Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Göken, Mathias

Eggeler, Gunther

Zhu, Yuntian

and

Lu, Lei

2017.

Introduction.

Journal of Materials Research,

Vol. 32,

Issue. 24,

p.

4463.

Göken, Mathias

Eggeler, Gunther

Zhu, Yuntian

and

Lu, Lei

2017.

Introduction.

Journal of Materials Research,

Vol. 32,

Issue. 23,

p.

4273.

Zhang, Yi

Fu, Huadong

Zhou, Xiaozhou

Zhang, Yuheng

and

Xie, Jianxin

2018.

Effects of aluminum and molybdenum content on the microstructure and properties of multi-component γ′-strengthened cobalt-base superalloys.

Materials Science and Engineering: A,

Vol. 737,

Issue. ,

p.

265.

Volz, N.

Zenk, C. H.

Cherukuri, R.

Kalfhaus, T.

Weiser, M.

Makineni, S. K.

Betzing, C.

Lenz, M.

Gault, B.

Fries, S. G.

Schreuer, J.

Vaßen, R.

Virtanen, S.

Raabe, D.

Spiecker, E.

Neumeier, S.

and

Göken, M.

2018.

Thermophysical and Mechanical Properties of Advanced Single Crystalline Co-base Superalloys.

Metallurgical and Materials Transactions A,

Vol. 49,

Issue. 9,

p.

4099.

Kimmel, A.-C.L.

Malkowski, Thomas F.

Griffiths, Steven

Hertweck, Benjamin

Steigerwald, Thomas G.

Freund, Lisa P.

Neumeier, Steffen

Göken, Mathias

Speck, James S.

and

Schluecker, Eberhard

2018.

High-temperature corrosion of Inconel®Alloy 718, Haynes®282®Alloy and CoWAlloy1&2 in supercritical ammonia/ammonium chloride solution.

Journal of Crystal Growth,

Vol. 498,

Issue. ,

p.

289.

Sani, Saeed Aliakbari

Arabi, Hossein

and

Ebrahimi, Gholam Reza

2019.

Hot deformation behavior and DRX mechanism in a γ-γ/ cobalt-based superalloy.

Materials Science and Engineering: A,

Vol. 764,

Issue. ,

p.

138165.

Zhang, Yi

Fu, Huadong

Zhou, Xiaozhou

Zhang, Yuheng

and

Xie, Jianxin

2019.

Enhanced mechanical properties of wrought γ′-strengthened Co-base superalloys by adjusting the relative content of Al and Ti.

Intermetallics,

Vol. 112,

Issue. ,

p.

106543.

Hausmann, D.

Solís, C.

Freund, L.P.

Volz, N.

Heinemann, A.

Göken, M.

Gilles, R.

and

Neumeier, S.

2020.

Enhancing the High-Temperature Strength of a Co-Base Superalloy by Optimizing the γ/γ′ Microstructure.

Metals,

Vol. 10,

Issue. 3,

p.

321.

Zhang, Yi

Fu, Huadong

Zhou, Xiaozhou

Zhang, Yuheng

Dong, Hongbiao

and

Xie, Jianxin

2020.

Microstructure Evolution of Multicomponent γ′-Strengthened Co-Based Superalloy at 750 °C and 1000 °C with Different Al and Ti Contents.

Metallurgical and Materials Transactions A,

Vol. 51,

Issue. 4,

p.

1755.

Zenk, Christopher H.

Volz, Nicklas

Zenk, Carolin

Felfer, Peter J.

and

Neumeier, Steffen

2020.

Impact of the Co/Ni-Ratio on Microstructure, Thermophysical Properties and Creep Performance of Multi-Component γ′-Strengthened Superalloys.

Crystals,

Vol. 10,

Issue. 11,

p.

1058.

Hagen, S. P.

Weiser, M.

Kubacka, D.

Spiecker, E.

and

Virtanen, S.

2020.

On the High-Temperature Oxidation Behavior of a Ta-Containing Quaternary Co-Base Model Alloy System with γ/γ′-Microstructure - Influence of γ′-Volume Fraction, Surface State, and Heating Condition on Alumina Growth.

Oxidation of Metals,

Vol. 94,

Issue. 5-6,

p.

477.

Zhong, Xiaokang

and

Han, Fusheng

2020.

Hot deformation behavior of a new tailored cobalt-based superalloy for turbine discs.

Journal of Materials Research,

Vol. 35,

Issue. 6,

p.

633.

Baler, Nithin

Pandey, Prafull

Chattopadhyay, Kamanio

and

Phanikumar, Gandham

2020.

Influence of thermomechanical processing parameters on microstructural evolution of a gamma-prime strengthened cobalt based superalloy during high temperature deformation.

Materials Science and Engineering: A,

Vol. 791,

Issue. ,

p.

139498.

Murray, Sean P.

Stinville, Jean-Charles

Callahan, Patrick G.

Rhein, Robert K.

and

Pollock, Tresa M.

2020.

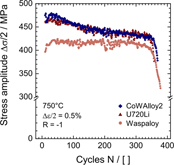

Low Cycle Fatigue of Single Crystal $$\gamma ^{\prime }$$-containing Co-based Superalloys at $$750\,^{\circ }\hbox {C}$$.

Metallurgical and Materials Transactions A,

Vol. 51,

Issue. 1,

p.

200.

Lass, Eric A.

2020.

The effects of Fe and Si on the phase equilibria in a γ′-strengthened Co–Al–W-based superalloy.

Journal of Alloys and Compounds,

Vol. 825,

Issue. ,

p.

154158.

Fu, Huadong

Zhang, Yuheng

Xue, Fei

Zhang, Yi

Xu, Huan

and

Xie, Jianxin

2020.

Microstructure and Properties Evolution of Co-Al-W-Ni-Cr Superalloys by Molybdenum and Niobium Substitutions for Tungsten.

Metallurgical and Materials Transactions A,

Vol. 51,

Issue. 1,

p.

299.

Wertz, Katelun

Weaver, Donald

Wen, Dongsheng

Titus, Michael S.

Shivpuri, Rajiv

Niezgoda, Stephen R.

Mills, Michael J.

and

Semiatin, S. Lee

2020.

Superalloys 2020.

p.

857.

Zhuang, Xiaoli

Lu, Song

Li, Longfei

and

Feng, Qiang

2020.

Microstructures and properties of a novel γ′-strengthened multi-component CoNi-based wrought superalloy designed by CALPHAD method.

Materials Science and Engineering: A,

Vol. 780,

Issue. ,

p.

139219.

Abedi, H. R.

and

Ojo, O. A.

2021.

Numerical Modeling of Gas Tungsten Arc Welding of a Newly Developed Cobalt-Based Superalloy.

Metallurgical and Materials Transactions A,

Vol. 52,

Issue. 11,

p.

5043.

Schlücker, Eberhard

and

Kimmel, Anna-Carina Luise

2021.

Ammonothermal Synthesis and Crystal Growth of Nitrides.

Vol. 304,

Issue. ,

p.

27.