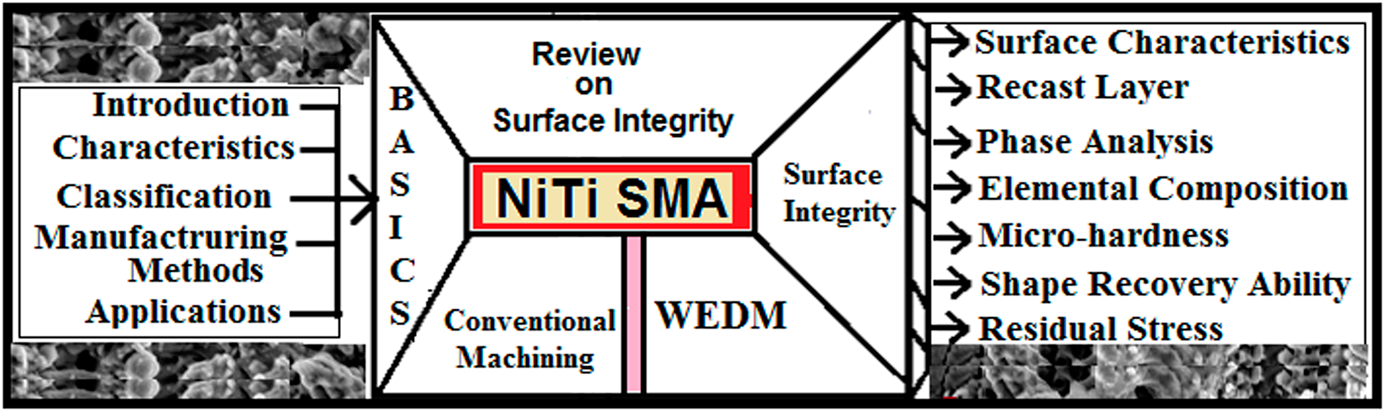

REVIEW

Surface integrity aspects for NiTi shape memory alloys during wire electric discharge machining: A review

-

- Published online by Cambridge University Press:

- 17 February 2020, pp. 537-558

-

- Article

- Export citation

Energy Conversion and Storage Materials

Invited Paper

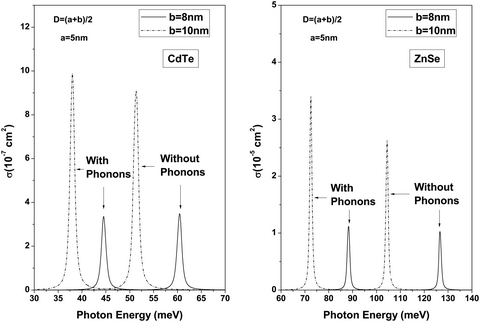

Phonons correction of the energy and photoionization cross section in polar semiconductors and hollow nanoparticles

-

- Published online by Cambridge University Press:

- 11 June 2020, pp. 2077-2086

-

- Article

- Export citation

Announcement

Announcement

-

- Published online by Cambridge University Press:

- 14 January 2020, p. 1

-

- Article

-

- You have access

- HTML

- Export citation

The Science and Technology of Vapor Phase Processing and Modification of Surfaces

The science and technology of vapor phase processing and modification of surfaces

-

- Published online by Cambridge University Press:

- 13 March 2020, p. 443

-

- Article

- Export citation

JMR Early Career Scholars in Materials Science Annual Issue

Introduction

-

- Published online by Cambridge University Press:

- 28 April 2020, p. 841

-

- Article

- Export citation

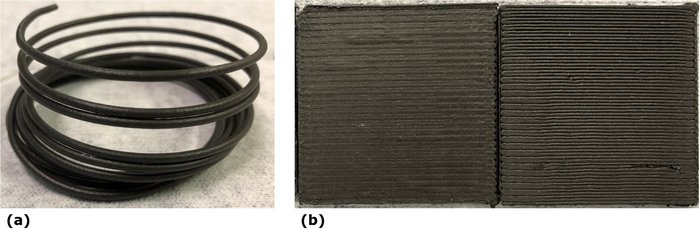

Organic and Hybrid Functional Materials

Invited Feature Paper

Fused filament fabrication of polymer composites for extreme environments

-

- Published online by Cambridge University Press:

- 11 June 2020, pp. 1493-1503

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Biomedical Materials, Regenerative Medicine and Drug Delivery

REVIEW

The virtuous potential of chitosan oligosaccharide for promising biomedical applications

-

- Published online by Cambridge University Press:

- 21 April 2020, pp. 1123-1134

-

- Article

- Export citation

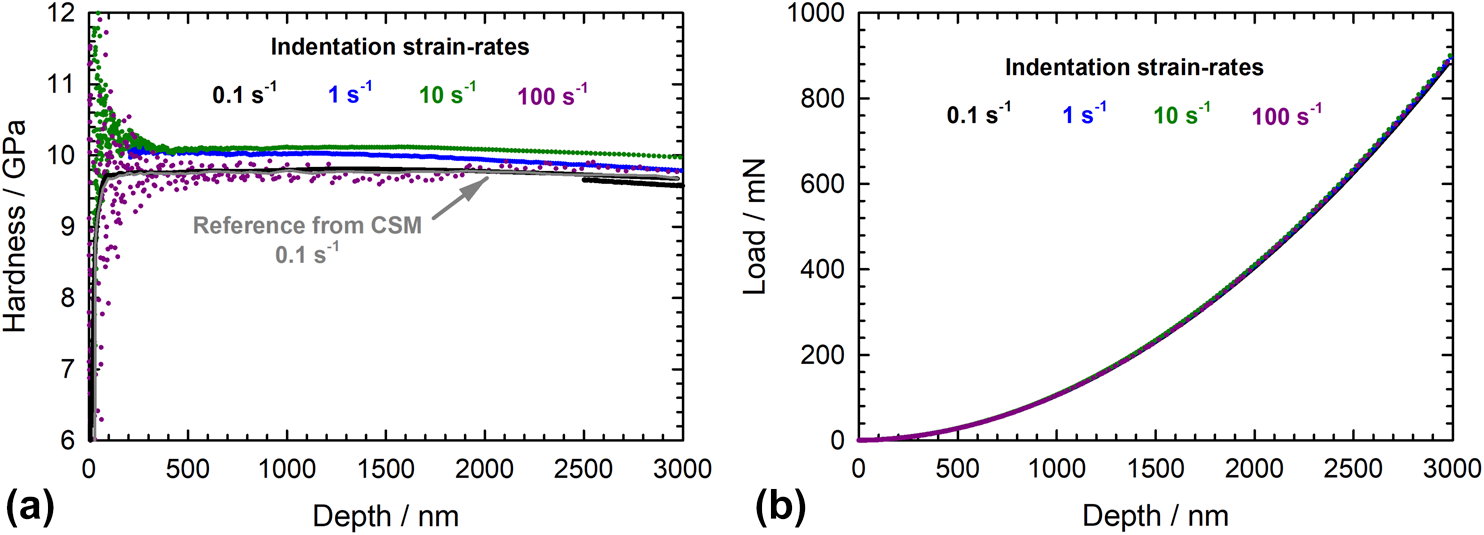

Nanomechanics and Testing

Article

Extending the range of constant strain rate nanoindentation testing

-

- Published online by Cambridge University Press:

- 20 January 2020, pp. 343-352

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

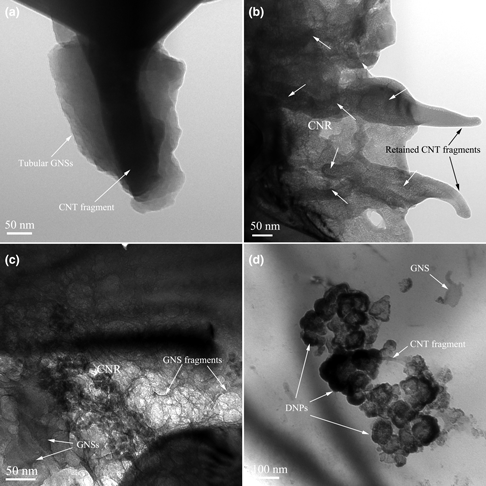

2D and Nanomaterials

Article

Study on the tensile and wear properties of laser-cladded IN718 superalloy reinforced by carbon nanoproducts transformed from carbon nanotubes

-

- Published online by Cambridge University Press:

- 02 October 2020, pp. 2643-2651

-

- Article

- Export citation

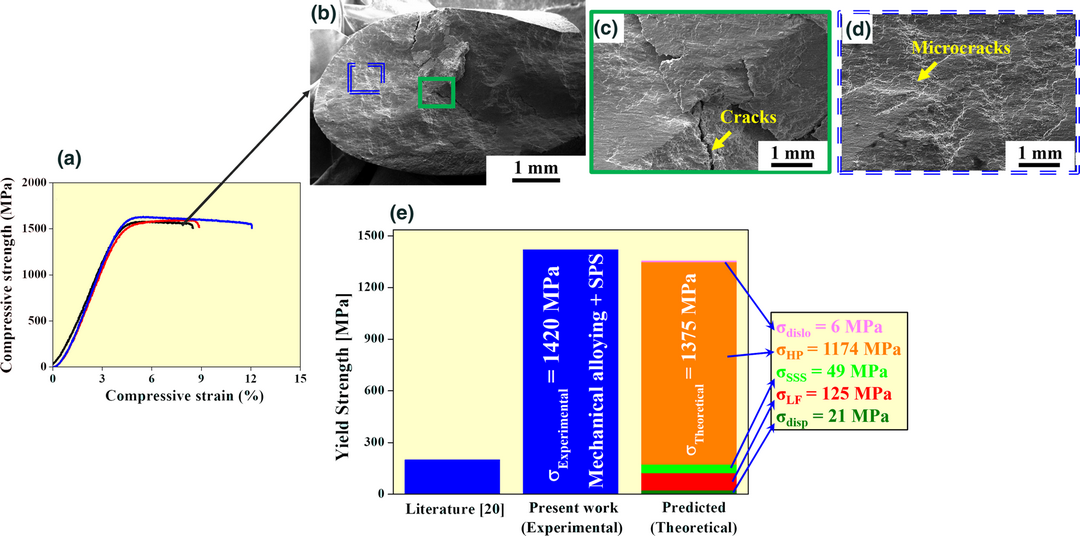

Novel Synthesis and Processing of Materials

Invited Feature Paper

Powder metallurgy of Al0.1CoCrFeNi high-entropy alloy

-

- Published online by Cambridge University Press:

- 05 October 2020, pp. 2835-2847

-

- Article

- Export citation

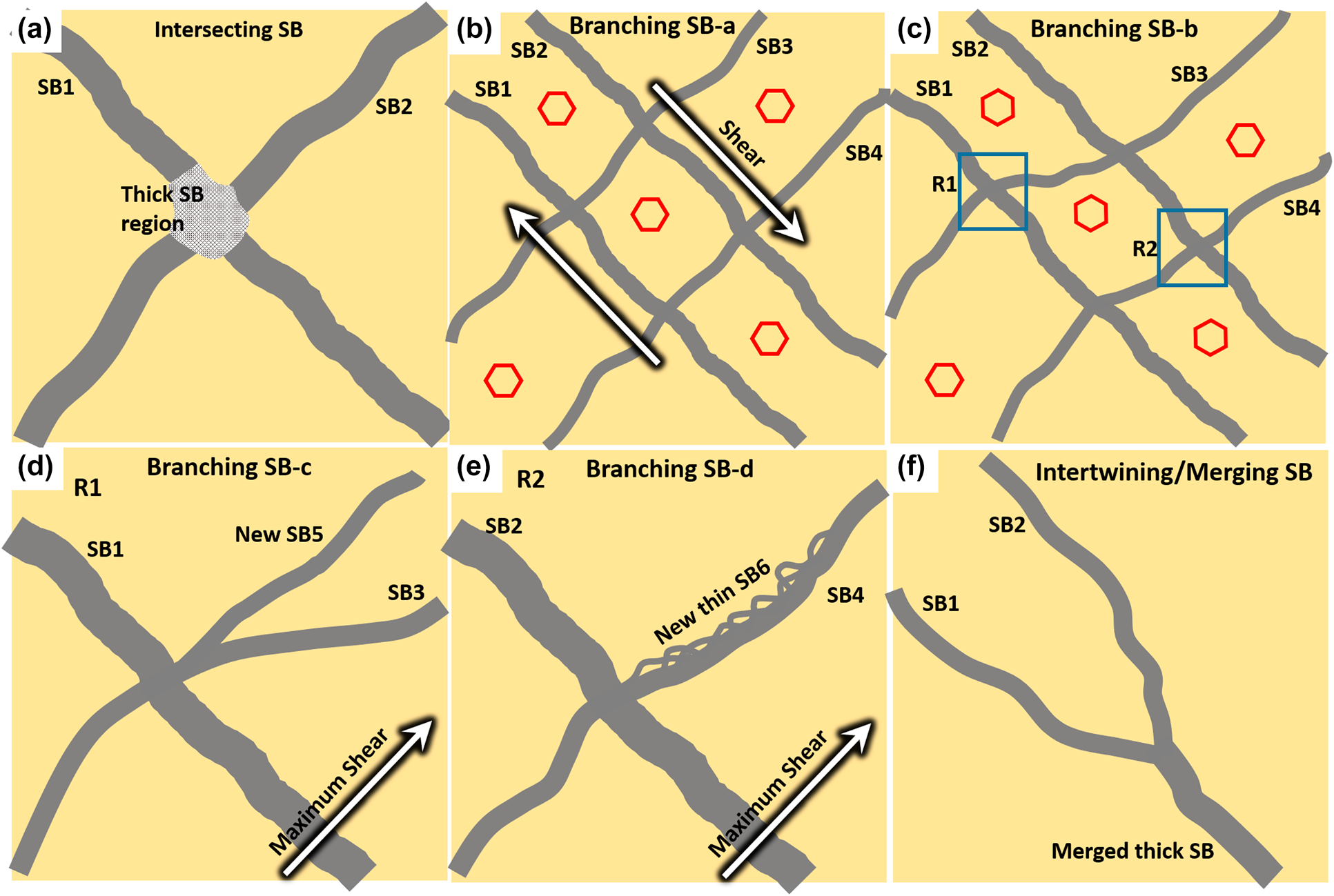

Article

Shear band widening mechanism in Ti–6Al–4V under high strain rate deformation

-

- Published online by Cambridge University Press:

- 12 March 2020, pp. 1623-1634

-

- Article

- Export citation

Introduction

Introduction - Porous Metals: From Nano to Macro

-

- Published online by Cambridge University Press:

- 14 October 2020, pp. 2529-2534

-

- Article

- Export citation

Atomic Layer Deposition for Emerging Thin-Film Materials and Applications

Introduction

-

- Published online by Cambridge University Press:

- 15 April 2020, p. 655

-

- Article

-

- You have access

- HTML

- Export citation

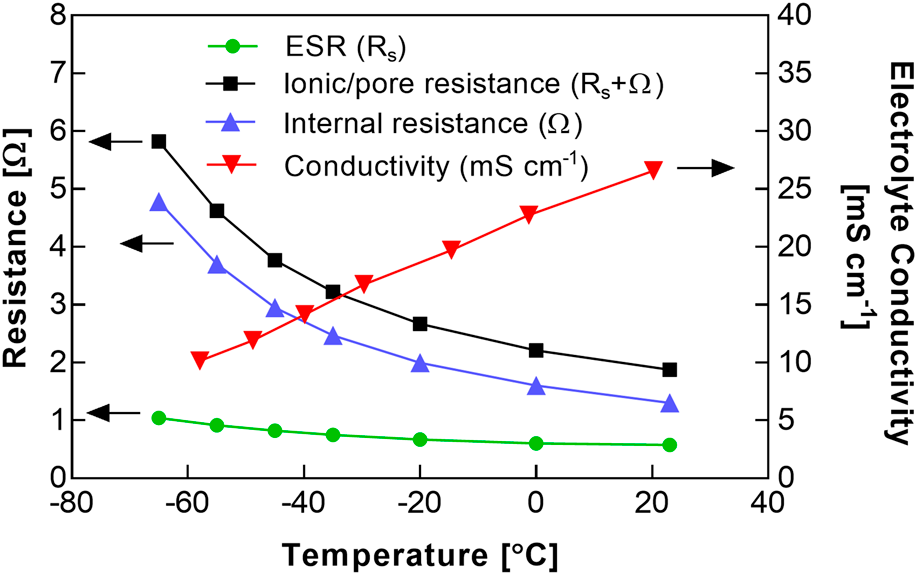

Organic and Hybrid Functional Materials

Invited Paper

Low-temperature performance of electrochemical capacitors using acetonitrile/methyl formate electrolytes and activated carbon fabric electrodes

-

- Published online by Cambridge University Press:

- 20 January 2020, pp. 113-121

-

- Article

- Export citation

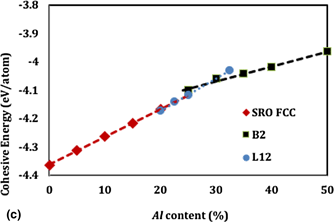

Computational Materials Science

Article

Model interatomic potentials for Fe–Ni–Cr–Co–Al high-entropy alloys

-

- Published online by Cambridge University Press:

- 20 October 2020, pp. 3031-3040

-

- Article

- Export citation

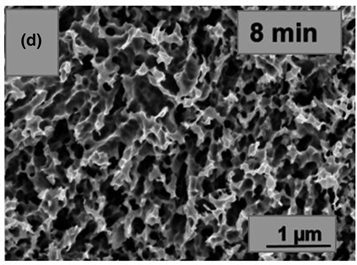

Structural Materials and Mechanical Properties

Invited Feature Paper

Formation of micro-mechanical interlocking sites by nanoscale sculpturing for composites or hybrid materials with stainless steel

-

- Published online by Cambridge University Press:

- 29 October 2020, pp. 3145-3156

-

- Article

- Export citation

Introduction

Introduction

-

- Published online by Cambridge University Press:

- 14 August 2020, p. 1899

-

- Article

- Export citation

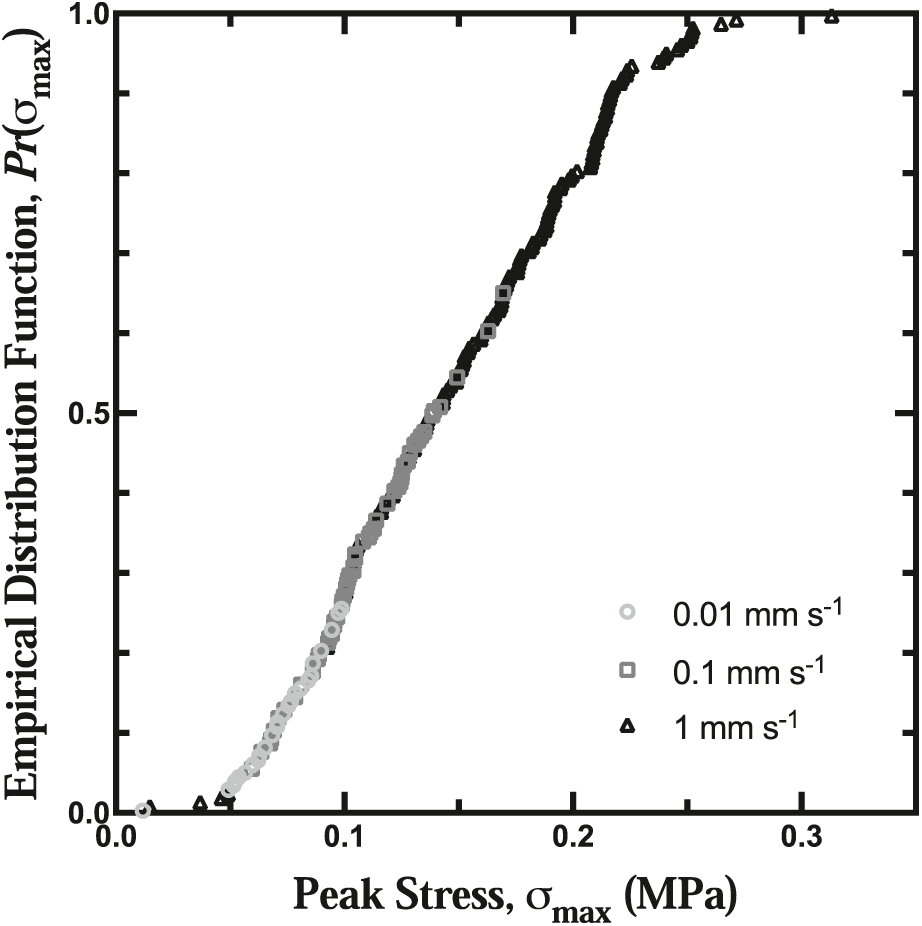

Biomedical Materials, Regenerative Medicine and Drug Delivery

Invited Feature Paper

Compressive failure of hydrogel spheres

-

- Published online by Cambridge University Press:

- 22 May 2020, pp. 1227-1235

-

- Article

- Export citation

Introduction

Introduction

-

- Published online by Cambridge University Press:

- 17 June 2020, p. 1349

-

- Article

- Export citation