1 Introduction

Integrating multiple fluidic processes into a single platform has become progressively important in modern lab-on-a-chip devices where separation and mixing often turn out to be two of the most critical processes (Hunter Reference Hunter1981; Probstein Reference Probstein1994; Stroock et al. Reference Stroock, Dertinger, Ajdari, Mezic, Stone and Whitesides2002; Ghosal Reference Ghosal2004; Stone, Stroock & Ajdari Reference Stone, Stroock and Ajdari2004; Masliyah & Bhattacherjee Reference Masliyah and Bhattacherjee2006; Whitesides Reference Whitesides2006). With the rapid advancement in microfabrication technologies, a large number of research efforts have been dedicated towards developing strategies for improved fluidic mixing or separation (Anderson et al. Reference Anderson, Galaktionov, Peters, Van De Vosse and Meijer2000; Glasgow, Batton & Aubry Reference Glasgow, Batton and Aubry2004; Karniadakis, Beskok & Aluru Reference Karniadakis, Beskok and Aluru2005; Zhang, He & Liu Reference Zhang, He and Liu2006; Chang & Yang Reference Chang and Yang2008; Sugioka Reference Sugioka2010; Ghosh & Chakraborty Reference Ghosh and Chakraborty2012). Towards achieving enhanced mixing in microdevices, diffusion and dispersion are undoubtedly the two most common phenomena. Accordingly, significant research interest in this domain has developed over the past years, with a vision of employing different flow-actuating mechanisms as well as geometric alterations in the fluidic pathways, so as to achieve the desired functionalities.

Although flow actuation using electric fields has wide spectrum of applications in both engineering and medical domains (Becker & Gärtner Reference Becker and Gärtner2000; Garcia et al. Reference Garcia, Ista, Petsev and López2005; Van Der Heyden, Stein & Dekker Reference Van Der Heyden, Stein and Dekker2005; Das, Das & Chakraborty Reference Das, Das and Chakraborty2006; Das & Chakraborty Reference Das and Chakraborty2007; Haeberle & Zengerle Reference Haeberle and Zengerle2007; Ohno, Tachikawa & Manz Reference Ohno, Tachikawa and Manz2008; Berli Reference Berli2010; Mark et al. Reference Mark, Haeberle, Roth, Von Stetten and Zengerle2010; Zhao Reference Zhao2011; Bandopadhyay & Chakraborty Reference Bandopadhyay and Chakraborty2012; Nguyen et al. Reference Nguyen, Xie, De Vreede, Van Den Berg and Eijkel2013; Goswami et al. Reference Goswami, Chakraborty, Bandopadhyay and Chakraborty2015; Das et al. Reference Das, Kar, Anwar, Saha and Chakraborty2018), one of the major aspects of the classical electro-osmotic flow in the presence of homogeneous interfacial conditions is the existence of the uniform velocity profile which arises when the electrical double layer (EDL) becomes very thin compared to the channel dimension (Ghosal Reference Ghosal2004; Masliyah & Bhattacherjee Reference Masliyah and Bhattacherjee2006). This results in a plug-type velocity distribution, thus reducing the extent of mixing significantly.

Hydrodynamic dispersion is the band broadening of a solute which mainly arises from the non-uniformity in the flow field (Taylor Reference Taylor1953; Aris Reference Aris1956, Reference Aris1959; Chatwin Reference Chatwin1970, Reference Chatwin1975; Chatwin & Sullivan Reference Chatwin and Sullivan1982; Smith Reference Smith1982; Barton Reference Barton1983; Watson Reference Watson1983; Mazumder & Das Reference Mazumder and Das1992; Ng & Yip Reference Ng and Yip2001; Zholkovskij & Masliyah Reference Zholkovskij and Masliyah2004; Ajdari, Bontoux & Stone Reference Ajdari, Bontoux and Stone2006; Ng Reference Ng2006; Ghosal Reference Ghosal2006; Jansons Reference Jansons2006; Sounart & Baygents Reference Sounart and Baygents2007; Dutta Reference Dutta2008; Datta & Ghosal Reference Datta and Ghosal2008; Ghosal & Chen Reference Ghosal and Chen2012; Arcos et al. Reference Arcos, Méndez, Bautista and Bautista2018; Chu et al. Reference Chu, Garoff, Przybycien, Tilton and Khair2019). Under ideal circumstances, the velocity profile of electro-osmotic flow does not contribute to shear-induced axial dispersion because of the flatness of the velocity profile as opposed to the case of Poiseuille flow (which is parabolic in nature) (Gaš, Štědrý & Kenndler Reference Gaš, Štědrý and Kenndler1997; Ghosal Reference Ghosal2004; Mukherjee et al. Reference Mukherjee, Dhar, Dasgupta and Chakraborty2019). However, in practice, any inhomogeneity in the flow condition or flow domain can give rise to strong perturbation in the flow field, thereby inducing an axial pressure gradient, which is accompanied by the generation of secondary flow component in order to maintain the flow continuity. In applications demanding augmented dispersion, classical electro-osmotic flow is modulated in two ways, either bringing non-uniformity in the channel geometry or introducing axial variation in the zeta potential (Ajdari Reference Ajdari1995, Reference Ajdari1996; Ghosal Reference Ghosal2002; Mandal et al. Reference Mandal, Ghosh, Bandopadhyay and Chakraborty2015; Ghosh, Mandal & Chakraborty Reference Ghosh, Mandal and Chakraborty2017; Arcos et al. Reference Arcos, Méndez, Bautista and Bautista2018).

Over the years, conventional studies of electrokinetics mainly directed their focus towards different techniques of flow actuation, energy conversion and zeta potential measurement under isothermal flow conditions (Levine et al. Reference Levine, Marriott, Neale and Epstein1975; Zeng et al. Reference Zeng, Chen, Mikkelsen and Santiago2001; Sinton et al. Reference Sinton, Escobedo-Canseco, Ren and Li2002; Brask, Kutter & Bruus Reference Brask, Kutter and Bruus2005; Gao et al. Reference Gao, Wong, Yang and Ooi2005; Venditti, Xuan & Li Reference Venditti, Xuan and Li2006; Li, Wong & Nguyen Reference Li, Wong and Nguyen2009; Mogensen et al. Reference Mogensen, Gangloff, Boggild, Teo, Milne and Kutter2009; Das & Chakraborty Reference Das and Chakraborty2010; Bandopadhyay & Chakraborty Reference Bandopadhyay and Chakraborty2011; Li, Wong & Nguyen Reference Li, Wong and Nguyen2011). The corresponding literature for non-isothermal flow is relatively scarce because of the lack of understanding of the physics involved. In non-isothermal systems, several complexities come into the picture. First, the modulated thermo-physical properties of an electrolyte solution, like viscosity, electrical permittivity, thermal conductivity, ionic diffusivity and thermophoretic mobility, in the presence of a thermal gradient, strongly influence the fluid motion. Besides this alteration in hydrodynamics, an additional contribution of dielectrophoretic body force due to permittivity variation, accompanied by an induced axial pressure gradient, comes into play in addition to the conventional electrokinetic forcing, thereby bringing complexity to the flow physics (Ghonge et al. Reference Ghonge, Chakraborty, Dey and Chakraborty2013; Dietzel & Hardt Reference Dietzel and Hardt2017). Additionally, zeta potential, which plays a crucial dole in governing the flow physics in electrokinetic flows, no longer remains constant in the presence of a thermal gradient (Revil et al. Reference Revil, Schwaeger, Cathles and Manhardt1999; Reppert Reference Reppert2003; Revil, Pezard & Glover Reference Revil, Pezard and Glover2003; Venditti et al. Reference Venditti, Xuan and Li2006; Ghonge et al. Reference Ghonge, Chakraborty, Dey and Chakraborty2013). Also, the determination of the temperature field may require a knowledge of other effects like heat generation due to induced streaming field or viscous dissipation which in turn affect fluid physical properties and convective contribution to the temperature distribution. Apart from this, contrary to the conventional electrokinetic studies, the assumption of mechanical equilibrium of ions within the electrical double layer (under isothermal conditions) is no longer valid where the effect of thermo-diffusion of ions needs to be incorporated in the transport equation of ionic species along with other components (Zhou et al. Reference Zhou, Xie, Yang and Cheong Lam2015; Zhang et al. Reference Zhang, Wang, Zeng and Zhao2019).

The distortion of the local equilibrium of ions in the electrical double layer (EDL) creates a departure from the classical Boltzmann distribution of ions which has direct consequences for the potential distribution. This alteration in charge distribution influences the flow dynamics via electrokinetic forcing, where the intricate coupling between thermal and electrical effects is already prevalent through the aforesaid property variation and an additional dielectrophoretic force. Further, in the absence of any external electric field, the net ionic current turns out to be zero. This condition is itself another source of nonlinearity in the analysis where both conduction and streaming current undergo marked alteration under the influence of finite temperature difference. In addition, it is worth mentioning that, when an electrolyte solution is subjected to an imposed temperature gradient, a thermoelectric field is induced by virtue of the movement of ions in response to the thermal driving force, commonly known as the Soret effect (Ghonge et al. Reference Ghonge, Chakraborty, Dey and Chakraborty2013; Zhou et al. Reference Zhou, Xie, Yang and Cheong Lam2015; Dietzel & Hardt Reference Dietzel and Hardt2016, Reference Dietzel and Hardt2017; Zhang et al. Reference Zhang, Wang, Zeng and Zhao2019). Moreover, an additional form of thermoelectric field can be induced within the system because of the diffusivity difference between the ions even if their Soret coefficients remain the same. Besides, the mode of application of thermal gradient can cause significant rearrangement of ions within the EDL and, hence, the subsequent potential distribution for a transverse temperature gradient may not necessarily be the same as that for longitudinal temperature gradient, altering the hydrodynamics in a rather profound manner. Considering the aforementioned intricacies in coupling thermal, electrical and hydrodynamical effects in micro-confinements, research efforts towards addressing various aspects of thermo-solutal convection of electrolyte solutions have turned out to be relatively inadequate, despite having widespread applications in processes like water treatment, charge separation, zeta potential determination, waste heat recovery and energy conversion (Würger Reference Würger2008, Reference Würger2010; Sandbakk, Bentien & Kjelstrup Reference Sandbakk, Bentien and Kjelstrup2013; Dietzel & Hardt Reference Dietzel and Hardt2016; Jokinen et al. Reference Jokinen, Manzanares, Kontturi and Murtomäki2016; Barragán & Kjelstrup Reference Barragán and Kjelstrup2017; Dietzel & Hardt Reference Dietzel and Hardt2017; Li & Wang Reference Li and Wang2018). As such, the research focus in this domain has been directed primarily towards incorporating non-isothermal effects as a secondary force in the alteration of hydrodynamics of simple fluids (Maynes & Webb Reference Maynes and Webb2003; Tang et al. Reference Tang, Yang, Chai and Gong2003; Xuan et al. Reference Xuan, Xu, Sinton and Li2004; Chakraborty Reference Chakraborty2006; Huang & Yang Reference Huang and Yang2006; Xuan Reference Xuan2008; Garai & Chakraborty Reference Garai and Chakraborty2009; Sadeghi et al. Reference Sadeghi, Yavari, Saidi and Chakraborty2011; Dey, Chakraborty & Chakraborty Reference Dey, Chakraborty and Chakraborty2011; Sánchez et al. Reference Sánchez, Ascanio, Méndez and Bautista2018). Therefore, except for some limited physical scenarios, such an exclusive effect has not been utilized to a significant practical benefit (Dietzel & Hardt Reference Dietzel and Hardt2016, Reference Dietzel and Hardt2017; Zhang et al. Reference Zhang, Wang, Zeng and Zhao2019).

Recently, incorporation of a thermal gradient has emerged as an alternative tool in augmenting dispersion where interplay between thermal and electrical effects over small length scales, almost exclusively, dictates the flow physics (Chen et al. Reference Chen, Lin, Lele and Santiago2005; Sánchez et al. Reference Sánchez, Ascanio, Méndez and Bautista2018; Mukherjee et al. Reference Mukherjee, Dhar, Dasgupta and Chakraborty2019). In addition, it may be noted that with the emergence of new-generation medical devices, complex bio-fluids have more prominently come into the paradigm of microfluidics (Das & Chakraborty Reference Das and Chakraborty2006; Berli & Olivares Reference Berli and Olivares2008; Olivares, Vera-Candioti & Berli Reference Olivares, Vera-Candioti and Berli2009; Berli Reference Berli2010; Zhao & Yang Reference Zhao and Yang2011, Reference Zhao and Yang2013). Such fluids exhibit strikingly distinct behaviour compared to the fluids obeying Newton’s law of viscosity (Owens Reference Owens2006; Fam, Bryant & Kontopoulou Reference Fam, Bryant and Kontopoulou2007; Moyers-Gonzalez, Owens & Fang Reference Moyers-Gonzalez, Owens and Fang2008; De Loubens et al. Reference De Loubens, Magnin, Doyennette, Tréléa and Souchon2011; Brust et al. Reference Brust, Schaefer, Doerr and Wagner2013; Silva, Alves & Oliveira Reference Silva, Alves and Oliveira2017). Some recent studies have demonstrated that the constitutive behaviour of these biological fluids has close resemblance to the rheology of viscoelastic fluids, and therefore the inclusion of fluid rheology and viscoelasticity in dispersion characteristics has attracted significant attention lately (Brust et al. Reference Brust, Schaefer, Doerr and Wagner2013; Arcos et al. Reference Arcos, Méndez, Bautista and Bautista2018; Hoshyargar et al. Reference Hoshyargar, Talebi, Ashrafizadeh and Sadeghi2018; Mukherjee et al. Reference Mukherjee, Dhar, Dasgupta and Chakraborty2019). While considering the thermally induced electrokinetic flow of viscoelastic fluids, an additional source of nonlinearity crops up as mediated by the constitutive behaviour of the fluid (Afonso, Alves & Pinho Reference Afonso, Alves and Pinho2009; Coelho, Alves & Pinho Reference Coelho, Alves and Pinho2012; Afonso, Alves & Pinho Reference Afonso, Alves and Pinho2013; Ghosh & Chakraborty Reference Ghosh and Chakraborty2015; Ferrás et al. Reference Ferrás, Afonso, Alves, Nóbrega and Pinho2016; Ghosh, Chaudhury & Chakraborty Reference Ghosh, Chaudhury and Chakraborty2016; Mukherjee et al. Reference Mukherjee, Das, Dhar, Chakraborty and Dasgupta2017a ,Reference Mukherjee, Goswami, Dhar, Dasgupta and Chakraborty b ). Moreover, the degree of viscoelasticity, which is determined using physical properties like fluid viscosity and relaxation time, is a strong function of the prevalent thermal gradient, augmenting the complexity of the problem to a large extent (Bautista et al. Reference Bautista, Sánchez, Arcos and Méndez2013; Mukherjee et al. Reference Mukherjee, Dhar, Dasgupta and Chakraborty2019).

To the best of our knowledge, dispersion characteristics of thermally induced electrokinetic transport of complex fluids in microfluidic environments, where the temperature gradient is solely used for flow manipulation, have not been addressed in the literature. Here, we report the effect of an external temperature gradient on the dispersion characteristics of an electrolyte solution in a parallel-plate microchannel. We subsequently discuss the charge redistribution upon application of the thermal gradient, subsequent perturbation of the fluid motion and its implications for hydrodynamic dispersion, considering both Newtonian and viscoelastic fluids. Our results reveal that by combining some of the electrokinetic, thermal and fluidic parameters coupled with rheological aspects, it is possible to achieve massively augmented solute dispersion, while for some combinations significant enhancement in streaming potential (compared to the solely pressure-driven flow) can also be obtained. We believe that the present analysis can be used as a fundamental basis in the design of thermally actuated micro- and bio-fluidic devices demanding improved solute dispersion where the interplay between electromechanics, thermal effects, hydrodynamics and rheological aspects in narrow confinement can be coupled together to a beneficial effect. Additionally, a wide variety of thermal and fluidic problems can also be approached on the basis of the present theoretical framework (Raj et al. Reference Raj, Sarkar, Chakraborty, Phanikumar, Dutta and Chattopadhyay2002; Das, Chakraborty & Dutta Reference Das, Chakraborty and Dutta2004; Chakraborty & Chakraborty Reference Chakraborty and Chakraborty2007; Ghatak & Chakraborty Reference Ghatak and Chakraborty2007; Chakraborty & Srivastava Reference Chakraborty and Srivastava2007; Chakraborty & Padhy Reference Chakraborty and Padhy2008).

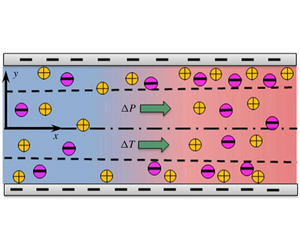

Figure 1. Schematic of the combined pressure-driven and temperature-gradient-induced flow of electrolyte solution through a parallel-plate microchannel. (a) Temperature gradient is applied in the axial direction. (b) Temperature gradient is applied in the transverse direction.

2 Problem formulation

We consider non-isothermal electrokinetic flow of a binary

![]() $1:1$

symmetric electrolyte solution through a parallel-plate microchannel. We choose a rectangular Cartesian coordinate system where

$1:1$

symmetric electrolyte solution through a parallel-plate microchannel. We choose a rectangular Cartesian coordinate system where

![]() $x$

and

$x$

and

![]() $y$

coordinates represent longitudinal and transverse directions, respectively, while the origin is placed at the centreline of the channel. Length scales in the two directions are

$y$

coordinates represent longitudinal and transverse directions, respectively, while the origin is placed at the centreline of the channel. Length scales in the two directions are

![]() $l$

and

$l$

and

![]() $h$

, respectively, where the half-channel height (

$h$

, respectively, where the half-channel height (

![]() $h$

) is very small compared to the channel length (

$h$

) is very small compared to the channel length (

![]() $l$

), i.e.

$l$

), i.e.

![]() $h\ll l$

or

$h\ll l$

or

![]() $\unicode[STIX]{x1D6FD}=h/l\ll 1$

. We have employed two different types of thermal gradients: case 1, axially applied temperature gradient; case 2, temperature gradient applied in the transverse direction (figure 1).

$\unicode[STIX]{x1D6FD}=h/l\ll 1$

. We have employed two different types of thermal gradients: case 1, axially applied temperature gradient; case 2, temperature gradient applied in the transverse direction (figure 1).

2.1 Dispersion coefficient: a broad perspective

We consider the hydrodynamic dispersion characteristics of a combined pressure-driven and thermal-gradient-driven electrokinetic flow of an electrolyte solution. According to the definition of the band-broadening phenomenon, the hydrodynamic dispersion coefficient

![]() $(\overline{D}_{eff})$

depends on the rate of change of variance of solute displacement band as

$(\overline{D}_{eff})$

depends on the rate of change of variance of solute displacement band as

![]() $D_{eff}=\frac{1}{2}(\text{d}/\text{d}t)\unicode[STIX]{x1D70E}^{2}(t)$

, where

$D_{eff}=\frac{1}{2}(\text{d}/\text{d}t)\unicode[STIX]{x1D70E}^{2}(t)$

, where

![]() $\unicode[STIX]{x1D70E}^{2}$

is the variance of solute displacement. This temporal variation with respect to the centroid of the band depends on the plate height (

$\unicode[STIX]{x1D70E}^{2}$

is the variance of solute displacement. This temporal variation with respect to the centroid of the band depends on the plate height (

![]() $h^{\prime }$

) as

$h^{\prime }$

) as

![]() $h^{\prime }=(\text{d}/\text{d}x^{\prime })\unicode[STIX]{x1D70E}^{2}(x^{\prime })$

, where

$h^{\prime }=(\text{d}/\text{d}x^{\prime })\unicode[STIX]{x1D70E}^{2}(x^{\prime })$

, where

![]() $x^{\prime }$

denotes the location of the band centroid. Knowledge of the plate height is necessary in determining the dispersion coefficient because of its ability to incorporate any change in the variance of the mean concentration. For a band of non-adsorbing solute flowing in a rectangular channel, the velocity of the centre mass becomes equal to the mean axial velocity of flow, i.e.

$x^{\prime }$

denotes the location of the band centroid. Knowledge of the plate height is necessary in determining the dispersion coefficient because of its ability to incorporate any change in the variance of the mean concentration. For a band of non-adsorbing solute flowing in a rectangular channel, the velocity of the centre mass becomes equal to the mean axial velocity of flow, i.e.

![]() $u_{avg}=\text{d}x^{\prime }/\text{d}t$

. Using the descriptions of

$u_{avg}=\text{d}x^{\prime }/\text{d}t$

. Using the descriptions of

![]() $h^{\prime }$

and

$h^{\prime }$

and

![]() $x^{\prime }$

, one can rewrite the expression of the dispersion coefficient as

$x^{\prime }$

, one can rewrite the expression of the dispersion coefficient as

Here,

![]() $u_{avg}$

is the mean velocity averaged cross-sectionally. As reported in the literature (Van Deemter, Zuiderweg & Klinkenberg Reference Van Deemter, Zuiderweg and Klinkenberg1956), the plate height is related to the mean velocity as

$u_{avg}$

is the mean velocity averaged cross-sectionally. As reported in the literature (Van Deemter, Zuiderweg & Klinkenberg Reference Van Deemter, Zuiderweg and Klinkenberg1956), the plate height is related to the mean velocity as

In (2.2),

![]() $h_{min}$

is the minimum plate height for a given flow condition and

$h_{min}$

is the minimum plate height for a given flow condition and

![]() $D$

is diffusivity. On the right-hand side, the contribution of the molecular diffusion is represented by the first term while the second term represents the contribution due to the non-uniformity in the flow field. By following some recent studies (Arcos et al.

Reference Arcos, Méndez, Bautista and Bautista2018; Hoshyargar et al.

Reference Hoshyargar, Talebi, Ashrafizadeh and Sadeghi2018), we have used the following expression for evaluating

$D$

is diffusivity. On the right-hand side, the contribution of the molecular diffusion is represented by the first term while the second term represents the contribution due to the non-uniformity in the flow field. By following some recent studies (Arcos et al.

Reference Arcos, Méndez, Bautista and Bautista2018; Hoshyargar et al.

Reference Hoshyargar, Talebi, Ashrafizadeh and Sadeghi2018), we have used the following expression for evaluating

![]() $h_{min}$

:

$h_{min}$

:

Combining all this, the dimensionless form of the dispersion coefficient

![]() $(\overline{D}_{eff})$

reads as

$(\overline{D}_{eff})$

reads as

where

![]() $Pe_{D}$

is the dispersion Peclet number,

$Pe_{D}$

is the dispersion Peclet number,

![]() $\overline{h}_{min}=h_{min}/h$

and

$\overline{h}_{min}=h_{min}/h$

and

![]() $\overline{u}_{avg}=u_{avg}/u_{c}$

is the dimensionless average flow velocity with

$\overline{u}_{avg}=u_{avg}/u_{c}$

is the dimensionless average flow velocity with

![]() $u_{c}$

being the characteristic velocity scale.

$u_{c}$

being the characteristic velocity scale.

For the sake of brevity, the detailed mathematical expressions for obtaining the hydrodynamic dispersion coefficient are presented in § A of the supplementary material, available at https://doi.org/10.1017/jfm.2020.369, which clearly illustrates the complicated mathematical and physical interplay of the solutal, hydrodynamic and thermal fields, restrained by the consideration of overall electroneutrality. As clear from the definition, the dispersion coefficient depends directly on the velocity field, which in turn is influenced strongly by the charge distribution modulated by external temperature gradient, mediated by a two-way coupling. The governing equations delineating the same are discussed in the subsequent subsection.

2.2 Governing equations and boundary conditions

In this section, we first present the governing equation for the temperature distribution. Unlike conventional streaming-field-induced electrokinetic flow, here temperature (

![]() $T$

) within the microchannel does not remain constant which is given by the following energy equation:

$T$

) within the microchannel does not remain constant which is given by the following energy equation:

where the left-hand side is the advective contribution, the first two terms on the right-hand side are the conductive contributions,

![]() $Q_{gen}=\unicode[STIX]{x1D70E}E_{x}^{2}=(2z^{2}e^{2}Dn_{\infty }/k_{B}T)(-\unicode[STIX]{x2202}\unicode[STIX]{x1D719}/\unicode[STIX]{x2202}x)^{2}$

is the heat generation term due to the induced streaming field and

$Q_{gen}=\unicode[STIX]{x1D70E}E_{x}^{2}=(2z^{2}e^{2}Dn_{\infty }/k_{B}T)(-\unicode[STIX]{x2202}\unicode[STIX]{x1D719}/\unicode[STIX]{x2202}x)^{2}$

is the heat generation term due to the induced streaming field and

![]() $Q_{vd}=\unicode[STIX]{x1D707}[2\{(\unicode[STIX]{x2202}u/\unicode[STIX]{x2202}x)^{2}+(\unicode[STIX]{x2202}v/\unicode[STIX]{x2202}y)^{2}\}+(\unicode[STIX]{x2202}u/\unicode[STIX]{x2202}y+\unicode[STIX]{x2202}v/\unicode[STIX]{x2202}x)^{2}]-\frac{2}{3}\unicode[STIX]{x1D707}(\unicode[STIX]{x1D735}\boldsymbol{\cdot }v)^{2}$

is the viscous dissipation term with

$Q_{vd}=\unicode[STIX]{x1D707}[2\{(\unicode[STIX]{x2202}u/\unicode[STIX]{x2202}x)^{2}+(\unicode[STIX]{x2202}v/\unicode[STIX]{x2202}y)^{2}\}+(\unicode[STIX]{x2202}u/\unicode[STIX]{x2202}y+\unicode[STIX]{x2202}v/\unicode[STIX]{x2202}x)^{2}]-\frac{2}{3}\unicode[STIX]{x1D707}(\unicode[STIX]{x1D735}\boldsymbol{\cdot }v)^{2}$

is the viscous dissipation term with

![]() $\unicode[STIX]{x1D707}=\unicode[STIX]{x1D707}_{ref}\exp [-\unicode[STIX]{x1D714}_{1}(T-T_{ref})]$

being the fluid viscosity. Parameters

$\unicode[STIX]{x1D707}=\unicode[STIX]{x1D707}_{ref}\exp [-\unicode[STIX]{x1D714}_{1}(T-T_{ref})]$

being the fluid viscosity. Parameters

![]() $\unicode[STIX]{x1D70C}$

and

$\unicode[STIX]{x1D70C}$

and

![]() $C_{p}$

are the density and specific capacities of the fluid,

$C_{p}$

are the density and specific capacities of the fluid,

![]() $E_{x}=-\unicode[STIX]{x2202}\unicode[STIX]{x1D719}/\unicode[STIX]{x2202}x$

is the induced streaming field and

$E_{x}=-\unicode[STIX]{x2202}\unicode[STIX]{x1D719}/\unicode[STIX]{x2202}x$

is the induced streaming field and

![]() $\unicode[STIX]{x1D70E}$

is the bulk electrical conductivity, where

$\unicode[STIX]{x1D70E}$

is the bulk electrical conductivity, where

![]() $\unicode[STIX]{x1D70E}=2z^{2}e^{2}Dn_{\infty }/k_{B}T$

with

$\unicode[STIX]{x1D70E}=2z^{2}e^{2}Dn_{\infty }/k_{B}T$

with

![]() $z$

,

$z$

,

![]() $e$

,

$e$

,

![]() $D$

,

$D$

,

![]() $n_{\infty }$

and

$n_{\infty }$

and

![]() $k_{B}$

being the valence of ions, elementary electronic charge, average diffusivity of ions, bulk ionic number density and Boltzmann constant, respectively. Using the respective scales of the pertinent variables, the corresponding dimensionless form can be written as

$k_{B}$

being the valence of ions, elementary electronic charge, average diffusivity of ions, bulk ionic number density and Boltzmann constant, respectively. Using the respective scales of the pertinent variables, the corresponding dimensionless form can be written as

$$\begin{eqnarray}\displaystyle & & \displaystyle \!\!\!\unicode[STIX]{x1D6FD}Pe_{T}\left(\overline{u}\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}{\unicode[STIX]{x2202}\overline{x}}+\overline{v}\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}{\unicode[STIX]{x2202}\overline{y}}\right)=\unicode[STIX]{x1D6FD}^{2}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\overline{x}}\left(\frac{k}{k_{ref}}\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}{\unicode[STIX]{x2202}\overline{x}}\right)\nonumber\\ \displaystyle & & \displaystyle \quad +\,\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\overline{y}}\left(\frac{k}{k_{ref}}\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}{\unicode[STIX]{x2202}\overline{y}}\right)+\unicode[STIX]{x1D6FD}^{2}\frac{\unicode[STIX]{x1D700}\unicode[STIX]{x1D705}^{2}D}{k_{ref}\unicode[STIX]{x0394}T_{ref}}\left(\frac{k_{B}T_{C}}{ze}\right)^{2}\left(\frac{\unicode[STIX]{x2202}\overline{\unicode[STIX]{x1D719}}}{\unicode[STIX]{x2202}\overline{x}}\right)^{2}\nonumber\\ \displaystyle & & \displaystyle \quad +\,\frac{\unicode[STIX]{x1D707}{u_{c}}^{2}}{k_{ref}\unicode[STIX]{x0394}T_{ref}}\left[2\unicode[STIX]{x1D6FD}^{2}\left\{\left(\frac{\unicode[STIX]{x2202}\overline{u}}{\unicode[STIX]{x2202}\overline{x}}\right)^{2}+\left(\frac{\unicode[STIX]{x2202}\overline{v}}{\unicode[STIX]{x2202}\overline{y}}\right)^{2}\right\}+\left(\frac{\unicode[STIX]{x2202}\overline{u}}{\unicode[STIX]{x2202}\overline{y}}+\unicode[STIX]{x1D6FD}^{2}\frac{\unicode[STIX]{x2202}\overline{v}}{\unicode[STIX]{x2202}\overline{x}}\right)^{2}\right],\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & & \displaystyle \!\!\!\unicode[STIX]{x1D6FD}Pe_{T}\left(\overline{u}\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}{\unicode[STIX]{x2202}\overline{x}}+\overline{v}\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}{\unicode[STIX]{x2202}\overline{y}}\right)=\unicode[STIX]{x1D6FD}^{2}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\overline{x}}\left(\frac{k}{k_{ref}}\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}{\unicode[STIX]{x2202}\overline{x}}\right)\nonumber\\ \displaystyle & & \displaystyle \quad +\,\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\overline{y}}\left(\frac{k}{k_{ref}}\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}{\unicode[STIX]{x2202}\overline{y}}\right)+\unicode[STIX]{x1D6FD}^{2}\frac{\unicode[STIX]{x1D700}\unicode[STIX]{x1D705}^{2}D}{k_{ref}\unicode[STIX]{x0394}T_{ref}}\left(\frac{k_{B}T_{C}}{ze}\right)^{2}\left(\frac{\unicode[STIX]{x2202}\overline{\unicode[STIX]{x1D719}}}{\unicode[STIX]{x2202}\overline{x}}\right)^{2}\nonumber\\ \displaystyle & & \displaystyle \quad +\,\frac{\unicode[STIX]{x1D707}{u_{c}}^{2}}{k_{ref}\unicode[STIX]{x0394}T_{ref}}\left[2\unicode[STIX]{x1D6FD}^{2}\left\{\left(\frac{\unicode[STIX]{x2202}\overline{u}}{\unicode[STIX]{x2202}\overline{x}}\right)^{2}+\left(\frac{\unicode[STIX]{x2202}\overline{v}}{\unicode[STIX]{x2202}\overline{y}}\right)^{2}\right\}+\left(\frac{\unicode[STIX]{x2202}\overline{u}}{\unicode[STIX]{x2202}\overline{y}}+\unicode[STIX]{x1D6FD}^{2}\frac{\unicode[STIX]{x2202}\overline{v}}{\unicode[STIX]{x2202}\overline{x}}\right)^{2}\right],\end{eqnarray}$$

where

![]() $\overline{u}=u/u_{c}$

is the dimensionless axial velocity component,

$\overline{u}=u/u_{c}$

is the dimensionless axial velocity component,

![]() $\overline{v}=vl/(u_{c}h)$

is the dimensionless transverse velocity component,

$\overline{v}=vl/(u_{c}h)$

is the dimensionless transverse velocity component,

![]() $\unicode[STIX]{x1D703}=(T-T_{C})/\unicode[STIX]{x0394}T_{ref}$

is the dimensionless temperature,

$\unicode[STIX]{x1D703}=(T-T_{C})/\unicode[STIX]{x0394}T_{ref}$

is the dimensionless temperature,

![]() $\overline{\unicode[STIX]{x1D719}}=(ze\unicode[STIX]{x1D719})/(k_{B}T_{C})$

is the dimensionless potential,

$\overline{\unicode[STIX]{x1D719}}=(ze\unicode[STIX]{x1D719})/(k_{B}T_{C})$

is the dimensionless potential,

![]() $\unicode[STIX]{x1D700}=\unicode[STIX]{x1D700}_{ref}\exp [-\unicode[STIX]{x1D714}_{2}(T-T_{ref})]$

is the electrical permittivity and

$\unicode[STIX]{x1D700}=\unicode[STIX]{x1D700}_{ref}\exp [-\unicode[STIX]{x1D714}_{2}(T-T_{ref})]$

is the electrical permittivity and

![]() $k=k_{ref}\exp [\unicode[STIX]{x1D714}_{3}(T-T_{ref})]$

is the thermal conductivity of the fluid. Parameters

$k=k_{ref}\exp [\unicode[STIX]{x1D714}_{3}(T-T_{ref})]$

is the thermal conductivity of the fluid. Parameters

![]() $u_{c}$

and

$u_{c}$

and

![]() $T_{C}=T_{ref}$

are taken as characteristic scales of velocity and temperature with

$T_{C}=T_{ref}$

are taken as characteristic scales of velocity and temperature with

![]() $\unicode[STIX]{x0394}T_{ref}=(T_{H}-T_{C})/2$

being the characteristic temperature difference. Here,

$\unicode[STIX]{x0394}T_{ref}=(T_{H}-T_{C})/2$

being the characteristic temperature difference. Here,

![]() $\unicode[STIX]{x1D705}$

is the inverse of the EDL thickness and

$\unicode[STIX]{x1D705}$

is the inverse of the EDL thickness and

![]() $Pe_{T}$

is the thermal Peclet number

$Pe_{T}$

is the thermal Peclet number

![]() $Pe_{T}=u_{c}h\unicode[STIX]{x1D70C}C_{p}/k_{ref}$

. The assumptions for the simplification of the energy equation are described in detail in § A1 of the supplementary material. For temperature gradient applied in the axial direction, the simplified non-dimensional equation is

$Pe_{T}=u_{c}h\unicode[STIX]{x1D70C}C_{p}/k_{ref}$

. The assumptions for the simplification of the energy equation are described in detail in § A1 of the supplementary material. For temperature gradient applied in the axial direction, the simplified non-dimensional equation is

This equation is subjected to a low temperature

![]() $T_{C}$

at the channel entrance (i.e. at

$T_{C}$

at the channel entrance (i.e. at

![]() $x=0$

) and a high temperature

$x=0$

) and a high temperature

![]() $T_{H}$

at the channel exit (i.e. at

$T_{H}$

at the channel exit (i.e. at

![]() $x=l$

).

$x=l$

).

For the transport of the ionic species, here, in the presence of a thermal gradient, ions no longer remain in equilibrium and one cannot consider a Boltzmann distribution assumption while obtaining the potential distribution. One needs to find the ionic number concentration (

![]() $n_{i}$

) first, which can be obtained by employing the classical Nernst–Planck equation

$n_{i}$

) first, which can be obtained by employing the classical Nernst–Planck equation

![]() $\unicode[STIX]{x1D735}\boldsymbol{\cdot }J_{i}=0$

, where

$\unicode[STIX]{x1D735}\boldsymbol{\cdot }J_{i}=0$

, where

Here, the ionic flux

![]() $J_{i}$

consists of four components: advective

$J_{i}$

consists of four components: advective

![]() $(n_{i}v)$

, diffusive

$(n_{i}v)$

, diffusive

![]() $(D_{i}\unicode[STIX]{x1D735}n_{i})$

, thermo-diffusive

$(D_{i}\unicode[STIX]{x1D735}n_{i})$

, thermo-diffusive

![]() $(n_{i}D_{Ti}\unicode[STIX]{x1D735}T)$

and electro-migrative

$(n_{i}D_{Ti}\unicode[STIX]{x1D735}T)$

and electro-migrative

![]() $(n_{i}\unicode[STIX]{x1D707}_{i}^{\ast }\unicode[STIX]{x1D735}\unicode[STIX]{x1D719})$

components. Parameter

$(n_{i}\unicode[STIX]{x1D707}_{i}^{\ast }\unicode[STIX]{x1D735}\unicode[STIX]{x1D719})$

components. Parameter

![]() $D_{i}$

is the diffusivity and

$D_{i}$

is the diffusivity and

![]() $D_{Ti}$

and

$D_{Ti}$

and

![]() $\unicode[STIX]{x1D707}_{i}^{\ast }=ez_{i}D_{i}/(k_{B}T)$

are the thermophoretic and electrophoretic mobilities, respectively. The dimensionless form of the Nernst–Planck equation reads as

$\unicode[STIX]{x1D707}_{i}^{\ast }=ez_{i}D_{i}/(k_{B}T)$

are the thermophoretic and electrophoretic mobilities, respectively. The dimensionless form of the Nernst–Planck equation reads as

$$\begin{eqnarray}\displaystyle & & \displaystyle \unicode[STIX]{x1D6FD}^{2}Pe_{i}\left(\overline{u}\frac{\unicode[STIX]{x2202}\overline{n}_{i}}{\unicode[STIX]{x2202}\overline{x}}+\overline{v}\frac{\unicode[STIX]{x2202}\overline{n}_{i}}{\unicode[STIX]{x2202}\overline{y}}\right)=\unicode[STIX]{x1D6FD}^{2}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\overline{x}}\left[\frac{D_{i}}{D}\left(\frac{\unicode[STIX]{x2202}\overline{n}_{i}}{\unicode[STIX]{x2202}\overline{x}}+\overline{n}_{i}\overline{S}_{Ti}\unicode[STIX]{x1D6FE}\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}{\unicode[STIX]{x2202}\overline{x}}\right.\right.\nonumber\\ \displaystyle & & \displaystyle \quad +\left.\left.\frac{\overline{z}_{i}\overline{n}_{i}}{1+\unicode[STIX]{x1D6FE}\unicode[STIX]{x1D703}}\frac{\unicode[STIX]{x2202}\overline{\unicode[STIX]{x1D719}}}{\unicode[STIX]{x2202}\overline{x}}\right)\right]+\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\overline{y}}\left[\frac{D_{i}}{D}\left(\frac{\unicode[STIX]{x2202}\overline{n}_{i}}{\unicode[STIX]{x2202}\overline{y}}+\overline{n}_{i}\overline{S}_{Ti}\unicode[STIX]{x1D6FE}\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}{\unicode[STIX]{x2202}\overline{y}}+\frac{\overline{z}_{i}\overline{n}_{i}}{1+\unicode[STIX]{x1D6FE}\unicode[STIX]{x1D703}}\frac{\unicode[STIX]{x2202}\overline{\unicode[STIX]{x1D719}}}{\unicode[STIX]{x2202}\overline{y}}\right)\right],\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & & \displaystyle \unicode[STIX]{x1D6FD}^{2}Pe_{i}\left(\overline{u}\frac{\unicode[STIX]{x2202}\overline{n}_{i}}{\unicode[STIX]{x2202}\overline{x}}+\overline{v}\frac{\unicode[STIX]{x2202}\overline{n}_{i}}{\unicode[STIX]{x2202}\overline{y}}\right)=\unicode[STIX]{x1D6FD}^{2}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\overline{x}}\left[\frac{D_{i}}{D}\left(\frac{\unicode[STIX]{x2202}\overline{n}_{i}}{\unicode[STIX]{x2202}\overline{x}}+\overline{n}_{i}\overline{S}_{Ti}\unicode[STIX]{x1D6FE}\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}{\unicode[STIX]{x2202}\overline{x}}\right.\right.\nonumber\\ \displaystyle & & \displaystyle \quad +\left.\left.\frac{\overline{z}_{i}\overline{n}_{i}}{1+\unicode[STIX]{x1D6FE}\unicode[STIX]{x1D703}}\frac{\unicode[STIX]{x2202}\overline{\unicode[STIX]{x1D719}}}{\unicode[STIX]{x2202}\overline{x}}\right)\right]+\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\overline{y}}\left[\frac{D_{i}}{D}\left(\frac{\unicode[STIX]{x2202}\overline{n}_{i}}{\unicode[STIX]{x2202}\overline{y}}+\overline{n}_{i}\overline{S}_{Ti}\unicode[STIX]{x1D6FE}\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}{\unicode[STIX]{x2202}\overline{y}}+\frac{\overline{z}_{i}\overline{n}_{i}}{1+\unicode[STIX]{x1D6FE}\unicode[STIX]{x1D703}}\frac{\unicode[STIX]{x2202}\overline{\unicode[STIX]{x1D719}}}{\unicode[STIX]{x2202}\overline{y}}\right)\right],\end{eqnarray}$$

where

![]() $\overline{S}_{Ti}=(D_{Ti}/D_{i})T_{C}$

is the Soret coefficient of ions,

$\overline{S}_{Ti}=(D_{Ti}/D_{i})T_{C}$

is the Soret coefficient of ions,

![]() $Pe_{i}=u_{c}l/D$

is the ionic Peclet number,

$Pe_{i}=u_{c}l/D$

is the ionic Peclet number,

![]() $\overline{n}_{i}=n_{i}/n_{0}$

is the non-dimensional ionic number concentration and

$\overline{n}_{i}=n_{i}/n_{0}$

is the non-dimensional ionic number concentration and

![]() $\overline{z}_{i}=z_{i}/z$

is the dimensionless valence of ions. Potential

$\overline{z}_{i}=z_{i}/z$

is the dimensionless valence of ions. Potential

![]() $\overline{\unicode[STIX]{x1D719}}$

consists of two terms:

$\overline{\unicode[STIX]{x1D719}}$

consists of two terms:

![]() $\overline{\unicode[STIX]{x1D719}}=\overline{\unicode[STIX]{x1D719}}(\overline{x})+\unicode[STIX]{x1D713}(\overline{x},\overline{y})$

, where

$\overline{\unicode[STIX]{x1D719}}=\overline{\unicode[STIX]{x1D719}}(\overline{x})+\unicode[STIX]{x1D713}(\overline{x},\overline{y})$

, where

![]() $\overline{\unicode[STIX]{x1D719}}(\overline{x})$

is the induced streaming field with

$\overline{\unicode[STIX]{x1D719}}(\overline{x})$

is the induced streaming field with

![]() $\overline{\unicode[STIX]{x1D713}}(x,y)$

being the potential induced within EDL. Equation (2.9) is subject to (

$\overline{\unicode[STIX]{x1D713}}(x,y)$

being the potential induced within EDL. Equation (2.9) is subject to (

![]() $a$

) the symmetry condition at the channel centreline (at

$a$

) the symmetry condition at the channel centreline (at

![]() $\overline{y}=0$

,

$\overline{y}=0$

,

![]() $\unicode[STIX]{x2202}\overline{n}_{i}/\unicode[STIX]{x2202}\overline{y}=0$

) and (

$\unicode[STIX]{x2202}\overline{n}_{i}/\unicode[STIX]{x2202}\overline{y}=0$

) and (

![]() $b$

) the number density being equal to the bulk number concentration in the electroneutral region (i.e.

$b$

) the number density being equal to the bulk number concentration in the electroneutral region (i.e.

![]() $\overline{n}_{i}=\overline{n}_{i\infty }$

at

$\overline{n}_{i}=\overline{n}_{i\infty }$

at

![]() $\overline{\unicode[STIX]{x1D713}}=0$

). Once the ionic number concentration is known, one can obtain the potential distribution using the Poisson equation:

$\overline{\unicode[STIX]{x1D713}}=0$

). Once the ionic number concentration is known, one can obtain the potential distribution using the Poisson equation:

The simplified form of the potential distribution is given by

The potential distribution described by (2.11) is subject to the temperature-dependent zeta potential boundary conditions at the channel walls (i.e. at

![]() $\overline{y}=\pm 1$

,

$\overline{y}=\pm 1$

,

![]() $\overline{\unicode[STIX]{x1D713}}=\unicode[STIX]{x1D713}/\unicode[STIX]{x1D701}=[1+C_{\unicode[STIX]{x1D701}}\unicode[STIX]{x1D6FE}\unicode[STIX]{x1D703}]$

). The simplifications of the ionic number concentration and subsequent potential distribution are presented in detail in § A2 of the supplementary material.

$\overline{\unicode[STIX]{x1D713}}=\unicode[STIX]{x1D713}/\unicode[STIX]{x1D701}=[1+C_{\unicode[STIX]{x1D701}}\unicode[STIX]{x1D6FE}\unicode[STIX]{x1D703}]$

). The simplifications of the ionic number concentration and subsequent potential distribution are presented in detail in § A2 of the supplementary material.

Now, we first address the flow field for Newtonian fluids, to provide as a basis for comparison. For the same, one can determine the velocity field using the momentum equation where the above-obtained temperature distribution and potential distribution are employed:

The left-hand side of (2.12) is zero because the flow is in the inertial regime (

![]() $Re\ll 1$

). Here,

$Re\ll 1$

). Here,

![]() $p$

is the hydrodynamic pressure,

$p$

is the hydrodynamic pressure,

![]() $\unicode[STIX]{x1D707}[\unicode[STIX]{x1D735}v+(\unicode[STIX]{x1D735}v)^{\text{T}}]$

the viscous stress,

$\unicode[STIX]{x1D707}[\unicode[STIX]{x1D735}v+(\unicode[STIX]{x1D735}v)^{\text{T}}]$

the viscous stress,

![]() $F_{EK}=-\unicode[STIX]{x1D70C}_{e}\unicode[STIX]{x1D735}\unicode[STIX]{x1D719}$

the electrokinetic force and

$F_{EK}=-\unicode[STIX]{x1D70C}_{e}\unicode[STIX]{x1D735}\unicode[STIX]{x1D719}$

the electrokinetic force and

![]() $F_{DEP}=-(1/2)(\unicode[STIX]{x1D735}\unicode[STIX]{x1D719})^{2}\unicode[STIX]{x1D735}\unicode[STIX]{x1D700}$

the dielectrophoretic force. The simplifications for the velocity distribution are discussed in detail in § A3 of the supplementary material. The simplified form of the two components of the momentum equation reads as

$F_{DEP}=-(1/2)(\unicode[STIX]{x1D735}\unicode[STIX]{x1D719})^{2}\unicode[STIX]{x1D735}\unicode[STIX]{x1D700}$

the dielectrophoretic force. The simplifications for the velocity distribution are discussed in detail in § A3 of the supplementary material. The simplified form of the two components of the momentum equation reads as

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}\displaystyle x\text{-}\text{component:}\quad 0=-\frac{\unicode[STIX]{x2202}\overline{p}}{\unicode[STIX]{x2202}\overline{x}}+\overline{\unicode[STIX]{x1D707}}\frac{\unicode[STIX]{x2202}^{2}\overline{u}}{\unicode[STIX]{x2202}\overline{y}^{2}}+\frac{\unicode[STIX]{x1D706}\overline{\unicode[STIX]{x1D700}}}{\overline{\unicode[STIX]{x1D705}}_{eff}^{2}}\left[\frac{\unicode[STIX]{x2202}^{2}\overline{\unicode[STIX]{x1D713}}}{\unicode[STIX]{x2202}\overline{y}^{2}}\frac{\unicode[STIX]{x2202}\overline{\unicode[STIX]{x1D719}}}{\unicode[STIX]{x2202}\overline{x}}+\frac{1}{2}\unicode[STIX]{x1D6FE}C_{\unicode[STIX]{x1D700}}\left(\frac{\unicode[STIX]{x2202}\overline{\unicode[STIX]{x1D713}}}{\unicode[STIX]{x2202}\overline{y}}\right)^{2}\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}{\unicode[STIX]{x2202}\overline{x}}\right],\\ \displaystyle y\text{-}\text{component:}\quad 0=-\frac{\unicode[STIX]{x2202}\overline{p}}{\unicode[STIX]{x2202}\overline{y}}+\frac{\unicode[STIX]{x1D706}\overline{\unicode[STIX]{x1D700}}}{\overline{\unicode[STIX]{x1D705}}_{eff}^{2}}\frac{\unicode[STIX]{x2202}^{2}\overline{\unicode[STIX]{x1D713}}}{\unicode[STIX]{x2202}\overline{y}^{2}}\frac{\unicode[STIX]{x2202}\overline{\unicode[STIX]{x1D713}}}{\unicode[STIX]{x2202}\overline{y}}.\end{array}\right\}\end{eqnarray}$$

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}\displaystyle x\text{-}\text{component:}\quad 0=-\frac{\unicode[STIX]{x2202}\overline{p}}{\unicode[STIX]{x2202}\overline{x}}+\overline{\unicode[STIX]{x1D707}}\frac{\unicode[STIX]{x2202}^{2}\overline{u}}{\unicode[STIX]{x2202}\overline{y}^{2}}+\frac{\unicode[STIX]{x1D706}\overline{\unicode[STIX]{x1D700}}}{\overline{\unicode[STIX]{x1D705}}_{eff}^{2}}\left[\frac{\unicode[STIX]{x2202}^{2}\overline{\unicode[STIX]{x1D713}}}{\unicode[STIX]{x2202}\overline{y}^{2}}\frac{\unicode[STIX]{x2202}\overline{\unicode[STIX]{x1D719}}}{\unicode[STIX]{x2202}\overline{x}}+\frac{1}{2}\unicode[STIX]{x1D6FE}C_{\unicode[STIX]{x1D700}}\left(\frac{\unicode[STIX]{x2202}\overline{\unicode[STIX]{x1D713}}}{\unicode[STIX]{x2202}\overline{y}}\right)^{2}\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D703}}{\unicode[STIX]{x2202}\overline{x}}\right],\\ \displaystyle y\text{-}\text{component:}\quad 0=-\frac{\unicode[STIX]{x2202}\overline{p}}{\unicode[STIX]{x2202}\overline{y}}+\frac{\unicode[STIX]{x1D706}\overline{\unicode[STIX]{x1D700}}}{\overline{\unicode[STIX]{x1D705}}_{eff}^{2}}\frac{\unicode[STIX]{x2202}^{2}\overline{\unicode[STIX]{x1D713}}}{\unicode[STIX]{x2202}\overline{y}^{2}}\frac{\unicode[STIX]{x2202}\overline{\unicode[STIX]{x1D713}}}{\unicode[STIX]{x2202}\overline{y}}.\end{array}\right\}\end{eqnarray}$$

In (2.13), the parameter

![]() $\unicode[STIX]{x1D706}$

is the ratio of the induced velocity due to osmotic pressure to the characteristic flow velocity. Now, we use the no-slip condition at the channel wall (i.e. at

$\unicode[STIX]{x1D706}$

is the ratio of the induced velocity due to osmotic pressure to the characteristic flow velocity. Now, we use the no-slip condition at the channel wall (i.e. at

![]() $\overline{y}=1$

,

$\overline{y}=1$

,

![]() $\overline{u}=0$

) and symmetry condition at the channel centreline (at

$\overline{u}=0$

) and symmetry condition at the channel centreline (at

![]() $\overline{y}=0$

,

$\overline{y}=0$

,

![]() $\unicode[STIX]{x2202}\overline{u}/\unicode[STIX]{x2202}\overline{y}=0$

) to obtain the velocity profile. For the completeness of the flow field, one needs to evaluate the streaming potential induced by the combined action of imposed pressure gradient and temperature gradient by using the electroneutrality constraint, i.e.

$\unicode[STIX]{x2202}\overline{u}/\unicode[STIX]{x2202}\overline{y}=0$

) to obtain the velocity profile. For the completeness of the flow field, one needs to evaluate the streaming potential induced by the combined action of imposed pressure gradient and temperature gradient by using the electroneutrality constraint, i.e.

![]() $I_{net}=I_{streaming}+I_{advection}=0$

.

$I_{net}=I_{streaming}+I_{advection}=0$

.

The final part of the present study is to highlight the effect of fluid viscoelasticity on the hydrodynamic dispersion coefficient for which the constitutive equation of the simplified Phan-Thien–Tanner (sPTT) model has been used. The stress components of the sPTT model take the following form (Afonso et al. Reference Afonso, Alves and Pinho2009; Bautista et al. Reference Bautista, Sánchez, Arcos and Méndez2013; Arcos et al. Reference Arcos, Méndez, Bautista and Bautista2018):

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}\displaystyle 2\unicode[STIX]{x1D707}_{eff}\frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}x}=F\unicode[STIX]{x1D70F}_{xx}+\unicode[STIX]{x1D706}_{eff}\left(u\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D70F}_{xx}}{\unicode[STIX]{x2202}x}+v\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D70F}_{xx}}{\unicode[STIX]{x2202}y}-2\frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}x}\unicode[STIX]{x1D70F}_{xx}-2\frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}y}\unicode[STIX]{x1D70F}_{yx}\right),\\ \displaystyle 2\unicode[STIX]{x1D707}_{eff}\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}y}=F\unicode[STIX]{x1D70F}_{yy}+\unicode[STIX]{x1D706}_{eff}\left(u\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D70F}_{yy}}{\unicode[STIX]{x2202}x}+v\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D70F}_{yy}}{\unicode[STIX]{x2202}y}-2\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}x}\unicode[STIX]{x1D70F}_{xy}-2\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}y}\unicode[STIX]{x1D70F}_{yy}\right),\\ \displaystyle \unicode[STIX]{x1D707}_{eff}\left(\frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}y}+\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}x}\right)=F\unicode[STIX]{x1D70F}_{xy}+\unicode[STIX]{x1D706}_{eff}\left(u\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D70F}_{xy}}{\unicode[STIX]{x2202}x}+v\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D70F}_{xy}}{\unicode[STIX]{x2202}y}-\frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}y}\unicode[STIX]{x1D70F}_{yy}-\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}x}\unicode[STIX]{x1D70F}_{xx}\right),\end{array}\right\}\end{eqnarray}$$

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}\displaystyle 2\unicode[STIX]{x1D707}_{eff}\frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}x}=F\unicode[STIX]{x1D70F}_{xx}+\unicode[STIX]{x1D706}_{eff}\left(u\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D70F}_{xx}}{\unicode[STIX]{x2202}x}+v\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D70F}_{xx}}{\unicode[STIX]{x2202}y}-2\frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}x}\unicode[STIX]{x1D70F}_{xx}-2\frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}y}\unicode[STIX]{x1D70F}_{yx}\right),\\ \displaystyle 2\unicode[STIX]{x1D707}_{eff}\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}y}=F\unicode[STIX]{x1D70F}_{yy}+\unicode[STIX]{x1D706}_{eff}\left(u\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D70F}_{yy}}{\unicode[STIX]{x2202}x}+v\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D70F}_{yy}}{\unicode[STIX]{x2202}y}-2\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}x}\unicode[STIX]{x1D70F}_{xy}-2\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}y}\unicode[STIX]{x1D70F}_{yy}\right),\\ \displaystyle \unicode[STIX]{x1D707}_{eff}\left(\frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}y}+\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}x}\right)=F\unicode[STIX]{x1D70F}_{xy}+\unicode[STIX]{x1D706}_{eff}\left(u\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D70F}_{xy}}{\unicode[STIX]{x2202}x}+v\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D70F}_{xy}}{\unicode[STIX]{x2202}y}-\frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}y}\unicode[STIX]{x1D70F}_{yy}-\frac{\unicode[STIX]{x2202}v}{\unicode[STIX]{x2202}x}\unicode[STIX]{x1D70F}_{xx}\right),\end{array}\right\}\end{eqnarray}$$

where

![]() $F=1+\unicode[STIX]{x1D6FF}\unicode[STIX]{x1D706}_{eff}(\unicode[STIX]{x1D70F}_{xx}+\unicode[STIX]{x1D70F}_{yy})/\unicode[STIX]{x1D707}_{eff}$

is the stress coefficient function with

$F=1+\unicode[STIX]{x1D6FF}\unicode[STIX]{x1D706}_{eff}(\unicode[STIX]{x1D70F}_{xx}+\unicode[STIX]{x1D70F}_{yy})/\unicode[STIX]{x1D707}_{eff}$

is the stress coefficient function with

![]() $\unicode[STIX]{x1D6FF}$

being the extensibility of the fluid and

$\unicode[STIX]{x1D6FF}$

being the extensibility of the fluid and

![]() $\unicode[STIX]{x1D706}_{eff}=\unicode[STIX]{x1D706}_{ref}\exp [-\unicode[STIX]{x1D714}_{4}(T-T_{ref})]$

the fluid relaxation time.

$\unicode[STIX]{x1D706}_{eff}=\unicode[STIX]{x1D706}_{ref}\exp [-\unicode[STIX]{x1D714}_{4}(T-T_{ref})]$

the fluid relaxation time.

3 Solution methodology

For a temperature gradient applied in the axial direction, we have obtained both exact solutions and approximate analytical solutions, while for a transverse temperature gradient, approximate analytical solution and numerical solution are obtained. For an approximate analytical solution, an asymptotic approach has been followed where any variable

![]() $\unicode[STIX]{x1D711}$

can be expanded as

$\unicode[STIX]{x1D711}$

can be expanded as

where

![]() $\unicode[STIX]{x1D6FE}=\unicode[STIX]{x0394}T/T_{C}$

is the thermal perturbation parameter which is the ratio of the imposed temperature difference to the cold-side temperature. Therefore,

$\unicode[STIX]{x1D6FE}=\unicode[STIX]{x0394}T/T_{C}$

is the thermal perturbation parameter which is the ratio of the imposed temperature difference to the cold-side temperature. Therefore,

![]() $\unicode[STIX]{x1D6FE}\rightarrow 0$

represents the isothermal condition. To check the validity of the asymptotic solution, we have compared it with the exact solution (for axial thermal gradient) and numerical solutions (for transverse thermal gradient) and the upper limit of

$\unicode[STIX]{x1D6FE}\rightarrow 0$

represents the isothermal condition. To check the validity of the asymptotic solution, we have compared it with the exact solution (for axial thermal gradient) and numerical solutions (for transverse thermal gradient) and the upper limit of

![]() $\unicode[STIX]{x1D6FE}$

has been fixed accordingly. This comparison is shown in § C2 of the supplementary material.

$\unicode[STIX]{x1D6FE}$

has been fixed accordingly. This comparison is shown in § C2 of the supplementary material.

4 Results and discussion

Since this analysis involves a large set of parameters, numerous results can be obtained by combining all pertinent parameters. However, for improved readability, we have highlighted some key results involving velocity distribution, induced streaming potential, volumetric flow rate and finally the dispersion coefficient (which in turn depends on previous parameters). For representing the results, we have employed some dimensionless parameters. These parameters along with their expressions, physical significance and typical ranges are given in table 1.

Table 1. The dimensionless parameters, their expressions, physical significance and typical ranges.

The reason for choosing the range of the dimensionless parameters is discussed in § C1 of the supplementary material.

Figure 2. Dependence of streaming potential ratio (

![]() $E_{r}$

) on (a)

$E_{r}$

) on (a)

![]() $\unicode[STIX]{x0394}\overline{S}_{T}$

, (b)

$\unicode[STIX]{x0394}\overline{S}_{T}$

, (b)

![]() $\unicode[STIX]{x1D712}$

, (c)

$\unicode[STIX]{x1D712}$

, (c)

![]() $C_{\unicode[STIX]{x1D707}}$

, (d)

$C_{\unicode[STIX]{x1D707}}$

, (d)

![]() $C_{\unicode[STIX]{x1D700}}$

, (e)

$C_{\unicode[STIX]{x1D700}}$

, (e)

![]() $\unicode[STIX]{x1D6FE}$

and (f)

$\unicode[STIX]{x1D6FE}$

and (f)

![]() $\overline{\unicode[STIX]{x1D705}}_{0}$

.

$\overline{\unicode[STIX]{x1D705}}_{0}$

.

4.1 Effect of axial temperature gradient

In figure 2, the variation of streaming potential ratio (

![]() $E_{r}$

) is plotted against some key parameters. Here,

$E_{r}$

) is plotted against some key parameters. Here,

![]() $E_{r}$

is defined as the ratio of the streaming potential induced due to the combined action of externally imposed thermal and pressure gradients to that induced due to the sole action of pressure gradient. While realizing the alteration in the flow field upon applying a thermal gradient, one can expect the effect of the electrical permittivity variation induced dielectrophorteic force on the flow field by inducing an axial pressure gradient, i.e. osmotic pressure gradient due to excess charge redistribution. Also, further source of alteration is expected through the physical property variation where these properties depend strongly on the temperature distribution thereby influencing strongly the fluid motion. However, the description of the flow physics is not completed here because one needs to look into the inherent temperature dependence of the ionic species. This contribution comes into the picture via the ionic species transport, typically known as the Soret effect. The movement of the ionic species in a thermal gradient is a response subject to the imposed temperature gradient. This effect is incorporated through the thermo-diffusion term

$E_{r}$

is defined as the ratio of the streaming potential induced due to the combined action of externally imposed thermal and pressure gradients to that induced due to the sole action of pressure gradient. While realizing the alteration in the flow field upon applying a thermal gradient, one can expect the effect of the electrical permittivity variation induced dielectrophorteic force on the flow field by inducing an axial pressure gradient, i.e. osmotic pressure gradient due to excess charge redistribution. Also, further source of alteration is expected through the physical property variation where these properties depend strongly on the temperature distribution thereby influencing strongly the fluid motion. However, the description of the flow physics is not completed here because one needs to look into the inherent temperature dependence of the ionic species. This contribution comes into the picture via the ionic species transport, typically known as the Soret effect. The movement of the ionic species in a thermal gradient is a response subject to the imposed temperature gradient. This effect is incorporated through the thermo-diffusion term

![]() $(n_{i}D_{Ti}\unicode[STIX]{x1D735}T)$

in the Nernst–Planck equation (the dimensionless form of Nernst–Planck equation is shown by equation (S9) of the supplementary material) where the Soret coefficient

$(n_{i}D_{Ti}\unicode[STIX]{x1D735}T)$

in the Nernst–Planck equation (the dimensionless form of Nernst–Planck equation is shown by equation (S9) of the supplementary material) where the Soret coefficient

![]() $(S_{Ti}=D_{Ti}/D_{i}=Q_{i}/k_{B}T^{2})$

depends on the heat of transport of ions (

$(S_{Ti}=D_{Ti}/D_{i}=Q_{i}/k_{B}T^{2})$

depends on the heat of transport of ions (

![]() $Q_{i}$

). Here,

$Q_{i}$

). Here,

![]() $Q_{i}$

is the quantification of the degree of sensitivity of ionic mobility with temperature, i.e. thermophoretic mobility of ions. Now, let us first consider the sole action of the Soret effect on the flow dynamics by assuming the absence of any other pertinent forces. A positive value of

$Q_{i}$

is the quantification of the degree of sensitivity of ionic mobility with temperature, i.e. thermophoretic mobility of ions. Now, let us first consider the sole action of the Soret effect on the flow dynamics by assuming the absence of any other pertinent forces. A positive value of

![]() $Q_{i}$

suggests that ions should have a propensity to move towards the cold region from the hot region and as a result a thermoelectric field should be induced in the same direction while role reversal should be observed for negative

$Q_{i}$

suggests that ions should have a propensity to move towards the cold region from the hot region and as a result a thermoelectric field should be induced in the same direction while role reversal should be observed for negative

![]() $Q_{i}$

. Interestingly, the conventional streaming field arising from the imposed pressure gradient is induced in the reverse direction to the applied pressure gradient, i.e. from the hot region to the cold region. So, the thermal-gradient-induced thermoelectric streaming field (assuming positive value of

$Q_{i}$

. Interestingly, the conventional streaming field arising from the imposed pressure gradient is induced in the reverse direction to the applied pressure gradient, i.e. from the hot region to the cold region. So, the thermal-gradient-induced thermoelectric streaming field (assuming positive value of

![]() $Q_{i}$

) seems to act in the same direction as the pressure-gradient-induced streaming field and intuition tells us that the combined action of these two gradients should result in an enhancement of the net induced streaming potential. However, the situation does not remain the same if there is a difference in thermophoretic mobilities between the co-ions (here negative ions) and counter-ions (positive ions). The extent of thermophobic behaviour, i.e. the tendency of ions to move away from the hot region, can change depending on the difference in the thermophoretic mobilities (

$Q_{i}$

) seems to act in the same direction as the pressure-gradient-induced streaming field and intuition tells us that the combined action of these two gradients should result in an enhancement of the net induced streaming potential. However, the situation does not remain the same if there is a difference in thermophoretic mobilities between the co-ions (here negative ions) and counter-ions (positive ions). The extent of thermophobic behaviour, i.e. the tendency of ions to move away from the hot region, can change depending on the difference in the thermophoretic mobilities (

![]() $\unicode[STIX]{x0394}\overline{S}_{T}$

) between cations and anions. Increasing

$\unicode[STIX]{x0394}\overline{S}_{T}$

) between cations and anions. Increasing

![]() $\unicode[STIX]{x0394}\overline{S}_{T}$

indicates higher heat of transport of counter-ions compared to co-ions, so the counter-ions are more likely to move towards the cold region than the co-ions. This leads to a clear axial separation between the ions and gives rise to an accumulation of the counter-ions in the upstream section, i.e. in the cold region. This induces a form of thermoelectric field downstream (because of

$\unicode[STIX]{x0394}\overline{S}_{T}$

indicates higher heat of transport of counter-ions compared to co-ions, so the counter-ions are more likely to move towards the cold region than the co-ions. This leads to a clear axial separation between the ions and gives rise to an accumulation of the counter-ions in the upstream section, i.e. in the cold region. This induces a form of thermoelectric field downstream (because of

![]() $\unicode[STIX]{x0394}\overline{S}_{T}$

) while another form of it is formed upstream (because of the sole action of the Soret effect). Hence, the net streaming field (due to combined pressure-driven and temperature-gradient-induced flow) depends on the relative strength of these two counteracting thermoelectric fields. For very low value of

$\unicode[STIX]{x0394}\overline{S}_{T}$

) while another form of it is formed upstream (because of the sole action of the Soret effect). Hence, the net streaming field (due to combined pressure-driven and temperature-gradient-induced flow) depends on the relative strength of these two counteracting thermoelectric fields. For very low value of

![]() $\unicode[STIX]{x0394}\overline{S}_{T}$

, these two opposing factors are comparable to each other and the streaming potential ratio (

$\unicode[STIX]{x0394}\overline{S}_{T}$

, these two opposing factors are comparable to each other and the streaming potential ratio (

![]() $E_{r}$

) is close to unity up to

$E_{r}$

) is close to unity up to

![]() $\unicode[STIX]{x0394}\overline{S}_{T}=0.05$

. As one starts increasing

$\unicode[STIX]{x0394}\overline{S}_{T}=0.05$

. As one starts increasing

![]() $\unicode[STIX]{x0394}\overline{S}_{T}$

, the effect of

$\unicode[STIX]{x0394}\overline{S}_{T}$

, the effect of

![]() $\unicode[STIX]{x0394}\overline{S}_{T}$

-induced streaming field overshadows the temperature-gradient-induced streaming field and net streaming potential ratio experiences a massive reduction. For higher

$\unicode[STIX]{x0394}\overline{S}_{T}$

-induced streaming field overshadows the temperature-gradient-induced streaming field and net streaming potential ratio experiences a massive reduction. For higher

![]() $\unicode[STIX]{x0394}\overline{S}_{T}$

, the effect becomes so pronounced that it completely nullifies the pressure-gradient-induced streaming field (shown by the red solid line in figure 2

a).

$\unicode[STIX]{x0394}\overline{S}_{T}$

, the effect becomes so pronounced that it completely nullifies the pressure-gradient-induced streaming field (shown by the red solid line in figure 2

a).

Now, we look into the expression of the bulk number density of ions which reads as

![]() $(\unicode[STIX]{x2202}\ln \overline{n}_{i}/\unicode[STIX]{x2202}\overline{x})=-\overline{S}_{Ti}(\unicode[STIX]{x2202}\unicode[STIX]{x1D703}/\unicode[STIX]{x2202}\overline{x})\unicode[STIX]{x1D6FE}$

(equation (S11) of the supplementary material, where

$(\unicode[STIX]{x2202}\ln \overline{n}_{i}/\unicode[STIX]{x2202}\overline{x})=-\overline{S}_{Ti}(\unicode[STIX]{x2202}\unicode[STIX]{x1D703}/\unicode[STIX]{x2202}\overline{x})\unicode[STIX]{x1D6FE}$

(equation (S11) of the supplementary material, where

![]() $\overline{x}$

is the dimensionless axial coordinate,

$\overline{x}$

is the dimensionless axial coordinate,

![]() $\overline{x}=x/l$

;

$\overline{x}=x/l$

;

![]() $\overline{n}_{i}$

the dimensionless bulk number concentration,

$\overline{n}_{i}$

the dimensionless bulk number concentration,

![]() $\overline{n}_{i}=n_{i}/n_{0}$

;

$\overline{n}_{i}=n_{i}/n_{0}$

;

![]() $\overline{S}_{Ti}$

the dimensionless Soret coefficient of ions,

$\overline{S}_{Ti}$

the dimensionless Soret coefficient of ions,

![]() $\overline{S}_{Ti}=(D_{Ti}/D_{i})T_{C}$

; and

$\overline{S}_{Ti}=(D_{Ti}/D_{i})T_{C}$

; and

![]() $\unicode[STIX]{x1D703}$

the dimensionless temperature,

$\unicode[STIX]{x1D703}$

the dimensionless temperature,

![]() $\unicode[STIX]{x1D703}=(T-T_{C})/\unicode[STIX]{x0394}T_{ref}$

), which clearly tells us that the application of the external

$\unicode[STIX]{x1D703}=(T-T_{C})/\unicode[STIX]{x0394}T_{ref}$

), which clearly tells us that the application of the external

![]() $\unicode[STIX]{x0394}T$

in the positive

$\unicode[STIX]{x0394}T$

in the positive

![]() $x$

direction induces an axial concentration gradient of ions in the opposite direction, i.e. from the hot region to the cold region. The concentration gradient

$x$

direction induces an axial concentration gradient of ions in the opposite direction, i.e. from the hot region to the cold region. The concentration gradient

![]() $(\unicode[STIX]{x2202}\overline{n}_{i}/\unicode[STIX]{x2202}\overline{x})$

creates a migration of the ions towards the upstream section. Now, we focus our attention towards the definition of the parameter

$(\unicode[STIX]{x2202}\overline{n}_{i}/\unicode[STIX]{x2202}\overline{x})$

creates a migration of the ions towards the upstream section. Now, we focus our attention towards the definition of the parameter

![]() $\unicode[STIX]{x1D712}=(D_{+}-D_{-})/(D_{+}+D_{-})$

which is an indicator of the diffusivity difference between the cations and anions. A positive value of

$\unicode[STIX]{x1D712}=(D_{+}-D_{-})/(D_{+}+D_{-})$

which is an indicator of the diffusivity difference between the cations and anions. A positive value of

![]() $\unicode[STIX]{x1D712}$

implies that the diffusivity of cations (here counter-ions) is higher than that of anions which leads to more migration of counter-ions upstream. As a result, there will be an accumulation of counter-ions upstream, while downstream there will be more co-ions. This segregation of ions in different axial locations creates an axial separation between them thus creating a stronger induced streaming field. A negative value of

$\unicode[STIX]{x1D712}$

implies that the diffusivity of cations (here counter-ions) is higher than that of anions which leads to more migration of counter-ions upstream. As a result, there will be an accumulation of counter-ions upstream, while downstream there will be more co-ions. This segregation of ions in different axial locations creates an axial separation between them thus creating a stronger induced streaming field. A negative value of

![]() $\unicode[STIX]{x1D712}$

means more mobility of anions thereby leading to more accumulation of co-ions in the upstream section resulting in a weaker streaming field. Here we show the variation of streaming potential ratio (

$\unicode[STIX]{x1D712}$

means more mobility of anions thereby leading to more accumulation of co-ions in the upstream section resulting in a weaker streaming field. Here we show the variation of streaming potential ratio (

![]() $E_{r}$

) for

$E_{r}$

) for

![]() $\unicode[STIX]{x1D712}$

ranging from

$\unicode[STIX]{x1D712}$

ranging from

![]() $-0.2$

to 0 (figure 2

b). Here, the value of

$-0.2$

to 0 (figure 2

b). Here, the value of

![]() $\unicode[STIX]{x1D712}$

is ion-specific. For typical electrolyte solutions like aqueous KCl, NaCl and LiCl, the value of

$\unicode[STIX]{x1D712}$

is ion-specific. For typical electrolyte solutions like aqueous KCl, NaCl and LiCl, the value of

![]() $\unicode[STIX]{x1D712}$

ranges between

$\unicode[STIX]{x1D712}$

ranges between

![]() $-0.3$

and 0 (approximately) (Zhang et al.

Reference Zhang, Wang, Zeng and Zhao2019) and we have chosen the range of

$-0.3$

and 0 (approximately) (Zhang et al.

Reference Zhang, Wang, Zeng and Zhao2019) and we have chosen the range of

![]() $\unicode[STIX]{x1D712}$

accordingly when presenting the results.

$\unicode[STIX]{x1D712}$

accordingly when presenting the results.

On closely observing the governing equations involving velocity profile and induced streaming field (equations (S21) and (S26) of the supplementary material), one can understand that the contribution of

![]() $C_{\unicode[STIX]{x1D707}}$

comes through the viscous resistance term in the fluid advective motion and the subsequent advective current calculation involved in the electroneutrality condition. Since

$C_{\unicode[STIX]{x1D707}}$

comes through the viscous resistance term in the fluid advective motion and the subsequent advective current calculation involved in the electroneutrality condition. Since

![]() $C_{\unicode[STIX]{x1D707}}$

indicates the temperature sensitivity of viscosity with temperature, increasing

$C_{\unicode[STIX]{x1D707}}$

indicates the temperature sensitivity of viscosity with temperature, increasing

![]() $C_{\unicode[STIX]{x1D707}}$

means viscosity becomes more susceptible to any change in temperature thus resulting in a strong reduction in fluid viscosity. Therefore, the viscous resistance to the flow reduces to a great extent. Thus, the induced streaming field due to migration of ions upon applying a pressure gradient and the streaming field due to migration of ions with induced concentration gradient assist each other (both are induced in the direction from the hot region to the cold region) resulting in significant augmentation in the streaming potential ratio (

$C_{\unicode[STIX]{x1D707}}$

means viscosity becomes more susceptible to any change in temperature thus resulting in a strong reduction in fluid viscosity. Therefore, the viscous resistance to the flow reduces to a great extent. Thus, the induced streaming field due to migration of ions upon applying a pressure gradient and the streaming field due to migration of ions with induced concentration gradient assist each other (both are induced in the direction from the hot region to the cold region) resulting in significant augmentation in the streaming potential ratio (

![]() $E_{r}$

). Here, increasing

$E_{r}$

). Here, increasing

![]() $C_{\unicode[STIX]{x1D707}}$

from 1 to 10 results in

$C_{\unicode[STIX]{x1D707}}$

from 1 to 10 results in

![]() ${\sim}3$

times (shown by the green solid line) augmentation of the streaming potential ratio (

${\sim}3$

times (shown by the green solid line) augmentation of the streaming potential ratio (

![]() $E_{r}$

), as seen in figure 2(c).

$E_{r}$

), as seen in figure 2(c).

Now, examining the equation describing the potential distribution (equation (S13) of the supplementary material), it can be observed that unlike the conventional electrokinetic problem, here the EDL thickness (

![]() $\unicode[STIX]{x1D706}_{D}$

) no longer remains constant. Instead, the effective EDL thickness (

$\unicode[STIX]{x1D706}_{D}$

) no longer remains constant. Instead, the effective EDL thickness (

![]() $\unicode[STIX]{x1D706}_{Deff}$

) becomes a strong function of temperature and departs significantly from its reference value (of isothermal condition) in the following way:

$\unicode[STIX]{x1D706}_{Deff}$

) becomes a strong function of temperature and departs significantly from its reference value (of isothermal condition) in the following way:

![]() $\overline{\unicode[STIX]{x1D706}}_{D_{eff}}=\overline{\unicode[STIX]{x1D706}}_{D_{0}}\sqrt{\exp \{-\unicode[STIX]{x1D6FE}\unicode[STIX]{x1D703}(C_{\unicode[STIX]{x1D700}}-\overline{S}_{Tavg})\}}$

. Keeping other parameters fixed, with increasing

$\overline{\unicode[STIX]{x1D706}}_{D_{eff}}=\overline{\unicode[STIX]{x1D706}}_{D_{0}}\sqrt{\exp \{-\unicode[STIX]{x1D6FE}\unicode[STIX]{x1D703}(C_{\unicode[STIX]{x1D700}}-\overline{S}_{Tavg})\}}$

. Keeping other parameters fixed, with increasing

![]() $C_{\unicode[STIX]{x1D700}}$

(which is the temperature sensitivity of the electrical permittivity) streaming potential ratio (

$C_{\unicode[STIX]{x1D700}}$

(which is the temperature sensitivity of the electrical permittivity) streaming potential ratio (

![]() $E_{r}$

) decreases sharply by following an exponential thinning behaviour. Since electrical permittivity decreases with temperature, the thickness of the EDL also decreases which results in less penetration of diffuse layer of the EDL to the bulk, so greater is the region of electroneutrality (which means the region where there is equal number of counter-ions and co-ions). Now, the strength of streaming current involved in the streaming potential estimation depends on this degree of penetration. In the region

$E_{r}$

) decreases sharply by following an exponential thinning behaviour. Since electrical permittivity decreases with temperature, the thickness of the EDL also decreases which results in less penetration of diffuse layer of the EDL to the bulk, so greater is the region of electroneutrality (which means the region where there is equal number of counter-ions and co-ions). Now, the strength of streaming current involved in the streaming potential estimation depends on this degree of penetration. In the region

![]() $10^{-1}\leqslant C_{\unicode[STIX]{x1D700}}\leqslant 1$

, the rate of reduction of

$10^{-1}\leqslant C_{\unicode[STIX]{x1D700}}\leqslant 1$

, the rate of reduction of

![]() $E_{r}$

with

$E_{r}$

with

![]() $C_{\unicode[STIX]{x1D700}}$

is not significant: it decreases slightly from 1.2 to 1.1. However, this reduction becomes amplified beyond

$C_{\unicode[STIX]{x1D700}}$

is not significant: it decreases slightly from 1.2 to 1.1. However, this reduction becomes amplified beyond

![]() $C_{\unicode[STIX]{x1D700}}\sim 1$

;

$C_{\unicode[STIX]{x1D700}}\sim 1$

;

![]() $E_{r}$

decreases sharply and falls to

$E_{r}$

decreases sharply and falls to

![]() ${\sim}0.2$

at

${\sim}0.2$

at

![]() $C_{\unicode[STIX]{x1D700}}=10$

(figure 2

d).

$C_{\unicode[STIX]{x1D700}}=10$

(figure 2

d).

For fixed value of the factors mentioned above, like

![]() $\unicode[STIX]{x0394}\overline{S}_{T}$

,

$\unicode[STIX]{x0394}\overline{S}_{T}$

,

![]() $\unicode[STIX]{x1D712}$

,

$\unicode[STIX]{x1D712}$

,

![]() $C_{\unicode[STIX]{x1D707}}$

and

$C_{\unicode[STIX]{x1D707}}$

and

![]() $C_{\unicode[STIX]{x1D700}}$

, since this analysis is restricted up to order

$C_{\unicode[STIX]{x1D700}}$

, since this analysis is restricted up to order

![]() $\unicode[STIX]{x1D6FE}$

, a linear dependence is expected of perturbation parameter on flow field and streaming potential. In figure 2(e),

$\unicode[STIX]{x1D6FE}$

, a linear dependence is expected of perturbation parameter on flow field and streaming potential. In figure 2(e),

![]() $C_{\unicode[STIX]{x1D701}}$

indicates the relative sensitivity of zeta potential with temperature. For constant zeta potential (

$C_{\unicode[STIX]{x1D701}}$

indicates the relative sensitivity of zeta potential with temperature. For constant zeta potential (

![]() $C_{\unicode[STIX]{x1D701}}=0$

),

$C_{\unicode[STIX]{x1D701}}=0$

),

![]() $E_{r}$

is increased up to

$E_{r}$

is increased up to

![]() ${\sim}1.12$

times as

${\sim}1.12$

times as

![]() $\unicode[STIX]{x1D6FE}$