Article contents

Well-ordered spherical LiNi0.8Co0.1Mn0.1O2 cathode material for lithium-ion batteries

Published online by Cambridge University Press: 11 November 2019

Abstract

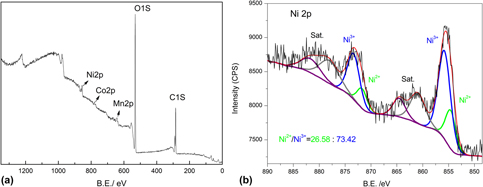

Nickel-rich layered oxide LiNi0.8Co0.1Mn0.1O2 suffers from severe structural instability and irreversible capacity loss during cycling due to cation disorder of Li+ and Ni2+. To solve this problem, the precursor Ni0.8Co0.1Mn0.1(OH)2 and well-ordered LiNi0.8Co0.1Mn0.1O2 cathode materials were successfully synthesized via controlled crystallization and high-temperature solid-state methods. The structure, morphology, and electrochemical performance of the precursor and LiNi0.8Co0.1Mn0.1O2 powders were investigated. The results show that the precursor Ni0.8Co0.1Mn0.1(OH)2 is made of sphere-like particles composed of needle-like primary crystal and LiNi0.8Co0.1Mn0.1O2 possesses a perfect layered structure with low Li/Ni disorder. Electrochemical data demonstrate that the material rate capabilities are 203.3, 187.7, 170.4, and 163 mA h/g from 0.1C to 10C, respectively. The capacity retention is 87.9% after 100 cycles at 1C, even the cut-off voltage was increased to 4.5 V. The high discharge capacity and outstanding cycling life can be attributed to the merits of a perfect crystal lattice with low Li/Ni disorder, fast lithium ion transport, and relatively low charge transfer resistance.

- Type

- Article

- Information

- Journal of Materials Research , Volume 35 , Issue 1: Focus Section: Advances in Battery Technology: Material Innovations in Design and Fabrication , 14 January 2020 , pp. 51 - 57

- Copyright

- Copyright © Materials Research Society 2019

References

- 10

- Cited by