Article contents

Crystallography and morphology of a lathy ferrite in Fe–Cr–Ni alloys during directional solidification

Published online by Cambridge University Press: 24 July 2013

Abstract

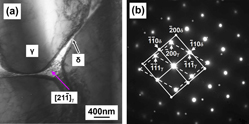

The relationship between morphology and crystallography of an entangled lathy ferrite during directional solidification in Fe–Cr–Ni alloy has been investigated. During solidification, morphology of the lathy ferrite depends on the orientation relationship between the lathy ferrite and austenite. When the plane in the austenite substrate is  ${(1\bar 11)_{\rm{\gamma }}}$, “Y-shaped” lathy ferrite grows in an entangled cluster and the orientation relationship between the lathy ferrite and austenite is the Nishiyama–Wassermann relationship. Lathy ferrite is preferentially elongated along

${(1\bar 11)_{\rm{\gamma }}}$, “Y-shaped” lathy ferrite grows in an entangled cluster and the orientation relationship between the lathy ferrite and austenite is the Nishiyama–Wassermann relationship. Lathy ferrite is preferentially elongated along  ${\langle 211\rangle _{\rm{\gamma }}}$ and

${\langle 211\rangle _{\rm{\gamma }}}$ and  ${\langle 011\rangle _{\rm{\gamma }}}$ directions on

${\langle 011\rangle _{\rm{\gamma }}}$ directions on  ${(1\bar 11)_{\rm{\gamma }}}$ plane due to lower misfit. The included angle among the “Y-shaped” lathy ferrite is about 120° because the angle between each pair of

${(1\bar 11)_{\rm{\gamma }}}$ plane due to lower misfit. The included angle among the “Y-shaped” lathy ferrite is about 120° because the angle between each pair of  ${[21\bar 1]_{\rm{\gamma }}}$,

${[21\bar 1]_{\rm{\gamma }}}$,  ${[\bar 112]_{\rm{\gamma }}}$, and

${[\bar 112]_{\rm{\gamma }}}$, and  ${[\bar 1\bar 2\bar 1]_{\rm{\gamma }}}$ crystal directions is equal to 120°. Formation mechanism of the perpendicular lathy ferrite has also been analyzed according to the relationship between

${[\bar 1\bar 2\bar 1]_{\rm{\gamma }}}$ crystal directions is equal to 120°. Formation mechanism of the perpendicular lathy ferrite has also been analyzed according to the relationship between  ${\langle 211\rangle _{\rm{\gamma }}}$ and

${\langle 211\rangle _{\rm{\gamma }}}$ and  ${\langle 011\rangle _{\rm{\gamma }}}$ on

${\langle 011\rangle _{\rm{\gamma }}}$ on  ${(1\bar 11)_{\rm{\gamma }}}$ plane. This indicates that required crystal morphology of the lathy ferrite in the solidified microstructure can be obtained by controlling the crystal plane of austenite.

${(1\bar 11)_{\rm{\gamma }}}$ plane. This indicates that required crystal morphology of the lathy ferrite in the solidified microstructure can be obtained by controlling the crystal plane of austenite.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2013

References

REFERENCES

- 4

- Cited by