Article contents

Revealing the ductility of nanoceramic MgAl2O4

Published online by Cambridge University Press: 15 May 2019

Abstract

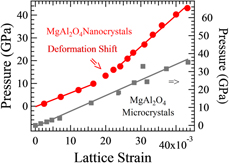

Ceramics are strong but brittle. According to the classical theories, ceramics are brittle mainly because dislocations are suppressed by cracks. Here, the authors report the combined elastic and plastic deformation measurements of nanoceramics, in which dislocation-mediated stiff and ductile behaviors were detected at room temperature. In the synchrotron-based deformation experiments, a marked slope change is observed in the stress–strain relationship of MgAl2O4 nanoceramics at high pressures, indicating that a deformation mechanism shift occurs in the compression and that the nanoceramics sample is elastically stiffer than its bulk counterpart. The bulk-sized MgAl2O4 shows no texturing at pressures up to 37 GPa, which is compatible with the brittle behaviors of ceramics. Surprisingly, substantial texturing is seen in nanoceramic MgAl2O4 at pressures above 4 GPa. The observed stiffening and texturing indicate that dislocation-mediated mechanisms, usually suppressed in bulk-sized ceramics at low temperature, become operative in nanoceramics. This makes nanoceramics stiff and ductile.

Keywords

- Type

- Invited Paper

- Information

- Copyright

- Copyright © Materials Research Society 2019

Footnotes

Present address: SLAC National Accelerator Laboratory, Menlo Park, CA 94,305, USA.

References

- 8

- Cited by