Article contents

Assessing failure in epitaxially encapsulated micro-scale sensors using micro and nano x-ray computed tomography

Published online by Cambridge University Press: 12 April 2018

Abstract

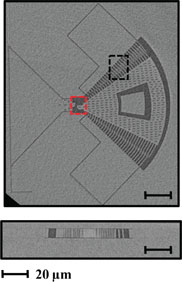

Millions of micro electro mechanical system sensors are fabricated each year using an ultra-clean process that allows for a vacuum-encapsulated cavity. These devices have a multi-layer structure that contains hidden layers with highly doped silicon, which makes common imaging techniques ineffective. Thus, examining device features post-fabrication, and testing, is a significant challenge. Here, we use a combination of micro- and nano-scale x-ray computed tomography to study device features and assess failure mechanisms in such devices without destroying the ultra-clean cavity. This provides a unique opportunity to examine surfaces and trace failure mechanisms to specific steps in the fabrication process.

- Type

- Research Letters

- Information

- Copyright

- Copyright © Materials Research Society 2018

References

- 4

- Cited by