Article contents

Multifunctional antifogging coatings based on ZrO2 and SiO2 nanoparticles by spray-spin-blow layer-by-layer assembly

Published online by Cambridge University Press: 24 October 2019

Abstract

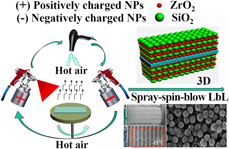

Multifunctional antifogging (AF) coatings consisting of alternating layers of positively charged ZrO2 nanoparticles (NPs) and negatively charged SiO2 NPs were rapidly fabricated via spray-spin-blow layer-by-layer electrostatic assembly followed by calcination. The resultant coatings of only three bilayers exhibited excellent AF, superhydrophilic, antireflective (AR), and self-cleaning (SC) properties, as well as high mechanical stability. These were demonstrated by various methods, e.g., transmission and scanning electron microscopy, X-ray diffraction, UV-Vis spectrometry, a contact angle test, a boiling test (constant 100 °C), a low-temperature test, and mechanical stability tests. ZrO2 and SiO2 NPs were synthesized and utilized as building blocks for fabricating the coatings. The resultant coatings exhibited excellent AF and SC properties due to the superhydrophilicity of the coating, showed excellent AR properties due to the quarter-wave coating with a low refractive index, and exhibited excellent superhydrophilic properties due to a rough microtextured surface. The simplicity of the fabrication process, easy availability of the nanomaterials, and excellent adhesion to substrates for the coating preparation might make the low-cost, nontoxic, and eco-friendly multifunctional coatings potentially useful in optical and display devices.

Keywords

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2019

Footnotes

These authors contributed equally to this work.

References

- 6

- Cited by