Due to their high strength and lightweight characteristics, carbon fibers are frequently used as reinforcement materials for polymer resins. However, the degree of enhancement of mechanical robustness due to the carbon fibers still has room for improvement. The smooth surfaces and limited surface functional groups in commercially available carbon fibers are such that the adhesion between the fibers and polymer matrices is weak, leading to weak interfaces and compromised strength. A potential solution to this problem has been provided by a research team led by Victor Tcherdyntsev at the National University of Science and Technology, Russia, who has shown that heating carbon fibers in air prior to their use in the composite materials effectively tackled the problem. Their work was published recently in Results in Physics (doi:10.1016/j.rinp.2019.102634).

Increasing the number of oxygen-containing moieties on carbon fiber surfaces could boost the fiber-matrix interfacial interaction. To realize this goal, the researchers adopted a thermal oxidation process to introduce oxygen-containing functional groups onto the carbon fiber surface. They heated the carbon fibers in a furnace to 500°C for 30 min in air. X-ray photoelectron spectroscopy revealed that the heating process introduced hydroxyl (–C–OH), ether or epoxy (–C–O–C–), carboxyl (–COOH), and carbonyl (–C=O) groups onto the carbon fiber surface. They showed that these functional groups could form chemical bonds with polysulfone when used as the matrix, and strengthen the fiber/polymer composite.

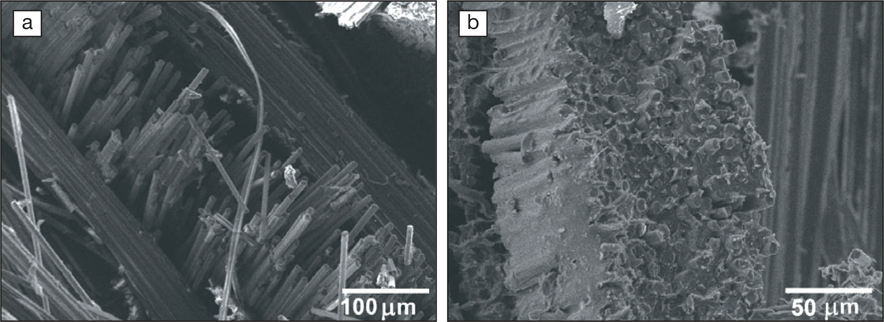

Scanning electron microscope images of fracture cross sections of (a) pristine carbon fiber/polysulfone and (b) oxidized carbon fiber/polysulfone. Credit: Results in Physics.

The shear strength of the oxidized carbon fiber/polysulfone was found to be enhanced by 47% compared to that of the pristine carbon fiber/polysulfone, reaching 62.9 ± 2.7 MPa. The scanning electron microscope image of the fracture surface of pristine carbon fiber/polysulfone showed multiple carbon fibers with clean and smooth surfaces, indicating that breakdown of the fiber/matrix interfaces was the reason for the mechanical failure. In contrast, the fracture surface of oxidized carbon fiber/polysulfone contained carbon fibers bundled with polysulfone. The attachment of polysulfone onto carbon fibers marked the reinforced fiber/matrix interfaces.

Juan Guan, professor of materials science and engineering at Beihang University, China, suggests a different mechanism for the enhancement in the shear strength: “Typically, oxidization in air appreciably decreases the strength of carbon fibers, which could lead to a different failure model that alters the composite’s shear strength.” Guan was not involved in this study.

The facile strategy of improving polysulfone adhesion to carbon fibers demonstrated in this work could potentially be applied to other oxygen-containing polymers such as poly(methyl methacrylate) and poly(dimethylsiloxane), thus creating opportunities for diversifying carbon fiber-reinforced polymers.