Article contents

Biocompatibility of a novel heat-treated and ceramic-coated magnesium alloy (Mg–1.2Zn–0.5Ca–0.5Mn) for resorbable skeletal fixation devices

Published online by Cambridge University Press: 10 August 2020

Abstract

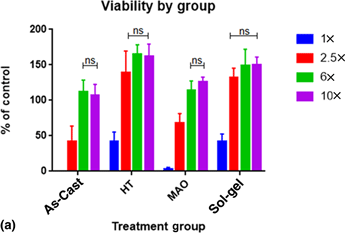

Our recent exploration into the use of biodegradable metals and surface treatments resulting in sufficient strength for skeletal reconstruction applications has led to the need to test these devices’ cytotoxicity. More specifically, our group has developed a resorbable magnesium alloy, Mg–1.2Zn–0.5Ca–0.5Mn, that can be strengthened by heat treatment and coated with a ceramic layer offering time-certain resorption of a medical device. This in vitro study shows that these treatments do not result in cytotoxicity. Both heat-treated (HT) and HT + ceramic-coated (sol–gel) coupons demonstrated more than 70% viability. Thus, these processing steps are likely to be useful in producing biocompatible, resorbable implants that incorporate our Mg–1.2Zn–0.5Ca–0.5Mn alloy.

- Type

- Research Letters

- Information

- Copyright

- Copyright © Materials Research Society, 2020

Footnotes

This author was an editor of this journal during the review and decision stage. For the MRC policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/editor-manuscripts/.

References

- 6

- Cited by