Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Song, Bo

Zhao, Xiao

Li, Shuai

Han, Changjun

Wei, Qingsong

Wen, Shifeng

Liu, Jie

and

Shi, Yusheng

2015.

Differences in microstructure and properties between selective laser melting and traditional manufacturing for fabrication of metal parts: A review.

Frontiers of Mechanical Engineering,

Vol. 10,

Issue. 2,

p.

111.

Leuders, Stefan

Vollmer, Malte

Brenne, Florian

Tröster, Thomas

and

Niendorf, Thomas

2015.

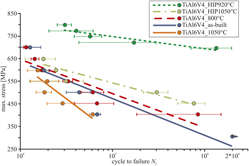

Fatigue Strength Prediction for Titanium Alloy TiAl6V4 Manufactured by Selective Laser Melting.

Metallurgical and Materials Transactions A,

Vol. 46,

Issue. 9,

p.

3816.

Lammers, Stefan

Adam, Guido

Schmid, Hans J.

Mrozek, Rafael

Oberacker, Rainer

Hoffmann, M. J.

Quattrone, Francesco

and

Ponick, Bernd

2016.

Additive Manufacturing of a lightweight rotor for a permanent magnet synchronous machine.

p.

41.

Li, Peipei

Warner, Derek

Fatemi, Ali

and

Phan, Nam D.

2016.

On the Fatigue Performance of Additively Manufactured Ti-6Al-4V to Enable Rapid Qualification for Aerospace Applications.

Beese, Allison M.

and

Carroll, Beth E.

2016.

Review of Mechanical Properties of Ti-6Al-4V Made by Laser-Based Additive Manufacturing Using Powder Feedstock.

JOM,

Vol. 68,

Issue. 3,

p.

724.

Grienitz, Volker

Tröster, Thomas

and

Meiners, Stefan

2016.

Selektives Laserschmelzen für Leichtbau mit Designfreiheit.

Lightweight Design,

Vol. 9,

Issue. 3,

p.

82.

Witkin, David B.

Albright, Thomas V.

and

Patel, Dhruv N.

2016.

Empirical Approach to Understanding the Fatigue Behavior of Metals Made Using Additive Manufacturing.

Metallurgical and Materials Transactions A,

Vol. 47,

Issue. 8,

p.

3823.

Wu, Ming-Wei

and

Lai, Pang-Hsin

2016.

The positive effect of hot isostatic pressing on improving the anisotropies of bending and impact properties in selective laser melted Ti-6Al-4V alloy.

Materials Science and Engineering: A,

Vol. 658,

Issue. ,

p.

429.

Li, P.

Warner, D.H.

Fatemi, A.

and

Phan, N.

2016.

Critical assessment of the fatigue performance of additively manufactured Ti–6Al–4V and perspective for future research.

International Journal of Fatigue,

Vol. 85,

Issue. ,

p.

130.

Smith, Jacob

Xiong, Wei

Yan, Wentao

Lin, Stephen

Cheng, Puikei

Kafka, Orion L.

Wagner, Gregory J.

Cao, Jian

and

Liu, Wing Kam

2016.

Linking process, structure, property, and performance for metal-based additive manufacturing: computational approaches with experimental support.

Computational Mechanics,

Vol. 57,

Issue. 4,

p.

583.

Brüggemann, Jan-Peter

Reschetnik, Wadim

Richard, Hans A

Kullmer, Gunter

and

Schramm, Britta

2016.

Rapid.Tech – International Trade Show & Conference for Additive Manufacturing.

p.

290.

Lewandowski, John J.

and

Seifi, Mohsen

2016.

Metal Additive Manufacturing: A Review of Mechanical Properties.

Annual Review of Materials Research,

Vol. 46,

Issue. 1,

p.

151.

Morita, Tatsuro

Tsuda, Chika

Sakai, Hitoshi

and

Higuchi, Norio

2017.

Fundamental Properties of Ti-6Al-4V Alloy Produced by Selective Laser Melting Method.

MATERIALS TRANSACTIONS,

Vol. 58,

Issue. 10,

p.

1397.

Zhang, Meng

Sun, Chen-Nan

Zhang, Xiang

Goh, Phoi Chin

Wei, Jun

Hardacre, David

and

Li, Hua

2017.

Fatigue and fracture behaviour of laser powder bed fusion stainless steel 316L: Influence of processing parameters.

Materials Science and Engineering: A,

Vol. 703,

Issue. ,

p.

251.

Hengsbach, Florian

Koppa, Peter

Duschik, Kristina

Holzweissig, Martin Joachim

Burns, Madison

Nellesen, Jens

Tillmann, Wolfgang

Tröster, Thomas

Hoyer, Kay-Peter

and

Schaper, Mirko

2017.

Duplex stainless steel fabricated by selective laser melting - Microstructural and mechanical properties.

Materials & Design,

Vol. 133,

Issue. ,

p.

136.

Ellyson, Benjamin

Brochu, Mathieu

and

Brochu, Myriam

2017.

Characterization of bending vibration fatigue of SLM fabricated Ti-6Al-4V.

International Journal of Fatigue,

Vol. 99,

Issue. ,

p.

25.

Lammers, S.

Quattrone, F.

Mrozek, R.

Zimmer, D.

Schmid, H.

Ponick, B.

and

Hoffmann, M.

2017.

Rapid.Tech – International Trade Show & Conference for Additive Manufacturing.

p.

80.

Leuders, S.

Meiners, S.

Wu, L.

Taube, A.

Tröster, T.

and

Niendorf, T.

2017.

Structural components manufactured by Selective Laser Melting and Investment Casting—Impact of the process route on the damage mechanism under cyclic loading.

Journal of Materials Processing Technology,

Vol. 248,

Issue. ,

p.

130.

Brüggemann, Jan-Peter

Risse, Lena

Kullmer, Gunter

and

Richard, Hans Albert

2017.

Rapid.Tech – International Trade Show & Conference for Additive Manufacturing.

p.

94.

Yadollahi, Aref

and

Shamsaei, Nima

2017.

Additive manufacturing of fatigue resistant materials: Challenges and opportunities.

International Journal of Fatigue,

Vol. 98,

Issue. ,

p.

14.