Article contents

Hard DLC coating deposited over nitrided martensitic stainless steel: analysis of adhesion and corrosion resistance

Published online by Cambridge University Press: 20 October 2016

Abstract

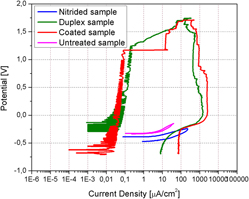

Surface modification treatments, such as the plasma nitriding improve the tribological properties of AISI 420 stainless steel; however, the corrosion resistance is deteriorated. The DLC (Diamond-Like Carbon) coatings were not only having a low friction coefficient but also good wear and corrosion resistance. In this work, both the corrosion behavior and the adhesion of the DLC hard coating, deposited on nitrided and non-nitrided AISI 420 stainless steel substrates, were studied. The coatings were characterized by means of EDS and Raman. In addition, nitrided layer microstructure and the coatings were analyzed by SEM-FIB and XRD. Corrosion behavior was evaluated by the salt spray fog test and cyclic potentiodynamic polarization tests in NaCl solution. The adhesion was assessed using Rockwell indentation and scratch tests. The a-C:H film and nitrided layer thicknesses were about 2.5 μm and 11 μm respectively. The nitrided layer improved adhesion in both tests. The coated AISI 420 stainless steel proved to have excellent atmospheric corrosion resistance and a passive behavior over 1 V (versus SCE) in the electrochemical tests. The adhesion and the corrosion performance were improved when the coating was deposited after the plasma nitriding treatment.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 8

- Cited by