Article contents

Hot deformation behaviors of a new hot isostatically pressed nickel based powder metallurgy superalloy

Published online by Cambridge University Press: 03 November 2016

Abstract

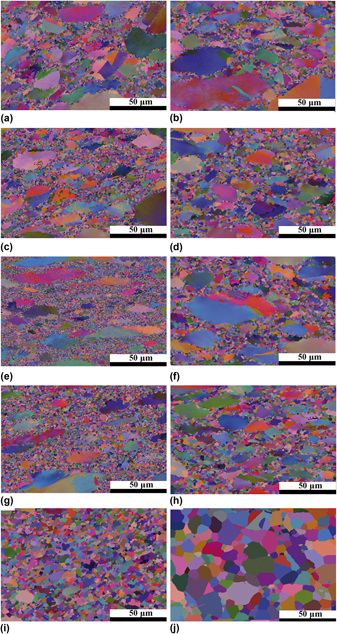

Hot compression tests of a hot isostatically pressed (HIPed) Ni based powder metallurgy (P/M) superalloy were carried out under various combinations of temperatures and strain rates. To bridge the relationship between stresses and strain rates, constitutive equations were established based on a hyperbolic sine Arrhenius equation, which yielded predicted stresses under the test conditions. It was found that the predict values fit the experimental values with good accuracy. Processing maps of the alloy under the test conditions were established; and the corresponding microstructures after test were examined to elaborate the workability of the alloy. It revealed that surface cracks occurred when strain was higher than 0.25, which initiated at the prior powder boundaries (PPBs) and propagated along the boundaries. The optimum hot working parameters for the alloy were proposed to beat the strain rate of 0.014 s−1 and 1075 °C.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 8

- Cited by