Article contents

Correlation between strain-rate sensitivity and viscous properties derived from dynamic nanoindentation of ultrafine-grained Al–Zn alloys

Published online by Cambridge University Press: 18 December 2018

Abstract

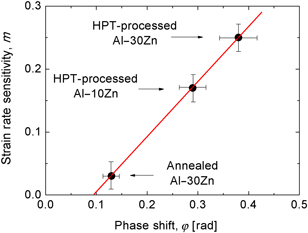

The relationship between the oscillatory force and the depth-response during dynamic indentation was analyzed mathematically and investigated experimentally in ultrafine-grained Al–Zn alloys processed by high-pressure torsion. We have shown for the first time that the phase shift between the local oscillatory force and depth signal, caused by the internal friction, is correlated to the strain-rate sensitivity, which is a key parameter indicating the ductility of materials. This correlation enables a new application of dynamic nanoindentation for studying the rate-dependent deformation-mechanisms of materials from a novel aspect.

- Type

- Research Letters

- Information

- Copyright

- Copyright © Materials Research Society 2018

References

- 4

- Cited by