Article contents

Investigation on annealing strengthening effect of laser cladding Fe5Cr5Co5SiTiNbMoW high-entropy alloy coating

Published online by Cambridge University Press: 17 September 2018

Abstract

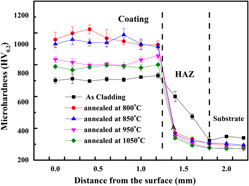

To improve the high-temperature properties of tool steel, a microstructure-dense and crack-free Fe5Cr5Co5SiTiNbMoW high-entropy alloy (HEA) coating was successfully fabricated by laser cladding. And its microstructure and hardness evolution after various annealing temperatures of 800 °C, 850 °C, 950 °C, and 1050 °C for 4 h were carefully investigated by OM, scanning electron microscope, energy dispersion spectrum, X-ray diffraction, and microhardness tester, respectively. The experimental results show that the HEAcoating was mainly composed of body-centered cubic and (Nb, Ti)C plus few Laves phase. The high-temperature annealing processing has little influence on the phase composition. The dendrites and matrix are decomposed with the annealing temperature increasing. While annealing at 950 °C, a eutectic microstructure appeared in the coating. Moreover, the thickness of the diffusion layer of HEA coating increased with the increasing of annealing temperatures. Surprisingly, the HEA coating after annealing at 850 °C possessed ultra-high average hardness, about 1050 HV0.2, huge improvement compared with as-cladding HEA coating (∼780 HV0.2). Therefore, it might reveal that the HEA coating exhibits excellent annealing strengthening ability.

Keywords

- Type

- Article

- Information

- Journal of Materials Research , Volume 33 , Issue 19: Focus Issue: Fundamental Understanding and Applications of High-Entropy Alloys , 14 October 2018 , pp. 3339 - 3346

- Copyright

- Copyright © Materials Research Society 2018

References

REFERENCES

- 9

- Cited by