Article contents

Optoelectronics properties of tin-doped indium oxide films fabricated by DC magnetron sputtering in pure argon with post-annealing in oxygen atmosphere

Published online by Cambridge University Press: 05 June 2015

Abstract

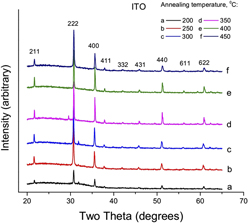

We report on the study of the characteristics of indium–tin oxide (ITO) films prepared by well-controlled and reproducible DC magnetron sputtering in argon with consequent annealing in oxygen atmosphere. The structural, electrical, and optical properties of the ITO films were investigated. It was found that the films deposited in argon atmosphere with a commercial ITO target have low transparency and high resistivity. The lower value of the resistivity around 3 × 10−4 Ω cm and the higher value of the figure of merit of 7.4 × 10−3 Ω−1 for 200 nm thick films are obtained after postannealing the films at the optimal temperature T = 300 °C for 1 h. It was found experimentally that postannealing at different temperatures allows tuning effective work function of the ITO films in the range of 4.2–5.5 eV. The latter is an important issue for applications in optoelectronic devices. The fabrication method is useful for the fabrication of ITO films with high electro-optical parameters on flexible polyimide substrates.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2015

References

REFERENCES

- 9

- Cited by