Article contents

Role of Ru on the microstructure and property of novel Co–Ti–V Superalloy

Published online by Cambridge University Press: 10 September 2020

Abstract

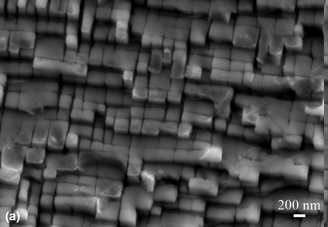

In the present paper, the authors investigated the microstructures and mechanical properties of dual-phase Co–Ti–V-based superalloys with different additions of Ru. The results showed that with the increase of Ru contents, the size of γ′ precipitates of the alloy gradually raised, the volume fraction of γ′ phase slightly, and the lattice misfit between γ/γ′ phases increased. Ru was enriched in the γ′ phase, and the elemental partition coefficients (KX = Cγ′/Cγ) of Ti and V increased with the increment of Ru. The Ru contents have no remarkable influence on the solvus temperatures of γ′ in the Co–Ti–V alloys. The yield strength at 1000 °C of the Co–10Ti–11V–0.5Ru alloy was the highest, while the yield strength of the 1Ru alloy was the smallest. Transmission electron microscopy and scanning electron microscopy observations showed that the γ′ shape in the compressed specimen containing 0.5Ru remain integrated, while the γ′ in other alloys were cut into several parts.

- Type

- Article

- Information

- Copyright

- Copyright © The Author(s), 2020. Published by Cambridge University Press on behalf of Materials Research Society

References

- 5

- Cited by