Article contents

Influence of tungsten content on microstructure and properties of tungsten-doped graphite-like carbon films

Published online by Cambridge University Press: 28 November 2016

Abstract

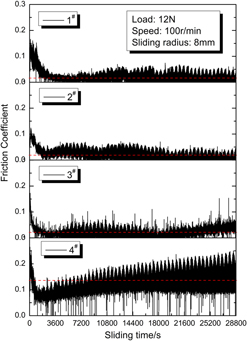

Four types of W-doped graphite-like carbon (W-GLC) films were deposited under different W target currents by magnetron sputtering method. The effects of W content on the microstructure and properties of the W-GLC films were analyzed via various characterization techniques. The results show that the microstructure of the W-GLC films tends to be loose, while the surface roughness distinctly increases with the increase in the W target current. Moderate W-doping can considerably improve the mechanical properties and wear resistance of the film, which will subsequently decrease as the W content becomes excessive. Moreover, the friction coefficient of the W-GLC films does not show a distinct change, but significantly increases when the W target current increases from 0.9 A to 1.2 A. In particular, when the W target current is 0.6 A, the friction coefficient and the wear rate of the W-GLC film are 0.02 and 3.8 × 10−17 m3/N·m, respectively, exhibiting excellent tribological properties.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 9

- Cited by