Article contents

The effects of intergranular sliding on the fracture toughness of nanocrystalline materials with finest grains

Published online by Cambridge University Press: 12 May 2014

Abstract

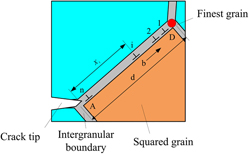

A new physical model of plastic deformation in nanocrystalline (NC) materials with finest grains (whose grain size is 2–4 nm) is suggested and theoretically described. The model represents the effect of the finest grains located at triple junctions on the fracture toughness of NC materials in the case that there are multiple dislocations pile-up at grain boundaries (GBs). The maximum number n of the pile-up dislocations is determined by both the capacity of dislocations emitting associated with the crack propagation and the capacity of dislocations pile-up due to the existence of the finest grains. The calculation indicates that the parameter n increases with increment of the grain size and decreases with the finest grain size increasing. The results theoretically reveal that the triple junctions with finest grains can significantly improve the fracture toughness of NC materials compared with the normal triple junctions in wide ranges of their structural parameters.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2014

References

REFERENCES

- 3

- Cited by