Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Liu, Han

Li, Yipeng

Fu, Zipeng

Li, Kevin

and

Bauchy, Mathieu

2020.

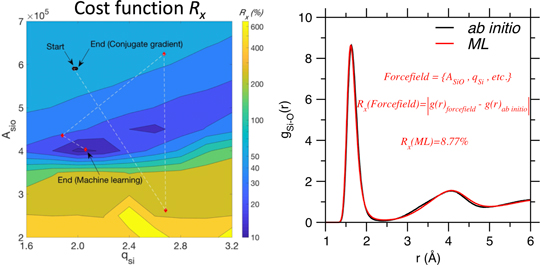

Exploring the landscape of Buckingham potentials for silica by machine learning: Soft vs hard interatomic forcefields.

The Journal of Chemical Physics,

Vol. 152,

Issue. 5,

Batra, Rohit

Song, Le

and

Ramprasad, Rampi

2020.

Emerging materials intelligence ecosystems propelled by machine learning.

Nature Reviews Materials,

Vol. 6,

Issue. 8,

p.

655.

Batra, Rohit

and

Sankaranarayanan, Subramanian

2020.

Machine learning for multi-fidelity scale bridging and dynamical simulations of materials.

Journal of Physics: Materials,

Vol. 3,

Issue. 3,

p.

031002.

Avula, Nikhil V. S.

Karmakar, Anwesa

Kumar, Rahul

and

Balasubramanian, Sundaram

2021.

Efficient Parametrization of Force Field for the Quantitative Prediction of the Physical Properties of Ionic Liquid Electrolytes.

Journal of Chemical Theory and Computation,

Vol. 17,

Issue. 7,

p.

4274.

Christensen, Rasmus

Sørensen, Søren S.

Liu, Han

Li, Kevin

Bauchy, Mathieu

and

Smedskjaer, Morten M.

2021.

Interatomic potential parameterization using particle swarm optimization: Case study of glassy silica.

The Journal of Chemical Physics,

Vol. 154,

Issue. 13,

Yu, Wei

Ji, Chaoyue

Wan, Xuhao

Zhang, Zhaofu

Robertson, John

Liu, Sheng

and

Guo, Yuzheng

2021.

Machine‐learning‐based interatomic potentials for advanced manufacturing.

International Journal of Mechanical System Dynamics,

Vol. 1,

Issue. 2,

p.

159.

Ravinder

Venugopal, Vineeth

Bishnoi, Suresh

Singh, Sourabh

Zaki, Mohd

Grover, Hargun Singh

Bauchy, Mathieu

Agarwal, Manish

and

Krishnan, N. M. Anoop

2021.

Artificial intelligence and machine learning in glass science and technology: 21 challenges for the 21st century.

International Journal of Applied Glass Science,

Vol. 12,

Issue. 3,

p.

277.

Befort, Bridgette J.

DeFever, Ryan S.

Tow, Garrett M.

Dowling, Alexander W.

and

Maginn, Edward J.

2021.

Machine Learning Directed Optimization of Classical Molecular Modeling Force Fields.

Journal of Chemical Information and Modeling,

Vol. 61,

Issue. 9,

p.

4400.

Liu, Han

Smedskjaer, Morten M.

and

Bauchy, Mathieu

2022.

Deciphering a structural signature of glass dynamics by machine learning.

Physical Review B,

Vol. 106,

Issue. 21,

Liu, Han

Zhao, Zhangji

Zhou, Qi

Chen, Ruoxia

Yang, Kai

Wang, Zhe

Tang, Longwen

and

Bauchy, Mathieu

2022.

Challenges and opportunities in atomistic simulations of glasses: a review.

Comptes Rendus. Géoscience,

Vol. 354,

Issue. S1,

p.

35.

Singh, Jashanpreet

and

Singh, Simranjit

2022.

A review on Machine learning aspect in physics and mechanics of glasses.

Materials Science and Engineering: B,

Vol. 284,

Issue. ,

p.

115858.

Erlebach, Andreas

Nachtigall, Petr

and

Grajciar, Lukáš

2022.

Accurate large-scale simulations of siliceous zeolites by neural network potentials.

npj Computational Materials,

Vol. 8,

Issue. 1,

Bertani, Marco

Pallini, Annalisa

Cocchi, Marina

Menziani, Maria Cristina

and

Pedone, Alfonso

2022.

A new self‐consistent empirical potential model for multicomponent borate and borosilicate glasses.

Journal of the American Ceramic Society,

Vol. 105,

Issue. 12,

p.

7254.

Bødker, Mikkel L.

Bauchy, Mathieu

Du, Tao

Mauro, John C.

and

Smedskjaer, Morten M.

2022.

Predicting glass structure by physics-informed machine learning.

npj Computational Materials,

Vol. 8,

Issue. 1,

Pedone, Alfonso

Bertani, Marco

Brugnoli, Luca

and

Pallini, Annalisa

2022.

Interatomic potentials for oxide glasses: Past, present, and future.

Journal of Non-Crystalline Solids: X,

Vol. 15,

Issue. ,

p.

100115.

Ge, Yang

Wang, Xueping

Zhu, Qiang

Yang, Yuqin

Dong, Hao

and

Ma, Jing

2023.

Machine Learning-Guided Adaptive Parametrization for Coupling Terms in a Mixed United-Atom/Coarse-Grained Model for Diphenylalanine Self-Assembly in Aqueous Ionic Liquids.

Journal of Chemical Theory and Computation,

Vol. 19,

Issue. 19,

p.

6718.

Liu, Han

Li, Liantang

Wei, Zhenhua

Smedskjaer, Morten M.

Zheng, Xiaoyu Rayne

and

Bauchy, Mathieu

2024.

De Novo Atomistic Discovery of Disordered Mechanical Metamaterials by Machine Learning.

Advanced Science,

Vol. 11,

Issue. 13,

Wang, Guanjie

Wang, Changrui

Zhang, Xuanguang

Li, Zefeng

Zhou, Jian

and

Sun, Zhimei

2024.

Machine learning interatomic potential: Bridge the gap between small-scale models and realistic device-scale simulations.

iScience,

Vol. 27,

Issue. 5,

p.

109673.