Article contents

Nanoscale mapping of in situ actuating microelectromechanical systems with AFM

Published online by Cambridge University Press: 26 January 2015

Abstract

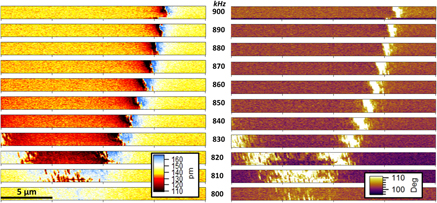

Microelectromechanical systems (MEMS) are increasingly at our fingertips. To understand and thereby improve their performance, especially given their ever-decreasing sizes, it is crucial to measure their functionality in situ. Atomic force microscopy (AFM) is well suited for such studies, allowing nanoscale lateral and vertical resolution of static displacements, as well as mapping of the dynamic response of these physically actuating microsystems. In this work, the vibration of a tuning fork based viscosity sensor is mapped and compared to model experiments in air, liquid, and a curing collagen gel. The switching response of a MEMS switch with nanosecond time-scale activation is also monitored – including mapping resonances of the driving microcantilever and the displacement of an overhanging contact structure in response to periodic pulsing. Such nanoscale in situ AFM investigations of MEMS can be crucial for enhancing modeling, design, and the ultimate performance of these increasingly important and sophisticated devices.

- Type

- Articles

- Information

- Journal of Materials Research , Volume 30 , Issue 3: Focus Issue: In-situ and Operando Characterization of Materials , 14 February 2015 , pp. 429 - 441

- Copyright

- Copyright © Materials Research Society 2015

References

REFERENCES

- 6

- Cited by