Article contents

Magnetic properties characterization of shear-textured 4 wt% Si electrical steel sheet

Published online by Cambridge University Press: 19 December 2016

Abstract

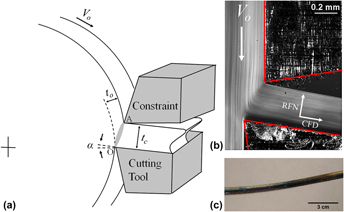

Simple shear deformation via hybrid cutting-extrusion is used to produce continuous electrical steel sheet from a commercial high-silicon (nominal 4 wt%) iron alloy of poor workability in a single deformation step, a fundamentally different route from the multi-step processing of rolling and annealing currently in use. The shear texture created in the sheet is found to be quite different from that produced by rolling. The magnetic properties of the shear-textured Fe–Si sheet are measured using closed-circuit permeametry and compared with those from sheet produced by rolling of the same alloy and a commercial non-grain-oriented sheet of similar composition. Properties compared include maximum relative permeability, induction, coercivity, and hysteresis loss. The results are interpreted in terms of microstructure, texture, and composition. A unit cell representation of the shear texture components is introduced that relates the expected orientation of easy magnetization directions with the sheet axes.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 7

- Cited by