Article contents

Quantification of hardening in Fe–Mn master alloys prepared by a mechanical alloying process via nanoindentation experiments

Published online by Cambridge University Press: 13 July 2011

Abstract

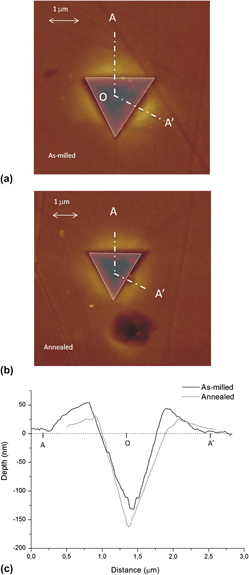

During the mechanical alloying of a prealloyed Fe–Mo and Mn powder, a large amount of energy is involved because of continuous collisions between the grinding media and the powder. The energy is transformed into massive plastic deformation and solid solution formation. Both phenomena increase in the hardness of the milled particles. To quantify the contribution of both effects to the hardening, nanoindentation experiments were performed on the as-milled powder and after an annealing treatment, based on the assumption that the thermal process would eliminate the lattice distortions due to plastic deformation. When the indentation profile was measured, a significant pileup around the perimeter of the indentation track was observed; therefore, it was necessary to measure the actual amount of contact area by atomic force microscopy. Thus, parameters of mechanical powders can be determined, giving to the conclusion that 40% of the hardening induced can be attributed to the plastic strain.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2011

References

REFERENCES

- 6

- Cited by