No CrossRef data available.

Article contents

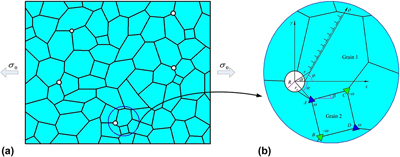

Quantitative understanding of the effect of grain rotation on the nanovoid growth

Published online by Cambridge University Press: 02 November 2018

Abstract

A mechanical model is developed to explain the influence of grain rotation on nanovoid growth in nanocrystalline solids in the current paper. In the framework of the mechanical model, the dislocations released from the nanovoid surface will be affected by four stresses: the driving stress induced by far-field stress, the stress arising from grain rotation, the image stress caused by the free surface of the nanovoid, and the back stress generated by the previously emitted dislocations. Furthermore, under the condition of different rotational strength and surface effects, we analyzed in detail the influence of the important parameters such as nanovoid radius, nucleation radius, dislocation emission angle, relative distance, rotation grain size, rotation coefficient, and direction angle on the critical stress. Finally, we discuss the effect of the coupling of rotational deformation and the grain boundary on the growth of the nanovoid. As a conclusion, the high stress nearby the nanovoid can be released by grain rotation, which inhibits the growth of the nanovoid.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2018