Article contents

First-principles study of structural, elastic and thermodynamic properties of Ni–Sn–P intermetallics

Published online by Cambridge University Press: 05 January 2017

Abstract

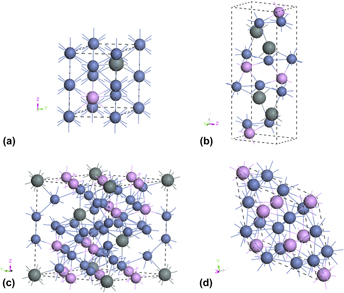

First-principles calculations are performed to investigate the structural, elastic, and thermodynamic properties of Ni3SnP, Ni2SnP, Ni10SnP3, and Ni2P (here, Ni2P is used for comparison with Ni2SnP). Through calculation, the three ternary Ni–Sn–P intermetallics are all thermodynamic stable but Ni3SnP is elastically unstable. Ni2SnP has the largest degree of elastic anisotropy and is more brittle than Ni2P while Ni10SnP3 is close to be isotropic. The Debye temperature together with the Cahill’s model and Clark’s model are used to investigate the thermal conductivity of the compounds. The Debye temperature follows the sequence of Ni10SnP3 > Ni2SnP > Ni2P. Based on the Clark’s model, the minimum thermal conductivity is ranked as Ni10SnP3 > Ni2P > Ni2SnP which means the heat transfer property of Ni2SnP is lower than Ni2P when the temperature is higher than Debye temperature. The electronic density of states is analyzed. The origin of the elastic anisotropy of Ni2SnP is investigated.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

References

REFERENCES

- 4

- Cited by