Article contents

Bimodal nanoporous platinum on sacrificial nanoporous copper for catalysis of the oxygen-reduction reaction

Published online by Cambridge University Press: 22 November 2018

Abstract

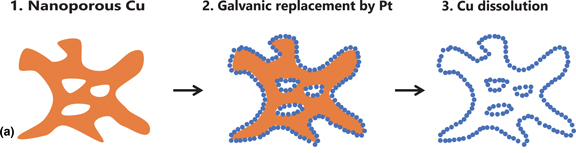

Bimodal nanoporous platinum (BNP-Pt) is synthesized by using a sacrificial nanoporous copper (NP-Cu) support for oxygen-reduction-reaction (ORR) catalysts in fuel cells. The specific ORR catalytic activity of BNP-Pt increases by the dissolution and removal of supporting NP-Cu, suggesting that the BNP structure improves the intrinsic catalytic properties of platinum. The lattice contraction of BNP-Pt containing residual copper even after NP-Cu removal is milder than predicted by Vegard's law. The BNP structure governs the intrinsic catalytic activity of the platinum by relaxing the lattice contraction and by alloying with copper and/or misfit strain at the Pt/Cu interface.

- Type

- Research Letters

- Information

- Copyright

- Copyright © Materials Research Society 2018

References

- 5

- Cited by