Article contents

Sound absorption properties of porous composites fabricated by a hydrogel templating technique

Published online by Cambridge University Press: 29 July 2013

Abstract

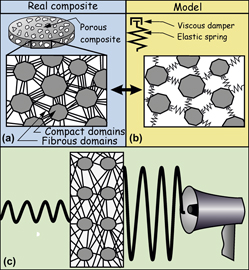

We have used a hydrogel templating technique followed by the subsequent evaporation of water present to fabricate porous cement and porous PDMS composites, and we have analyzed their sound absorption properties. All experiments were carried out with hydrogel slurries of broad bead size distributions. Porous PDMS and cement composites were produced with porosities of up to 80% and 70%, respectively. Scanning electron microscope analysis shows fibrous domains within the voids created by the hydrogel in the cement samples and open pore network in the PDMS composites of initial hydrogel content higher than 70 vol%. Sound absorption was improved with respect to control nonporous samples in all composites with porosities higher than 60 vol%, where an open pore structure was formed. The porous PDMS and porous cement produced by this method show better sound absorption at 200–400 Hz and 1200–1800 Hz frequency ranges when compared with the sound absorption in the intermediate frequencies range between 400 and 1000 Hz.

- Type

- Articles

- Information

- Journal of Materials Research , Volume 28 , Issue 17: Focus Issue: Advances in the Synthesis, Characterization, and Properties of Bulk Porous Materials , 14 September 2013 , pp. 2409 - 2414

- Copyright

- Copyright © Materials Research Society 2013

References

REFERENCES

- 10

- Cited by