Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Feng, Junzong

Su, Bao-Lian

Xia, Hesheng

Zhao, Shanyu

Gao, Chao

Wang, Lukai

Ogbeide, Osarenkhoe

Feng, Jian

and

Hasan, Tawfique

2021.

Printed aerogels: chemistry, processing, and applications.

Chemical Society Reviews,

Vol. 50,

Issue. 6,

p.

3842.

Yang, Jianming

Wang, Hongqiang

Zhou, Bin

Shen, Jun

Zhang, Zhihua

and

Du, Ai

2021.

Versatile Direct Writing of Aerogel-Based Sol–Gel Inks.

Langmuir,

Vol. 37,

Issue. 6,

p.

2129.

Blyweert, P.

Nicolas, V.

Fierro, V.

and

Celzard, A.

2021.

3D printing of carbon-based materials: A review.

Carbon,

Vol. 183,

Issue. ,

p.

449.

Tetik, Halil

Wang, Ying

Sun, Xiao

Cao, Daxian

Shah, Nasrullah

Zhu, Hongli

Qian, Fang

and

Lin, Dong

2021.

Additive Manufacturing of 3D Aerogels and Porous Scaffolds: A Review.

Advanced Functional Materials,

Vol. 31,

Issue. 45,

Yang, Jianming

Cui, Ningxin

Lu, Jialu

Han, Dongxiao

Shen, Jun

Zhang, Zhihua

Qin, Lili

Zhou, Bin

and

Du, Ai

2022.

A Facile and Versatile Post-Treatment Method to Efficiently Functionalize 3D-Printed Carbon Aerogels via Introducing Tailored Metal Elements.

ACS Applied Energy Materials,

Vol. 5,

Issue. 10,

p.

11970.

Chandrasekaran, Swetha

Feaster, Jeremy

Ynzunza, Jenna

Li, Frances

Wang, Xueqiao

Nelson, Art J.

and

Worsley, Marcus A.

2022.

Three-Dimensional Printed MoS2/Graphene Aerogel Electrodes for Hydrogen Evolution Reactions.

ACS Materials Au,

Vol. 2,

Issue. 5,

p.

596.

Wang, Lukai

Feng, Junzong

Luo, Yi

Jiang, Yonggang

Zhang, Guojie

and

Feng, Jian

2022.

Versatile Thermal‐Solidifying Direct‐Write Assembly towards Heat‐Resistant 3D‐Printed Ceramic Aerogels for Thermal Insulation.

Small Methods,

Vol. 6,

Issue. 5,

Zhu, Jie

Wu, Peiwen

Chao, Yanhong

Yu, Jiangtao

Zhu, Wenshuai

Liu, Zhichang

and

Xu, Chunming

2022.

Recent advances in 3D printing for catalytic applications.

Chemical Engineering Journal,

Vol. 433,

Issue. ,

p.

134341.

Yang, Jianming

Cui, Ningxin

Han, Dongxiao

Shen, Jun

Wu, Guangming

Zhang, Zhihua

Qin, Lili

Zhou, Bin

and

Du, Ai

2022.

A Simple Strategy for Constructing Hierarchical Composite Electrodes of PPy‐Posttreated 3D‐Printed Carbon Aerogel with Ultrahigh Areal Capacitance over 8000 mF cm–2.

Advanced Materials Technologies,

Vol. 7,

Issue. 7,

Zhu, Xiurong

Hope-Weeks, Lousia J.

Baghi, Roya

Charles, Vanessa R.

Yu, Yi

Zhu, Lingwei

Wang, Xinghua

Li, Dongbo

and

Zeng, Xianghua

2022.

Enhanced compressive strength of carbon aerogels with low density and high specific surface areas.

Journal of Porous Materials,

Vol. 29,

Issue. 4,

p.

1279.

Zhu, Xiurong

Hope-Weeks, Lousia J.

Yu, Yi

Yuan, Jvjun

Zhang, Xianke

Yu, Huajun

Liu, Jiajun

Li, Xiaofen

and

Zeng, Xianghua

2022.

Effect of concentration of glycidol on the properties of resorcinol-formaldehyde aerogels and carbon aerogels.

RSC Advances,

Vol. 12,

Issue. 31,

p.

20191.

Kumar, Satendra

Goswami, Manoj

Singh, Netrapal

Natarajan, Sathish

and

Kumar, Surender

2022.

A comprehensive review of the 3D printing of sp2 carbons: Materials, properties and applications.

New Carbon Materials,

Vol. 37,

Issue. 6,

p.

1046.

Chandrasekaran, Swetha

Lin, Dun

Li, Yat

and

Worsley, Marcus A.

2023.

Aerogels, additive manufacturing, and energy storage.

Joule,

Vol. 7,

Issue. 5,

p.

866.

Li, Yongxia

Ren, Xueyong

Zhu, Lin

and

Li, Chunmiao

2023.

Biomass 3D Printing: Principles, Materials, Post-Processing and Applications.

Polymers,

Vol. 15,

Issue. 12,

p.

2692.

Shen, Jun

and

Zhang, Xiaoxue

2023.

Recent progress and applications of aerogels in China.

Journal of Sol-Gel Science and Technology,

Vol. 106,

Issue. 2,

p.

290.

Wang, Lukai

Feng, Junzong

Jiang, Yonggang

Lu, Di

Men, Jing

Luo, Yi

Wang, Xin

and

Feng, Jian

2023.

Ultraviolet-assisted direct-write printing strategy towards polyorganosiloxane-based aerogels with freeform geometry and outstanding thermal insulation performance.

Chemical Engineering Journal,

Vol. 455,

Issue. ,

p.

140818.

Yang, Jianming

Lu, Jialu

Xi, Shuang

Wang, Hongqiang

Han, Dongxiao

Fan, Caide

Zhang, Zhihua

Shen, Jun

Zhou, Bin

and

Du, Ai

2023.

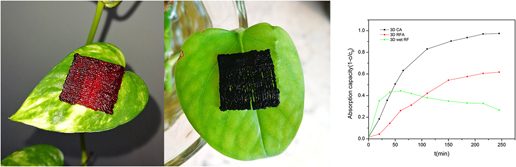

Direct 3D print polyimide aerogels for synergy management of thermal insulation, gas permeability and light absorption.

Journal of Materials Chemistry A,

Vol. 11,

Issue. 39,

p.

21272.

Cipriani, Ciera E.

Dornbusch, Donald A.

Vivod, Stephanie L.

and

Pentzer, Emily B.

2024.

Direct ink writing of polyimide aerogels for battery thermal mitigation.

RSC Applied Polymers,

Vol. 2,

Issue. 1,

p.

71.

Parra‐Marfil, Adriana

Pérez‐Cadenas, Agustín Francisco

Carrasco‐Marín, Francisco

Ocampo‐Pérez, Raúl

and

Bailón‐García, Esther

2024.

Revolutionizing Monolithic Catalysts: The Breakthroughs of Design Control through Computer‐Aided‐Manufacturing.

Advanced Materials Technologies,

Vol. 9,

Issue. 12,