Article contents

Revealing deformation mechanisms in Mg–Y alloy by in situ deformation of nano-pillars with mediated lateral stiffness

Published online by Cambridge University Press: 15 May 2019

Abstract

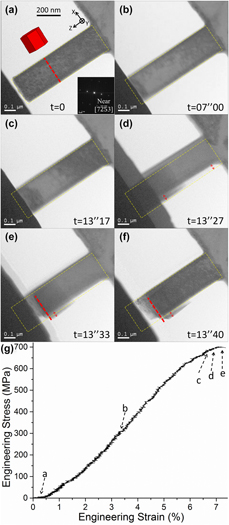

In our previous study, we observed a lack of  $\left\{ {10\bar{1}2} \right\}$ twinning in a deformed Mg–Y alloy, which contributed to the observed yield “symmetry.” However, the effects of texture and grain size on polycrystalline deformation made it difficult to fully understand why twinning was not active. Therefore, we report herein in-depth study by in situ transmission electron microscopy, i.e., in situ TEM. The in situ deformation of nano-sized Mg–Y pillars revealed that prismatic slip was favored over twinning, namely, the critical stress required to activate prismatic slip was lower than that for twinning. This finding diametrically differs from that reported in other nano/micro-pillar deformation studies, where twinning is always the dominant deformation mechanism. By measuring the critical stresses for basal, prismatic, and pyramidal slip systems, this in situ TEM study also sheds light on the effects of the alloying element Y on reducing the intrinsic plastic anisotropy in the Mg matrix.

$\left\{ {10\bar{1}2} \right\}$ twinning in a deformed Mg–Y alloy, which contributed to the observed yield “symmetry.” However, the effects of texture and grain size on polycrystalline deformation made it difficult to fully understand why twinning was not active. Therefore, we report herein in-depth study by in situ transmission electron microscopy, i.e., in situ TEM. The in situ deformation of nano-sized Mg–Y pillars revealed that prismatic slip was favored over twinning, namely, the critical stress required to activate prismatic slip was lower than that for twinning. This finding diametrically differs from that reported in other nano/micro-pillar deformation studies, where twinning is always the dominant deformation mechanism. By measuring the critical stresses for basal, prismatic, and pyramidal slip systems, this in situ TEM study also sheds light on the effects of the alloying element Y on reducing the intrinsic plastic anisotropy in the Mg matrix.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2019

Footnotes

Present address: Pacific Northwest National Laboratory.

References

- 4

- Cited by