Article contents

Dislocation surface nucleation in surfactant-passivated metallic nanocubes

Published online by Cambridge University Press: 20 June 2019

Abstract

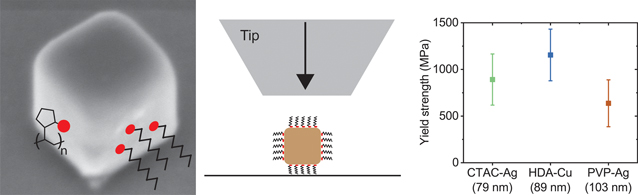

The strength of single-crystalline nanoscale metals is controlled by dislocation nucleation from free surfaces. Surface properties such as crystallographic orientation, surface stress, and surface diffusion have been proposed as key parameters that control dislocation surface nucleation, but have not been confirmed experimentally. To investigate the influence of surface parameters, in situ scanning electron microscope mechanical testing is used to compress defect-free Ag and Cu nanocubes that are passivated with organic surfactants in order to tune their surface properties. Comparison between passivated nanocubes indicates that yield strength may depend on surfactant binding energy, but is also dependent on intrinsic material properties.

- Type

- Research Letters

- Information

- Copyright

- Copyright © Materials Research Society 2019

Footnotes

These authors contributed equally to this work.

References

- 7

- Cited by