Article contents

Hot deformation behavior of a new tailored cobalt-based superalloy for turbine discs

Published online by Cambridge University Press: 22 January 2020

Abstract

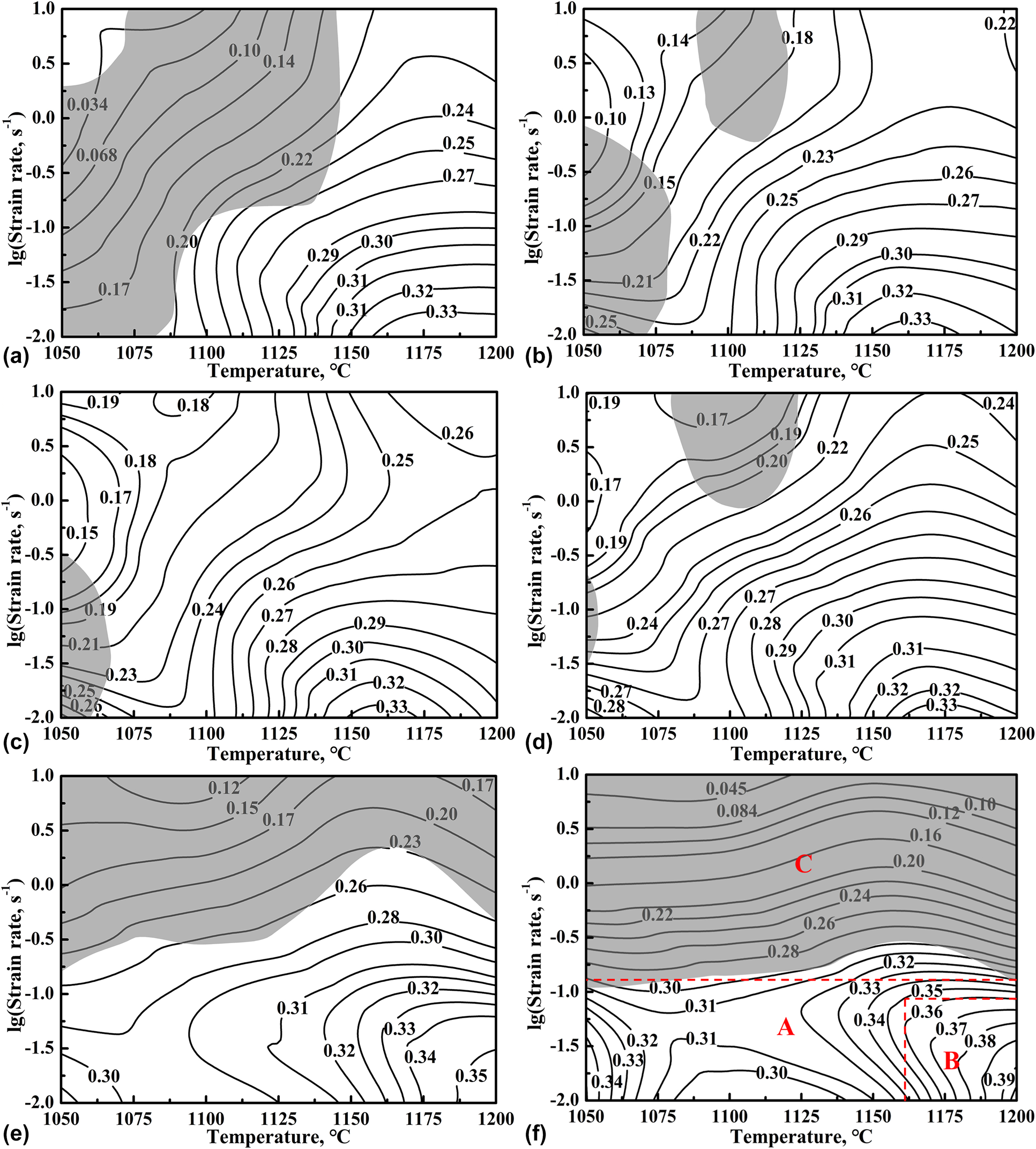

Hot deformation behavior of a new tailored cobalt-based superalloy for turbine discs was investigated in the temperature range of 1050–1200 °C and the strain rate range of 0.01–10 s−1. The results show that the flow stress is closely related to the deformation temperature and strain rate, and the flow stress curve of the new tailored alloy belongs to a typical dynamic recrystallization (DRX) type. Microstructure observation reveals that the dominant nucleation mechanism of DRX for the new tailored alloy belongs to discontinuous DRX, while continuous DRX only acts as an assistant nucleation mechanism. The optimum processing parameters of hot working are obtained in the temperature range of 1155–1200 °C and the strain rate range of 0.01–0.1 s−1. The activation energy for the new tailored alloy is determined to be 833.0 kJ/mol, and the relationship between grain size and processing parameters is established by appropriate constitutive equations.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2020

References

- 4

- Cited by