Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Zheng, Liuwei

Nie, Kaibo

Nie, Huihui

Zhang, Wanggang

Liang, Wei

and

Wang, Yide

2017.

Microstructure evolution and enhanced mechanical properties of hot rolled Mg–3Al–Zn alloy with the addition of Al and Si as a eutectic alloy.

Journal of Materials Research,

Vol. 32,

Issue. 18,

p.

3564.

Gopi, Karekere Rangaraju

and

Shivananda Nayaka, Hanumanthappa

2017.

Tribological and corrosion properties of AM70 magnesium alloy processed by equal channel angular pressing.

Journal of Materials Research,

Vol. 32,

Issue. 11,

p.

2153.

Li, Gang

Li, Ming

Wang, Hongxia

Zhang, Zengyao

Cheng, Weili

Liang, Wei

and

Zhang, Changjiang

2018.

Dependence of microstructure characteristics and mechanical properties on nanosize SiCp contents in Mg–9Al matrix composites fabricated by ultrasonic-assisted semisolid powder hot pressing.

Journal of Materials Research,

Vol. 33,

Issue. 18,

p.

2689.

Zhou, Pengwen

Wang, Hongxia

Nie, Huihui

Cheng, Weili

Niu, Xiaofeng

Wang, Zhiwen

and

Liang, Wei

2018.

Effect of ECAP temperature on precipitation and strengthening mechanisms of Mg–9Al–1Si alloys.

Journal of Materials Research,

Vol. 33,

Issue. 12,

p.

1822.

Zhang, Shaoxiong

Li, Ming

Wang, Hongxia

Cheng, Weili

Lei, Weiwei

Liu, Yiming

and

Liang, Wei

2018.

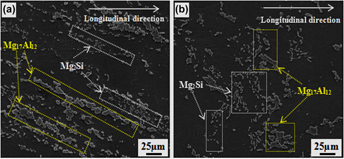

Microstructure and Tensile Properties of ECAPed Mg-9Al-1Si-1SiC Composites: The Influence of Initial Microstructures.

Materials,

Vol. 11,

Issue. 1,

p.

136.

JIA, Qing-gong

ZHANG, Wen-xin

SUN, Yi

XU, Chun-xiang

ZHANG, Jin-shan

and

KUAN, Jun

2019.

Microstructure and mechanical properties of as-cast and extruded biomedical Mg-Zn-Y-Zr-Ca alloy at different temperatures.

Transactions of Nonferrous Metals Society of China,

Vol. 29,

Issue. 3,

p.

515.

Zhang, Zengyao

Wang, Hongxia

Wang, Zhiwen

Li, Hang

Li, Ziyan

Zheng, Liuwei

and

Cheng, Weili

2019.

Enhanced Mechanical Properties of ECAPed Mg-9Al-1Si Alloy by a Two-Stage Pretreatment.

JOM,

Vol. 71,

Issue. 7,

p.

2178.

2019.

Studying the effect of equal channel angular extrusion on microstructure and properties of Mg<sub>2</sub>Si vehicle magnesium alloy .

Functional Materials,

Vol. 26,

Issue. 3,

Shayan, Mehrdad

Eghbali, Beitallah

and

Niroumand, Behzad

2019.

Synthesis of AA2024-(SiO2np+TiO2np) hybrid nanocomposite via stir casting process.

Materials Science and Engineering: A,

Vol. 756,

Issue. ,

p.

484.

Li, Jian

Zhang, Ming

Zhao, Junyu

Cui, Youming

and

Luo, Xian

2020.

Atomic insight into the interfacial bonding and role of carbon atoms on β-SiC(1 1 1)/Al2MgC2(0 0 0 1): A first-principles study.

Applied Surface Science,

Vol. 511,

Issue. ,

p.

145633.

Zhou, Pengwen

Zhang, Shaoxiong

Li, Ming

Wang, Hongxia

Cheng, Weili

Wang, Lifei

Li, Hang

Liang, Wei

and

Liu, Yiming

2020.

The creep behavior of Mg–9Al–1Si–1SiC composite at elevated temperature.

Journal of Magnesium and Alloys,

Vol. 8,

Issue. 3,

p.

944.

Murugan, Srinivasan

Bau Nguyen, Quy

and

Gupta, Manoj

2020.

Magnesium - The Wonder Element for Engineering/Biomedical Applications.

Zhang, Xiangpeng

Zhang, Zengyao

Wang, Hongxia

Zhuang, Yongpeng

Wang, Lifei

Cheng, Weili

and

Liang, Wei

2020.

Synergistic effect of broken Mg2Si and sub-micron Mg17Al12 induced by EX- ECAP on the strength and ductility of deformed Mg-4Al-1Si-1Gd alloy.

Journal of Materials Research and Technology,

Vol. 9,

Issue. 3,

p.

4230.

Shayan, Mehrdad

Eghbali, Beitallah

and

Niroumand, Behzad

2021.

Synthesis and Characterization of Aa2024-Sio2 Nanocomposites Through the Vortex Method.

International Journal of Metalcasting,

Vol. 15,

Issue. 4,

p.

1427.

Zhang, Xiang-peng

Wang, Hong-xia

Bian, Li-ping

Zhang, Shao-xiong

Zhuang, Yong-peng

Cheng, Wei-li

and

Liang, Wei

2021.

Microstructure evolution and mechanical properties of Mg-9Al-1Si-1SiC composites processed by multi-pass equal-channel angular pressing at various temperatures.

International Journal of Minerals, Metallurgy and Materials,

Vol. 28,

Issue. 12,

p.

1966.

Zarghami, Mohammad

Emamy, Massoud

and

Malekan, Mehdi

2021.

Microstructure, mechanical properties and wear behaviour of the AZ91–Mg2Si–SiC hybrid composites.

Materials Science and Technology,

Vol. 37,

Issue. 16,

p.

1333.

Kayang, Kevin W.

and

Volkov, Alexey N.

2021.

Mechanical properties, phase transitions, and fragmentation mechanisms of 6H, 3C, and amorphous SiC nanoparticles under compression.

Applied Physics A,

Vol. 127,

Issue. 12,