Article contents

Effects of morphological characteristics of Pt nanoparticles supported on poly(acrylic acid)-wrapped multiwalled carbon nanotubes on electrochemical performance of direct methanol fuel cells

Published online by Cambridge University Press: 07 June 2012

Abstract

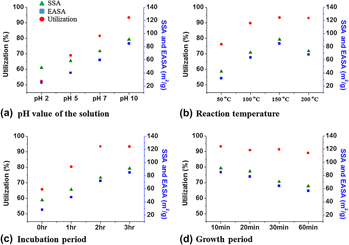

The catalytic activity of Pt nanoparticles (NPs) significantly influences the electrochemical performance of direct methanol fuel cells. Information about the factors that influence the electrochemical activity of the catalyst themselves is scarce; hence, guidelines for the preparation of Pt NPs that yields the best performances are lacking. With consideration for this situation, we systematically investigated the relationship(s) between the characteristics of Pt NPs and their electrochemical performance. The general characteristics of Pt NPs, such as the average size, loading density, and dispersion status on the support, were varied in the presence of poly(acrylic acid)-wrapped multiwalled carbon nanotubes by controlling the preparation conditions, including the pH of the aqueous solution, the reaction temperature, and the reaction time. The enhanced catalytic activity is attributable to higher degree of dispersion, specific surface area, and electrochemically active surface area of Pt NPs. The optimized catalyst exhibits a ∼165% higher catalytic activity toward methanol oxidation than the commercial E-TEK.

- Type

- Articles

- Information

- Journal of Materials Research , Volume 27 , Issue 15: Focus Issue: Advanced Materials for Fuel Cells , 14 August 2012 , pp. 2035 - 2045

- Copyright

- Copyright © Materials Research Society 2012

References

REFERENCES

- 6

- Cited by