Article contents

Simulation and experimental investigation of strain rate impact on martensitic transformation in 304L steel through dome test

Published online by Cambridge University Press: 14 July 2016

Abstract

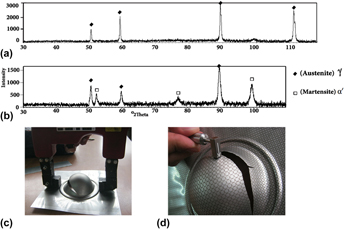

The present study aims to investigate the effect of strain rate on volume fraction of martensite (VFM) in 304L austenitic stainless steel through dome test. Findings of this study show that martensitic transformation affects the deformation mode and formability of this material. Three strain rates are applied by controlling forming punch speed to conduct the stretching experiments and VFM is measured using magnetic saturation method. Results of the present study reveal that maximum VFM of 56% forms at the pole at low strain rates, whereas VFM of 47% is seen at high strain rates, and transforms in the region close to the flange. It is noted that blanks show good formability under low strain rate and poor formability at high strain rates. The relationship between VFM and strain rate, strain, percentage of shell reduction, equivalent of stress, and triaxiality are discussed. The experimental procedure is simulated and predicted findings show good agreement with the experimental results.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

Footnotes

Contributing Editor: Jürgen Eckert

References

REFERENCES

- 6

- Cited by