Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Zhang, Rui-Zhi

and

Reece, Michael J.

2019.

Review of high entropy ceramics: design, synthesis, structure and properties.

Journal of Materials Chemistry A,

Vol. 7,

Issue. 39,

p.

22148.

Xing, Qiuwei

Wang, Haijiang

Chen, Mingbiao

Chen, Zhaoyun

Li, Rongbin

Jin, Peipeng

and

Zhang, Yong

2019.

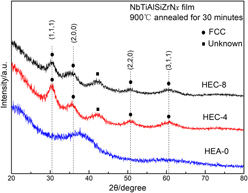

Mechanical Properties and Corrosion Resistance of NbTiAlSiZrNx High-Entropy Films Prepared by RF Magnetron Sputtering.

Entropy,

Vol. 21,

Issue. 4,

p.

396.

Gild, Joshua

Kaufmann, Kevin

Vecchio, Kenneth

and

Luo, Jian

2019.

Reactive flash spark plasma sintering of high-entropy ultrahigh temperature ceramics.

Scripta Materialia,

Vol. 170,

Issue. ,

p.

106.

Zhang, Hanzhu

Hedman, Daniel

Feng, Peizhong

Han, Gang

and

Akhtar, Farid

2019.

A high-entropy B4(HfMo2TaTi)C and SiC ceramic composite.

Dalton Transactions,

Vol. 48,

Issue. 16,

p.

5161.

Dippo, Olivia F.

Mesgarzadeh, Neda

Harrington, Tyler J.

Schrader, Grant D.

and

Vecchio, Kenneth S.

2020.

Bulk high-entropy nitrides and carbonitrides.

Scientific Reports,

Vol. 10,

Issue. 1,

ZHANG, Fengnian

GUO, Meng

MIAO, Yang

GAO, Feng

CHENG, Chufei

CHENG, Fuhao

and

LIU, Yufeng

2021.

Preparation and Sintering Behavior of High Entropy Ceramic (Zr1/7Hf1/7Ce1/7Y2/7La2/7)O2-δ.

Journal of Inorganic Materials,

Vol. 36,

Issue. 4,

p.

372.

Yan, XueHui

Liaw, Peter K.

and

Zhang, Yong

2021.

Order and Disorder in Amorphous and High-Entropy Materials.

Metallurgical and Materials Transactions A,

Vol. 52,

Issue. 6,

p.

2111.

Wang, Chunyang

Qin, Mingde

Lei, Tianjiao

He, Yubin

Kisslinger, Kim

Rupert, Timothy J.

Luo, Jian

and

Xin, Huolin L.

2021.

Synergic grain boundary segregation and precipitation in W- and W-Mo-containing high-entropy borides.

Journal of the European Ceramic Society,

Vol. 41,

Issue. 10,

p.

5380.

Li, Yasong

Zhou, Shichao

and

Zhang, Yong

2021.

High-Entropy Materials: Theory, Experiments, and Applications.

p.

721.

Huang, Haiyun

Shao, Lihuan

and

Liu, Huazhu

2021.

Stacking fault energies of high-entropy nitrides from first-principles calculations.

Solid State Communications,

Vol. 327,

Issue. ,

p.

114210.

Zhao, Shuai-Sheng

Qiu, Xiao-Li

He, Cheng-Yu

Yu, Dong-Mei

Liu, Gang

and

Gao, Xiang-Hu

2021.

Nanometer-Thick High-Entropy Alloy Nitride Al0.4Hf0.6NbTaTiZrN-Based Solar Selective Absorber Coatings.

ACS Applied Nano Materials,

Vol. 4,

Issue. 5,

p.

4504.

Xia, Ao

Dedoncker, Robin

Glushko, Oleksandr

Cordill, Megan J.

Depla, Diederik

and

Franz, Robert

2021.

Influence of the nitrogen content on the structure and properties of MoNbTaVW high entropy alloy thin films.

Journal of Alloys and Compounds,

Vol. 850,

Issue. ,

p.

156740.

Kretschmer, Andreas

Kirnbauer, Alexander

Moraes, Vincent

Primetzhofer, Daniel

Yalamanchili, Kumar

Rudigier, Helmut

and

Mayrhofer, Paul Heinz

2021.

Improving phase stability, hardness, and oxidation resistance of reactively magnetron sputtered (Al,Cr,Nb,Ta,Ti)N thin films by Si-alloying.

Surface and Coatings Technology,

Vol. 416,

Issue. ,

p.

127162.

Saghir, A. Vojdani

Beidokhti, S. Mollazadeh

Khaki, J. Vahdati

and

Salimi, A.

2021.

One-step synthesis of single-phase (Co, Mg, Ni, Cu, Zn) O High entropy oxide nanoparticles through SCS procedure: Thermodynamics and experimental evaluation.

Journal of the European Ceramic Society,

Vol. 41,

Issue. 1,

p.

563.

Akrami, Saeid

Edalati, Parisa

Fuji, Masayoshi

and

Edalati, Kaveh

2021.

High-entropy ceramics: Review of principles, production and applications.

Materials Science and Engineering: R: Reports,

Vol. 146,

Issue. ,

p.

100644.

Huang, Haiyun

Shao, Lihuan

and

Liu, Huazhu

2021.

Prediction of Single‐Phase High‐Entropy Nitrides from First‐Principles Calculations.

physica status solidi (b),

Vol. 258,

Issue. 8,

Zhang, Lu

Wang, Wenqing

Zhou, Niping

Dong, Xingjie

Yuan, Fang

and

He, Rujie

2022.

Low temperature fabrication of Cf/BNi/(Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)C-SiCm high entropy ceramic matrix composite by slurry coating and laminating combined with precursor infiltration and pyrolysis.

Journal of the European Ceramic Society,

Vol. 42,

Issue. 7,

p.

3099.

Si, Yanxin

Wang, Ganggang

Wen, Mao

Tong, Yang

Wang, Weiwei

Li, Yang

Yan, Linhui

Yu, Wanjun

Zhang, Shangzhou

and

Ren, Ping

2022.

Corrosion and friction resistance of TiVCrZrWNx high entropy ceramics coatings prepared by magnetron sputtering.

Ceramics International,

Vol. 48,

Issue. 7,

p.

9342.

Li, Yasong

Ma, Jiang

Liaw, Peter K.

and

Zhang, Yong

2022.

Exploring the amorphous phase formation and properties of W-Ta-(Cr, Fe, Ni) high-entropy alloy gradient films via a high-throughput technique.

Journal of Alloys and Compounds,

Vol. 913,

Issue. ,

p.

165294.

Su, Jingyao

Cao, Zhenzhu

Jiang, Zhipeng

Chen, Guohua

Zhu, Yuxuan

Wang, Liying

and

Li, Guorong

2022.

High entropy oxide nanofiber by electrospun method and its application for lithium battery anode material.

International Journal of Applied Ceramic Technology,

Vol. 19,

Issue. 4,

p.

2004.