Article contents

Evolution of microstructure and mechanical properties in Zn–Cu–Ti alloy during severe hot rolling at 300 °C

Published online by Cambridge University Press: 25 July 2017

Abstract

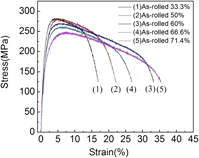

The present investigation aims to explore the evolution of microstructure and mechanical properties in Zn–Cu–Ti alloys during severe hot-rolling deformation. Twin deformation and dynamic recrystallisation are two important deformation modes of Zn–Cu–Ti alloys during hot rolling at 300 °C. Twin deformation and dynamic recrystallisation (DRX) appear one after the other. They not only consume the deformation stored energy but also inhibit initiation and growth of cracks. The elongation rate of Zn–Cu–Ti alloys has a rising trend with the increase in hot-rolling deformation. It is mainly due to grain refinement caused by increasing the ratio of DRX and twin deformation. The tensile strength of Zn–Cu–Ti alloys is found to decrease with the increase in hot-rolling deformation. This is because the solid-solution strengthening effect of copper is weakened by more deformation-induced precipitation of ε phase (CuZn5). The solid-solution strengthening effect of copper plays an important role in the strengthening effect of Zn–Cu–Ti alloys.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Jürgen Eckert

References

REFERENCES

- 6

- Cited by