Article contents

Strain rate sensitivity, temperature sensitivity, and strain hardening during the isothermal compression of BT25y alloy

Published online by Cambridge University Press: 30 August 2016

Abstract

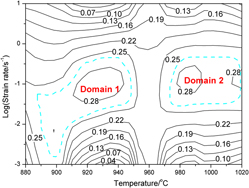

The high-temperature flow behavior and flow stress sensitivity of BT25y alloy were investigated. Results show that hot deformation is accompanied by the dynamic competition between work hardening and flow softening. The strain rate sensitivity exponent m tends to decrease with the strain rate after a first rise, and reaches the maximum at strain rate of 0.1 s−1. There is a large temperature range exhibiting m values above 0.2 at strain rates of 0.01–0.1 s−1. The temperature sensitivity exponent s shows an overall dropping trend with elevated temperature. The strain hardening exponent n first decreases and then increases with the strain at strain rate of 0.01 s−1. Large positive n values lie in areas with high strain rate, and small negative n values are located in areas with lower temperature and small strain rate. Secondary lamellar α appears near the phase transition temperature. The microstructure presents elongated characteristics at high strain rate.

- Type

- Articles

- Information

- Journal of Materials Research , Volume 31 , Issue 18: Focus Section: Reinventing Boron Chemistry for the 21st Century , 28 September 2016 , pp. 2863 - 2875

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 8

- Cited by